A kind of preparation method of n-type bismuth telluride-based thermoelectric material

A thermoelectric material, bismuth telluride-based technology, applied in thermoelectric devices, thermoelectric devices, circuits, etc. with thermal changes in dielectric constant, can solve unfavorable electrical and thermal performance synergistic optimization, limited improvement of material ZT value, and damage to orientation structure and other problems, to achieve the effect of reducing the thermal conductivity of the lattice, increasing the ZT value, and improving the coordinated regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

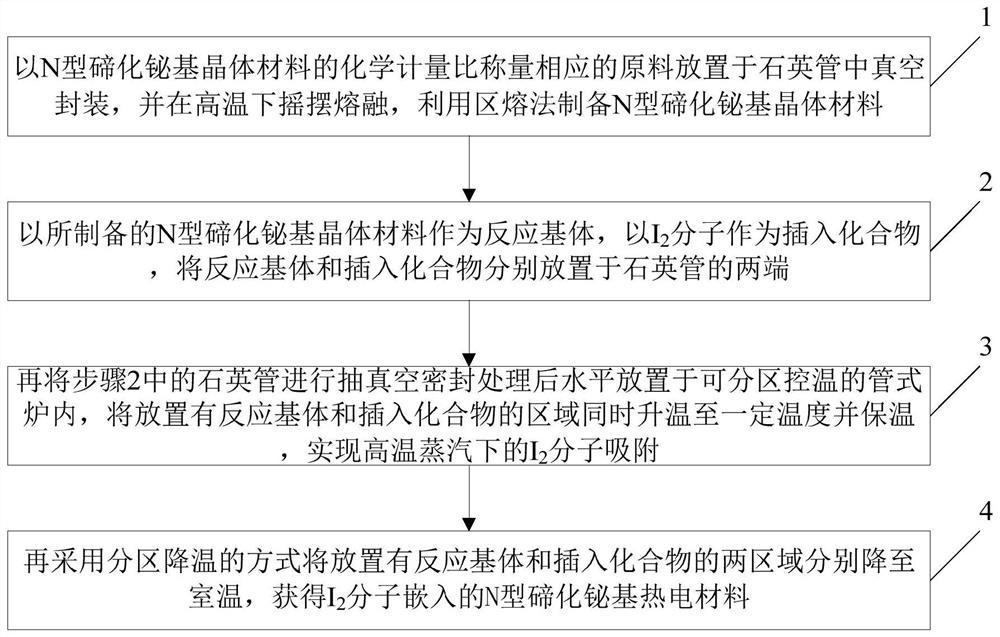

Method used

Image

Examples

example 1

[0039] Example 1, with N-type Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of the raw materials Bi, Te, Se powder is weighed, and the original powder is placed in a quartz tube and evacuated to 10 -5 After Pa post-packaging treatment, the quartz tube was melted in a swing furnace at 800°C for 4 hours and then cooled to room temperature with the furnace;

[0040] Then put the quartz tube into the zone melting growth furnace, set the zone melting conditions: melting temperature 720°C, heating rate 25°C / min, melting zone width 30mm, temperature gradient 25°C / cm, growth rate 25mm / h, to prepare N Type Bi 2 Te 2.7 Se 0.3 crystal material.

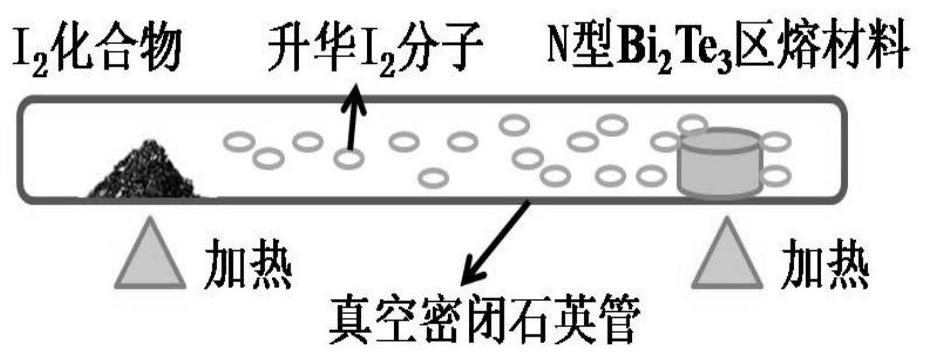

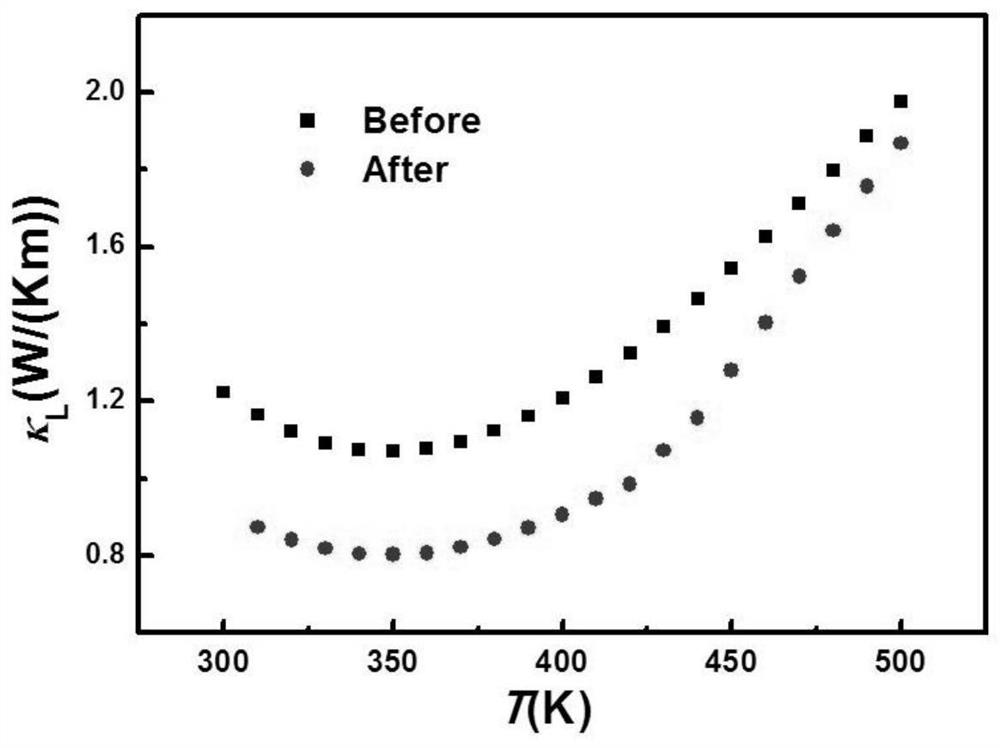

[0041] N-type Bi 2Te 2.7 Se 0.3 crystal as a reaction matrix, an appropriate amount of I 2 The powder is placed on both ends of the quartz tube as an insertion compound, and the quartz tube is evacuated (to 10 -5 Pa) after the sealing treatment, it is placed horizontally in a tube furnace with zoneable temperature control, and the bismu...

example 2

[0046] Example 2, with N-type Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of the raw materials Bi, Te, Se powder is weighed, and the original powder is placed in a quartz tube and evacuated to 10 -5 After Pa packaging treatment, the quartz tube is melted in a swing furnace at 800°C for 4 hours and then cooled to room temperature with the furnace; then the quartz tube is placed in a zone melting growth furnace, and the zone melting conditions are set: melting temperature 720°C, heating rate 25 ℃ / min, melting zone width 30mm, temperature gradient 25℃ / cm, growth rate 25mm / h, prepared N-type Bi 2 Te 2.7 Se 0.3 crystal material. N-type Bi 2 Te 2.7 Se 0.3 crystal as a reaction matrix, an appropriate amount of I 2 The powder is placed on both ends of the quartz tube as an insertion compound, and the quartz tube is evacuated (to 10 -5 Pa) after the sealing treatment, it is placed horizontally in a tube furnace with zoneable temperature control, and the bismuth telluride regi...

example 3

[0048] Example 3, with N-type Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of the raw materials Bi, Te, Se powder is weighed, and the original powder is placed in a quartz tube and evacuated to 10 -5 After Pa packaging treatment, the quartz tube is melted in a swing furnace at 800°C for 4 hours and then cooled to room temperature with the furnace; then the quartz tube is placed in a zone melting growth furnace, and the zone melting conditions are set: melting temperature 720°C, heating rate 25 ℃ / min, melting zone width 30mm, temperature gradient 25℃ / cm, growth rate 25mm / h, prepared N-type Bi 2 Te 2.7 Se 0.3 crystal material. N-type Bi 2 Te 2.7 Se 0.3 crystal as a reaction matrix, an appropriate amount of I 2 The powder is placed on both ends of the quartz tube as an insertion compound, and the quartz tube is evacuated (to 10 -5 Pa) after the sealing treatment, it is placed horizontally in a tube furnace with zoneable temperature control, and the bismuth telluride regi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com