Straw base composite material and preparation method thereof

A composite material and rice stalk technology, which is applied to flat products, other household utensils, wood processing appliances, etc., can solve the problems of poor shape selectivity of rice stalks, low proportion of rice stalks, cumbersome preparation process, etc., and achieve improved Environmental compatibility, easy mold assembly, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

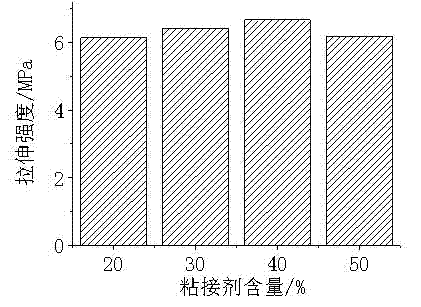

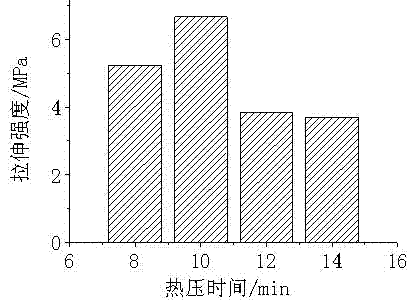

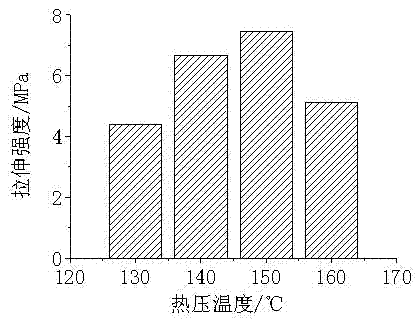

[0032] Cut dry rice stalks with a water content below 1% into small sections of 1.5 cm, cut them in a four-bladed turbo mechanical mixer for 20 seconds, and pass through a 20-mesh sieve to remove dust and powder generated during the crushing process. The product is a mixture of filamentous and flaky rice stalks. Weigh 18 grams of silky and flaky rice stalks, place them in a mixing tank, add 10ml of tap water, and stir for 1 minute to make the rice stalks evenly wetted by water, and then weigh 12 grams. Add the polyvinyl alcohol powder with a degree of polymerization of 1700 and an alcoholysis degree of 88% to the raw material tank, stir for 1 minute to mix the rice straw and the adhesive evenly, and put the mixed material into an iron mold coated with rapeseed oil In the process, place the mold with the material between the pressing plates at a temperature of 140°C, pressurize to 10MPa, heat press for 10min, remove the mold, cool to 30°C and open the mold to obtain the straw-ba...

Embodiment 2

[0037] Cut the dry rice stalks with a water content of 3% into 2.0cm segments, cut them in a four-blade turbine mechanical mixer for 3 minutes, and pass through a 20-mesh sieve to remove dust and powder generated during the crushing process. It is a mixture of filamentous and flake rice stalks. Weigh 15 grams of flaked rice stalks, place them in a stirring tank, add 7ml polyvinyl acetate emulsion, stir for 1 min, so that the rice stalks are evenly wetted by the emulsion, then weigh 15 grams of stalks with a degree of polymerization of 1000 and a degree of alcoholysis of 99% polyvinyl alcohol short filaments are added to the raw material tank, and stirred for 1 minute to evenly mix the rice straw and the adhesive. Put the mixed material into an iron mold coated with simethicone oil, place the mold with the material between platens at a temperature of 150°C, pressurize to 7MPa, heat press for 12min, remove the mold, and cool to After 30°C, the mold was opened to obtain the stra...

Embodiment 3

[0039] Dry the rice stalks until the water content is 5%, then cut them into 4cm lengths of rice stalks, then mechanically shear the rice stalks for 3 minutes, and then pass through a 40-mesh sieve. mixture. Weigh 15 grams of flaked rice stalks, place them in a stirring tank, add 5ml of polyvinyl acetate emulsion, stir for 1 min, so that the rice stalks are evenly wetted by the emulsion, then weigh 15 grams of stalks with a degree of polymerization of 3000 and a degree of alcoholysis of 99% polyvinyl alcohol short filaments are added to the raw material tank, and stirred for 1 minute to evenly mix the rice straw and the adhesive. Put the mixed material into an iron mold coated with simethicone oil, place the mold with the material between platens at a temperature of 160°C, pressurize to 7MPa, heat press for 12min, remove the mold, and cool to After 30°C, the mold was opened to obtain the straw-based composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com