Thermoelectric thin film with chemical composition of Mg3.2Bi1.5Sb0.5 and preparation method thereof

A thermoelectric thin film, chemical composition technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of low energy conversion efficiency of thermoelectric materials, inability to realize wide application of thermoelectric materials, etc., to achieve good energy Conversion capacity, thermoelectric performance increase, effect of improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a chemical composition of Mg 3.2 Bi 1.5 Sb 0.5 The preparation method of the thermoelectric thin film, comprises the following steps:

[0029] (1) Mix metal Mg, Bi and Sb according to the molar ratio of Mg:Bi:Sb=3.05~3.3:1.5:0.5, and perform ball milling and hot pressing in sequence to obtain Mg 3.2 Bi 1.5 Sb 0.5 alloy target;

[0030](2) the Mg 3.2 Bi 1.5 Sb 0.5 Alloy Target Vacuum Magnetron Sputtering on c-axis Oriented LaAlO 3 On the surface of a single crystal substrate, a magnetron sputtering film is obtained;

[0031] (3) the magnetron sputtering film is annealed and heat-treated to obtain Mg 3.2 Bi 1.5 Sb 0.5 thermoelectric film.

[0032] In the present invention, metal Mg, Bi and Sb are mixed according to the molar ratio of Mg:Bi:Sb=3.05~3.3:1.5:0.5, followed by ball milling and hot pressing to obtain Mg 3.2 Bi 1.5 Sb 0.5 alloy target. In the present invention, the purity of said metals Mg, Bi and Sb is independently prefe...

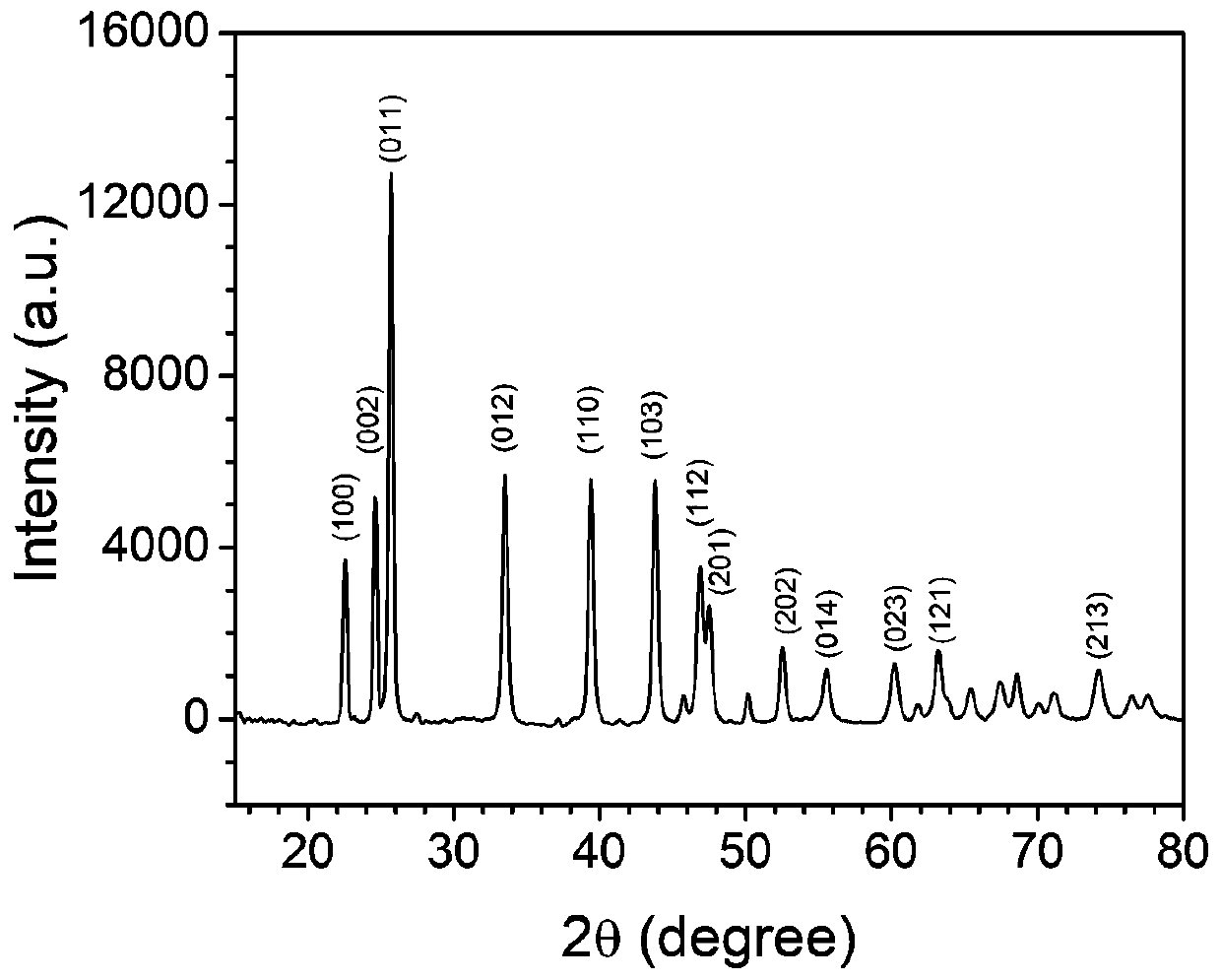

Embodiment 1

[0051] (1) According to the molar ratio of Mg:Bi:Sb=3.05:1.5:0.5, metal Mg, Bi and Sb with a purity of 99.999% are placed in a stainless steel ball mill jar, and ball milled for 12 hours. Under the conditions of hot pressing for 10min, Mg 3.2 Bi 1.5 Sb 0.5 Alloy target, and put Mg 3.2 Bi 1.5 Sb 0.5 The alloy target is installed in the vacuum chamber of the magnetron sputtering equipment;

[0052] (2) Orienting the c-axis to LaAlO 3 (LAO) single crystal was soaked in a mixed solution containing concentrated sulfuric acid (98% by mass fraction) and hydrogen peroxide (20% by mass fraction) at a volume ratio of 1:3 for 20 min, and then placed in a beaker filled with acetone, alcohol In the beaker and the beaker of ultrapure water, respectively, ultrasonically clean it at 50W power for 10 minutes, and then blow dry the LAO single crystal with high-purity nitrogen;

[0053] (3) Install the cleaned LAO single crystal in the vacuum chamber of the vacuum magnetron sputtering dev...

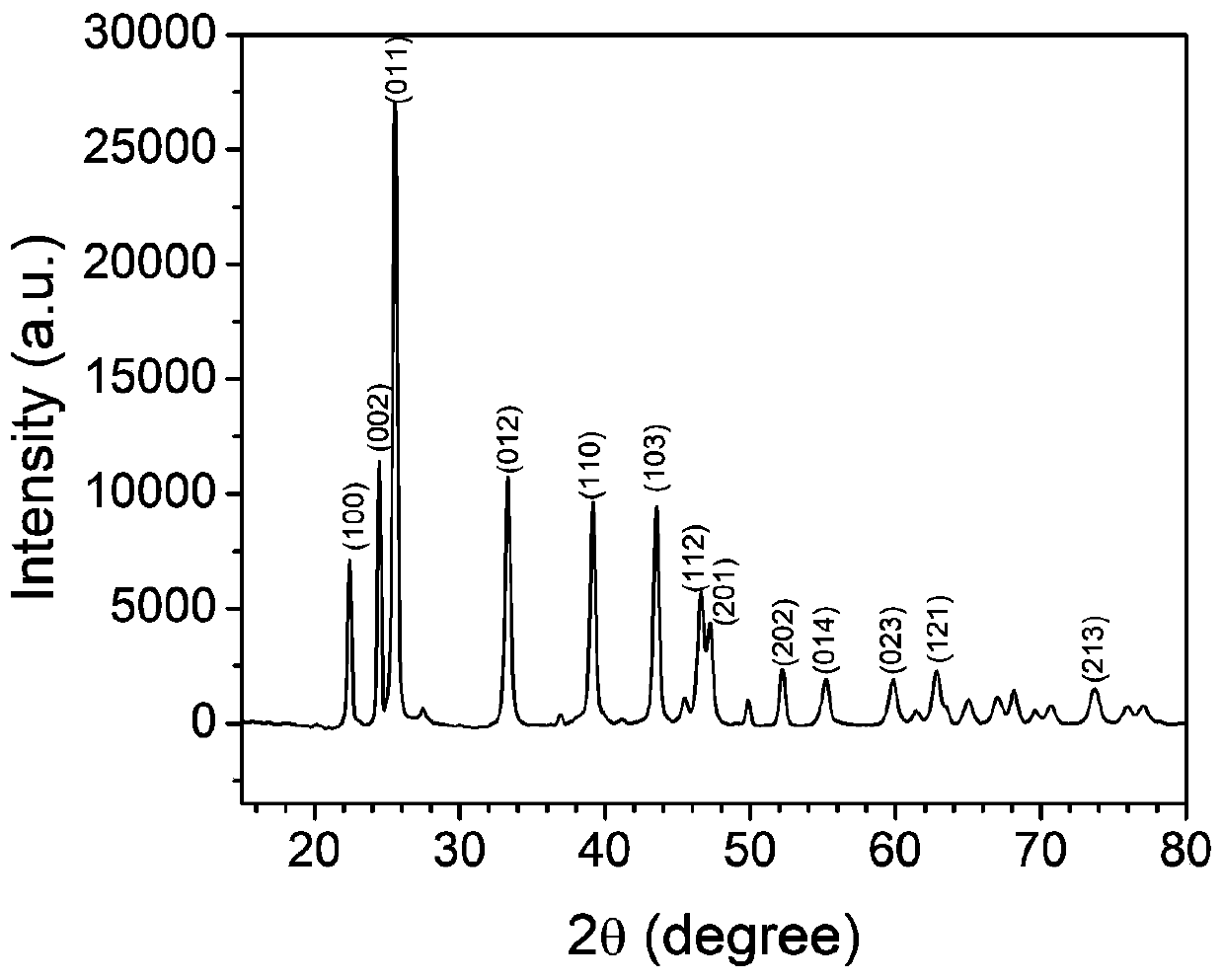

Embodiment 2

[0060] (1) According to the molar ratio of Mg:Bi:Sb=3.2:1.5:0.5, metal powders Mg, Bi and Sb with a purity of 99.999% are placed in a stainless steel ball mill jar, and ball milled for 16 hours. Hot pressing at ℃ for 20min to obtain Mg 3.2 Bi 1.5 Sb 0.5 Alloy target, and put Mg 3.2 Bi 1.5 Sb 0.5 The alloy target is installed in the vacuum chamber of the magnetron sputtering equipment;

[0061] (2) Orienting the c-axis to LaAlO 3 (LAO) single crystal was soaked in a mixed solution containing concentrated sulfuric acid (98% by mass fraction) and hydrogen peroxide (20% by mass fraction) at a volume ratio of 1:3 for 25 min, and then placed in a beaker filled with acetone, alcohol In the beaker and the beaker of ultrapure water, respectively, ultrasonically clean it at 60W for 15 minutes, and then dry the LAO single crystal with high-purity nitrogen;

[0062] (3) Install the cleaned LAO single crystal in the vacuum chamber of the vacuum magnetron sputtering device, and bake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com