Manufacturing method of high-flame-retardance low-release environment-friendly shield cable

A shielded cable, green and environmental protection technology, used in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems of high toxicity, high smoke, and flame retardant wires and cables cannot be achieved, and achieve strong flame retardant performance, The effect of blocking the transmission of oxygen and good metal shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

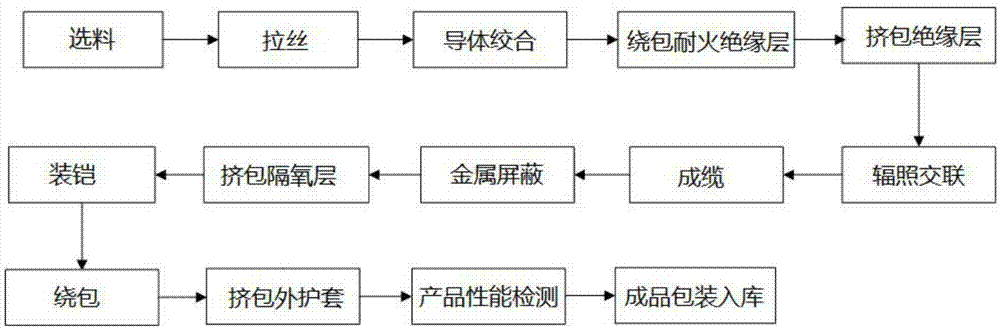

[0040] A method for manufacturing a high flame-retardant and low-emission green and environment-friendly shielded cable, the method has the following steps: (1) material selection; (2) wire drawing; (3) conductor twisting; (4) wrapping a fire-resistant insulating layer; (5) extruding (6) radiation cross-linking; (7) cabling; (8) metal shielding; (9) extruded oxygen barrier layer; (10) armoring; (11) wrapped; (12) extruded Sheath; (13) Product performance testing; (14) Finished product packaging and storage.

[0041] The wire drawing is made of circular copper monofilaments of various specifications by using electric round copper rods through a plurality of wire drawing dies of special wire drawing equipment, and the wire drawing dies can be selected according to the specifications of the wire cores.

[0042] The conductor stranding refers to twisting a plurality of round copper monofilaments on the conductor stranding equipment according to the predetermined number, rule, twis...

Embodiment 2

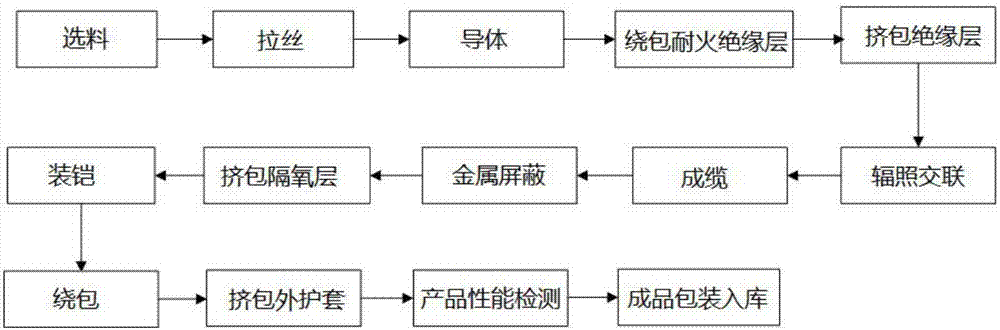

[0062] In Embodiment 2, the steps of the method for manufacturing the cable are as follows: (1) material selection; (2) wire drawing; (3) conductor; (4) wrapping refractory insulating layer; (5) extrusion insulation; (6) irradiation Cross-linking; (7) cabling; (8) metal shielding; (9) extruded oxygen barrier layer; (10) armoring; (11) wrapping; (12) extruded outer sheath; (13) product performance Detection; (14) the finished product is packaged into the warehouse, and the conductor stranding step in embodiment 1 is changed into the conductor step, and the conductor step refers to the circular copper monofilament formed by the wire drawing step directly as the conductor of the product, and the extruded Change the total thickness of the insulation layer to 0.7mm, change the thickness of the inner layer insulation to 0.2mm, change the thickness of the outer layer insulation to 0.5mm, change the extrusion line speed of the insulation layer to 80-100m / min, and change the flame retar...

Embodiment 3

[0072] In embodiment 3, the method for manufacturing the cable is consistent with the method for manufacturing the cable in embodiment 1, the total thickness of the extruded insulation layer in embodiment 1 is changed to 1.0mm, and the thickness of the inner layer insulation is changed to 0.3mm, Change the thickness of the outer layer insulation to 0.7mm, change the extrusion line speed of the insulation layer to 5-7m / min, change the thickness of the flame-retardant glass fiber wrapping tape to 60-80mm, and change the stranding pitch of the cabling step Change to 20 times, the thickness of the metal strip in the armoring process is changed to 0.2mm or the diameter of the metal strip is changed to 1.25mm.

[0073] The cables manufactured by Example 3 also meet the requirements in the "Code for Electrical Design of Civil Buildings": super high-rise buildings should choose combustion performance B 1 Grade and above, smoke toxicity is t 0 Level, burning droplets / particles level i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com