Preparation method for cadmium supported bismuth telluride nanowires

A technology of bismuth telluride nanometer and tellurium nanowire, which is applied in the direction of chemical instruments and methods, nanotechnology, selenium/tellurium compound, etc. It can solve the problems of complicated use, achieve uniform heating, simple test process, and easy large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

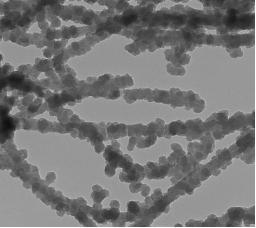

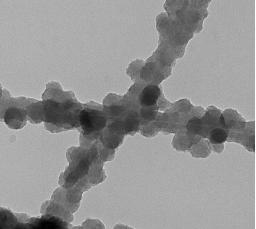

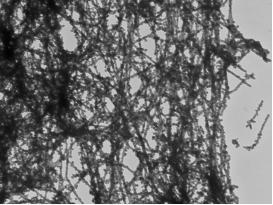

Image

Examples

Embodiment 1

[0026] First, take 80mL of tellurium nanowires prepared in advance, then add 0.52g of bismuth nitrate, stir evenly, then add 0.4mL of hydrazine hydrate to the mixed solution, and adjust the pH of the solution to 8 with sodium hydroxide, and then mix the The solution was transferred to a hydrothermal reactor and reacted at 160°C for 10 h. After the reaction, the reactor was obtained and the bismuth telluride nanowires were washed by centrifugation; secondly, the obtained bismuth telluride nanowires were dispersed in ethylene glycol, The concentration of the solution is 0.1mg / mL. After the dispersion is uniform, add chromium chloride and 1mL sodium citrate solution; finally, transfer the mixed solution to an Erlenmeyer flask, and use a sealing film to seal it against oxygen, and place it on a shaker. Adjust the temperature of the shaking table to 60°C and the speed to 190rpm after the middle and back, and keep it for 8h. After the reaction, the product was washed with deionized ...

Embodiment 2

[0028] First, take 80mL of tellurium nanowires prepared in advance, then add 0.52g of bismuth nitrate, stir evenly, then add 0.4mL of hydrazine hydrate to the mixed solution, and adjust the pH of the solution to 8 with sodium hydroxide, and then mix the The solution was transferred to a hydrothermal reactor and reacted at 180°C for 8 hours. After the reaction, the reactor was taken out and the bismuth telluride nanowires were washed by centrifugation; secondly, the obtained bismuth telluride nanowires were dispersed in ethylene glycol, The concentration of the solution is 0.1mg / mL. After the dispersion is uniform, add chromium chloride and 1mL sodium citrate solution; finally, transfer the mixed solution to an Erlenmeyer flask, and use a sealing film to seal it against oxygen, and place it on a shaker. Adjust the temperature of the shaking table to 60°C and the speed to 190rpm after the middle and back, and keep it for 8h. After the reaction, the product was washed with deioni...

Embodiment 3

[0030] First, take 80mL of tellurium nanowires prepared in advance, then add 0.52g of bismuth nitrate, stir evenly, then add 0.4mL of hydrazine hydrate to the mixed solution, and adjust the pH of the solution to 8 with sodium hydroxide, and then mix the The solution was transferred to a hydrothermal reactor and reacted at 180°C for 8 hours. After the reaction, the reactor was taken out and the bismuth telluride nanowires were washed by centrifugation; secondly, the obtained bismuth telluride nanowires were dispersed in ethylene glycol, The concentration of the solution is 0.1mg / mL. After the dispersion is uniform, add chromium chloride and 1mL sodium citrate solution; finally, transfer the mixed solution to an Erlenmeyer flask, and use a sealing film to seal it against oxygen, and place it on a shaker. Adjust the temperature of the shaker to 80°C and the speed to 160rpm, and keep it for 7h. After the reaction, the product was washed with deionized water and ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com