Preparation method for ferric oxide-modified titanium dioxide high-efficiency visible photocatalyst

A technology for ferric oxide and titanium dioxide, which is applied in the field of environmental sewage treatment, can solve problems such as restricting large-scale industrialized production, and achieve the effects of simple method, low visible light catalysis efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

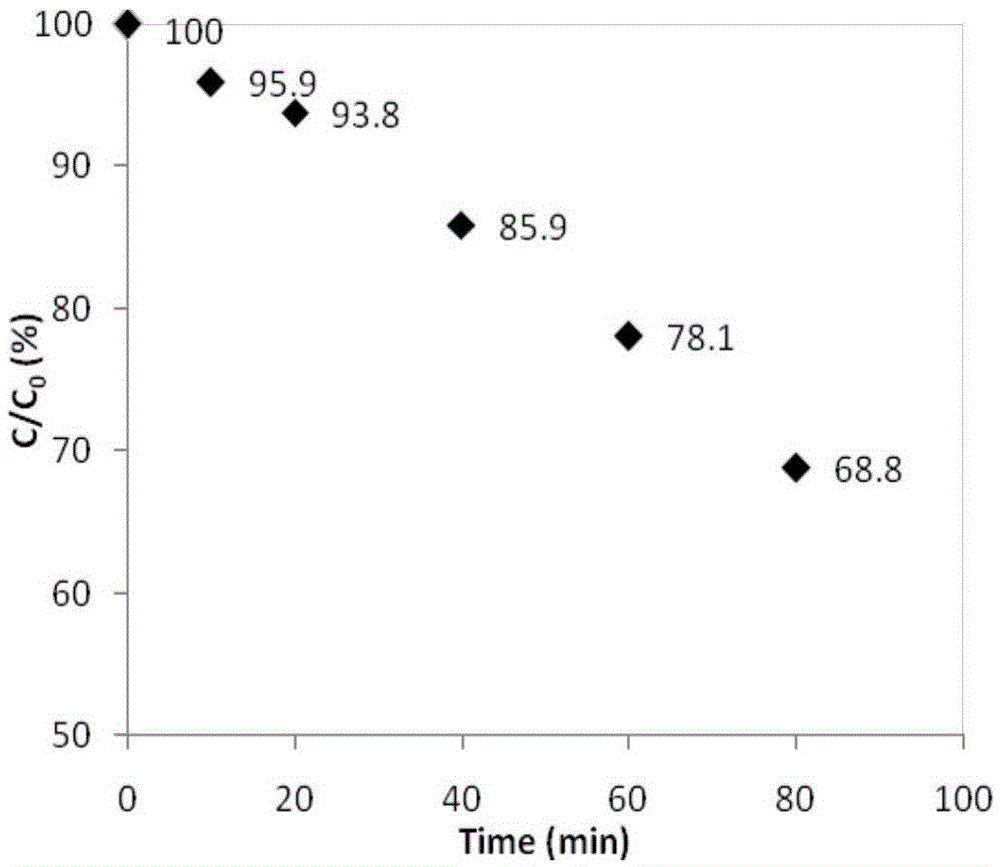

[0038] Ferric iron tetroxide (Fe 3 o 4 ) powder evenly spread in the dry pot, placed in the muffle furnace through a step-by-step heating program (heating from 25°C to 250°C takes 250 minutes and keeps for 60 minutes; heats up from 250°C to 300°C takes 100 minutes and keeps for 30 minutes; heats up at 300°C To 350°C, take 200min, keep 120min; 350°C to 400°C, take 200min, keep 60min; 400°C to 450°C, take 200min, keep 120min) calcining, so that Fe 3 o 4The powder is directly transformed into ferric oxide (Fe 2 o 3 ). Subsequently, take ferric oxide (Fe 2 o 3 , solid content, 1.0g / L) powder was added to 50ml of methylene blue solution (MB, concentration: 1.0x10 -5 g / L), after fully stirring in the dark room for 30 minutes, put it into a xenon light catalytic instrument (XD350W-1, filter out ≤450nm) visible light instrument for degradation, take out 5ml from the system at regular intervals, centrifuge and separate , and then measure its residual MB value under ultraviolet ...

Embodiment 2

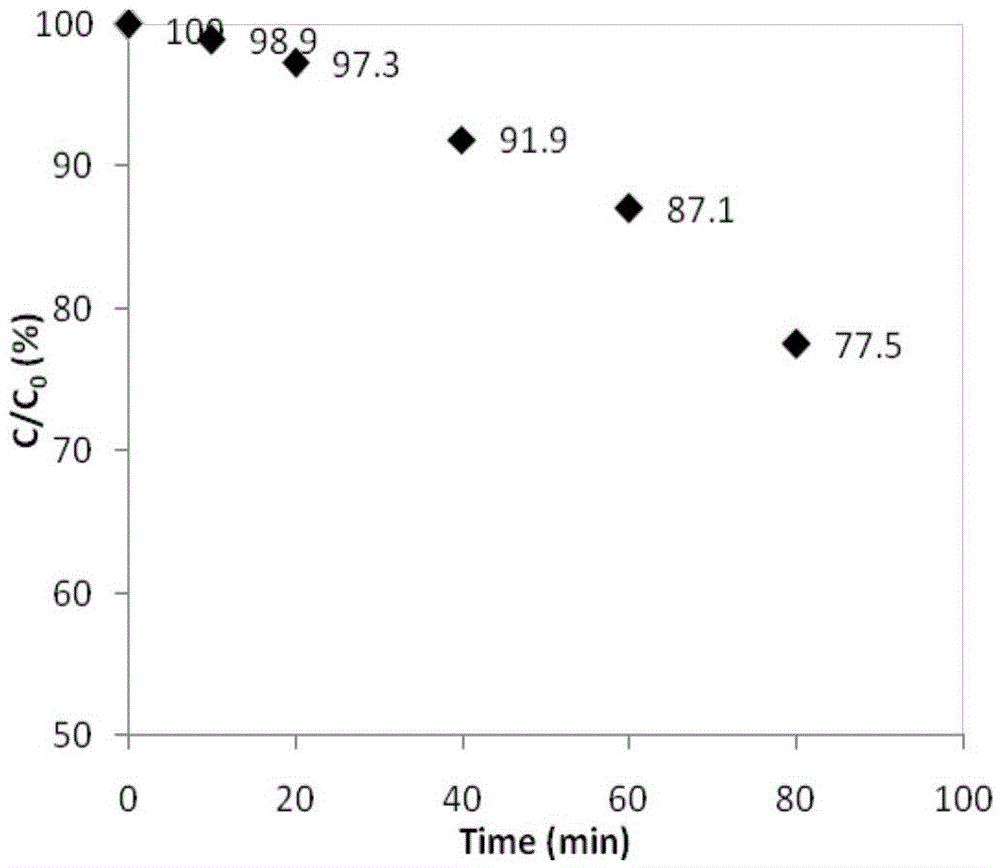

[0040] From the production of P25 produced by Sigma-aldrich company and Aladdin company, the ferric iron tetroxide (Fe 3 o 4 ) powder by mass ratio is P25: Fe 3 o 4 =1:0.2 Mix well, and then evenly spread in the dry pot, put in the muffle furnace and calcined by staged temperature rise program, so that Fe 3 o 4 The powder is directly transformed into ferric oxide (Fe 2 o 3 ) at the same time, it can fully integrate with P25. Finally, P25-20% Fe was prepared 2 o 3 catalyst of light. Subsequently, take P25-20% Fe 2 o 3 (solid content, 1.0g / L) powder was added to 50ml of methylene blue solution (MB, concentration: 1.0x10 -5 g / L), after fully stirring in the dark room for 30 minutes, put it into a xenon light catalytic instrument (XD350W-1, filter out ≤450nm) visible light instrument for degradation, take out 5ml from the system at regular intervals, centrifuge and separate , and then measure its residual MB value under ultraviolet light (663nm), with real-time concent...

Embodiment 3

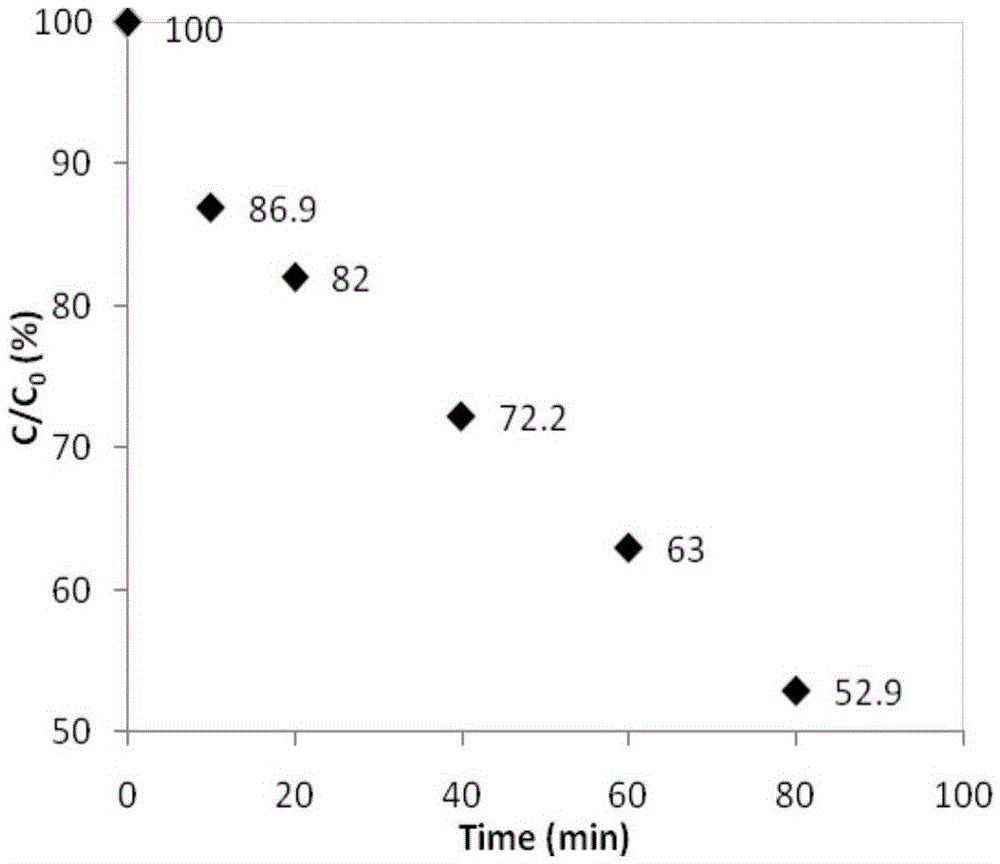

[0042] From the production of P25 produced by Sigma-Aldrich Company and Aladdin Company, ferric iron tetroxide (Fe 3 o 4 ) powder by mass ratio is P25: Fe 3 o 4 =1:0.4 Mix well, then evenly spread in the dry pot, put in the muffle furnace and calcined by staged temperature rise program, so that Fe 3 o 4 The powder is directly transformed into ferric oxide (Fe 2 o 3 ) at the same time, it can fully integrate with P25. Finally, the P25-40% Fe 2 o 3 catalyst of light. Subsequently, take P25-40% Fe 2 o 3 (solid content, 1.0g / L) powder was added to 50ml of methylene blue solution (MB, concentration: 1.0x10 -5 g / L), after fully stirring in the dark room for 30 minutes, put it into a xenon light catalytic instrument (XD350W-1, filter out ≤450nm) visible light instrument for degradation, take out 5ml from the system at regular intervals, centrifuge and separate , and then measure its residual MB value under ultraviolet light (663nm), with real-time concentration / original c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com