Device for assembling inner conductor assembly of air dielectric radio frequency coaxial connector

A radio frequency coaxial and air medium technology is applied in the field of assembling devices for inner conductor components of air medium radio frequency coaxial connectors, and achieves the effects of simple assembly process, high versatility and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

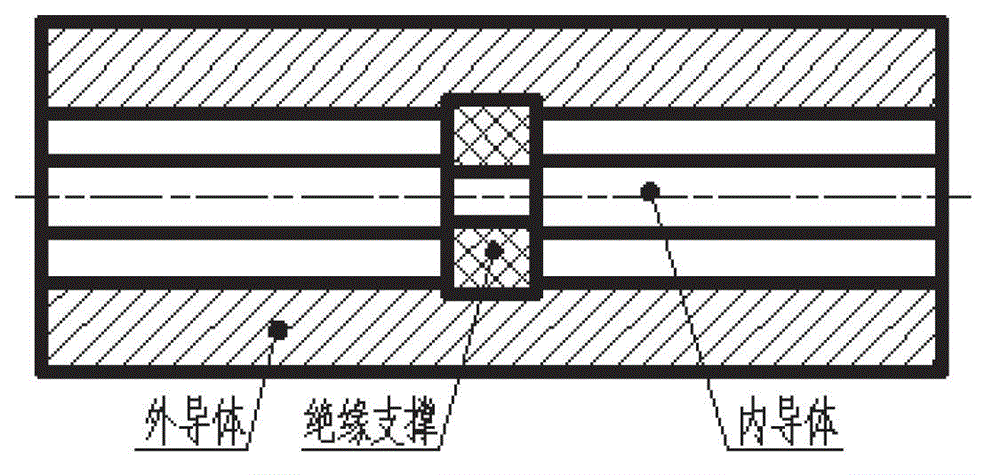

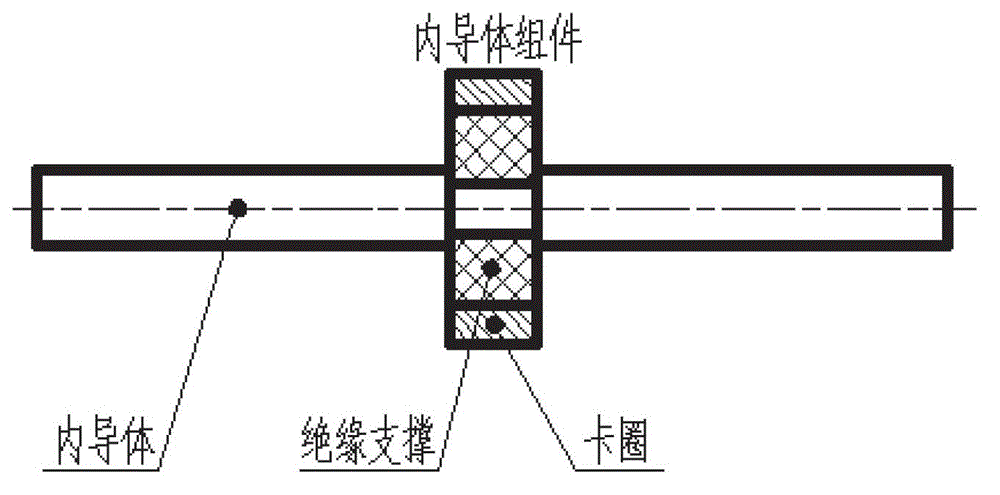

[0034] Combined with the comprehensive analysis of different actual situations, the structural diagram of the inner conductor assembly formed by the insulating support segmentation method can be obtained, as shown in Figure 4 As shown, the inner conductor assembly is composed of an inner conductor 01 , an insulating support 02 and a collar 03 . Collar 03 is annular. The insulating support 02 is ring-shaped. There is an insulating support ring groove 011 in the middle part of the inner conductor, and its width is equal to the thickness of the insulating support and the collar. One port of the inner conductor is connected with a standard male pin 012 (or a standard female claw), and the other end is also provided with a corresponding standard male pin or a standard female claw.

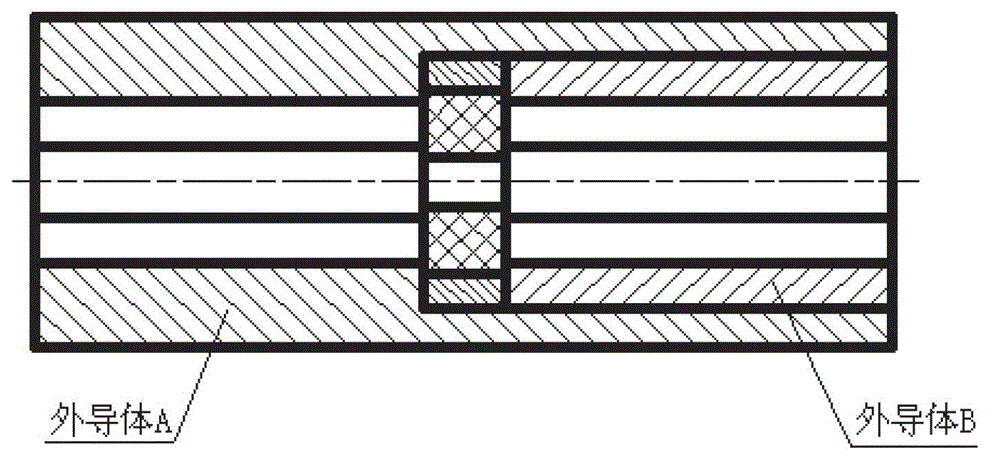

[0035] In order to complete the assembly of the aforementioned inner conductor assembly, the present application has invented an assembly device for the inner conductor assembly of an air-dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com