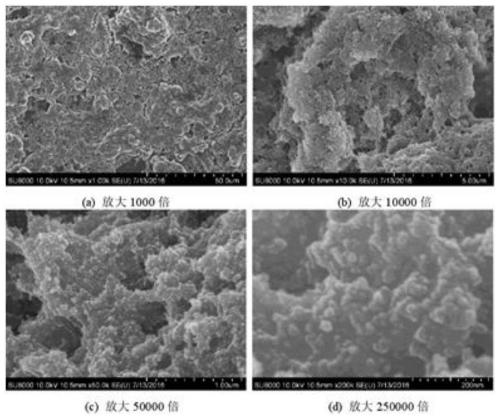

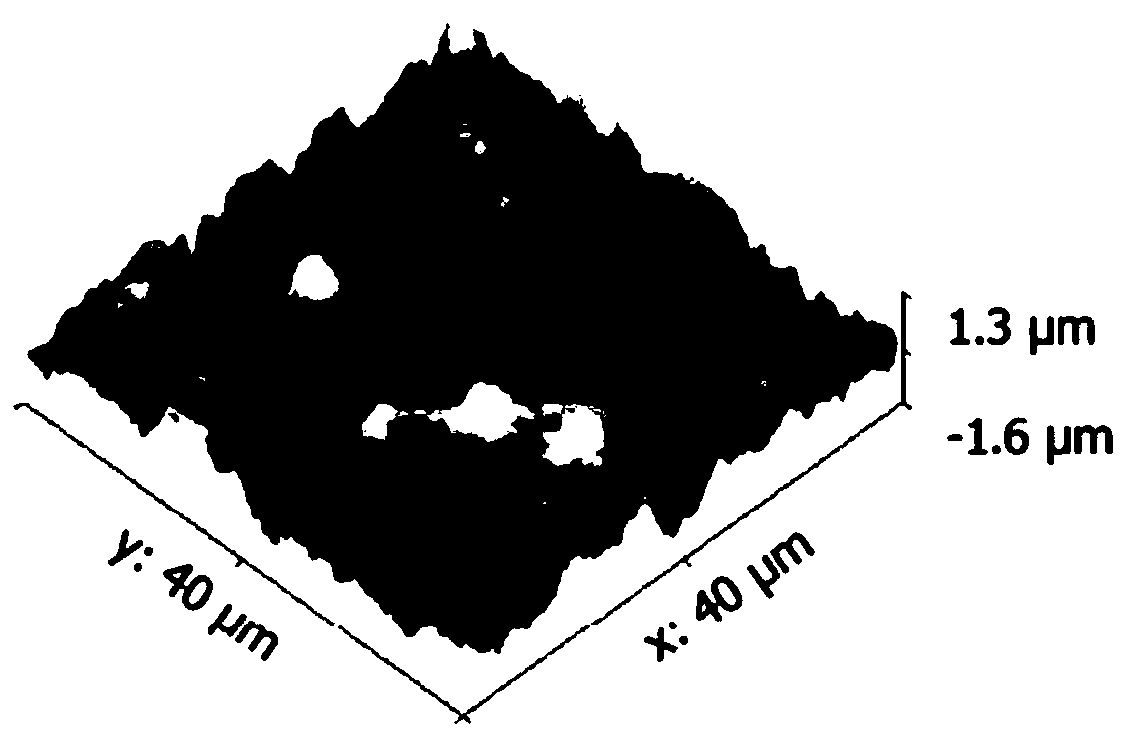

Nano-silica modified silicon resin super-hydrophobic coating, and preparation method and application thereof

A nano-silica, super-hydrophobic coating technology, applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of decreased electrical insulation performance, poor hydrophobicity of surface coatings, etc., to reduce the surface energy, the preparation method is simple and easy, and the effect of increasing the micro-nano scale roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Weigh 400mL of absolute ethanol and 30mL of tetraethyl orthosilicate solution, pour the mixture of tetraethyl orthosilicate and absolute ethanol into a three-necked electric stirring bottle with a capacity of 1000mL, and configure the volume ratio of distilled water and ammonia water to be 2 :7 mixed solution. 20 mL of distilled aqueous ammonia solution was dropped into a three-neck flask at a rate of 10 mL / min, and the reaction temperature and stirring speed were controlled to uniformly stir the mixed solution for 24 hours to obtain a nano-silica dispersion. The nano-silica was separated from the solvent by centrifugation, the solvent and by-products were removed, and after washing with ethanol three times, vacuum-dried at 120° C. for 12 h to obtain dried nano-silica particles.

[0026] Disperse 3 g of nano-silica particles and 5 g of tridecafluorooctyl triethoxy silicon in 40 g of ethanol solution, add to an electric stirring three-neck flask, and mix thoroughly at roo...

Embodiment 2

[0029] Weigh 200mL of absolute ethanol and 10mL of tetraethyl orthosilicate solution, pour the mixture of tetraethyl orthosilicate and absolute ethanol into a three-necked electric stirring bottle with a capacity of 1000mL, and configure the volume ratio of distilled water and ammonia water to be 2 :5 mixed solution. 10 mL of distilled aqueous ammonia solution was dropped into a three-neck flask at a rate of 10 mL / min, and the reaction temperature and stirring speed were controlled to uniformly stir the mixed solution for 24 hours to obtain a nano-silica dispersion. The nano-silica was separated from the solvent by centrifugation, the solvent and by-products were removed, and after washing with ethanol three times, vacuum-dried at 120° C. for 12 h to obtain dried nano-silica particles.

[0030] Disperse 2g of nano-silica particles and 4g of heptadecafluorodecyltriethoxysilane in 30g of ethanol solution, add to a three-neck flask with electric stirring, and mix thoroughly at ro...

Embodiment 3

[0033] Weigh 500mL of absolute ethanol and 40mL of tetraethyl orthosilicate solution, pour the mixture of tetraethyl orthosilicate and absolute ethanol into a three-neck electric stirring bottle with a capacity of 1000m L, and configure the volume ratio of distilled water and ammonia water to be 2 :5 mixed solution. 25 mL of distilled aqueous ammonia solution was dropped into a three-neck flask at a rate of 10 mL / min, and the reaction temperature and stirring speed were controlled to uniformly stir the mixed solution for 24 hours to obtain a nano-silica dispersion. The nano-silica was separated from the solvent by centrifugation, the solvent and by-products were removed, and after washing with ethanol three times, vacuum-dried at 120° C. for 12 h to obtain dried nano-silica particles.

[0034] Disperse 4g of nano-silica particles and 6g of tridecafluorooctyltriethoxysilicon in 50g of ethanol solution, add into a three-neck flask with electric stirring, and mix thoroughly at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com