Method for processing metallic lithium belt

A processing method and metal lithium technology, applied in metal processing equipment, metal extrusion, metal extrusion control equipment, etc., can solve the problem of small extrusion capacity, affecting the performance and service life of lithium batteries, and unstable winding tension control And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

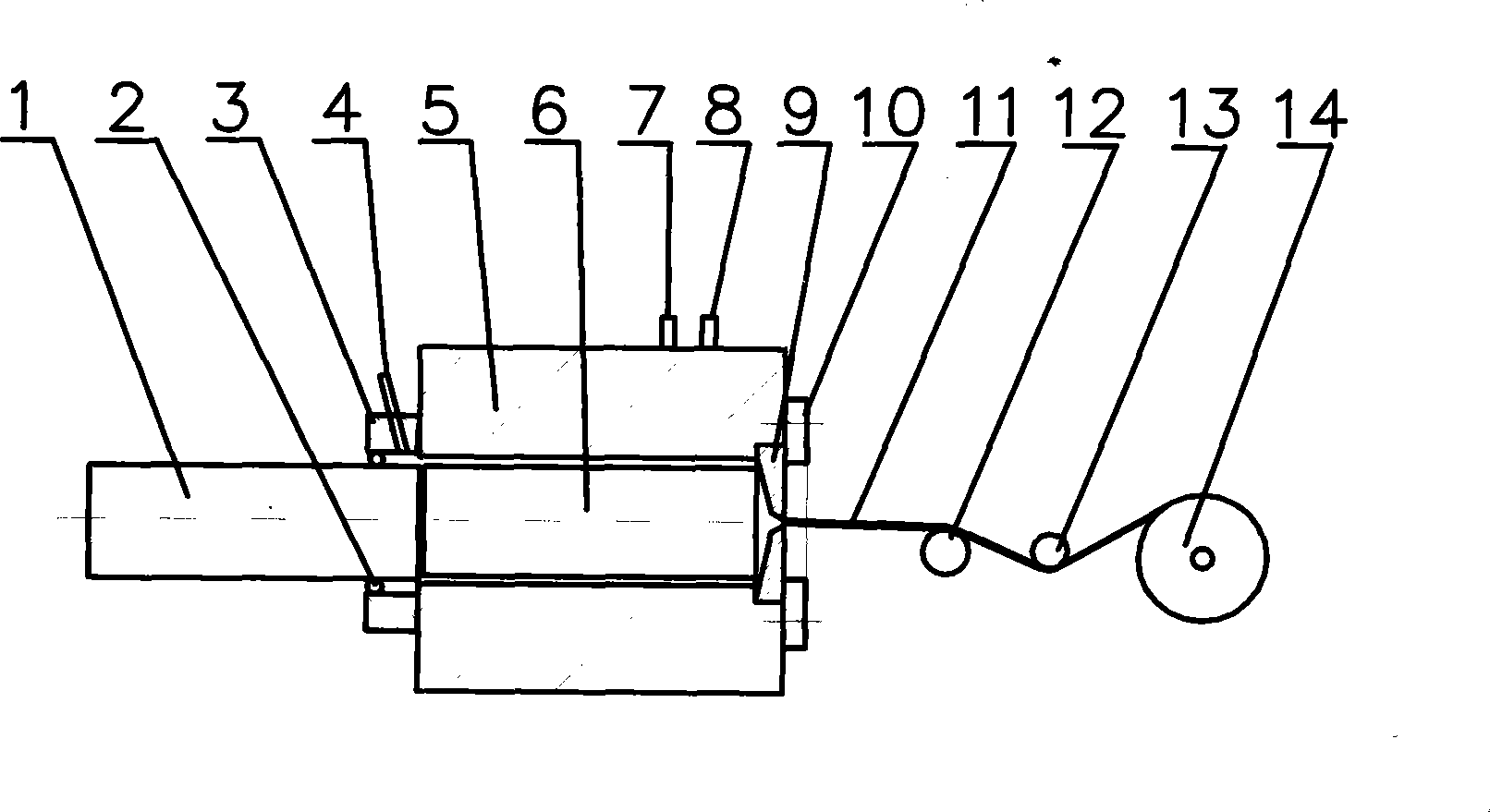

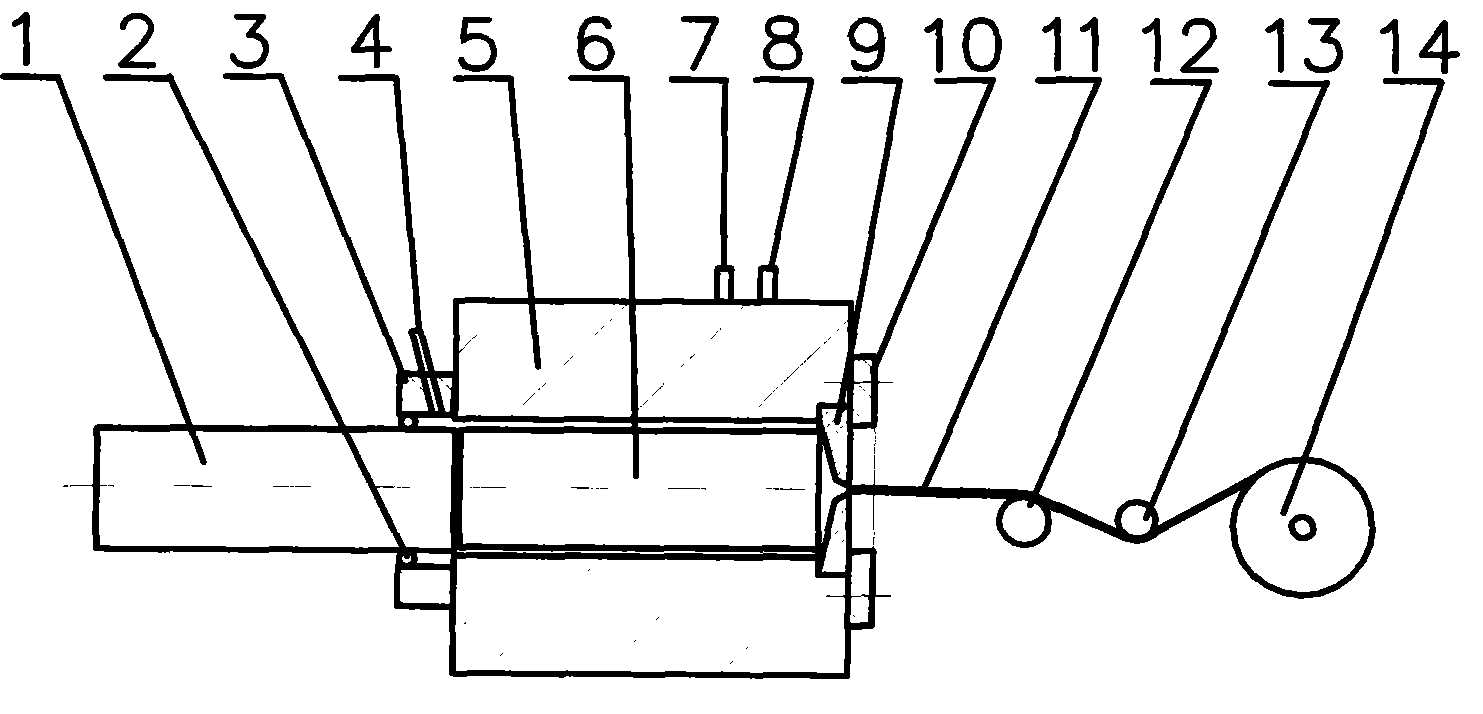

[0015] The raw material lithium ingot is weighed in an environment with a humidity below 1%, the lithium ingot 6 is added to the extrusion cylinder 5, the coiling disc 14 is fixed on the winding machine, and the middle position of the coiling disc 14 is pasted on both sides The length of the double-sided adhesive tape is 2 mm shorter than the width of the product, and the position of the winder is initially adjusted so that the center of the coiling disc 14 is aligned with the die outlet.

[0016] The extrusion rod 1 of the forming extruder first enters the rubber sealing ring 2 before the formal extrusion work; the rubber sealing ring 2 is fixed in the vacuum sealing ring 3; the vacuum sealing ring 3 and the extrusion cylinder 5 are sealed and fastened with bolts ; Open the air exhaust hole 4 for vacuuming on the vacuum sealing ring 3; first vacuumize, and extract the air in the extrusion cylinder cavity.

[0017] Start the vacuum pump and the low pressure pump, start the low...

specific Embodiment 2

[0018] The raw material lithium ingot is weighed in an environment with a humidity below 1%, the lithium ingot 6 is added to the extrusion cylinder 5, the coiling disc 14 is fixed on the winding machine, and the double The length of the double-sided tape is 2 mm shorter than the width of the product, and the position of the winder is preliminarily adjusted so that the center of the winding disc 14 is aligned with the die outlet.

[0019] The extrusion rod 1 of the forming extruder first enters the rubber sealing ring 2 before the formal extrusion work; the rubber sealing ring 2 is fixed in the vacuum sealing ring 3; the vacuum sealing ring 3 and the extrusion cylinder 5 are sealed and fastened with bolts ; Open the air exhaust hole 4 for vacuuming on the vacuum sealing ring 3; first vacuumize, and extract the air in the extrusion cylinder cavity.

[0020] Start the vacuum pump and the low-pressure pump, start the low-pressure feed until the sealing copper sleeve is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com