Spray-coating device and method for restraining secondary electron yield of solid dielectric material

A technology of secondary electrons and solid media, applied in the field of plasma, can solve the problems of high system equipment requirements, harsh processing conditions, long time, etc., and achieve the effect of expanding the processing area, enhancing the processing effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

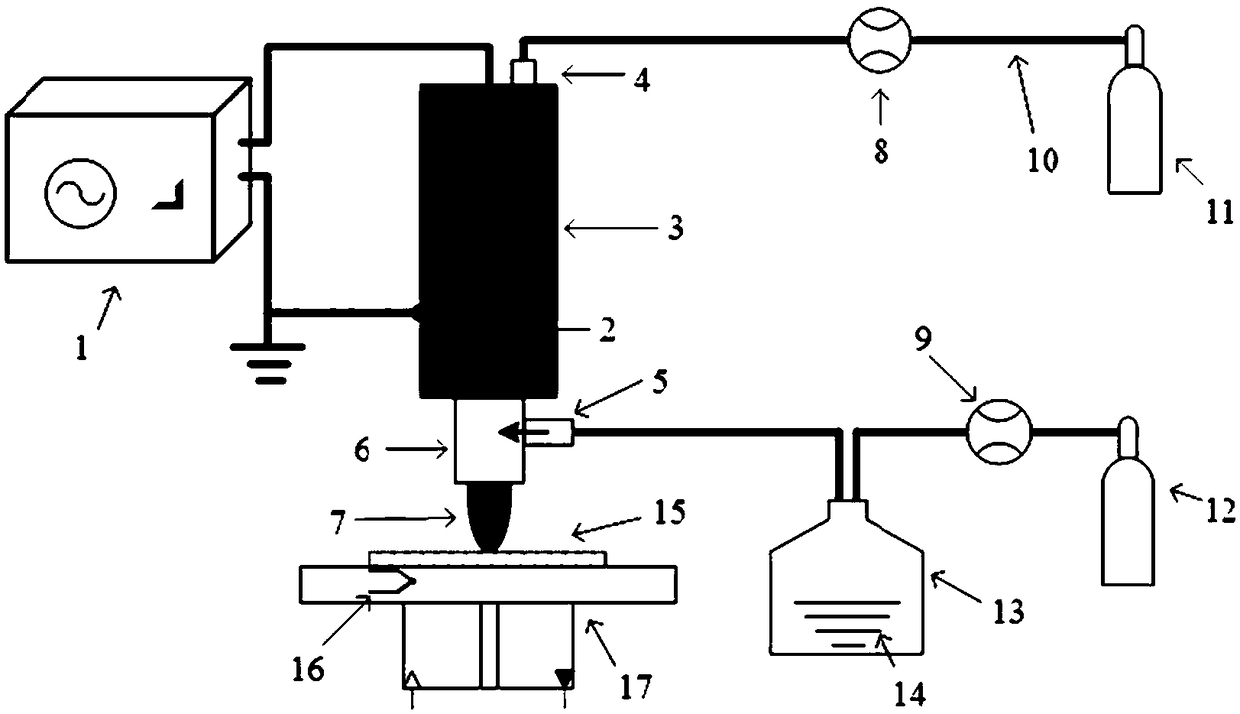

Method used

Image

Examples

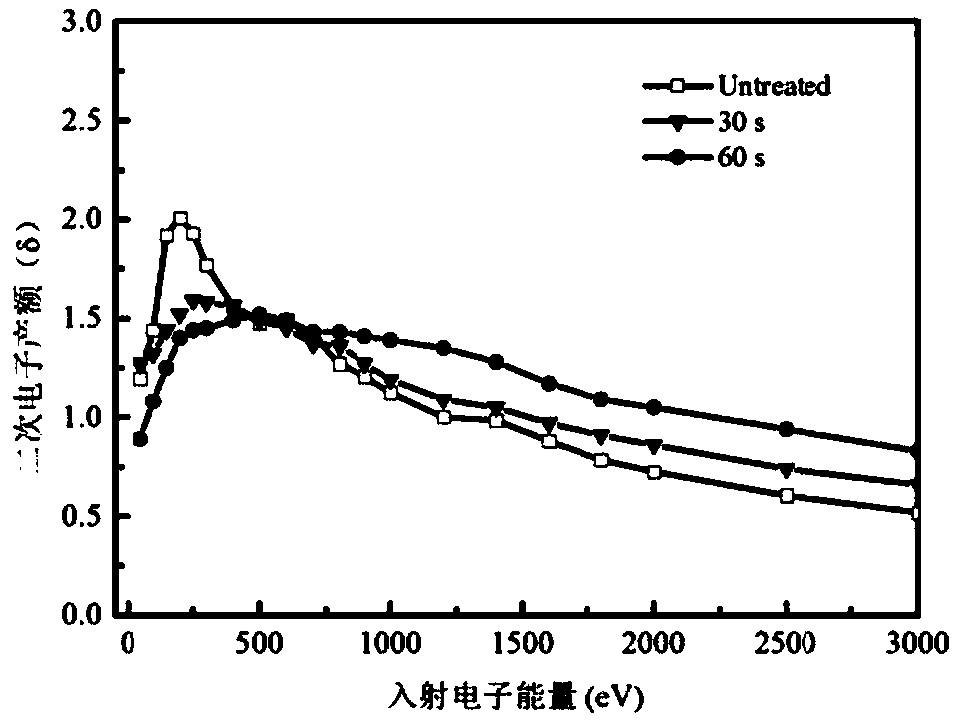

Embodiment 1

[0050] A spray coating method for suppressing secondary electron yield of solid dielectric materials, comprising the following steps:

[0051] Step 1, select 2 groups of polystyrene materials with a thickness of 2 mm, a size of 50×50 mm, and a smooth and clean surface; one group is used as an untreated sample for comparison; the other two groups are processed by the spray coating device respectively . The samples to be treated were washed and dried. Wherein, the cleaning of the sample to be treated includes: firstly use absolute ethanol or deionized water to wipe and clean, then put it into an ultrasonic cleaner for cleaning for 10-30 minutes, remove impurities and oil stains on the surface of the sample, and finally clean the sample to be treated The samples were placed in a vacuum drying oven to remove surface moisture. The drying conditions of the sample to be treated are as follows: the air pressure in the vacuum drying oven is 3000-5000 Pa, the temperature is 50-80° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com