Patents

Literature

40 results about "Preferential growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

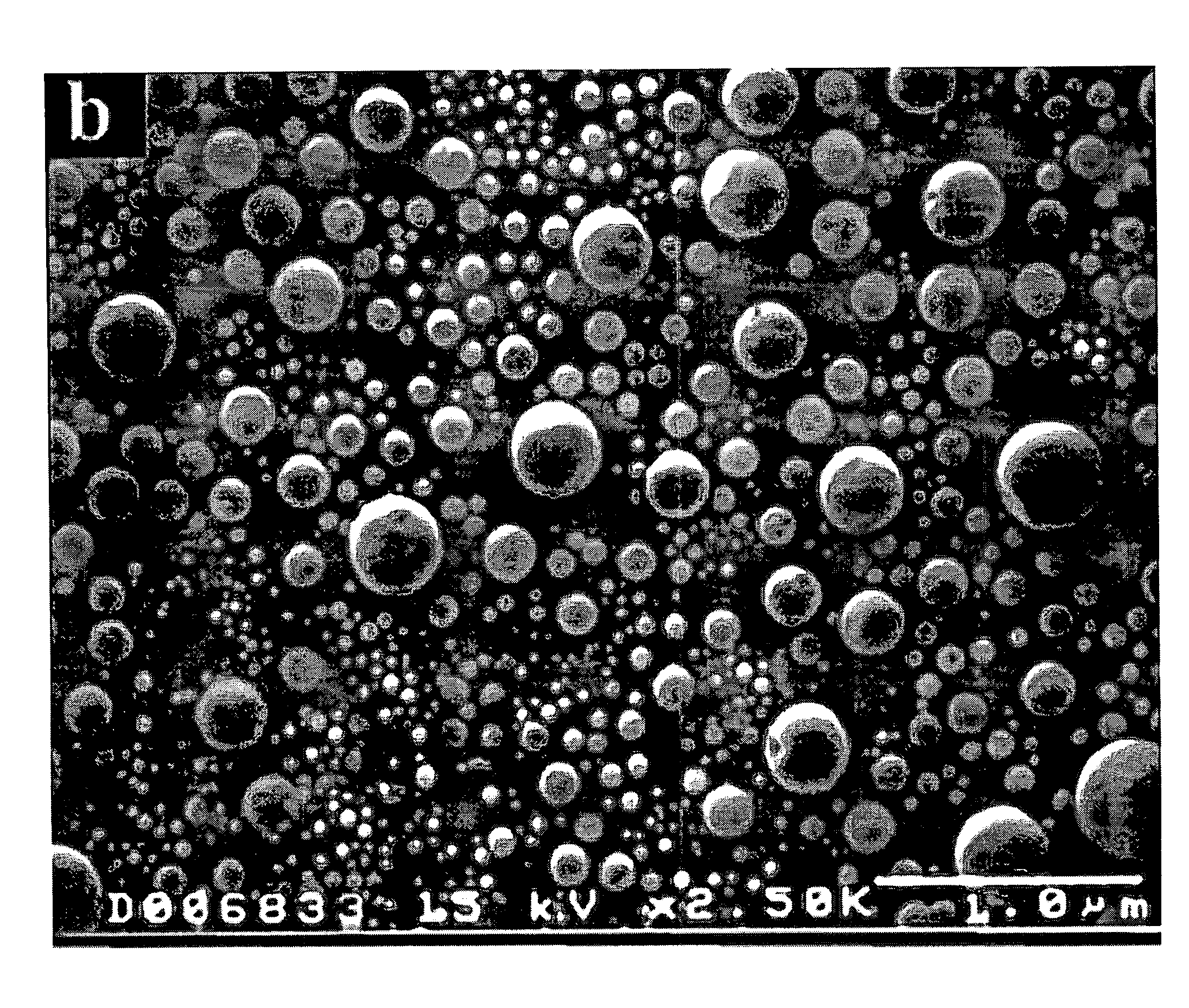

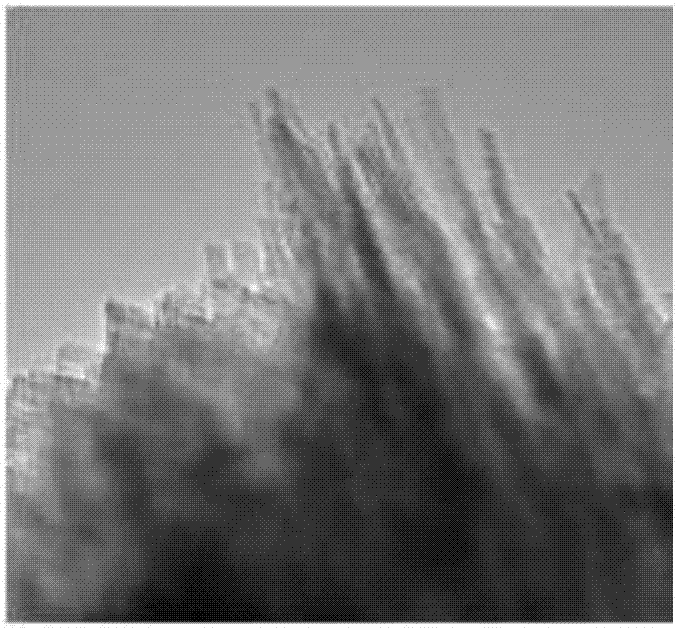

Directionally controlled growth of nanowhiskers

InactiveUS7354850B2Optimized structural formWell-defined surfaceMaterial nanotechnologyPolycrystalline material growthStacking faultOrganic vapor

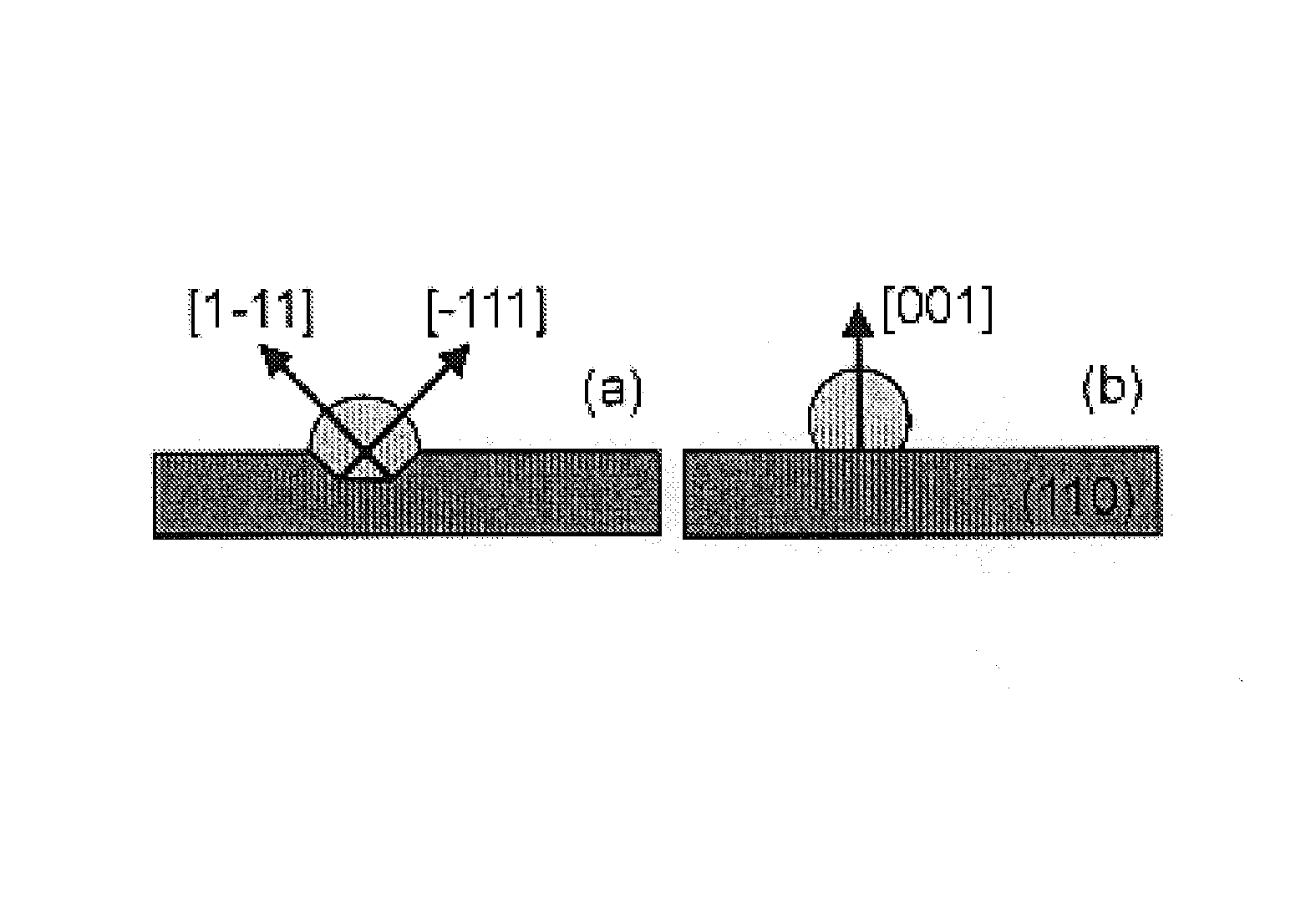

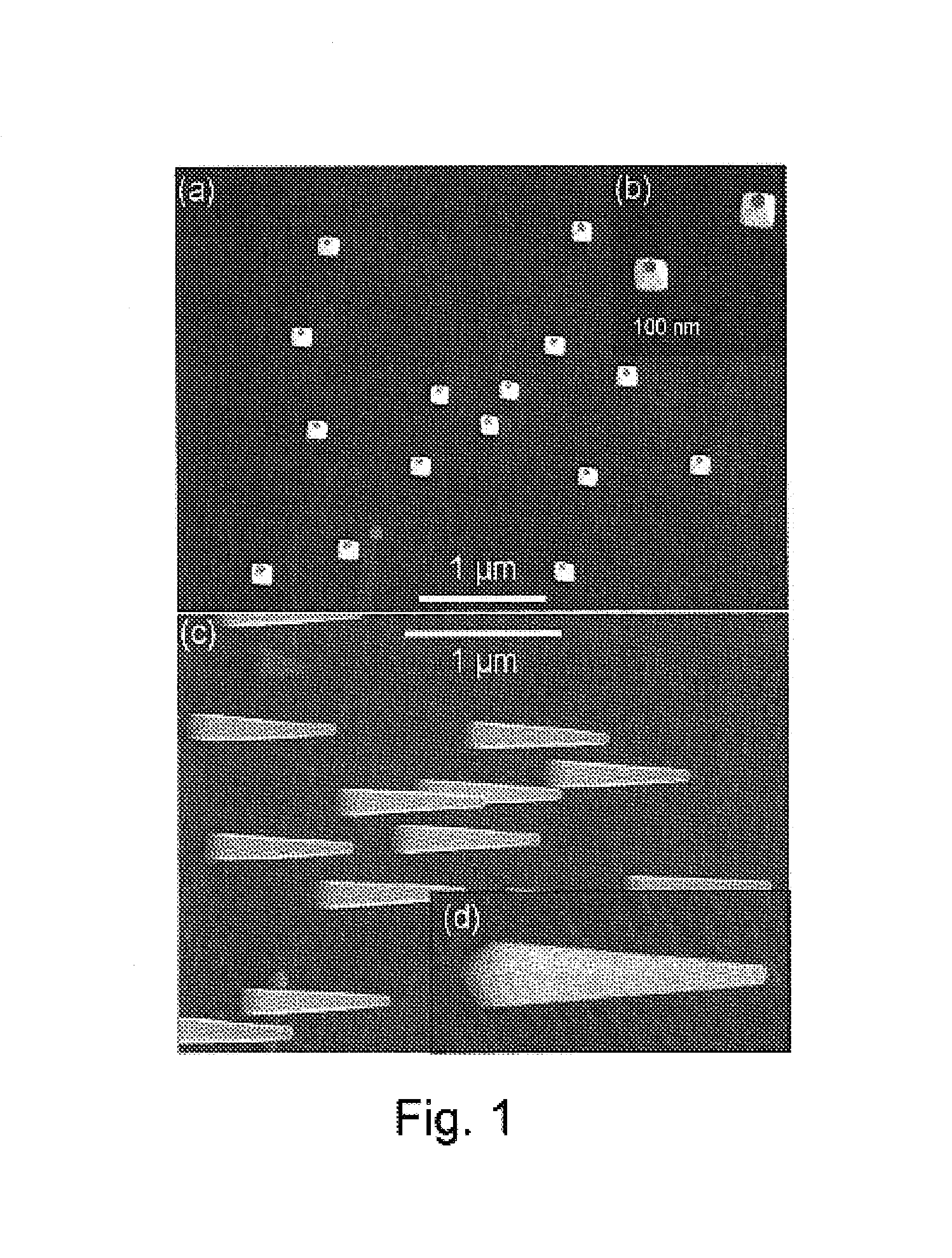

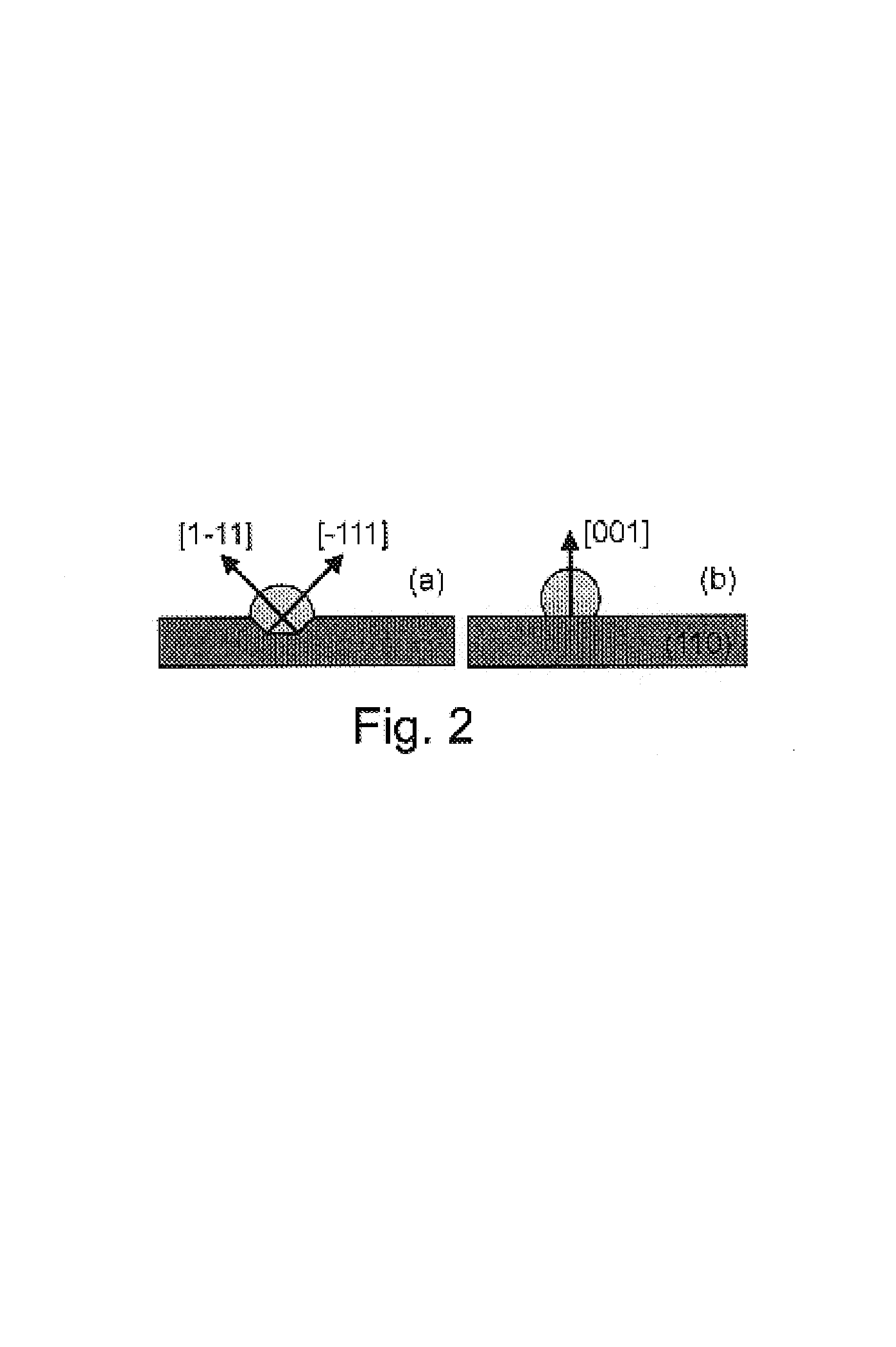

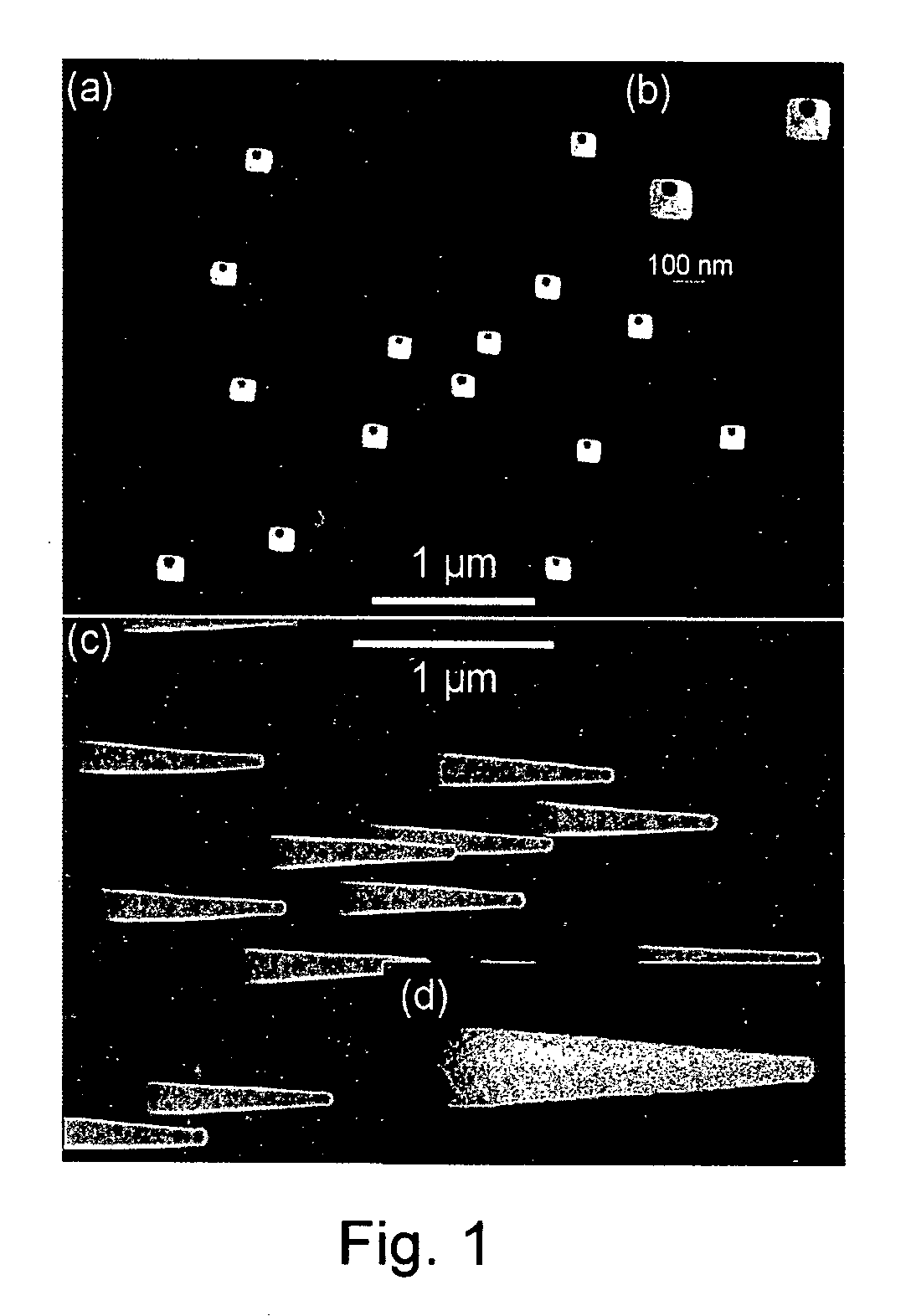

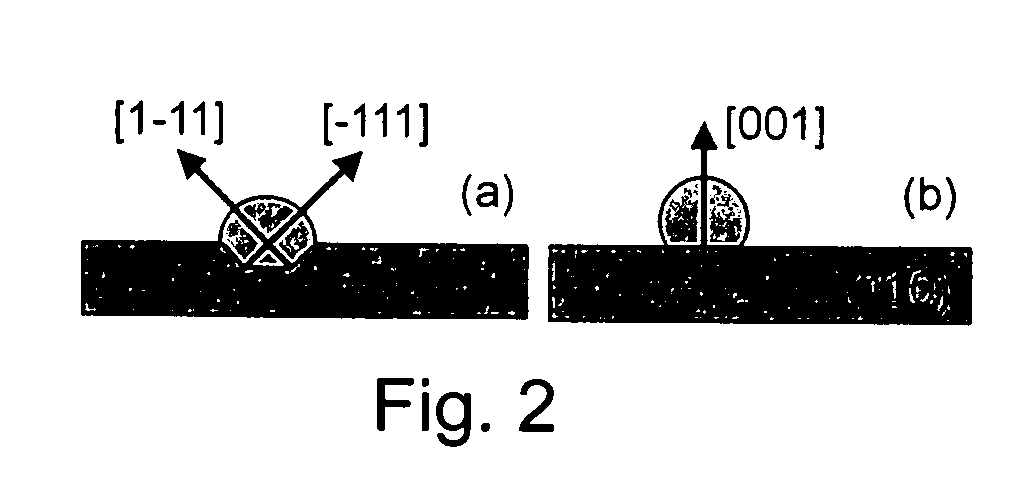

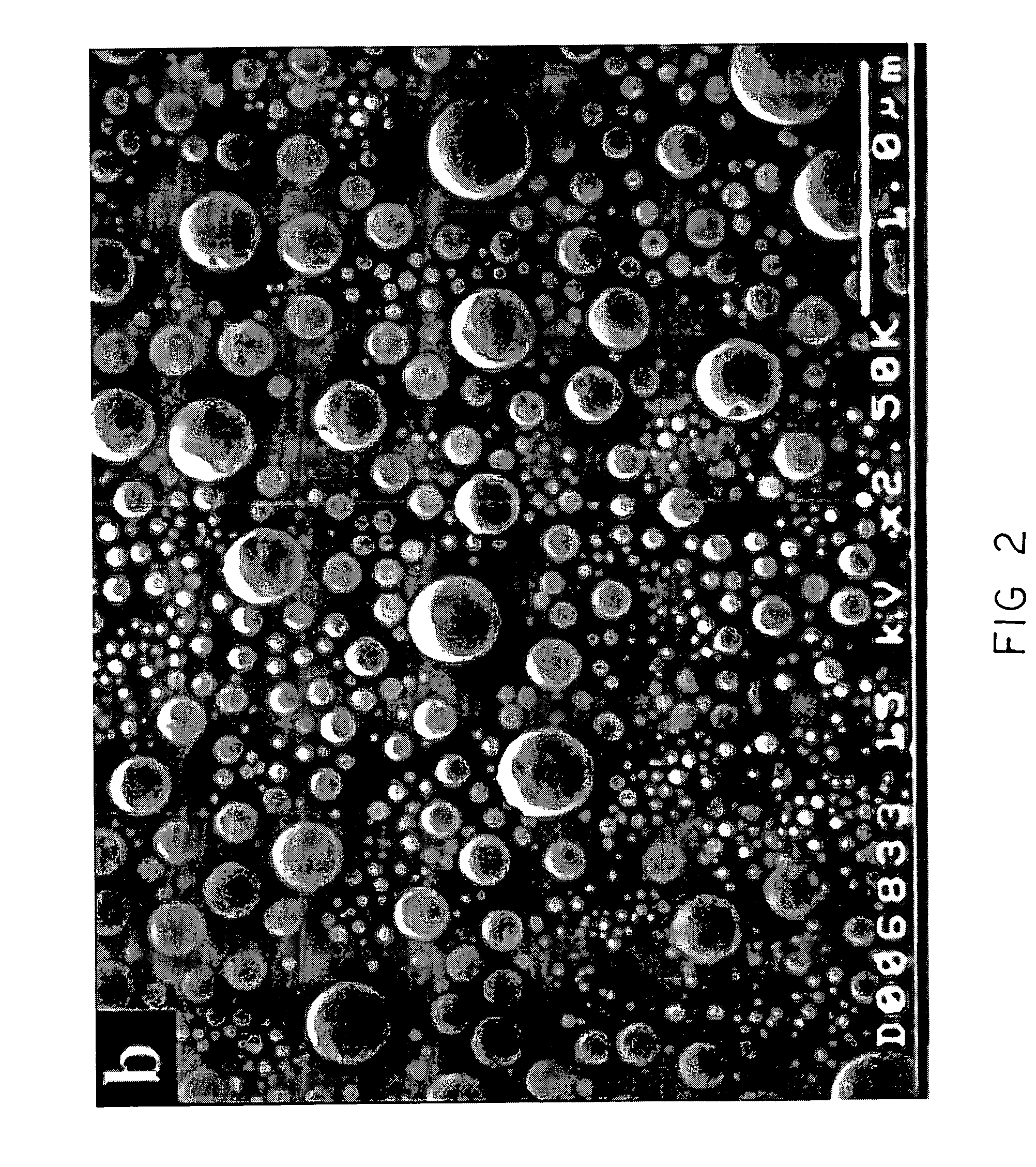

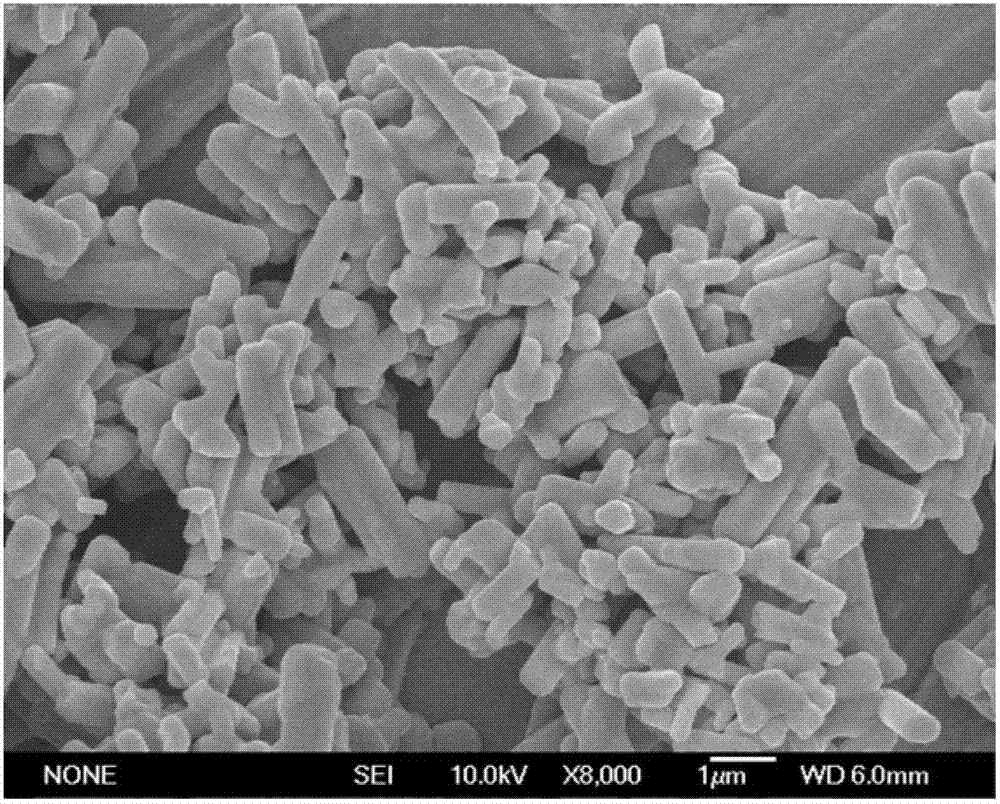

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

Directionally controlled growth of nanowhiskers

InactiveUS20060019470A1Well-defined surfaceReduce the temperatureMaterial nanotechnologyPolycrystalline material growthNanowireStacking fault

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

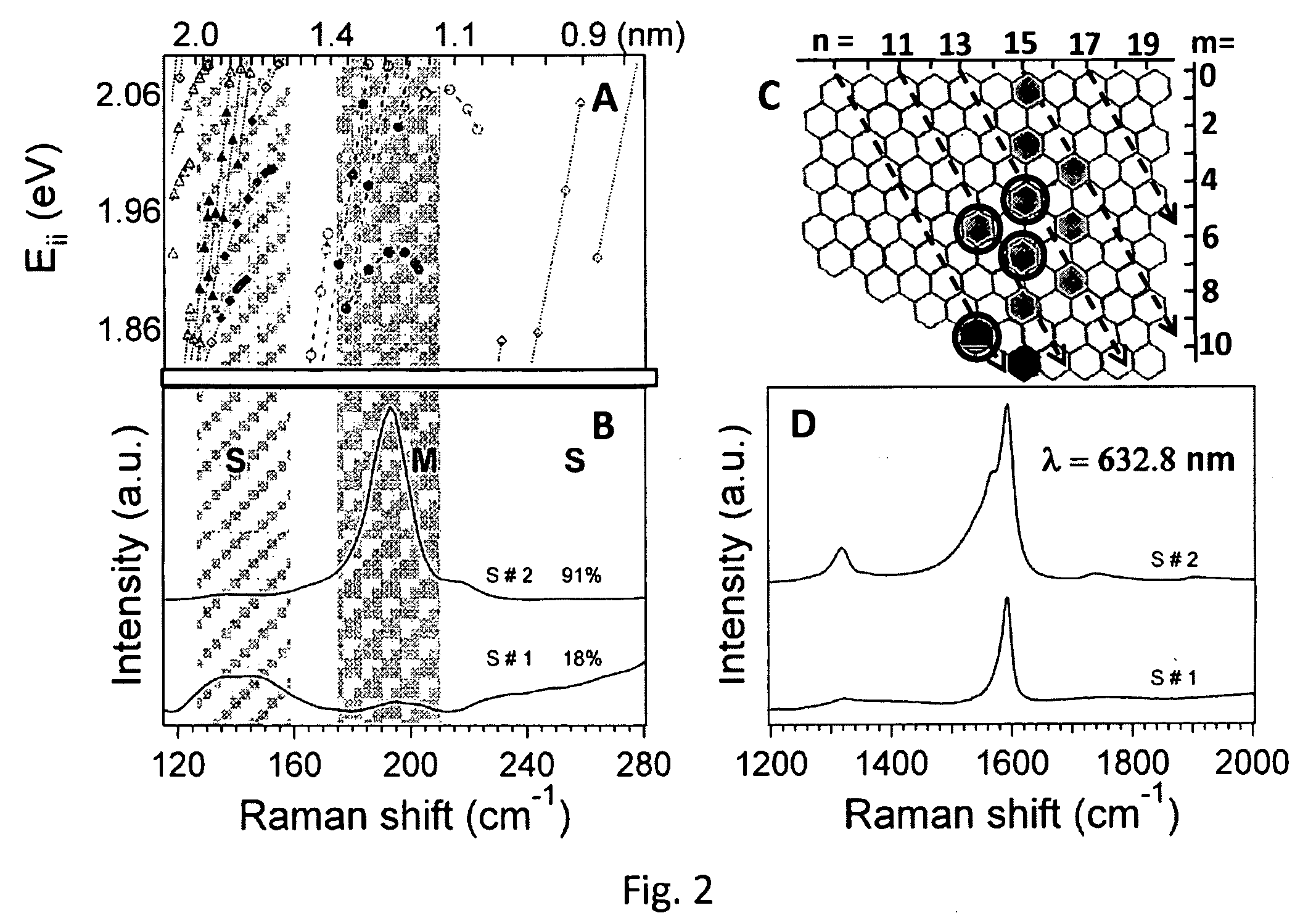

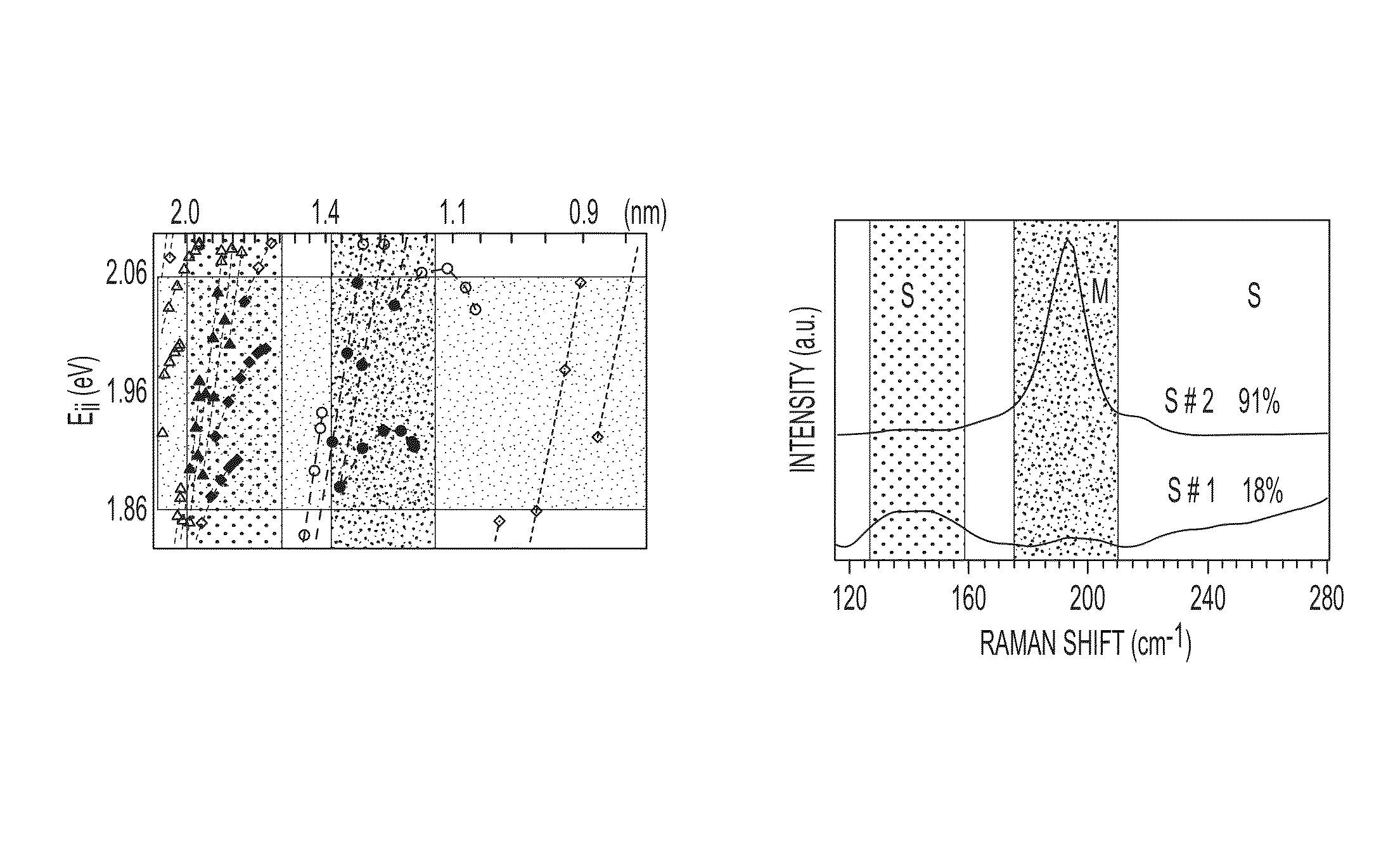

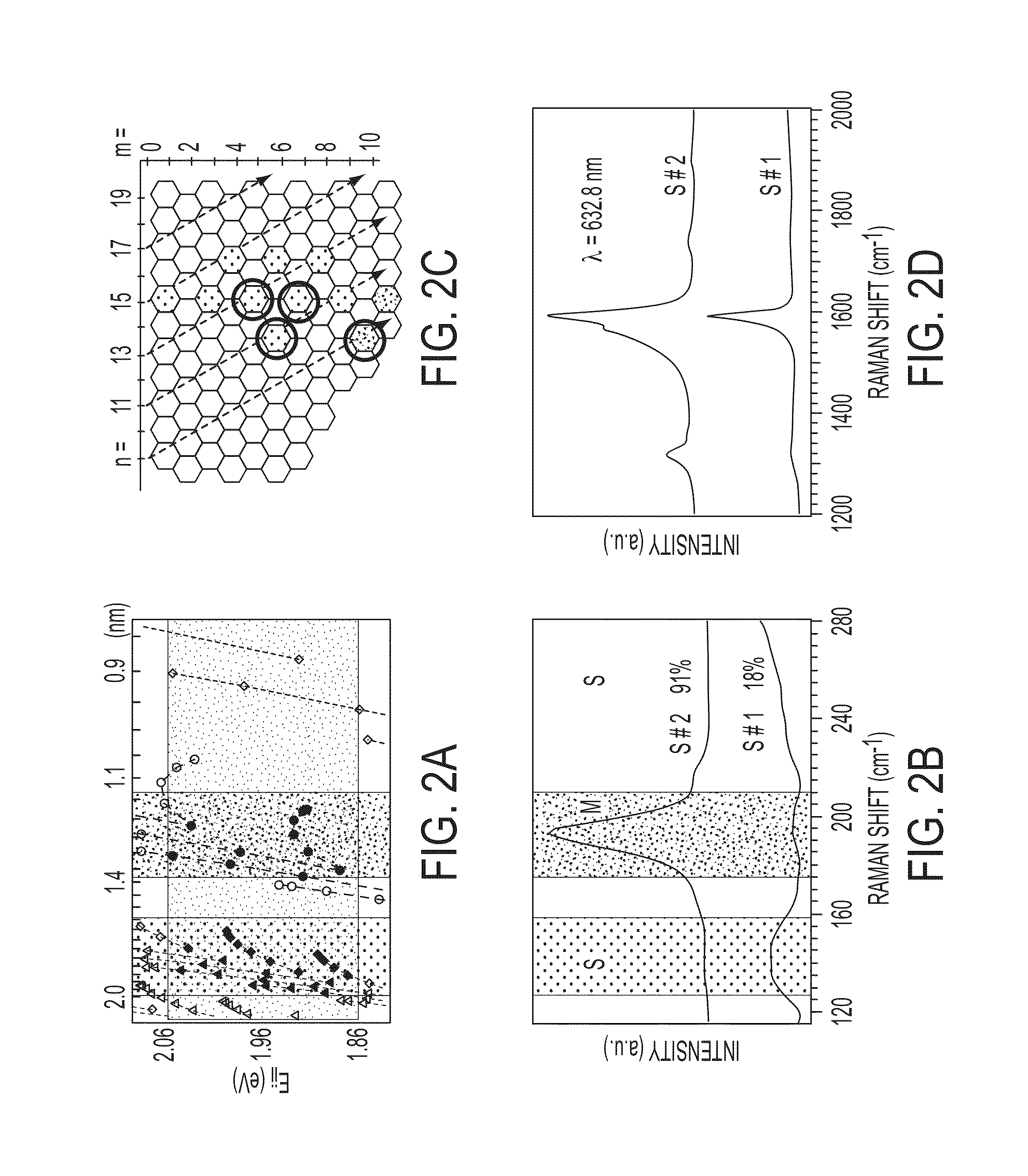

Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity

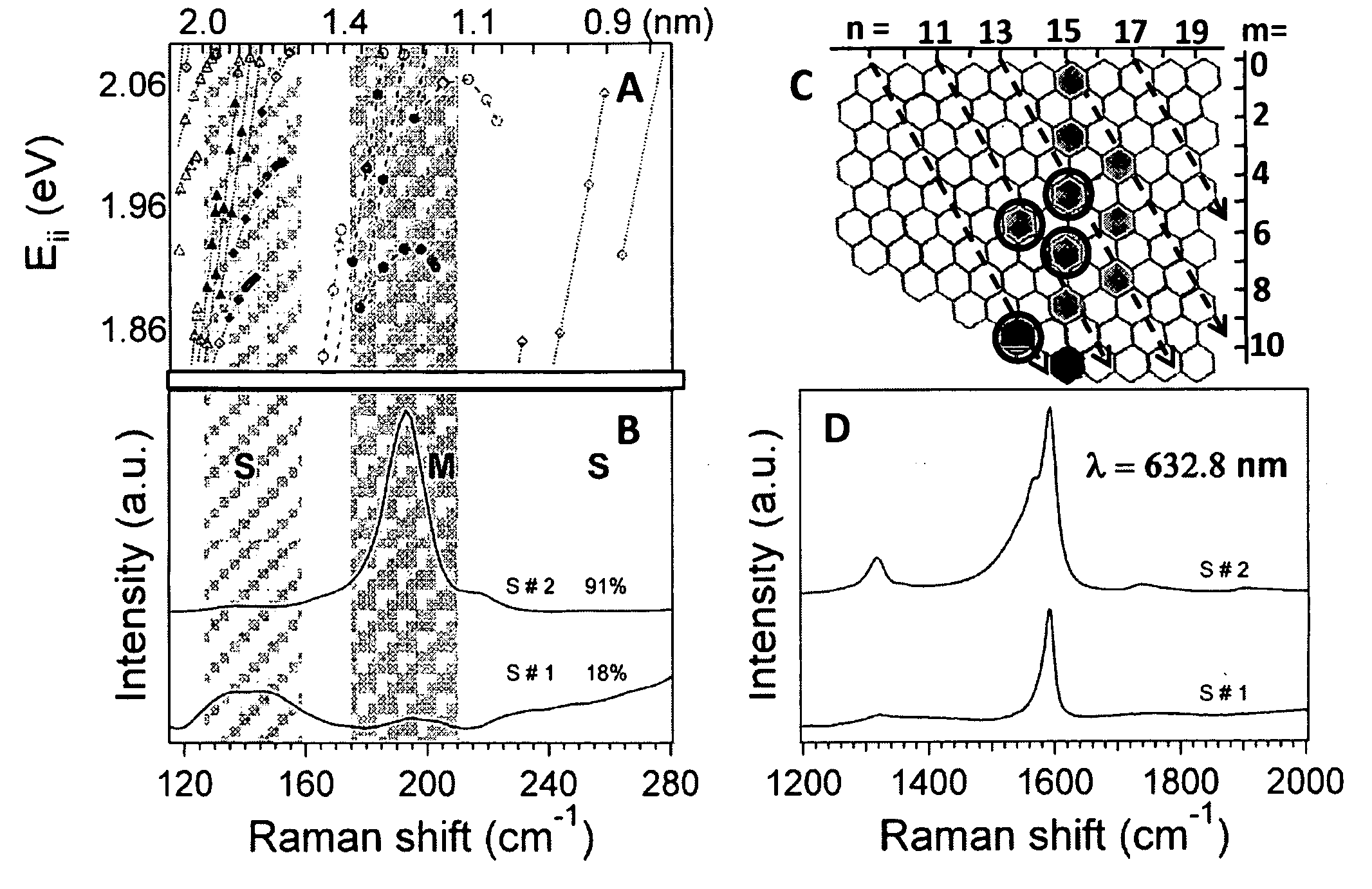

ActiveUS20100034725A1High yieldMaterial nanotechnologySingle-walled nanotubesSufficient timePresent method

The present disclosure is directed to a method of producing metallic single-wall carbon nanotubes by treatment of carbon nanotube producing catalysts to obtain the desired catalyst particle size to produce predominantly metallic single wall carbon nanotubes. The treatment of the carbon nanotube producing catalyst particles involves contacting the catalyst particles with a mixture of an inert gas, like He, a reductant, such as H2, and an adsorbate, like water, at an elevated temperature range, for example, at 500° C. to 860° C., for a sufficient time to obtain the catalyst particle size. In some of the present methods, the preferential growth of nanotubes with metallic conductivity of up to 91% has been demonstrated.

Owner:HONDA MOTOR CO LTD

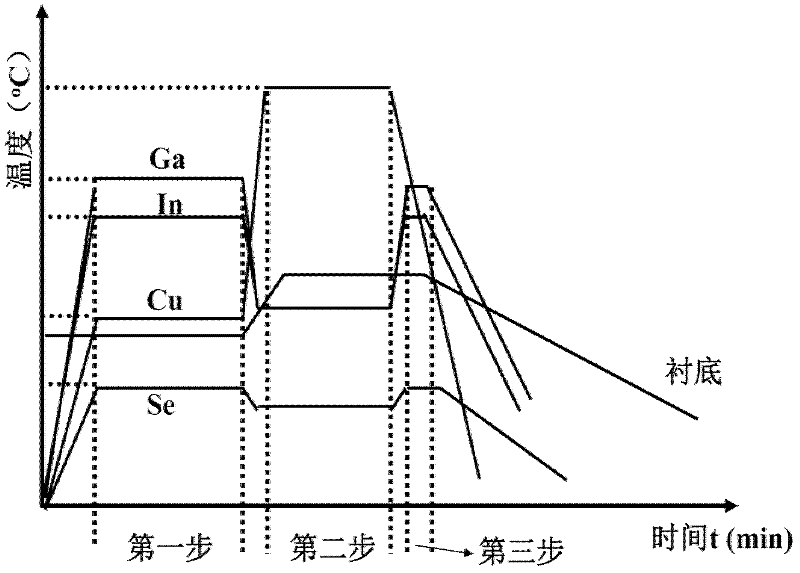

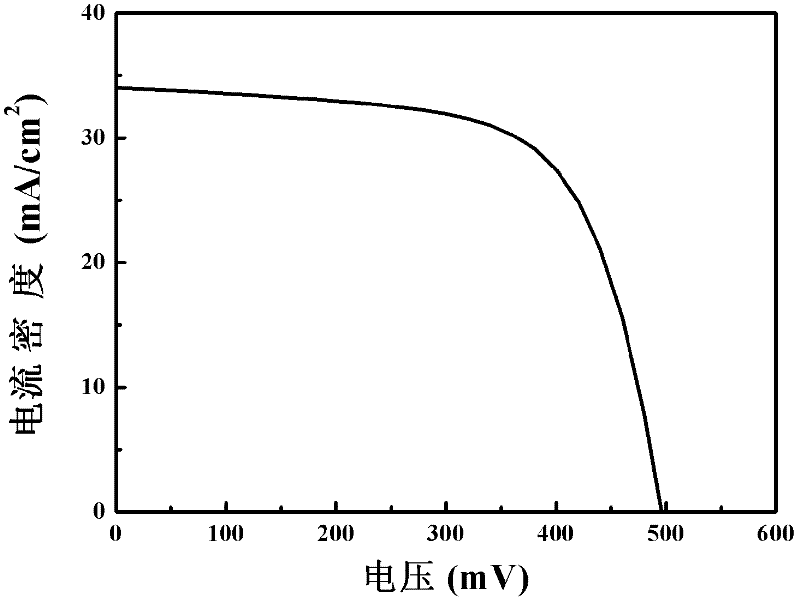

Flexible stainless steel substrate copper-indium-gallium-selenium film battery and preparation method thereof

InactiveCN102509737AOvercoming the problem of poor binding forceSimple manufacturing processFinal product manufacturePhotovoltaic energy generationWater bathsIndium

The invention relates to a flexible stainless steel substrate copper-indium-gallium-selenium film battery which has a combined structure comprising a stainless steel foil substrate and a multi-layer film, wherein the multi-layer film comprises a bottom electrode, an absorption layer, a buffer layer, an intrinsic ZnO layer, an aluminum-doped ZnO layer and a gate electrode which are superimposed together in order. A preparation method of the flexible stainless steel substrate copper-indium-gallium-selenium film battery comprises the following steps of: depositing a double-layer Mo back electrode on the stainless steel substrate by adopting a magnetron sputtering method; preparing a copper-indium-gallium-selenium absorption layer by adopting a three-step co-evaporation method; preparing a CdS buffer layer by adopting a chemical water bath method; preparing the intrinsic ZnO layer and the aluminum-doped ZnO layer by adopting the magnetron sputtering method; and preparing a Ni / Al gate electrode by adopting a thermal evaporation method. The flexible stainless steel substrate copper-indium-gallium-selenium film battery and the preparation method thereof disclosed by the invention have the advantages that: a copper-indium-gallium-selenium film with a preferential growth structure (220) is prepared by using the method, so that the problem that the bonding force between a blocking layer and other contact layers is poor is solved, and the preparation process is simplified; and under the condition of AM1.5 illumination, the battery efficiency of the film solar battery is more than 11.0 percent, and the film solar battery plays an important promotion role when applied to the field of solar batteries.

Owner:NANKAI UNIV

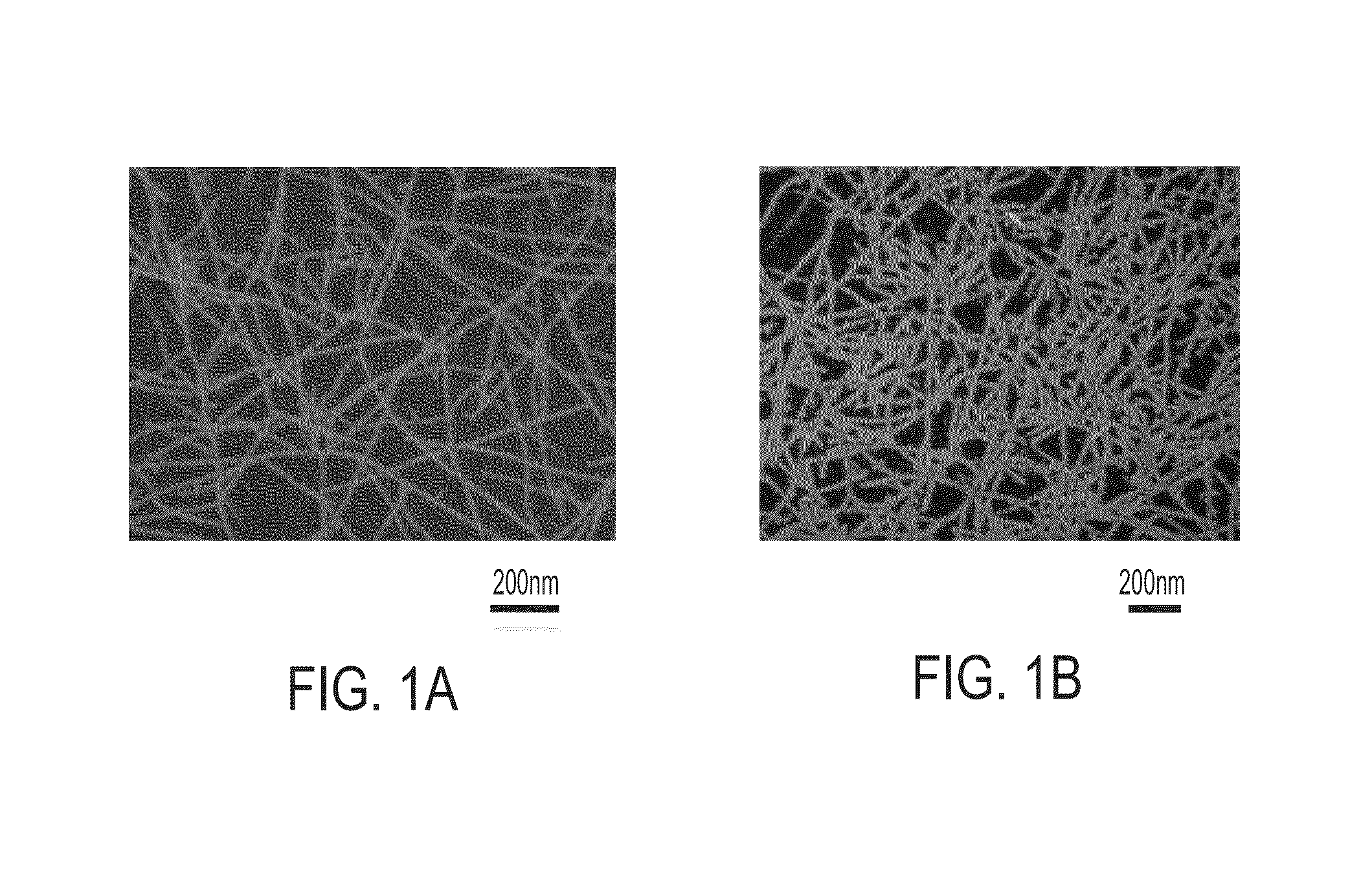

Formation of metal oxide nanowire networks (nanowebs) of low-melting metals

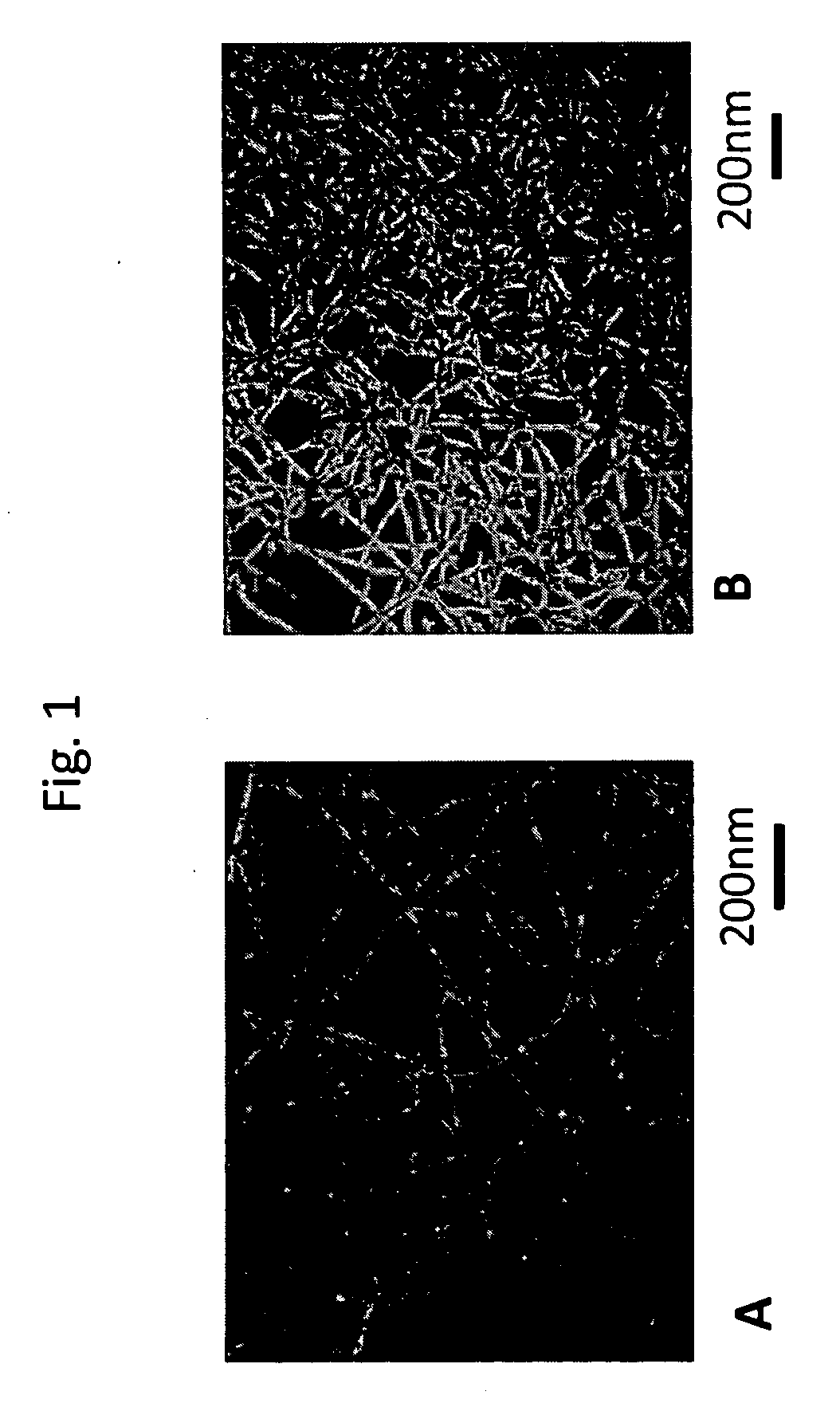

InactiveUS7445671B2Easy to liftSuitable and interesting for large-scale productionMaterial nanotechnologyPolycrystalline material growthNanowireGas phase

A method of producing networks of low melting metal oxides such as crystalline gallium oxide comprised of one-dimensional nanostructures. Because of the unique arrangement of wires, these crystalline networks defined as “nanowebs”, “nanowire networks”, and / or “two-dimensional nanowires”. Nanowebs contain wire densities on the order of 109 / cm2. A possible mechanism for the fast self-assembly of crystalline metal oxide nanowires involves multiple nucleation and coalescence via oxidation-reduction reactions at the molecular level. The preferential growth of nanowires parallel to the substrate enables them to coalesce into regular polygonal networks. The individual segments of the polygonal network consist of both nanowires and nanotubules of β-gallium oxide. The synthesis of highly crystalline noncatalytic low melting metals such as β-gallium oxide tubes, nanowires, and nanopaintbrushes is accomplished using molten gallium and microwave plasma containing a mixture of monoatomic oxygen and hydrogen. Gallium oxide nanowires were 20-100 nm thick and tens to hundreds of microns long. Transmission electron microscopy (TEM) revealed the nanowires to be highly crystalline and devoid of any structural defects. Results showed that multiple nucleation and growth of gallium oxide nanostructures can occur directly out of molten gallium exposed to appropriate composition of hydrogen and oxygen in the gas phase. The method of producing nanowebs is extendible to other low melting metals and their oxides such as for example: zinc oxide, tin oxide, aluminum oxide, bismuth oxide, and titanium dioxide.

Owner:UNIV OF LOUISVILLE +2

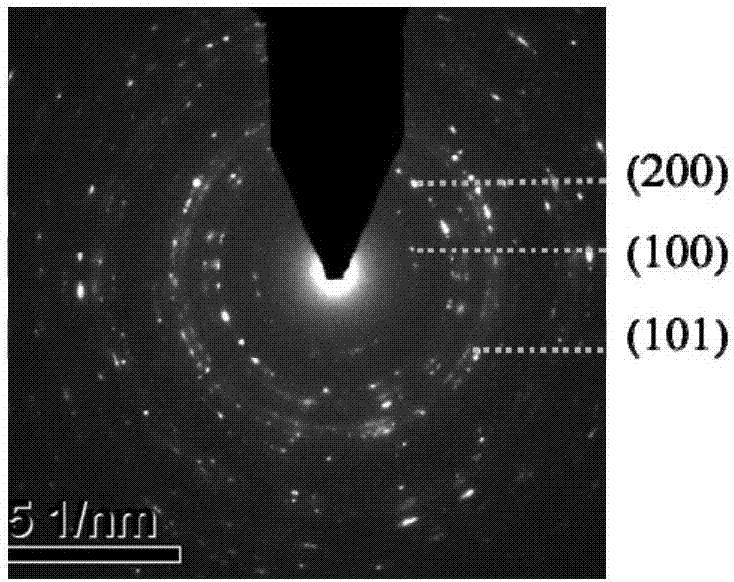

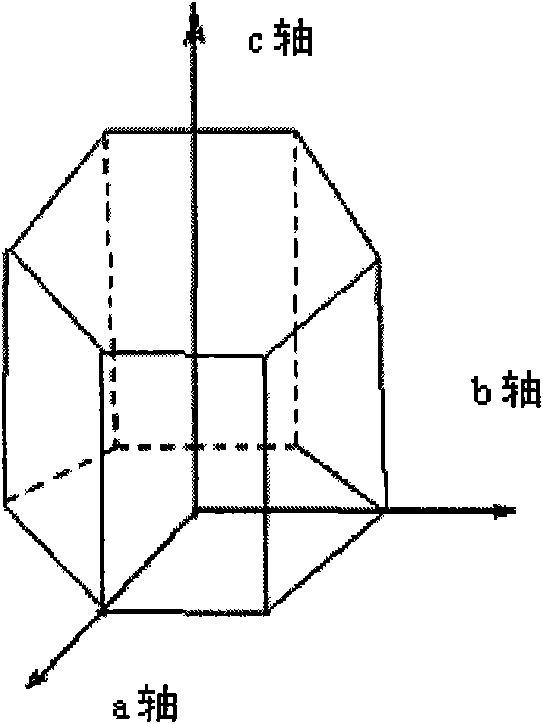

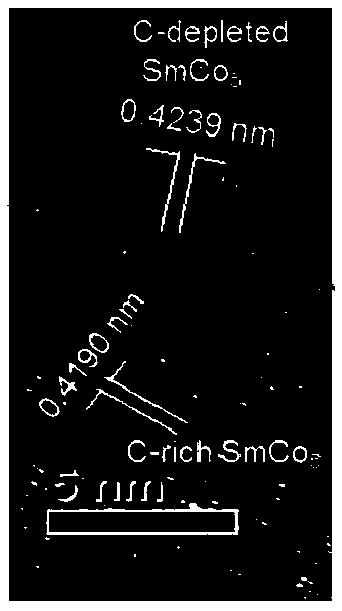

Anisotropic SmCo<5> type rare earth permanent magnet material and preparation method therefor

ActiveCN106935350AIncrease the use of high temperatureImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsRare earthCurie temperature

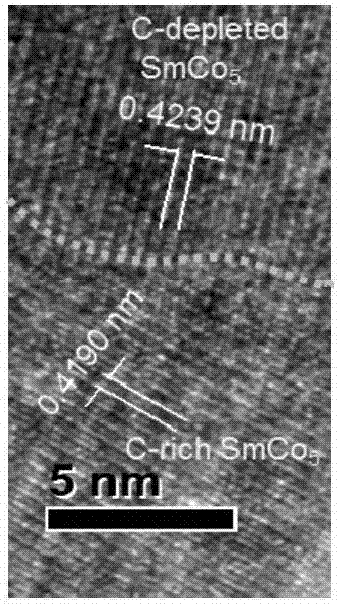

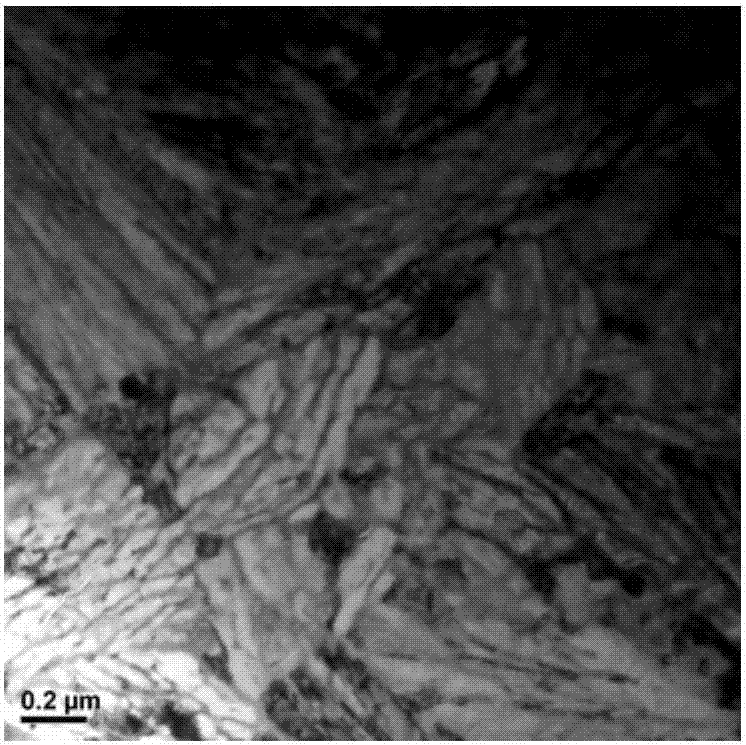

The invention discloses an anisotropic SmCo<5> type rare earth permanent magnet material and a preparation method therefor. The permanent magnet material comprises the following components with the general formula as follows: SmCo<5-x>C<x> or Sm(Co<1-y>M<y>)<5-x>C<x>, where y is greater than or equal to 0.01 and less than or equal to 0.3; x is greater than or equal to 0.02 and less than or equal to 2; M is selected from one or more of metals Fe, Ni, Cr, Cu, V, Ti, Zr, Mn, W or Mo; the preparation process comprises the steps of preparing materials, smelting and performing rapid quenching on melt, wherein the step of rapid quenching on the melt is performed by a vacuum melt-spinning machine with the copper roller rotary speed V of greater than or equal to 40m / s. The rare earth permanent magnet material is reasonable in component matching, and capable of effectively improving degree of supercooling of the alloy component system; the preparation process is simple, and the easily magnetized axis, namely, a C axis, of the prepared anisotropic SmCo<5> nanocrystal permanent magnet material is perpendicular to the surface of a thin strip, and a structure of preferential growth is formed on the C axis; therefore, the alloy has excellent magnetic performance in a direction perpendicular to the thin strip, the crystal particles are fine and small, and the alloy is high in remanent magnetization strength, coercivity, magnetic energy product and the Curie temperature; and the use temperature of the temperature can be effectively improved, so that the rare earth permanent magnet material is suitable for industrial application.

Owner:CENT SOUTH UNIV

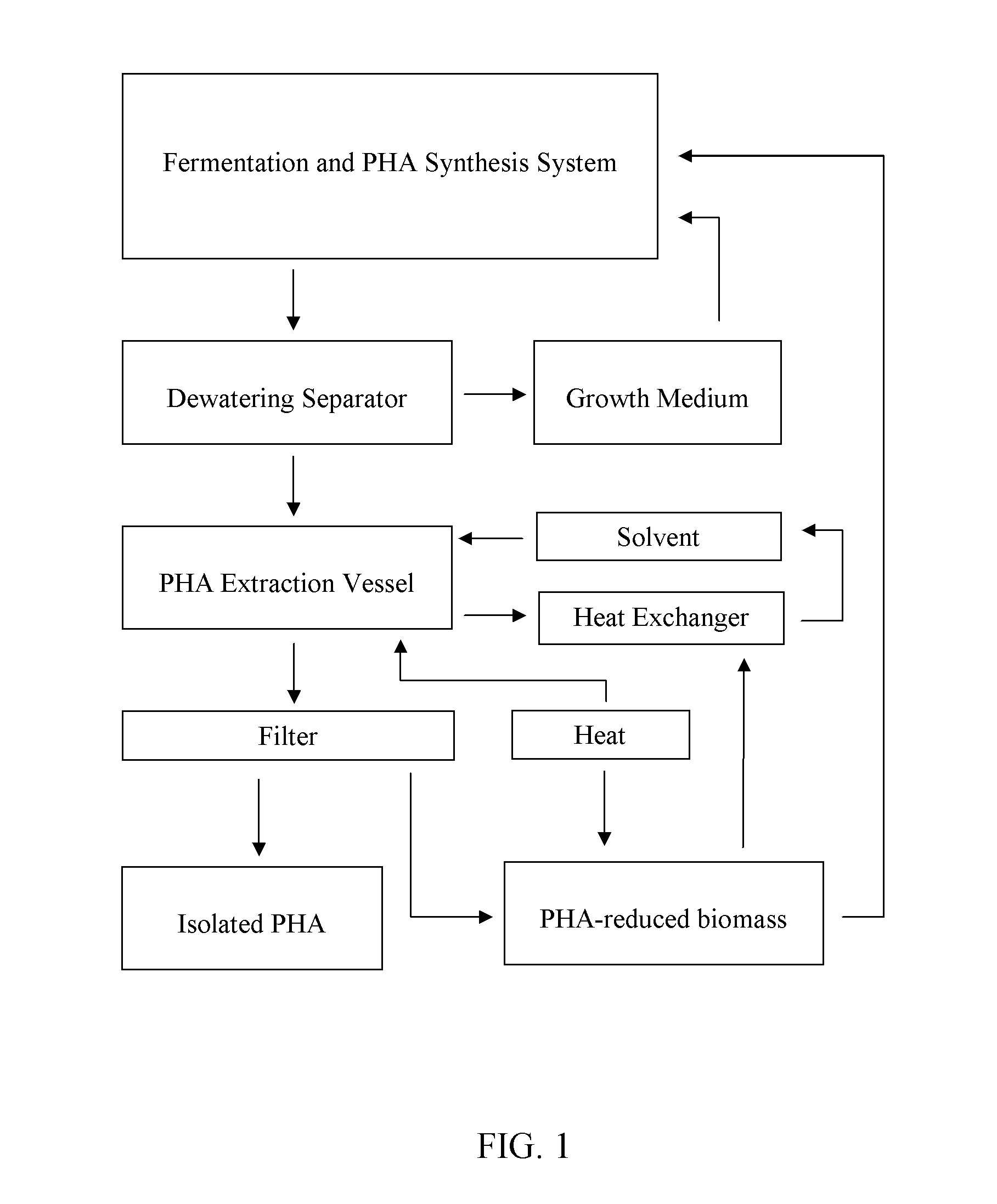

Polyhydroxyalkanoate production methods and materials and microorganisms used in same

ActiveUS20150275241A1Reduce carbon input costWide availabilityFermentationBiotechnologyMicroorganism

Embodiments of the invention relate generally to methods to generate microorganisms and / or microorganism cultures that exhibit the ability to produce polyhydroxyalkanoates (PHA) from carbon sources at high efficiencies. In several embodiments, preferential expression of, or preferential growth of microorganisms utilizing certain metabolic pathways, enables the high efficiency PHA production from carbon-containing gases or materials. Several embodiments relate to the microorganism cultures, and / or microorganisms isolated therefrom.

Owner:NEWLIGHT TECH

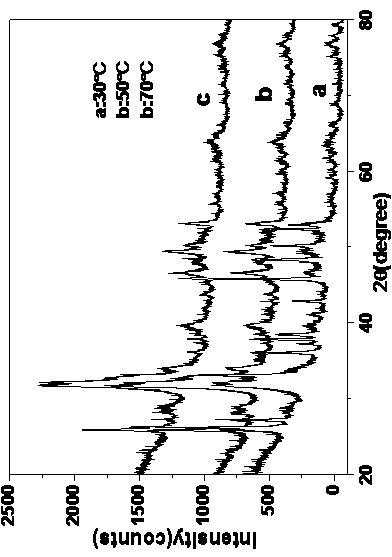

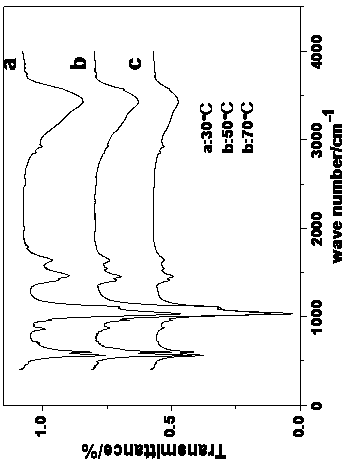

Preparation method of hydroxyapatite nanosheets

InactiveCN103991856ASimple requirementsReduce manufacturing costMaterial nanotechnologyPhosphorus compoundsWater bathsSolubility

The invention relates to a preparation method of hydroxyapatite nanosheets, which comprises the following step: by using shell powder or egg shells as a calcium source, ammonium phosphate as a phosphorus source and water as a solvent, reacting at 30-70 DEG C to obtain the hydroxyapatite nanosheets. According to the method, the reaction occurs at lower temperature, the prepared shell calcium carbonate crystal grains have favorable crystallinity and obvious oriented preferential growth shape, are sheet-shaped, and have low solubility in the water solution. In the reaction process, calcium carbonate crystal grain dissolution, hydroxyapatite recrystallization and hydroxyapatite grain growth are performed, the calcium carbonate sheet-like crystal grains gradually grow into the hydroxyapatite nanosheets. The method has simple requirements for reactors, and can perform production only by using a glass container, a stirrer, a thermostatic water bath box and other low-temperature reactors; and the production process is easy to operate and does not need any high-temperature high-pressure apparatus, thereby effectively lowering the production cost of hydroxyapatite.

Owner:HUAIHAI INST OF TECH +2

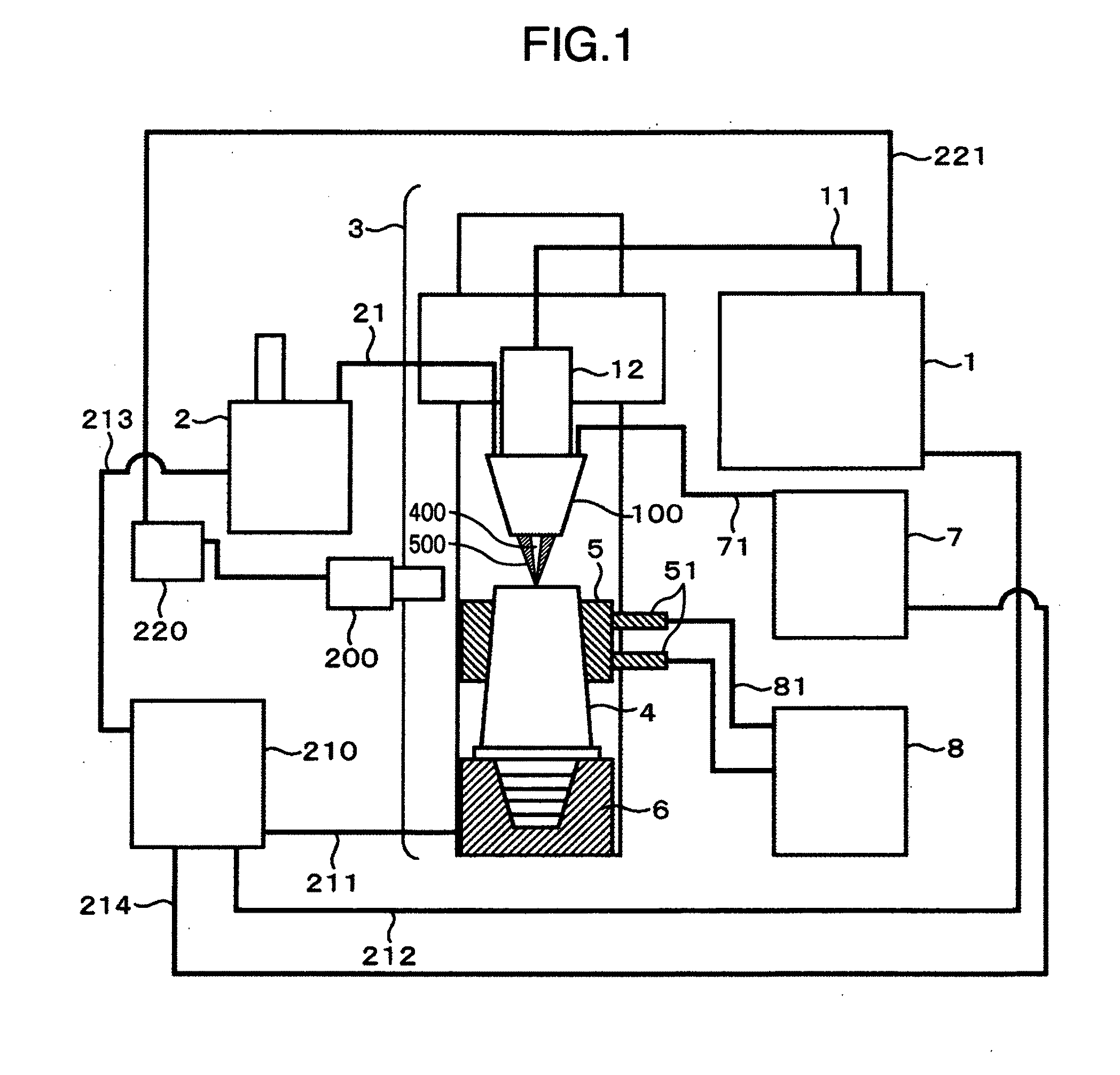

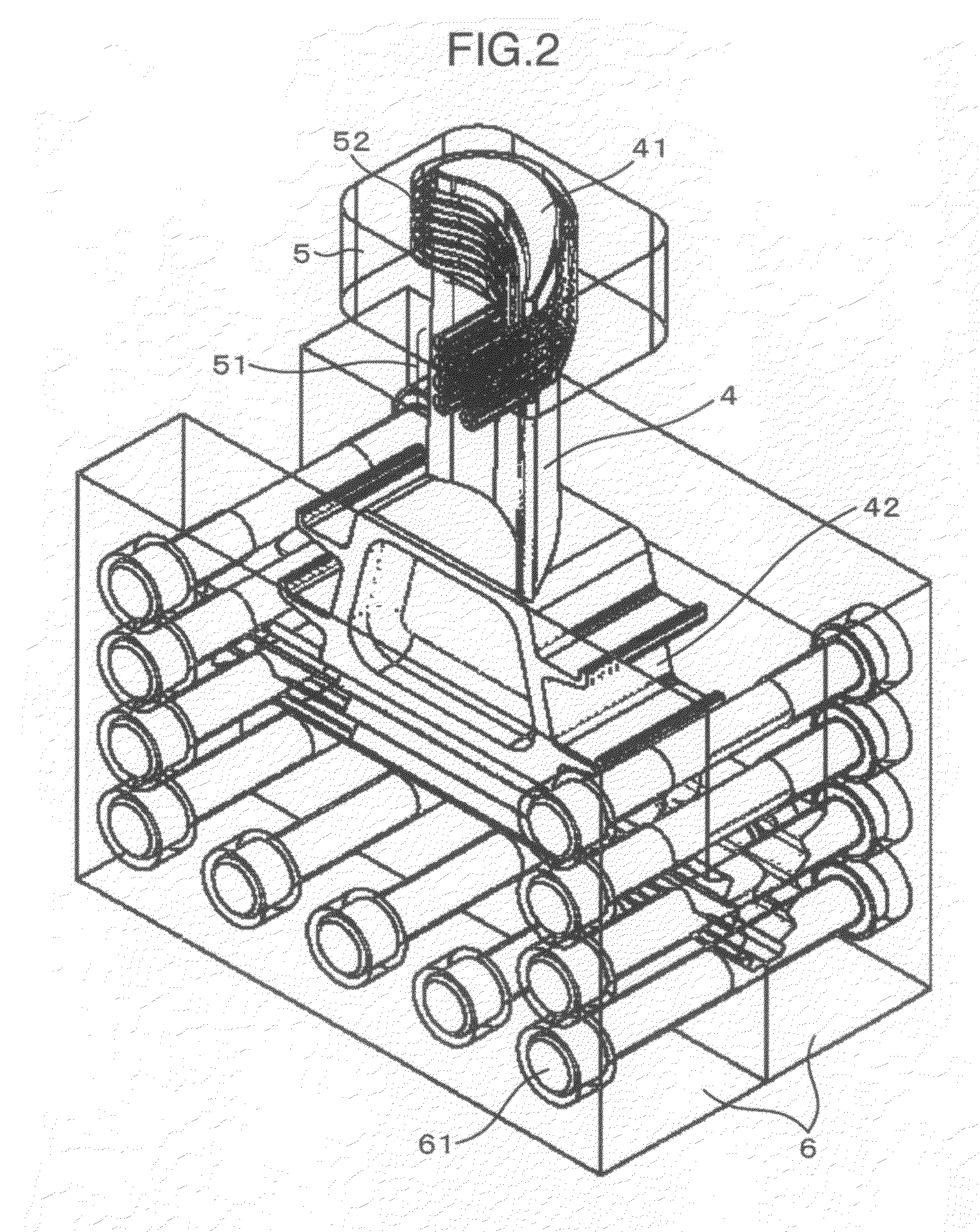

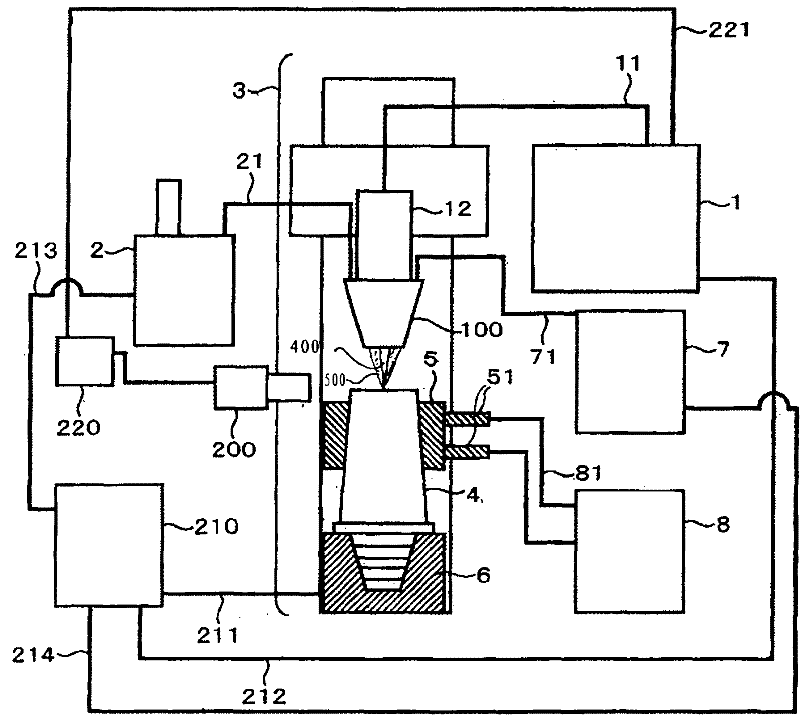

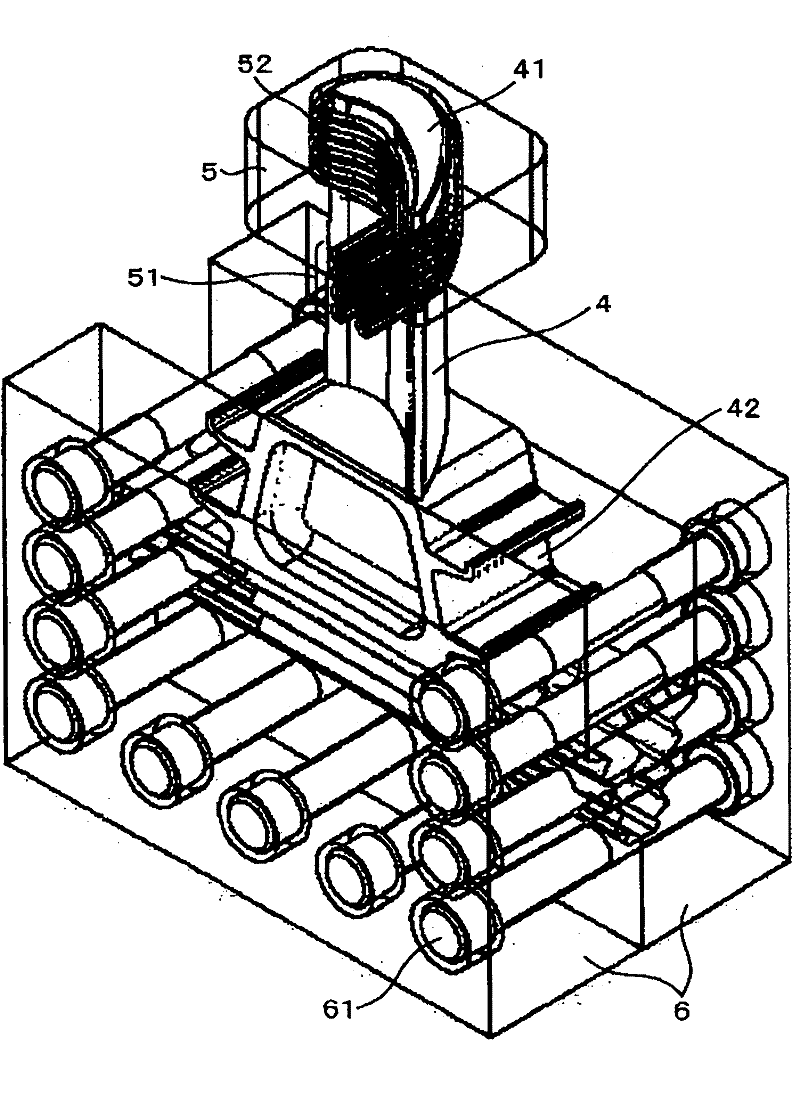

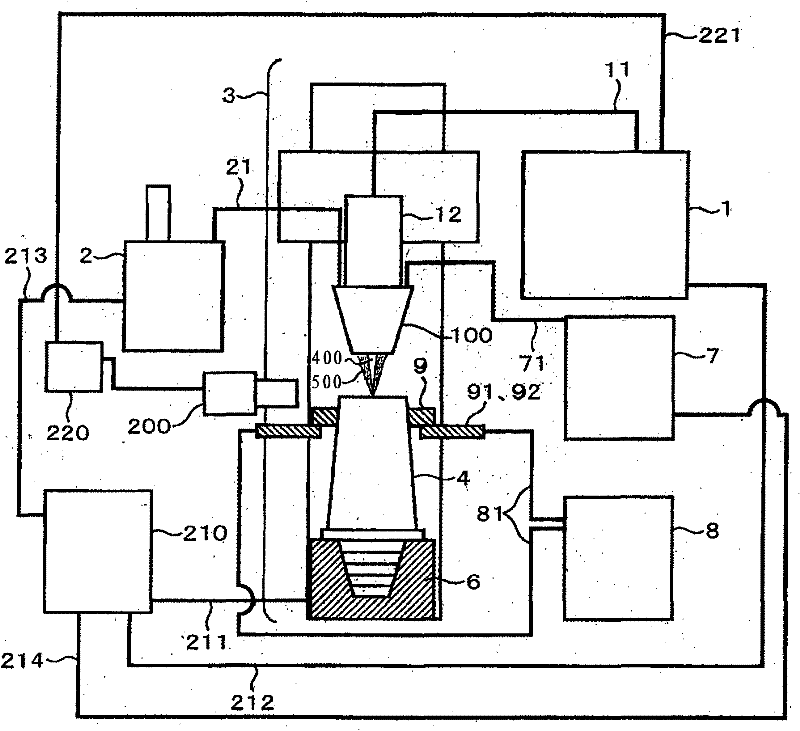

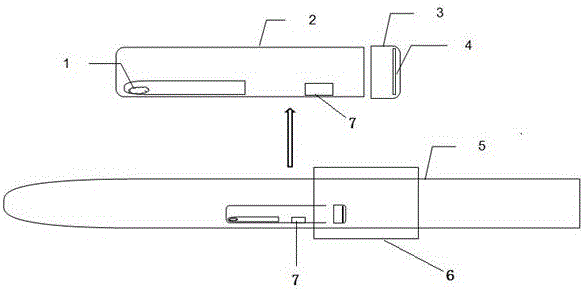

Metal deposition method and laser metal deposition apparatus

InactiveUS20110248001A1Control coarseningLimit solidification rateTurbinesPolycrystalline material growthSingle crystalDirectional solidification

In a deposition method of forming a buildup on a single crystal or directionally solidified crystal parent material, metal deposition is performed from an extension in a preferential growth orientation of parent material crystals while forcedly cooling a portion of the parent material somewhat below a processed surface and beforehand giving a temperature gradient to the parent material so that a maximum temperature gradient is oriented along the preferential growth orientation of parent material crystals.

Owner:HITACHI LTD

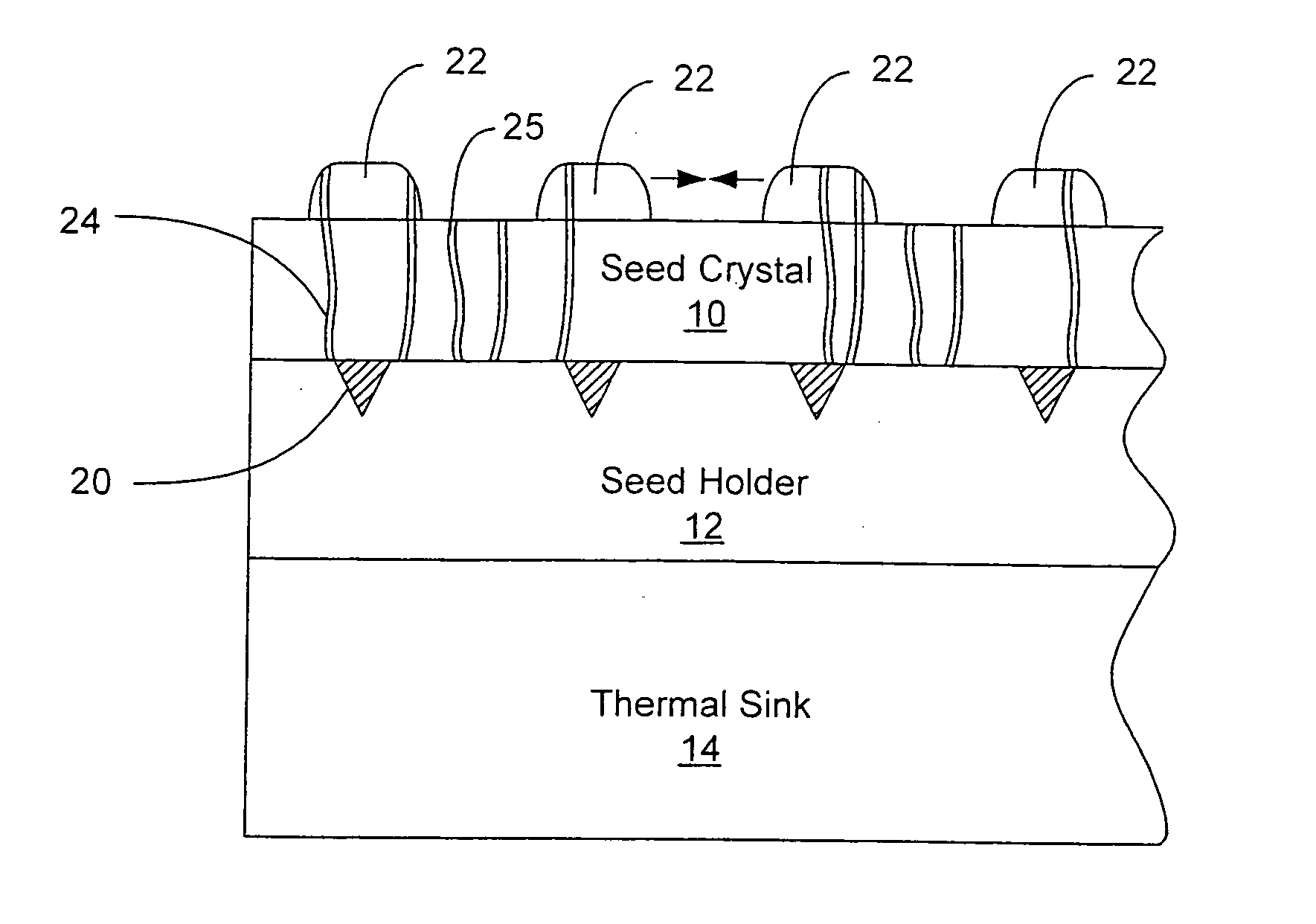

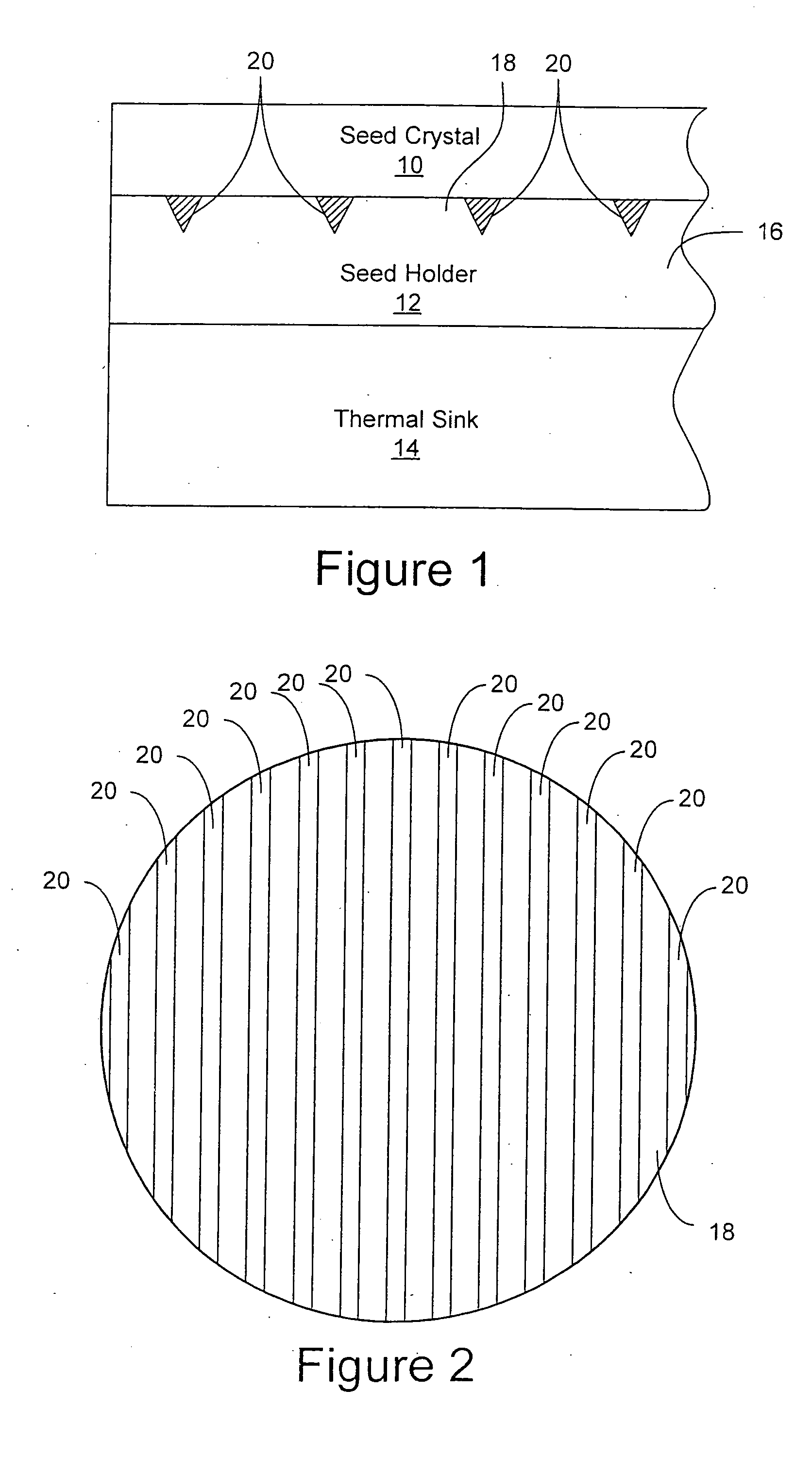

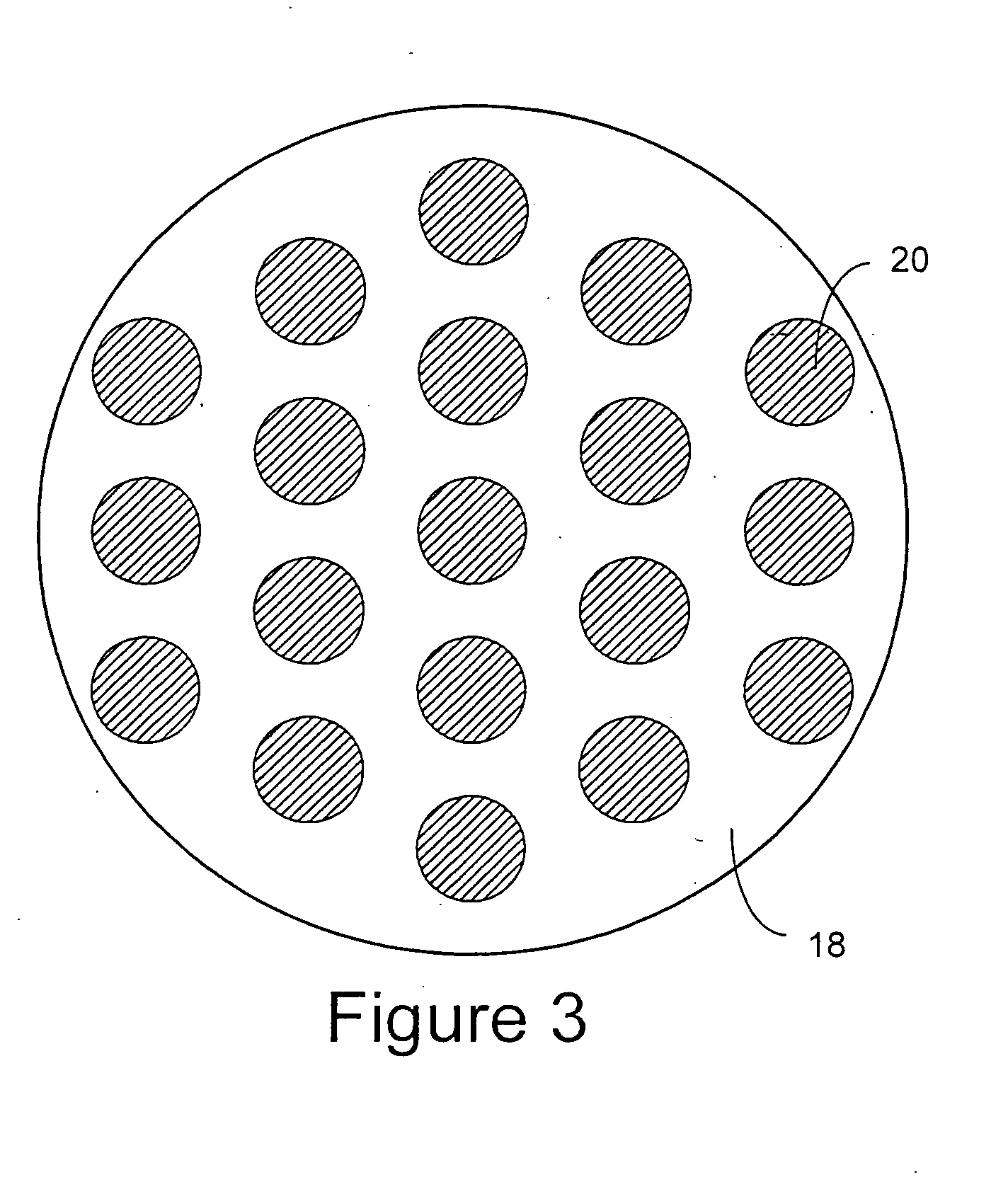

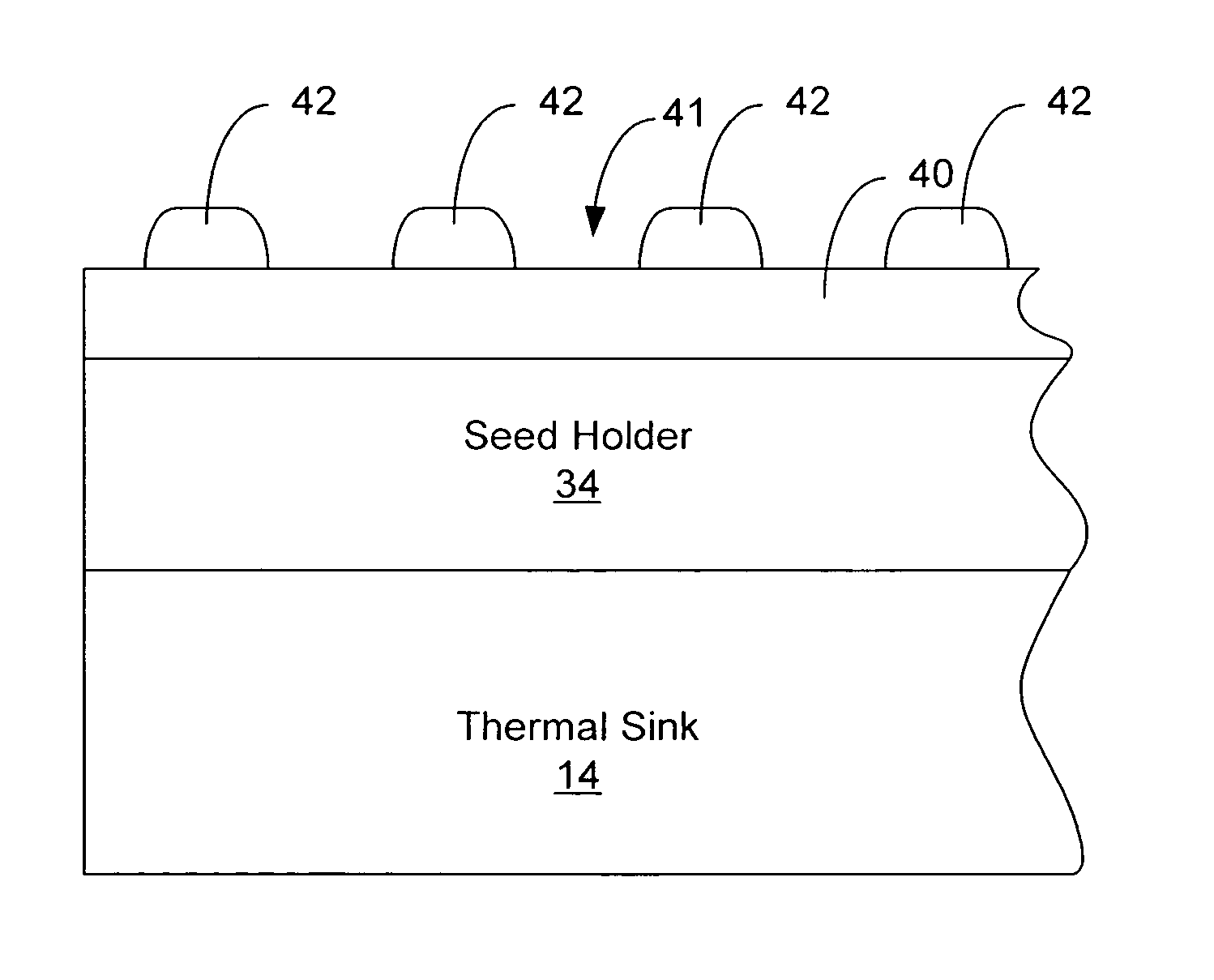

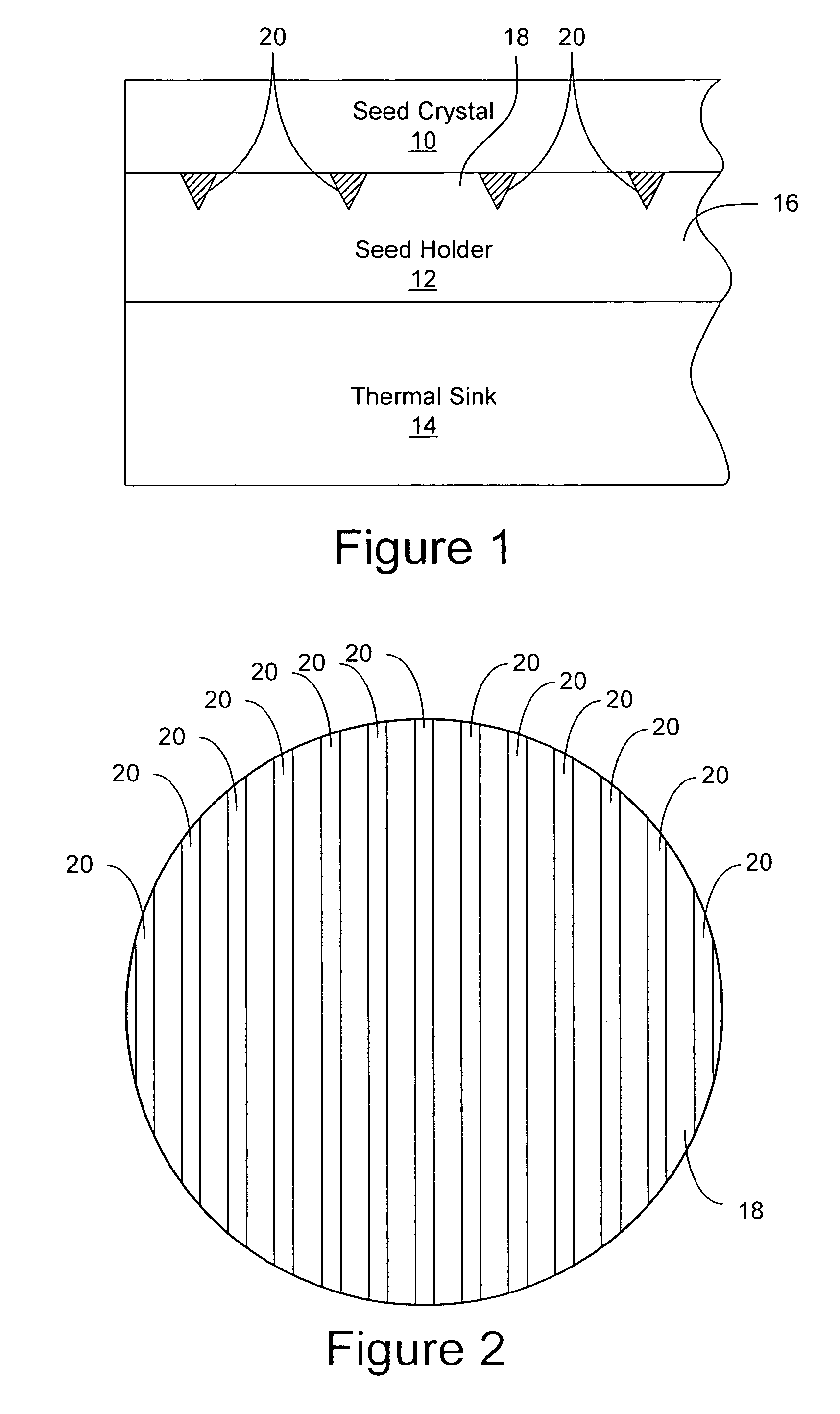

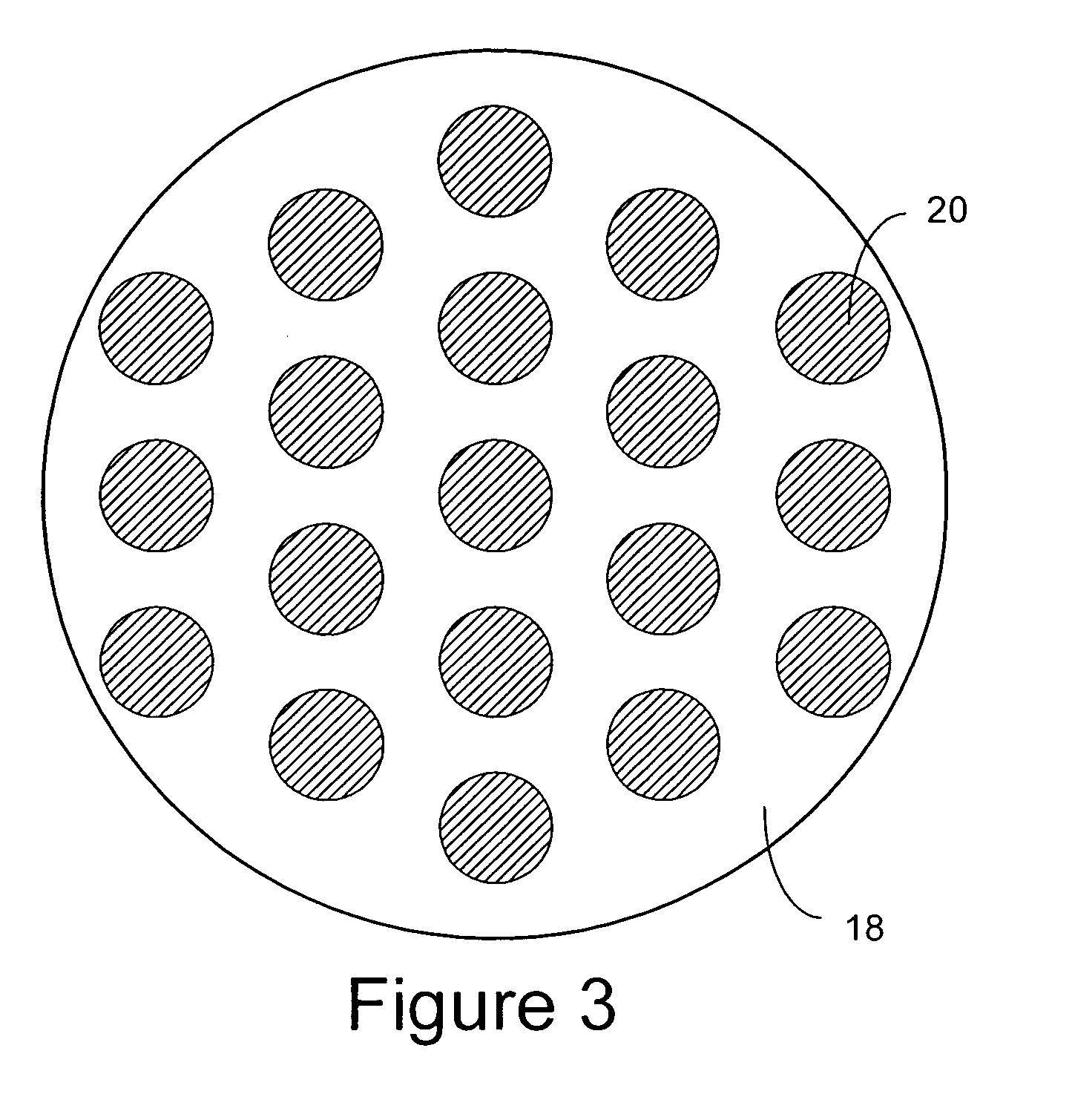

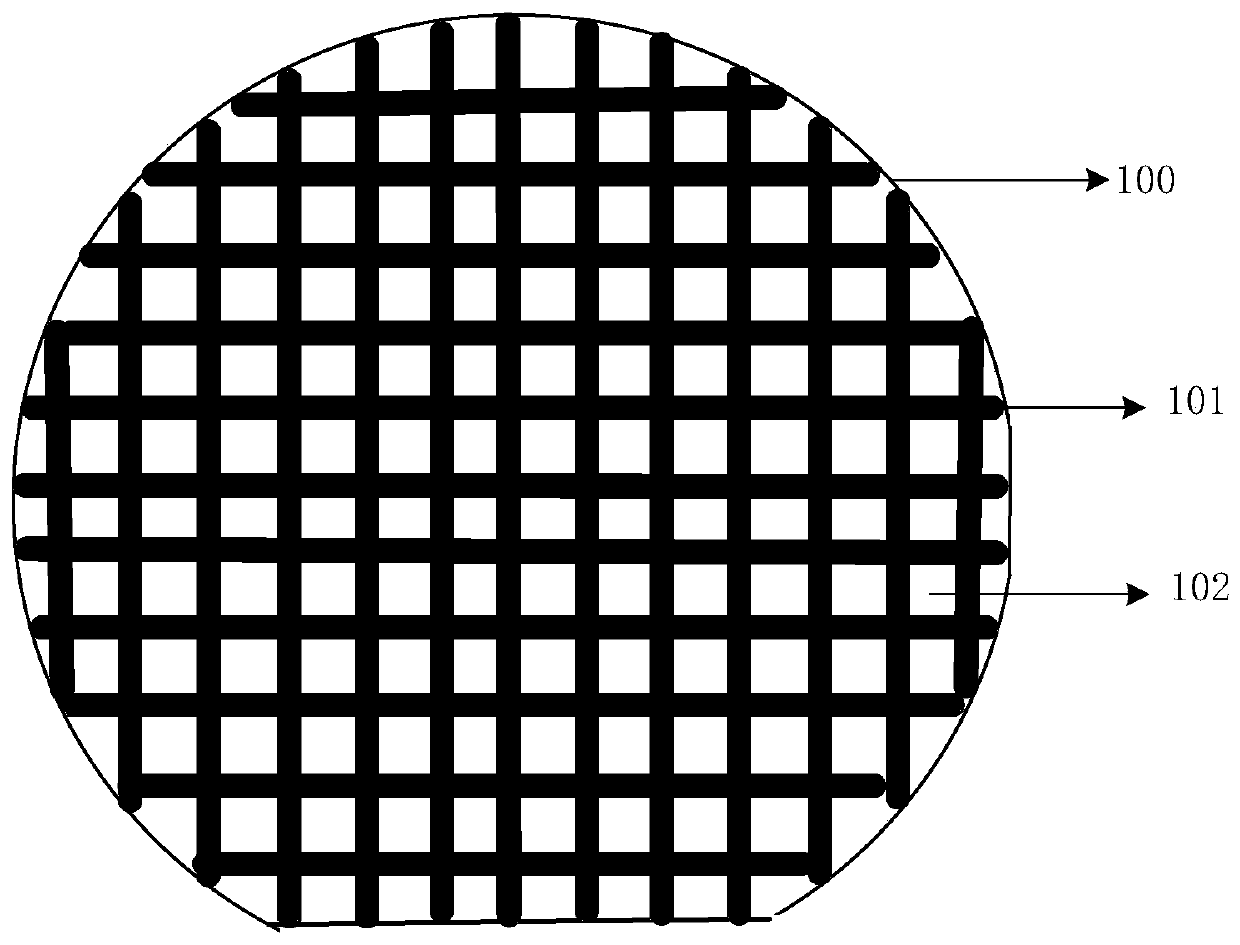

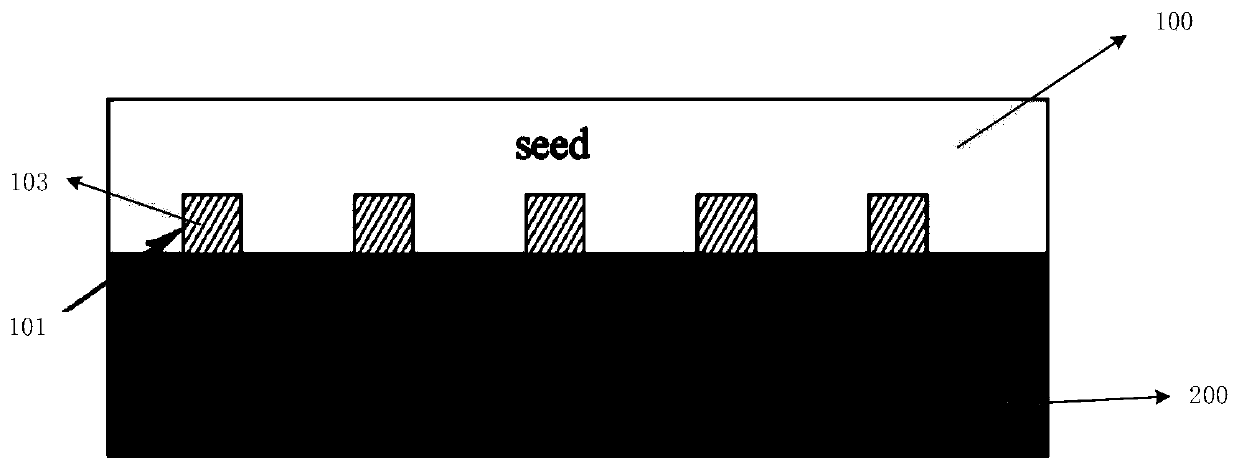

Methods of fabricating silicon carbide crystals

InactiveUS20070022945A1Polycrystalline material growthFrom chemically reactive gasesGas phaseOptoelectronics

Methods for producing silicon carbide crystals, seed crystal holders and seed crystal for use in producing silicon carbide crystals and silicon carbide crystals are provided. Silicon carbide crystals are produced by forcing nucleation sites of a silicon carbide seed crystal to a predefined pattern and growing silicon carbide utilizing physical vapor transport (PVT) so as to provide selective preferential growth of silicon carbide corresponding to the predefined pattern. Seed holders and seed crystals are provided for such methods. Silicon carbide crystals having regions of higher and lower defect density are also provided.

Owner:CREE INC

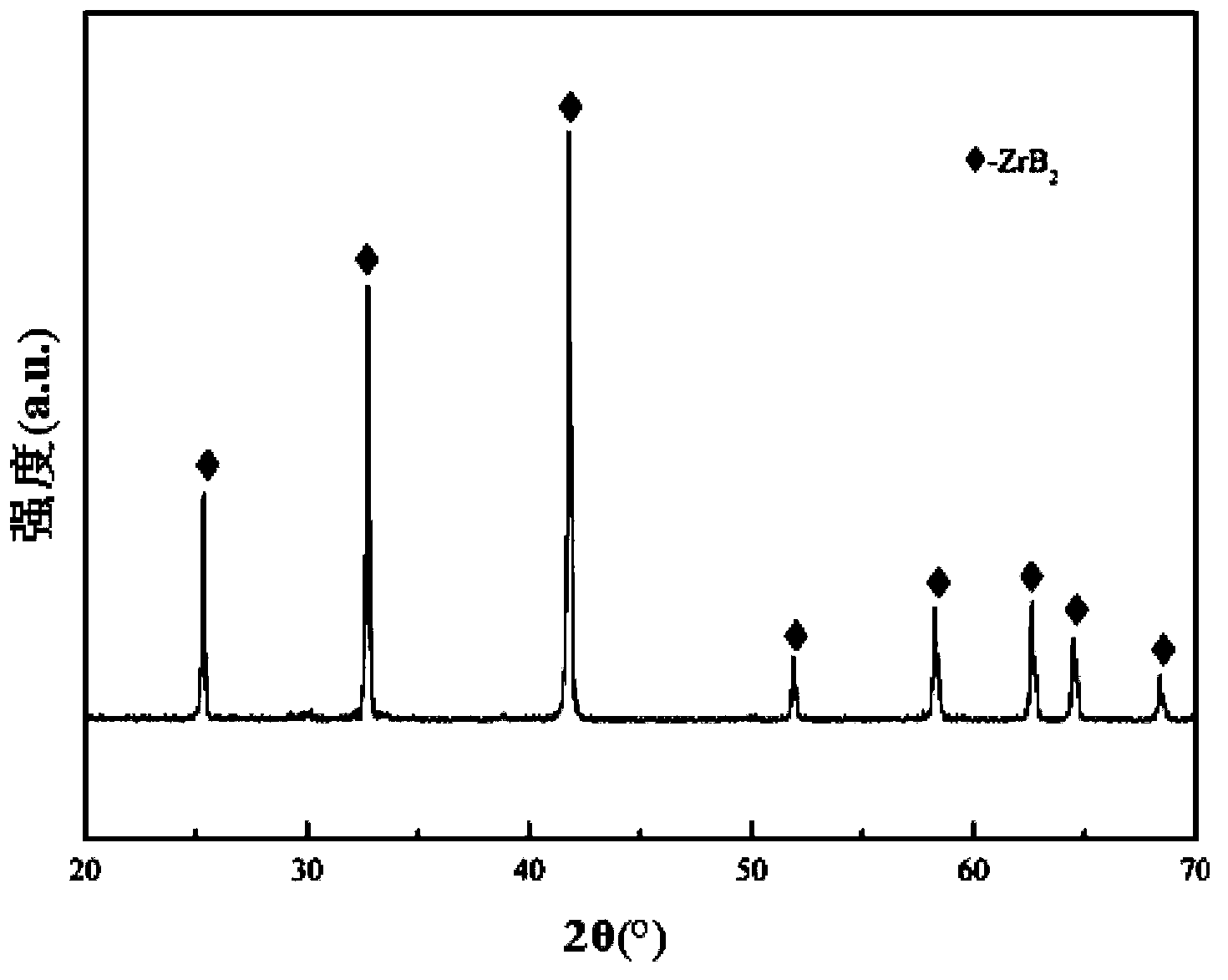

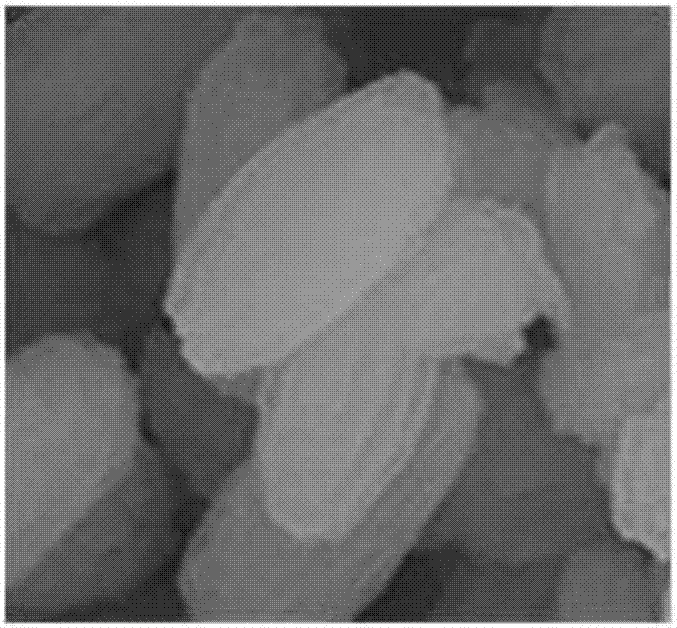

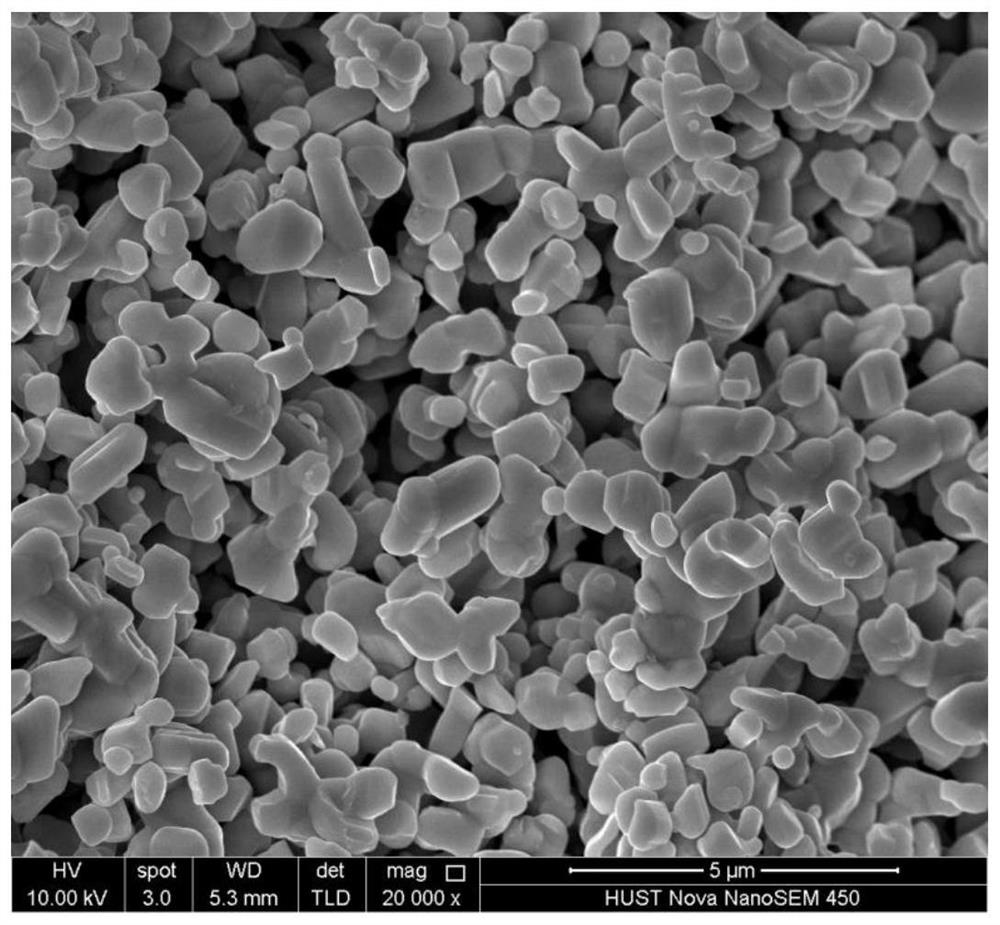

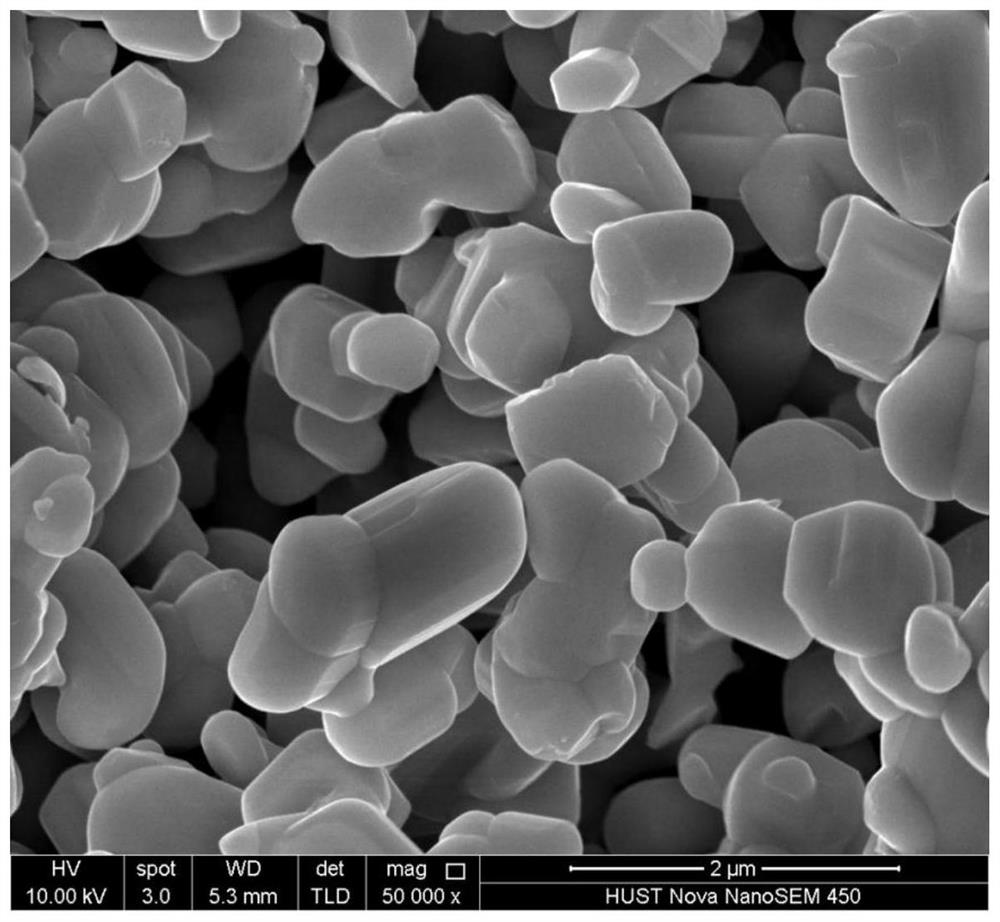

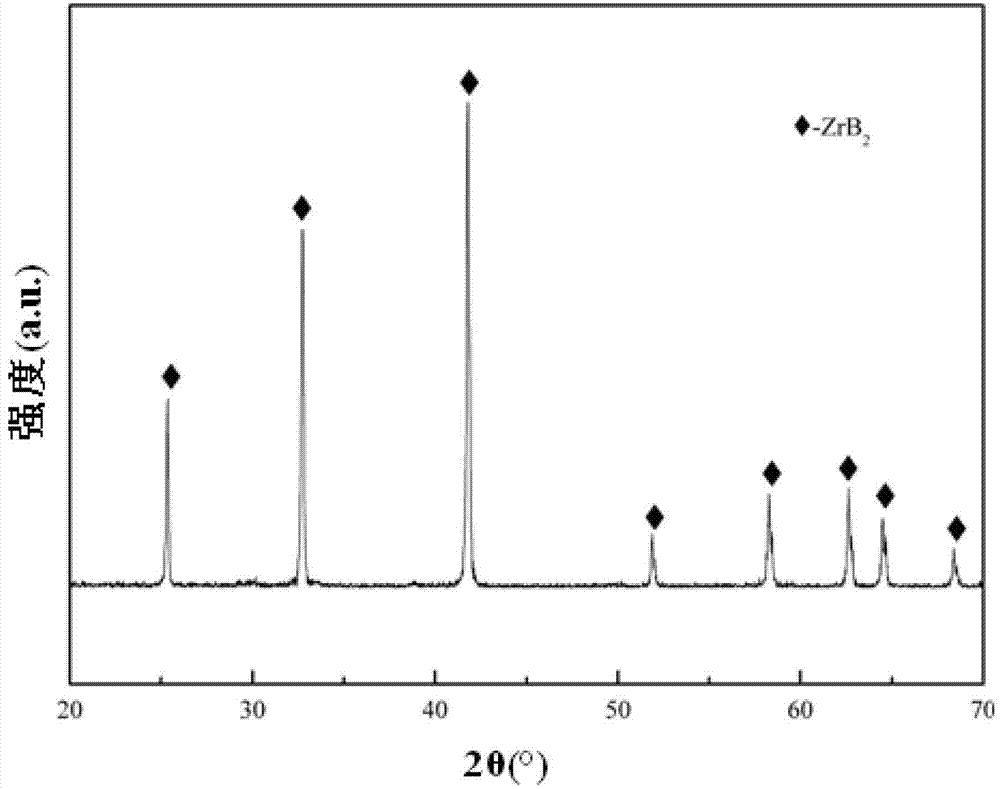

Method for preparing zirconium boride powder with rod-like morphology

A disclosed method for preparing a zirconium boride powder with rod-like morphology comprises: based on the boron-thermal / carbon-thermal reduction reaction, taking zirconium dioxide, boron carbide and graphite as raw materials, so as to prepare a mixed powder; employing a pressure of 20-100 Kg / cm<2>, compacting the uniformly mixed powder into a blank body; and performing heat treatment on the blank body with the vacuum degree lower than 10 Pa or in the inert atmosphere. By controlling the blank body forming pressure, under the condition that no auxiliary agents are added, the method employs the boron-thermal / carbon-thermal reduction reaction, and helps to realize preferential growth of crystal grains in a specific direction and to synthesize the ZrB2 high-purity powder with the rod-like morphology; also in the prepared powder, the content of ZrB2 particles with the rod-like morphology is larger than 90 wt%, the length-diameter ratio of the rod-like particles is 3-15, the average particle size is 1.5-10 mu m, the purity is high, and the oxygen content is low; and the preparation technology is simple and strong in controllability, no special equipment is needed, and large-scale production is easily realized.

Owner:中科西卡思(苏州)科技发展有限公司

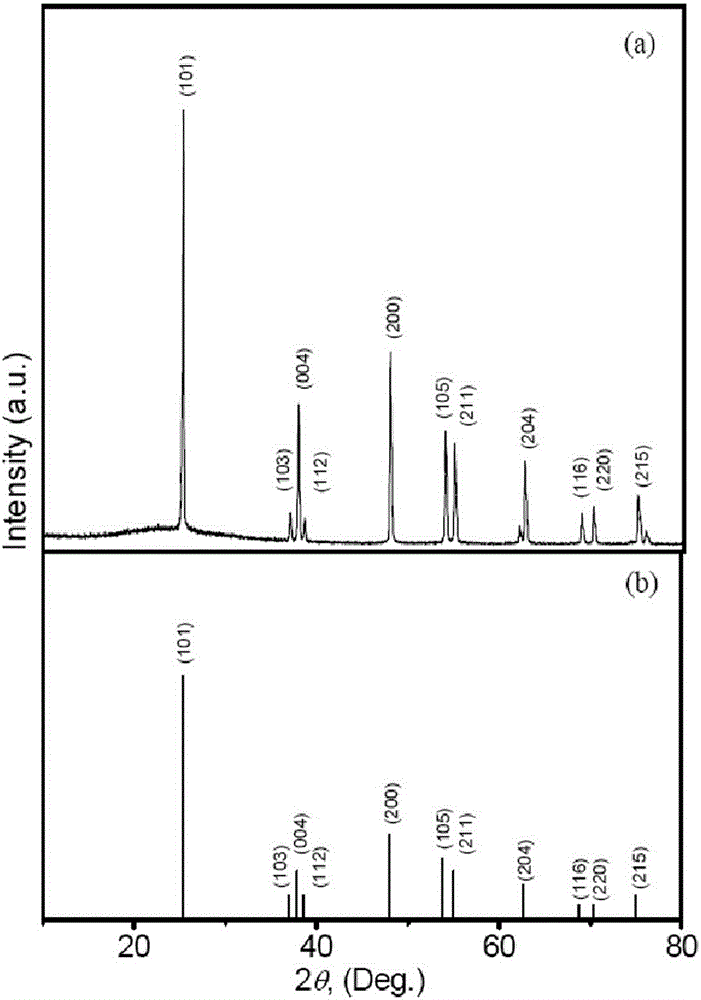

Three-dimensional hollow titanium dioxide assembled from (001) surfaces, and preparation method and application thereof

InactiveCN105133013AEffective control of the hydrolysis processPromote selective growthMaterial nanotechnologyPolycrystalline material growthMicro nanoDischarge efficiency

The invention discloses a three-dimensional hollow titanium dioxide assembled from (001) surfaces, and a preparation method and application thereof. The three-dimensional hollow titanium dioxide can be applied to the field of manufacturing of positive electrode materials of lithium batteries. According to the invention, a hydro-thermal method is employed for preparation of titanium dioxide, and under the co-action of hydrofluoric acid and hydrogen peroxide, the hydrolysis process of a reaction intermediate peroxotitanic acid is effectively regulated and controlled. The formation process of a hollow structure is related to an Ostwald ripening mechanism, fluoride ions promote preferential growth of a crystal along [001] direction, and finally, the three-dimensional hollow product is formed. The method has the advantages of low cost, simple and controllable process, mild reaction, obtainment of the pure product and a high exposure rate of the (001) surfaces; and the titanium dioxide material prepared by using the method has the high-exposure (001) surfaces, is of a hollow micro-nano structure, can be applied to preparation of positive pole pieces of the lithium battery, shortens a diffusion path of lithium ions, facilitates intercalation / deintercalation behavior of lithium ions and alleviates volume expansion of the material during charging and discharging, and thus, the lithium battery has improved charging and discharging efficiency and prolonged cycle life.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

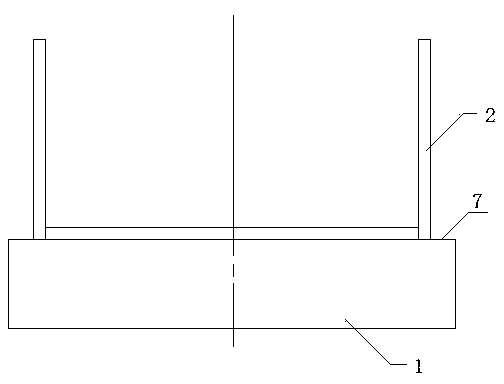

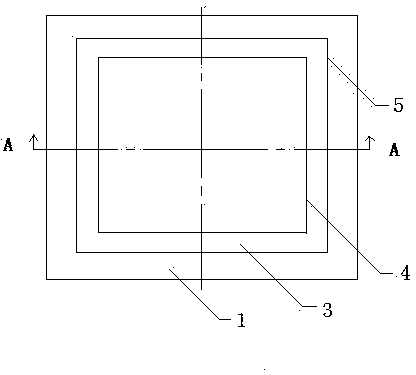

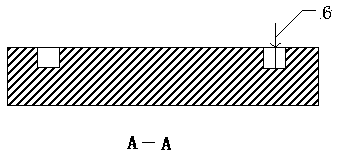

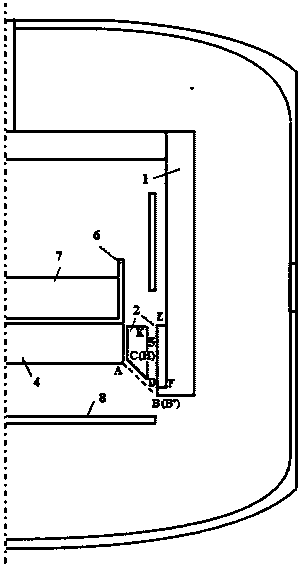

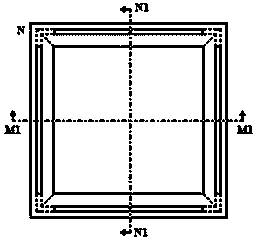

Cooling block for polycrystalline silicon ingot furnace

ActiveCN103361714AInhibition of preferential growthQuality improvementPolycrystalline material growthFrom frozen solutionsCrucibleGraphite

The invention relates to a cooling block for a polycrystalline silicon ingot furnace, and belongs to the fields of novel energy and photovoltaics. The cooling block comprises a cooling block body and a crucible, the crucible is disposed at the top surface of the cooling block body; the top surface of the cooling block body is provided with a groove; the crucible covers on the groove; and the central line of the groove, the central line of the crucible and the central line of the cooling block overlap with one another. Proper heat preservation for corner parts of the crucible by arranging a square groove and utilizing difference between thermal conductivities of the air and graphite, so that preferential growth of crystal grains near the wall of the crucible is inhibited; relatively flat solid-liquid interface can be obtained; and the quality of directionally solidified polycrystalline silicon can be increased.

Owner:浙江省机电设计研究院有限公司

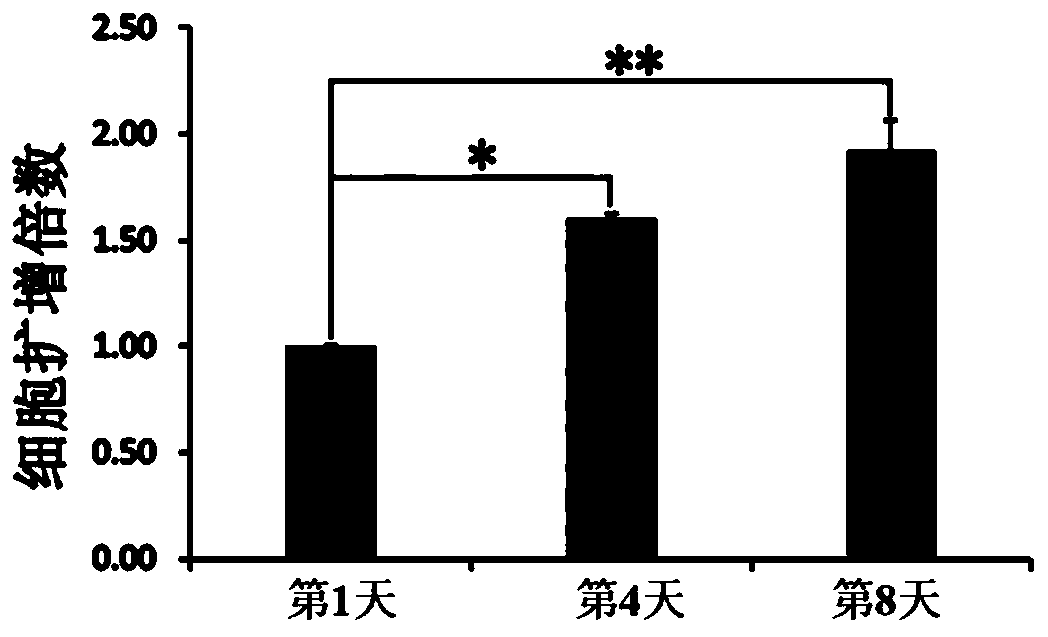

3D culture system of primary tumor cells, and culture method and application of 3D culture system

ActiveCN110607279AAchieve superior growthReflect characteristicsMicrobiological testing/measurementCulture processCell-Extracellular Matrix3D cell culture

The invention provides a 3D culture system of primary tumor cells, and an application of the 3D culture system. The 3D culture system comprises lower layer gelatin, a middle layer cell substrate and an upper layer culture medium, wherein the middle layer cell substrate comprises improved agarose gel, a condition culture medium containing addition factors and tumor cells; the improved agarose gel comprises low melting-point agarose, polylysine and an extracellular matrix; the lower layer gelatin comprises agarose gel and a conditioned medium; and the upper layer culture medium is the conditionculture medium containing the addition factors. The 3D culture system provided by the invention can screen tumor cells and normal epithelial cells, besides, can realize preferential growth of the tumor cells, is high in culture success rate, can really reflect the properties of entire tumor cell groups, and can accurately represent the growth condition of in vivo tumors, and after the 3D culture system is used for medicine susceptibility detection, the obtained results are high in reliability, and clinical promotion is facilitated.

Owner:SHENZHEN YOUSHENGKANG MEDICAL LAB CO LTD

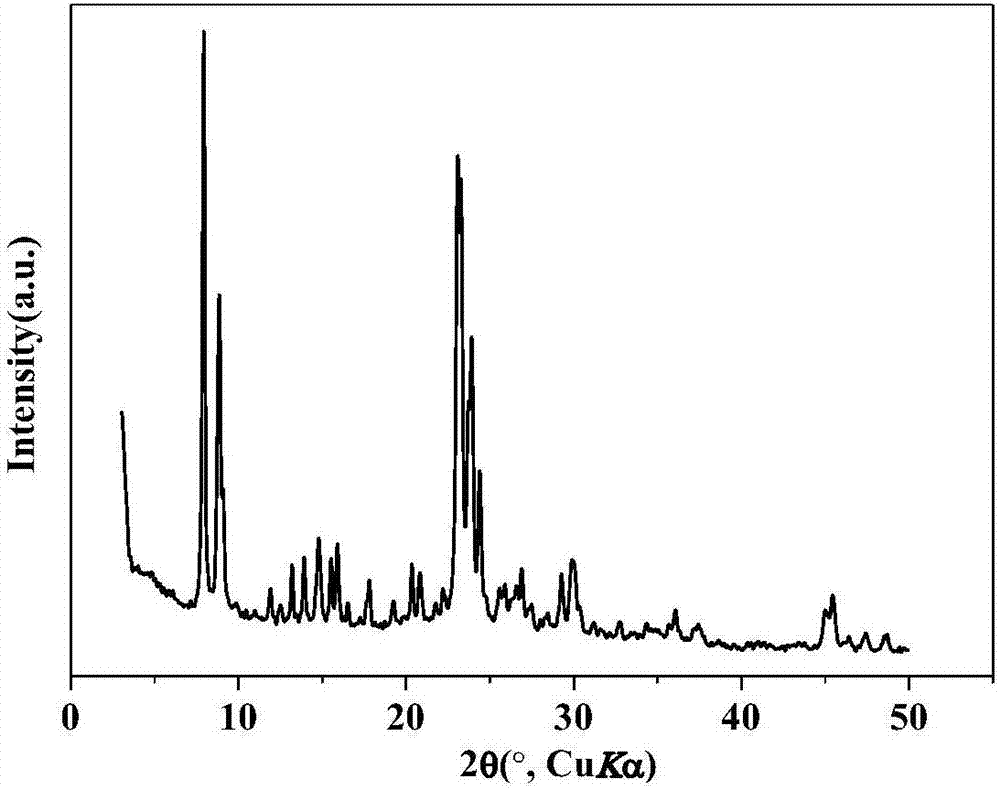

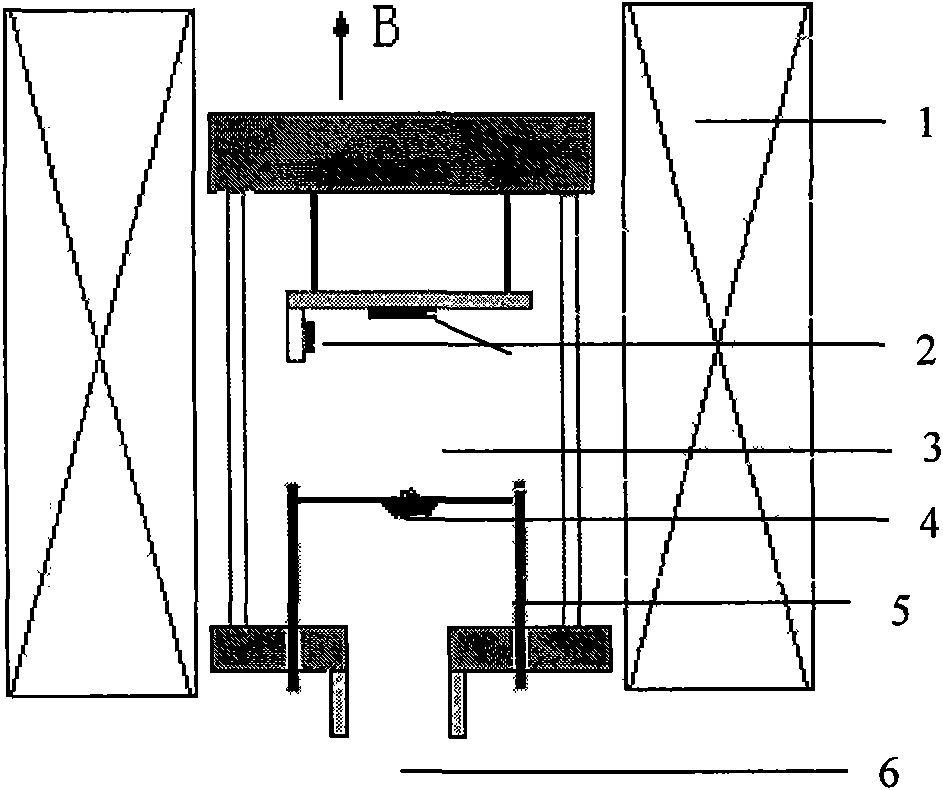

Synthetic method of c-axis orientated type Zn-ZSM-5 molecular sieve under action of external magnetic field

ActiveCN107089669ASolve the problem of preferential growth of morphology and structure orientationSolve excessive dosagePentasil aluminosilicate zeoliteSeed crystalMonomer

The invention provides a synthetic method of a c-axis orientated type Zn-ZSM-5 molecular sieve under the action of an external magnetic field, and belongs to synthetic methods of Zn-ZSM-5 molecular sieves. Through the specific action of the external magnetic field, the problem of orientated preferential growth of the morphology and structure in the crystal growth process of ZSM-5 is solved. The synthetic method comprises the following steps: adding prefabricated silicalite-1 seed crystals into a Zn<2+> doped mixed gel, conducting aging under the action of an external magnetic field with a specific strength, and then conducting crystallization, drying and roasting to obtain the c-axis orientated type Zn-ZSM-5. The technique has the characteristics that the external magnetic field with the specific strength has an obvious guiding action on the grain growth of the molecular sieve, the synthesized molecular sieve monomer when placed in the position of a horizontal magnetic induction line has a c-axis orientated structure, simultaneously a zinc type ZSM-5 molecular sieve new material with c-axis direction preferential growth can be successfully synthesized by doping once, the synthetic process is simple and has good repeatability, the specific area of the new material is larger, and the technique shows excellent methanol conversion, aromatic hydrocarbon yield, anti-carbon property and stability when applied to methanol aromatization reaction.

Owner:CHINA UNIV OF MINING & TECH

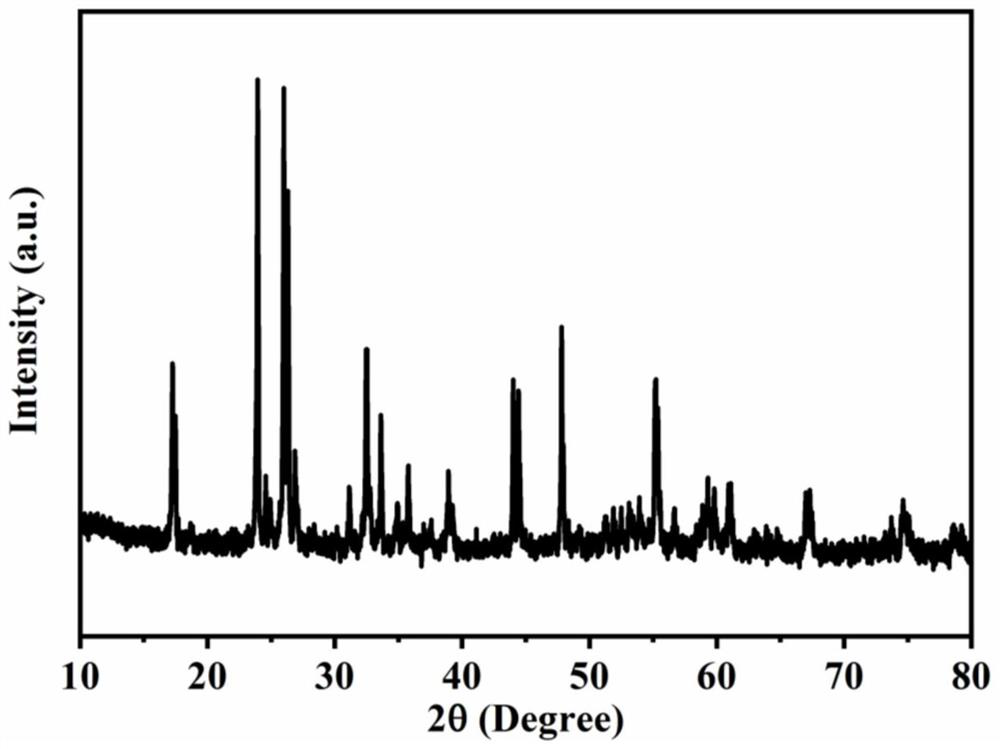

TiNb2O7 material with preferential growth of (010) crystal face and preparation method and application of TiNb2O7 material

ActiveCN113206240AImproved magnification performanceLow defect contentCell electrodesSecondary cellsChemical physicsLithium-ion battery

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a TiNb2O7 material with preferential growth of a (010) crystal face and a preparation method and application of the TiNb2O7 material. The preparation method comprises the following steps: (1) dispersing a niobium source and a titanium source into a solvent, performing uniform mixing, performing drying, and removing the solvent to obtain a precursor; (2) performing heat treatment on the precursor in an oxygen-containing atmosphere to obtain an intermediate; (3) cooling the intermediate to a tempering temperature according to a set cooling rate, and then performing natural cooling to room temperature to obtain the TiNb2O7 material with preferential growth of the (010) crystal face. The TiNb2O7 material prepared by the method preferentially grows along the (010) crystal face, the migration distance of lithium ions is short, the lithium ions can rapidly migrate along the crystallographic direction, and the TiNb2O7 material has high specific capacity, excellent rate capability and small specific surface area; and when the material is used as a negative electrode of a lithium ion battery, high electrode compaction density and volume energy density can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Methods of fabricating silicon carbide crystals

InactiveUS7135072B2Polycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseOptoelectronics

Methods for producing silicon carbide crystals, seed crystal holders and seed crystal for use in producing silicon carbide crystals and silicon carbide crystals are provided. Silicon carbide crystals are produced by forcing nucleation sites of a silicon carbide seed crystal to a predefined pattern and growing silicon carbide utilizing physical vapor transport (PVT) so as to provide selective preferential growth of silicon carbide corresponding to the predefined pattern. Seed holders and seed crystals are provided for such methods. Silicon carbide crystals having regions of higher and lower defect density are also provided.

Owner:CREE INC

A method for preparing zirconium boride powder with rod-like morphology

A disclosed method for preparing a zirconium boride powder with rod-like morphology comprises: based on the boron-thermal / carbon-thermal reduction reaction, taking zirconium dioxide, boron carbide and graphite as raw materials, so as to prepare a mixed powder; employing a pressure of 20-100 Kg / cm<2>, compacting the uniformly mixed powder into a blank body; and performing heat treatment on the blank body with the vacuum degree lower than 10 Pa or in the inert atmosphere. By controlling the blank body forming pressure, under the condition that no auxiliary agents are added, the method employs the boron-thermal / carbon-thermal reduction reaction, and helps to realize preferential growth of crystal grains in a specific direction and to synthesize the ZrB2 high-purity powder with the rod-like morphology; also in the prepared powder, the content of ZrB2 particles with the rod-like morphology is larger than 90 wt%, the length-diameter ratio of the rod-like particles is 3-15, the average particle size is 1.5-10 mu m, the purity is high, and the oxygen content is low; and the preparation technology is simple and strong in controllability, no special equipment is needed, and large-scale production is easily realized.

Owner:中科西卡思(苏州)科技发展有限公司

Metal deposition method and laser metal deposition apparatus

The invention provides a metal deposition method and a laser metal deposition apparatus. In the metal deposition method, a buildup is formed on a single crystal or directionally solidified crystal parent material such that the deposition part and the parent material are deposited in the same direction. In a deposition method of forming a buildup on a single crystal or directionally solidified crystal parent material, metal deposition is performed from an extension in a preferential growth orientation of parent material crystals while forcedly cooling a portion of the parent material somewhat below a processed surface and beforehand giving a temperature gradient to the parent material so that a maximum temperature gradient is oriented along the preferential growth orientation of parent material crystals.

Owner:HITACHI LTD

Heat insulation block for polysilicon ingot casting furnace and polysilicon ingot casting furnace comprising heat insulation block

ActiveCN104372403AAvoid cloggingAvoid hindering radiative heat transferPolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a heat insulation block for a polysilicon ingot casting furnace, which is arranged on the periphery of the bottom of a crucible of the polysilicon ingot casting furnace and used for heat insulation in the process of heating or cooling polysilicon with the crucible. The heat insulation block is a hollow square cylinder structure, wherein the wall of the cylinder is a hollow sandwich structure; the inner wall is used for coating the peripheral wall surface of a heat exchange block on the bottom of the crucible; a clearance is arranged between the inner wall and the peripheral wall surface of the heat exchange block; the outer wall is used for fixedly contacting a vertical heat insulation plate on the periphery of the crucible; the central line of the crucible, the central line of the heat exchange block and the central line of the heat insulation block coincide; and the top of the heat insulation block is lower than the top of the heat exchange block. The invention also discloses an ingot casting furnace provided with the heat insulation block. The heat insulation block can shorten the material melting time in the silicon ingot casting process, lowers the energy consumption, and can effectively inhibit the preferential growth of crystal grains near the crucible wall in the early nucleation period to obtain a slightly-convex and flat freezing interface, thereby enhancing the quality of the silicon ingot.

Owner:HUAZHONG UNIV OF SCI & TECH

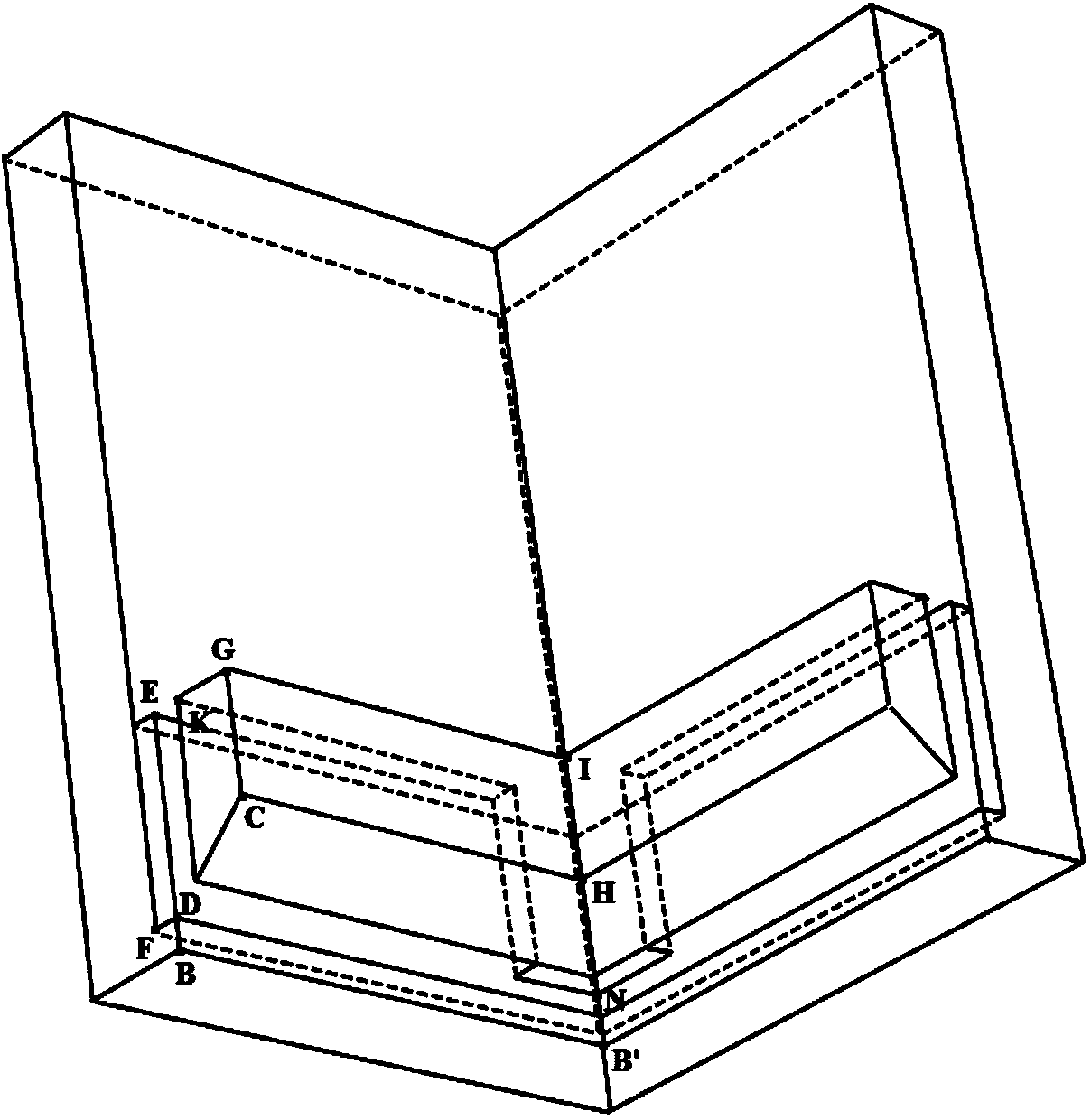

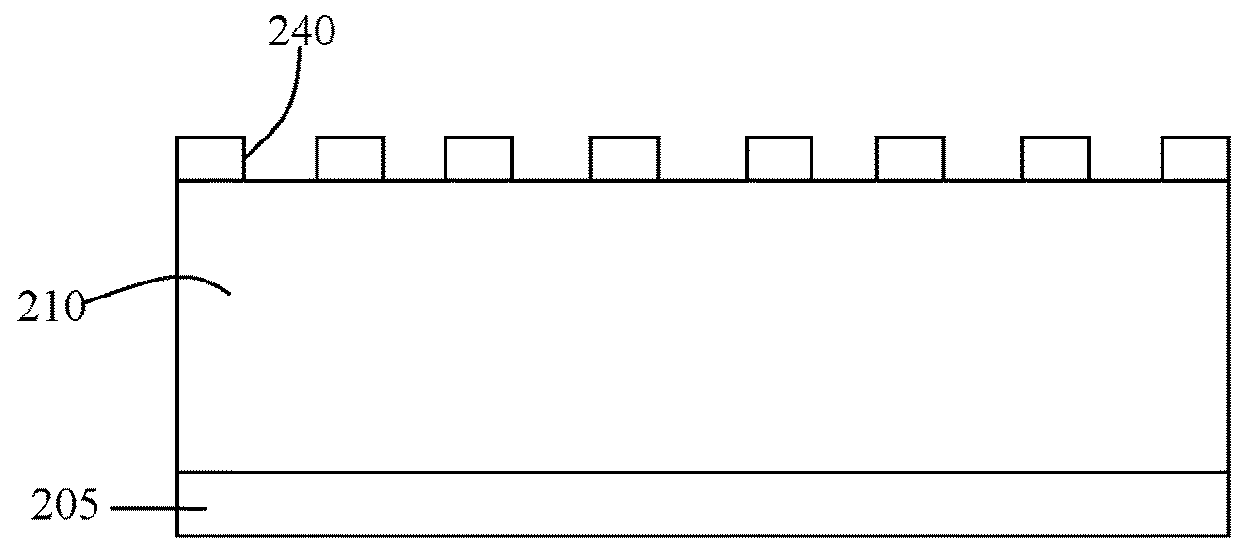

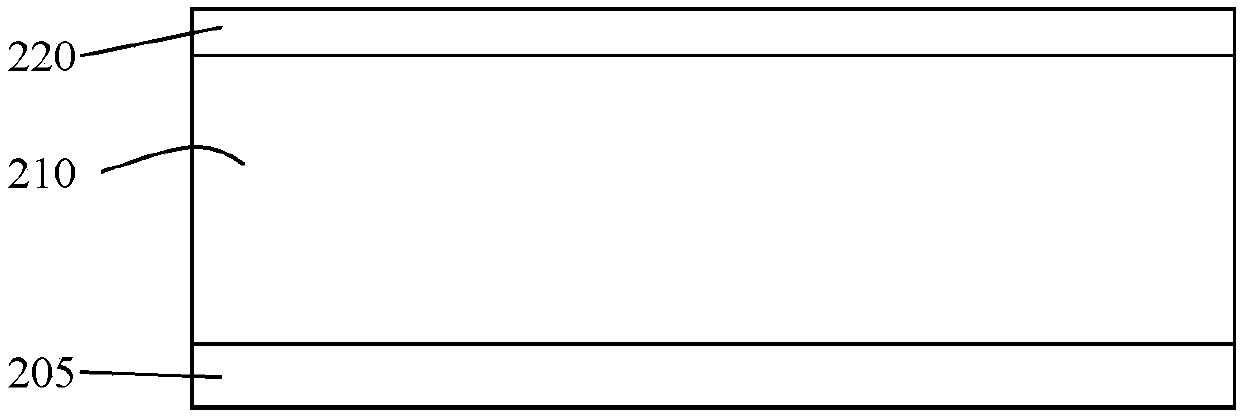

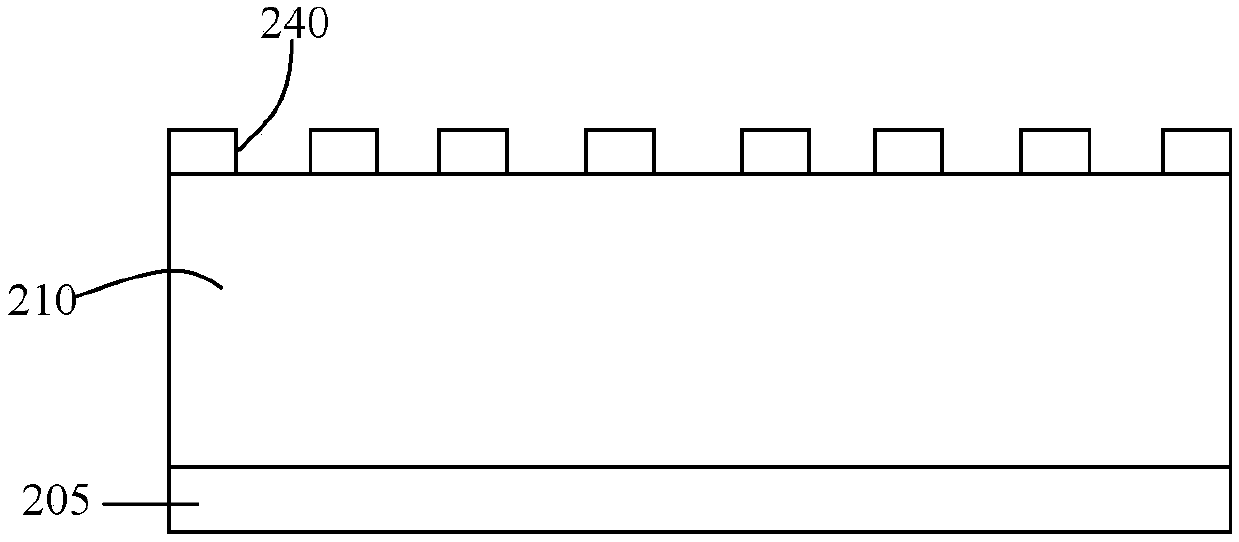

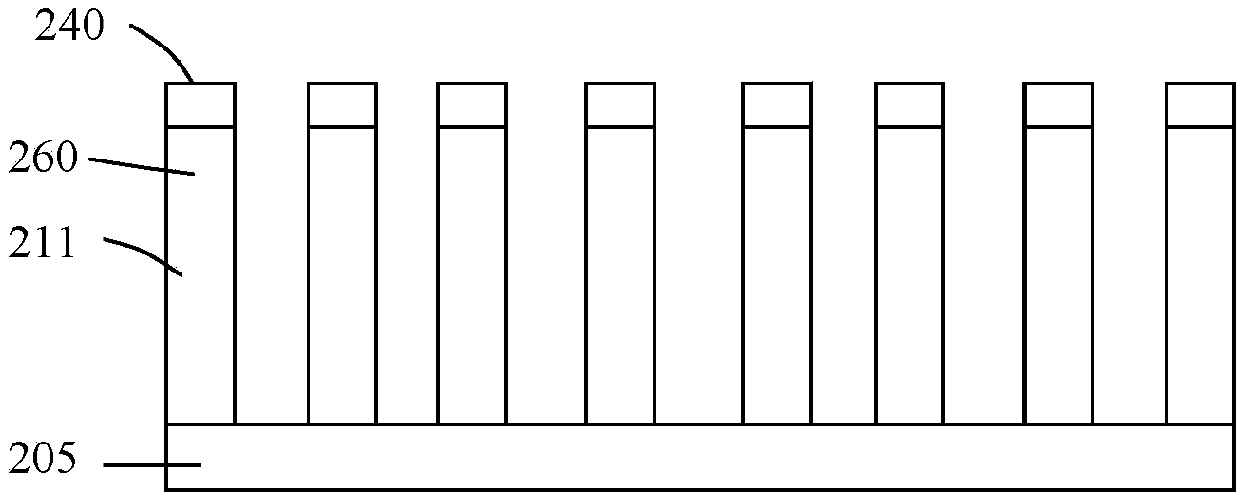

Semiconductor templates and fabrication methods

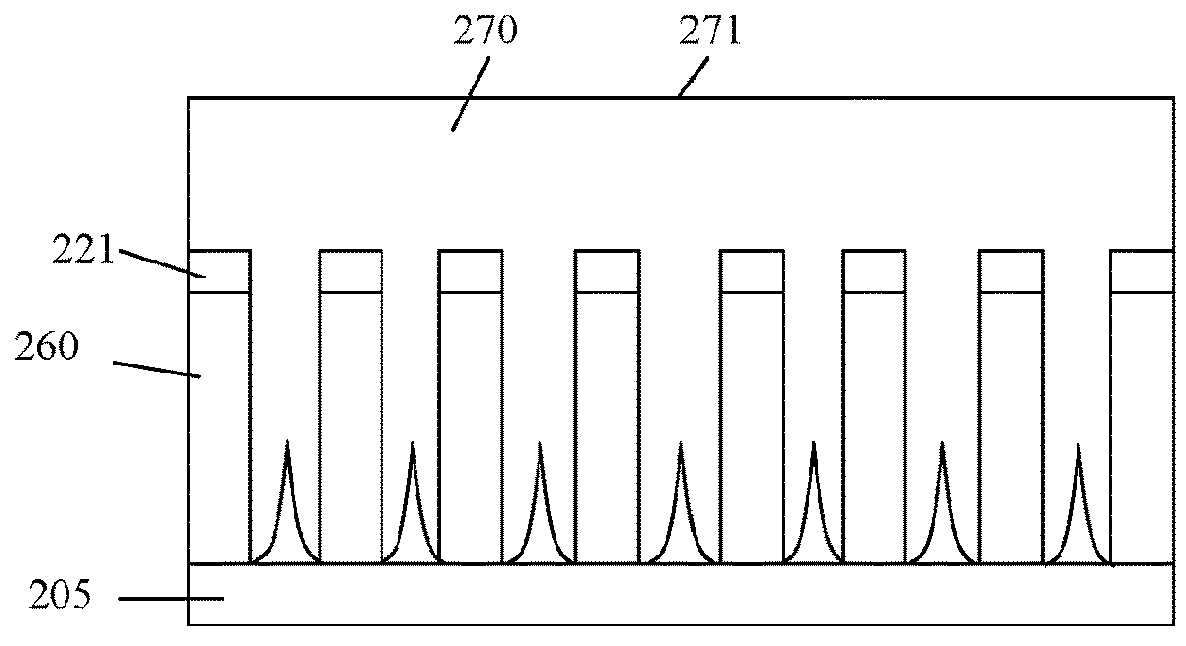

InactiveUS20180166275A1Growth inhibitionEncouraging growthSemiconductor/solid-state device manufacturingSemiconductor materialsSemiconductor structure

A method of making a semi-polar semiconductor template comprises providing a semi-polar semiconductor wafer; etching the semiconductor wafer to form a regular semiconductor structure comprising a plurality of semiconductor regions (260) with a plurality of gaps between the regions, each of the regions (260) having a sidewall facing a respective one of the gaps, and growing semiconductor material over the semiconductor structure. The semiconductor material has a preferential growth direction (c) in which growth proceeds most rapidly from each of the sidewalls, and each of the sidewalls has at least a part which faces a vertical centre line of the respective one of the gaps so that growth in the preferential direction from said part extends towards said vertical centre line.

Owner:SEREN PHOTONICS

Silicon carbide seed crystal and method for reducing penetration type dislocation density in silicon carbide single crystal

InactiveCN111270311AReduce threading dislocation densityPolycrystalline material growthFrom condensed vaporsCarbide siliconDislocation

The invention provides a silicon carbide seed crystal and a method for reducing the penetration type dislocation density in a silicon carbide single crystal. A groove is formed in the back of the seedcrystal, the groove is filled with a material with the heat conductivity different from that of silicon carbide, or the back of the seed crystal is directly plated with a film with the heat conductivity different from that of the silicon carbide, so that two substances with the different heat conductivities exist on the back of the seed crystal, and uneven distribution of a temperature field on the surface of the seed crystal is caused when heat dissipation is uneven. Therefore, periodic distribution of the two substances with different thermal conductivities on the back of the seed crystal can be utilized, the distribution of a seed crystal surface temperature field in the SiC physical vapor transport growth process is modulated, preferential nucleation is forced to be carried out in a low-temperature area corresponding to a predefined pattern, selective preferential growth is carried out according to the predefined pattern, and then lateral growth is carried out, so that the purposeof reducing the penetration type dislocation density is achieved.

Owner:广州南砂晶圆半导体技术有限公司

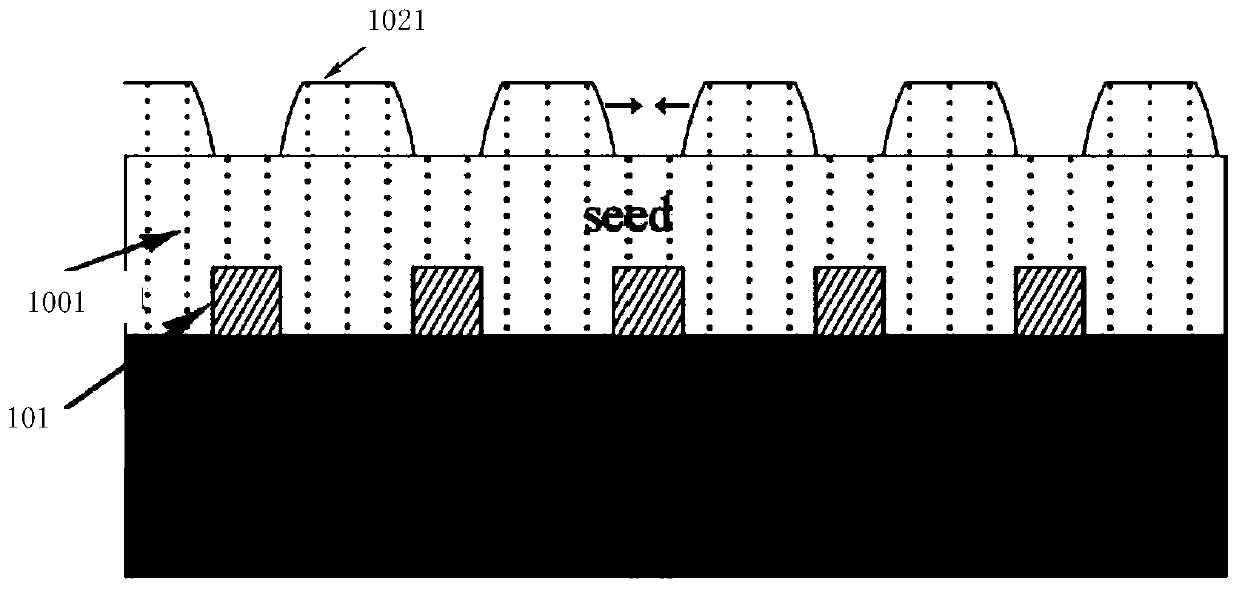

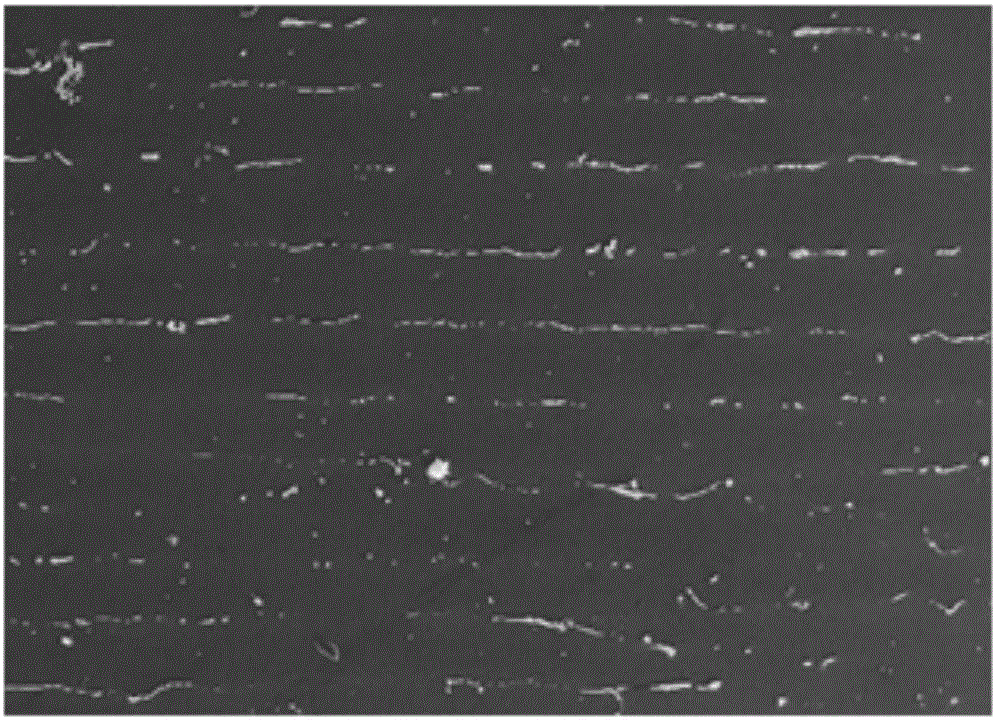

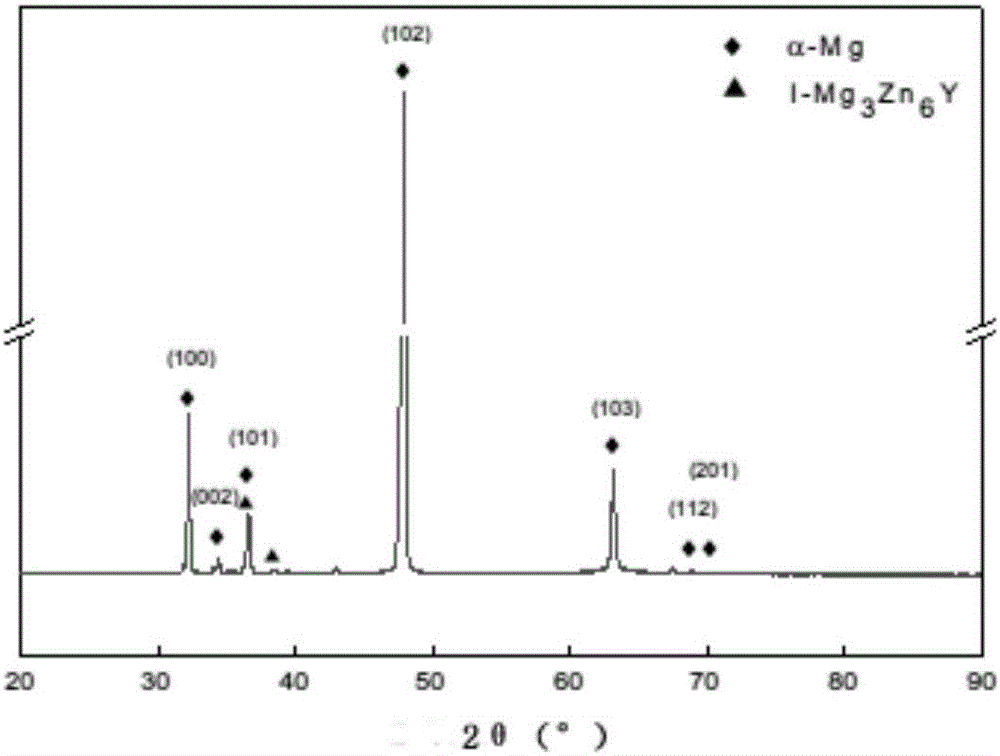

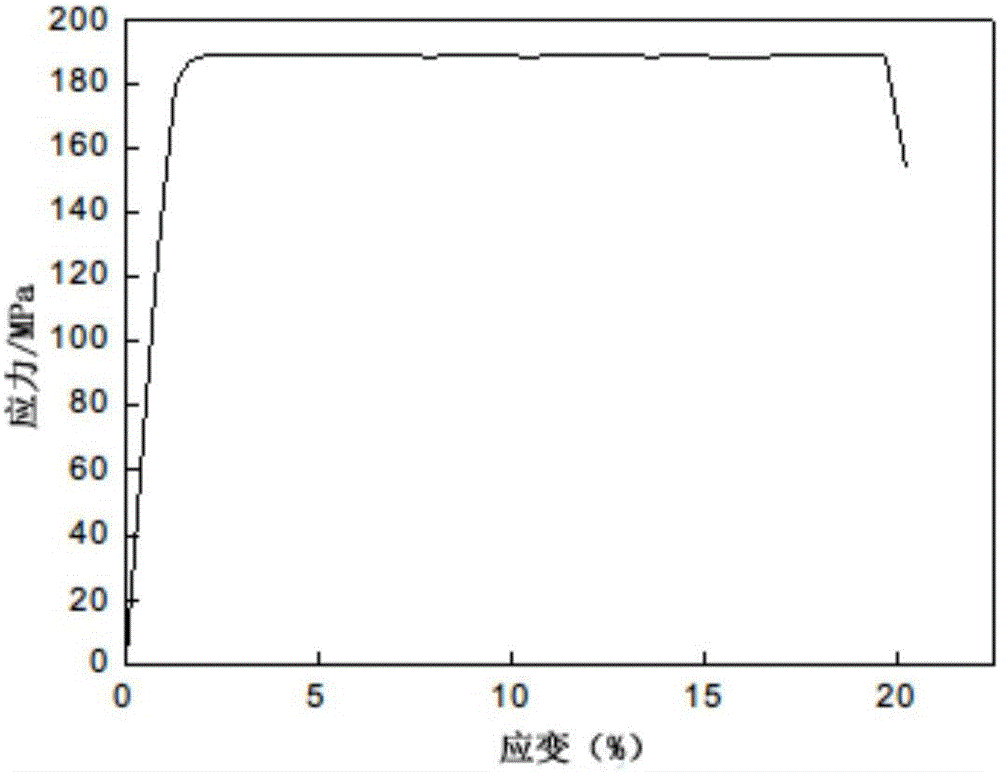

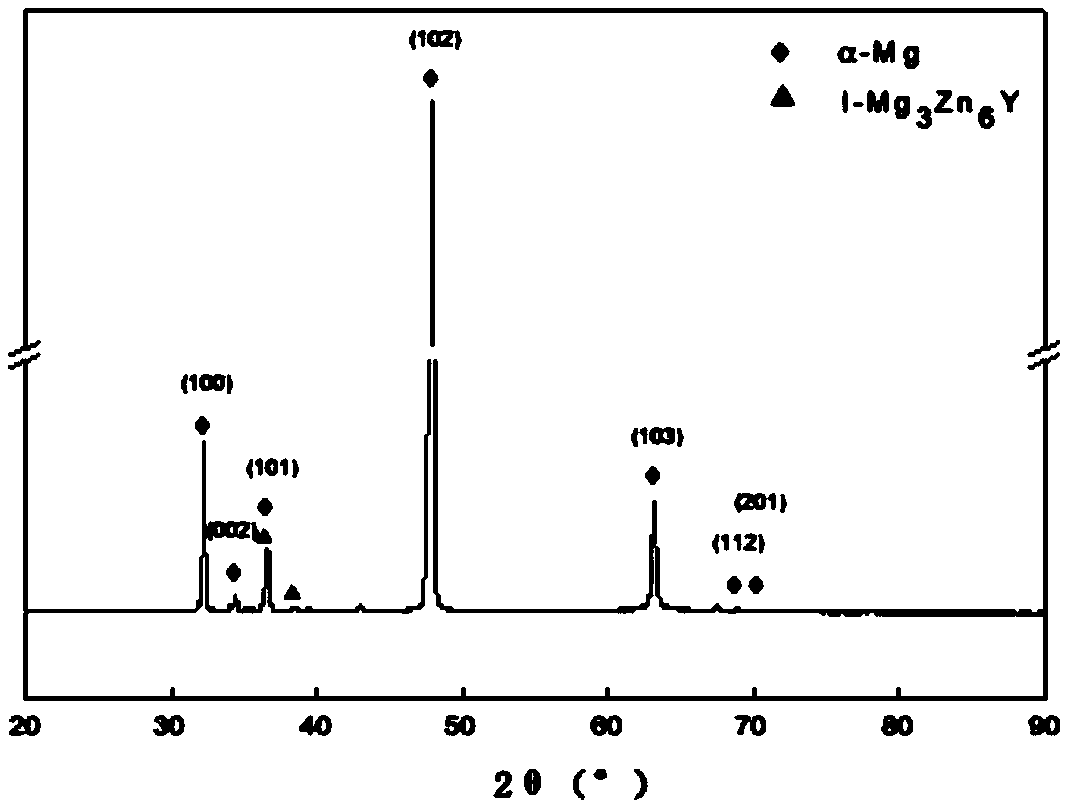

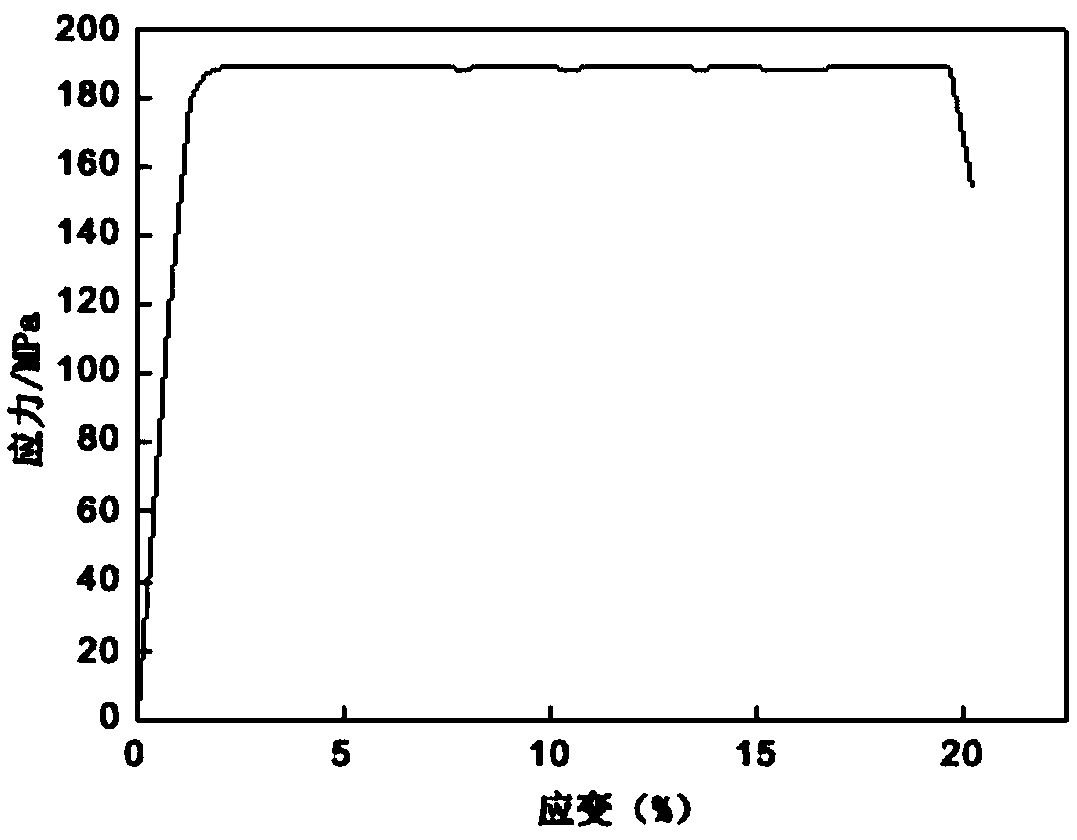

Preparation method of magnesium alloy with good room-temperature plasticity and product

ActiveCN106623865ALongitudinal grain boundaries are straightNo transverse grain boundariesPlastic propertyCrystallite

The invention discloses a preparation method of magnesium alloy with good room-temperature plasticity. The preparation method comprises the following steps: taking Mg ingot with the purity of 99.9wt%, Zn ingot with the purity of 99.9wt%, Mg-30Y intermediate alloy and Mg-30Zr intermediate alloy, putting the alloys into a crucible, and melting to obtain alloy liquid; then controlling casting temperature, casting the alloy liquid into a graphite mould of vacuum directional solidification equipment, carrying out heat preservation by virtue of a heat preservation sleeve; pulling down by controlling the pulling speed of a pull-down system, promoting cast alloy to grow on a specific preferential growth crystal face, and finally solidifying, thus obtaining the magnesium alloy. A columnar crystal structure prepared by adopting the preparation method disclosed by the invention has the advantages that primary arms grow in parallel, longitudinal crystal boundary is straight, no transverse crystal boundary exists, specific grain orientation is specific, preferential growth crystal face and growth direction are described in the specification, and the space between the primary arms is about 50 micrometers; sigmab of the magnesium alloy at room temperature is 188MPa, and elongation reaches up to 24%.

Owner:东北大学秦皇岛分校

Method for controlling film orientation in vacuum evaporation film making process

The invention relates to a method for controlling film orientation in a vacuum evaporation film making process, belonging to the technical field of vacuum evaporation deposited film process. The method is characterized in that, based on a traditional vacuum evaporation deposit device which is commonly used, an intense magnetic field generation device is additionally arranged outside the vacuum evaporation deposit device, and the strength of the magnetic field of the vacuum evaporation deposit device is required to be larger than 4T (Tesla), and different orientation magnetic energy differences of the magnetic field on metal films cause preferential growth of crystal orientation, thereby achieving the aim of controlling the film orientation through adjusting the strength of the magnetic field.

Owner:SHANGHAI UNIV

Preferential growth of single-walled carbon nanotubes with metallic conductivity

The present disclosure is directed to a method of producing metallic single-wall carbon nanotubes by treatment of carbon nanotube producing catalysts to obtain the desired catalyst particle size to produce predominantly metallic single wall carbon nanotubes. The treatment of the carbon nanotube producing catalyst particles involves contacting the catalyst particles with a mixture of an inert gas, like He, a reductant, such as H2, and an adsorbate, like water, at an elevated temperature range, for example, at 500° C. to 860° C., for a sufficient time to obtain the catalyst particle size. In some of the present methods, the preferential growth of nanotubes with metallic conductivity of up to 91% has been demonstrated.

Owner:HONDA MOTOR CO LTD

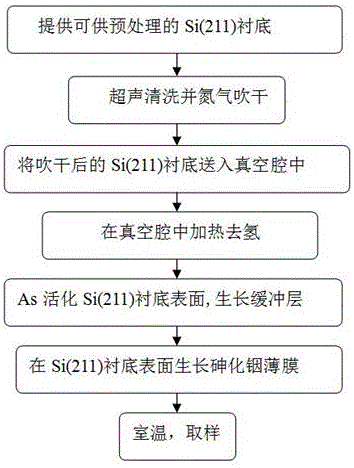

Preparation method and device of indium arsenide thin film material

ActiveCN106783549AWon't fall offPromotes deposition growthSemiconductor/solid-state device manufacturingIndium arsenideDehydrogenation

The invention discloses a preparation method and device of an indium arsenide thin film material and belongs to the technical field of semiconductor manufacturing. The method comprises the steps of ultrasonically cleaning a single-side polished mono-crystalline Si substrate and drying, and then feeding the dried mono-crystalline Si substrate into a vacuum chamber for heating and dehydrogenation; heating an arsenic simple substance for volatilization, and driving As air to flow through the surface of the mono-crystalline Si substrate to form an Si-As bond; activating the surface of the mono-crystalline Si substrate, and then growing a buffer layer at a low temperature; growing an indium arsenide thin film on the surface of the mono-crystalline Si substrate; and carrying out furnace cooling to a room temperature, thereby obtaining the indium arsenide thin film material. The method is low in demands on instrument and equipment, low in cost, easy to operate and relatively good in repeatability; and the obtained indium arsenide thin film is uniform and smooth in appearance and surface, preferential growth along (111) orientation is achieved, the thickness is 4.83 microns and the crystal quality is good.

Owner:KUNMING UNIV OF SCI & TECH

Semiconductor templates and fabrication methods

InactiveCN107710382ASemiconductor/solid-state device manufacturingSemiconductor materialsSemiconductor structure

A method of making a semi-polar semiconductor template comprises providing a semi-polar semiconductor wafer; etching the semiconductor wafer to form a regular semiconductor structure comprising a plurality of semiconductor regions (260) with a plurality of gaps between the regions, each of the regions (260) having a sidewall facing a respective one of the gaps, and growing semiconductor material over the semiconductor structure. The semiconductor material has a preferential growth direction (c) in which growth proceeds most rapidly from each of the sidewalls, and each of the sidewalls has at least a part which faces a vertical centre line of the respective one of the gaps so that growth in the preferential direction from said part extends towards said vertical centre line.

Owner:SEREN PHOTONICS

A kind of anisotropic smco5 type rare earth permanent magnet material and its preparation method

ActiveCN106935350BIncrease the use of high temperatureImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsRare earthCurie temperature

The invention discloses an anisotropic SmCo<5> type rare earth permanent magnet material and a preparation method therefor. The permanent magnet material comprises the following components with the general formula as follows: SmCo<5-x>C<x> or Sm(Co<1-y>M<y>)<5-x>C<x>, where y is greater than or equal to 0.01 and less than or equal to 0.3; x is greater than or equal to 0.02 and less than or equal to 2; M is selected from one or more of metals Fe, Ni, Cr, Cu, V, Ti, Zr, Mn, W or Mo; the preparation process comprises the steps of preparing materials, smelting and performing rapid quenching on melt, wherein the step of rapid quenching on the melt is performed by a vacuum melt-spinning machine with the copper roller rotary speed V of greater than or equal to 40m / s. The rare earth permanent magnet material is reasonable in component matching, and capable of effectively improving degree of supercooling of the alloy component system; the preparation process is simple, and the easily magnetized axis, namely, a C axis, of the prepared anisotropic SmCo<5> nanocrystal permanent magnet material is perpendicular to the surface of a thin strip, and a structure of preferential growth is formed on the C axis; therefore, the alloy has excellent magnetic performance in a direction perpendicular to the thin strip, the crystal particles are fine and small, and the alloy is high in remanent magnetization strength, coercivity, magnetic energy product and the Curie temperature; and the use temperature of the temperature can be effectively improved, so that the rare earth permanent magnet material is suitable for industrial application.

Owner:CENT SOUTH UNIV

A kind of preparation method and product of magnesium alloy with good room temperature plasticity

ActiveCN106623865BLongitudinal grain boundaries are straightNo transverse grain boundariesMaterials sciencePlastic property

The invention discloses a method for preparing a magnesium alloy with good room temperature plasticity, which comprises the following steps: taking Mg ingot with a purity of 99.9wt.%, Zn ingot with a purity of 99.9wt.%, Mg-30Y master alloy and Mg- The 30Zr intermediate alloy is put into the crucible for melting to obtain the alloy liquid; then the casting temperature is controlled, and the alloy liquid is cast into the graphite mold of the vacuum directional solidification equipment, and the insulation sleeve is kept warm; the pull-down is carried out by controlling the pulling speed of the pull-down system to promote casting The alloy grows on a specific preferential growth crystal plane, and finally solidifies to obtain a magnesium alloy. The method of the invention prepares a columnar grain structure in which the primary arms grow in parallel, the longitudinal grain boundaries are relatively straight, there is no transverse grain boundary, and there is a specific grain orientation, the preferential growth crystal plane is the growth direction, and the primary arm spacing is about 50 μm. The magnesium alloy σb is 188MPa at room temperature, and the elongation is as high as 24%.

Owner:东北大学秦皇岛分校

Composite material for the making of decorative items and procedure for the making of a decorative item

ActiveUS9353241B2Improved aesthetic property of brilliance and lusterIncrease elasticityTransportation and packagingMetal-working apparatusMetal powderPolymer

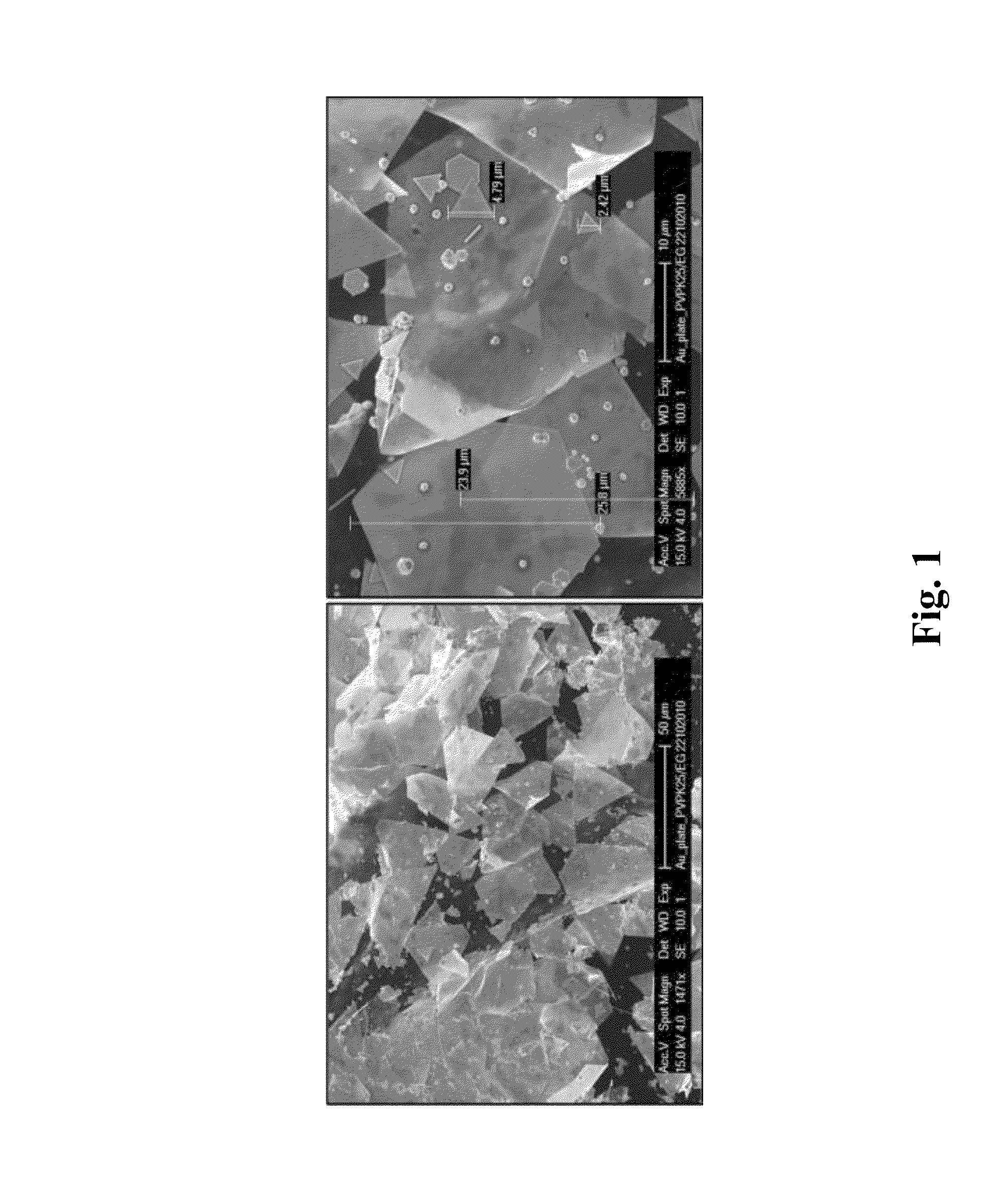

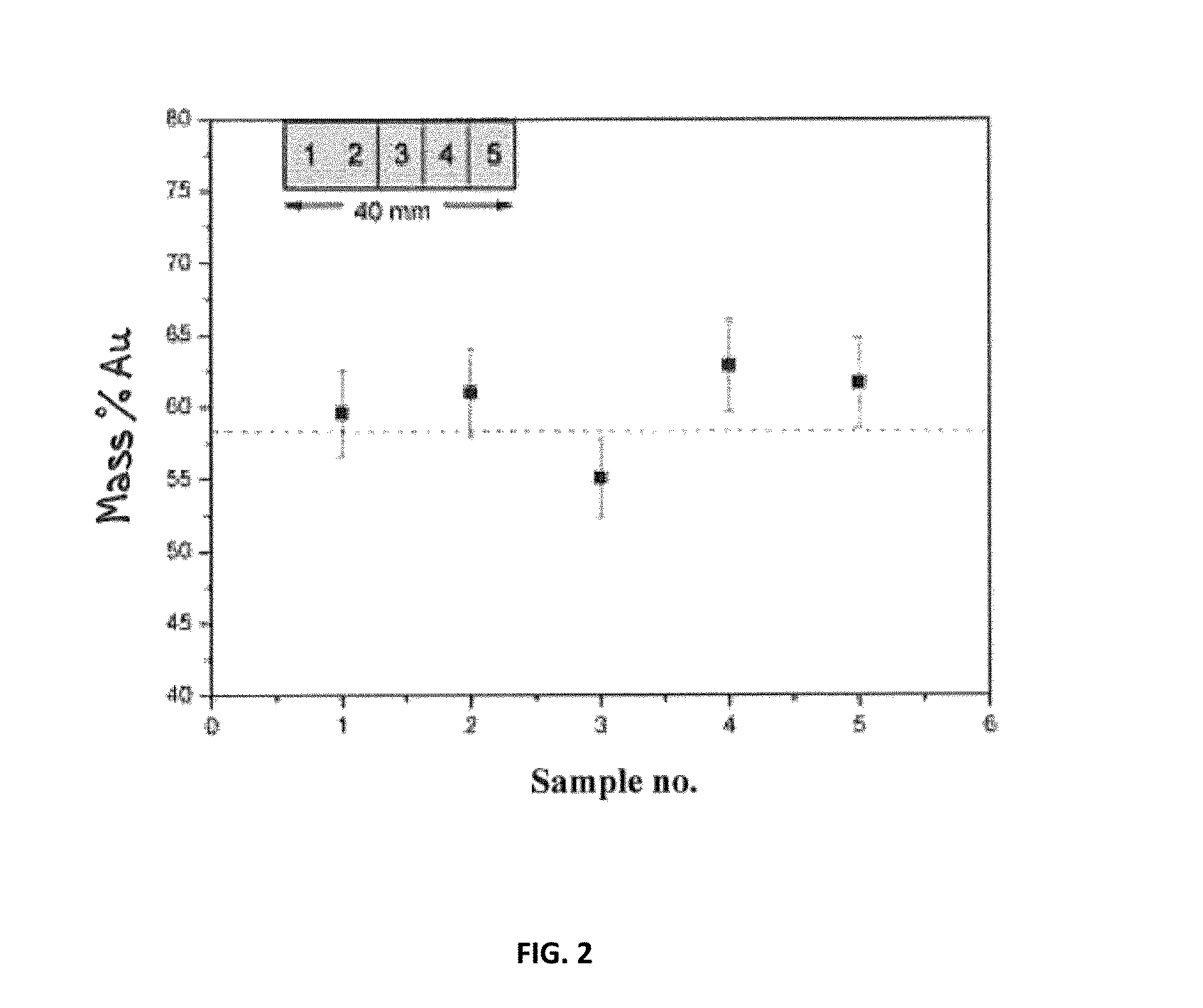

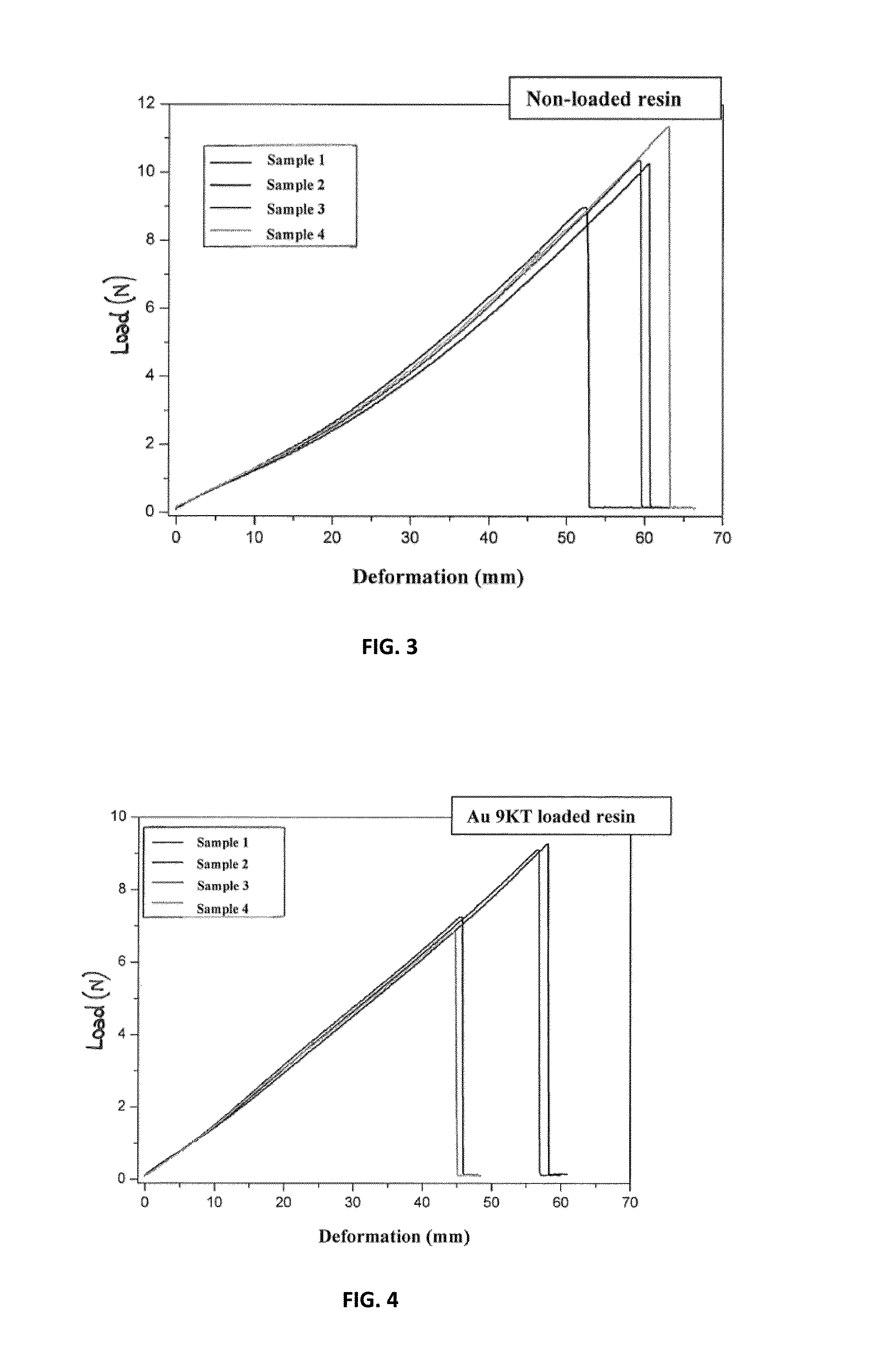

Composite material for the making of decorative items which contains at least a polymeric component and at least a metallic powder dispersed in the polymeric component in an amount in weight between 2% and 95%. The metallic powder includes plate-like particles with a nanometric thickness of between 5 and 300 nm and a preferential growth in a two-dimensional surface with at least a dimension of between 0.6 and 100 μm. A procedure for the making of an ornamental article includes at least a phase for preparing at least a base component of a silicone resin; at least a phase for preparing the metallic powder; at least an initial phase for mixing the metallic powder with the silicone resin base component to obtain an even mixture; and at least an initial phase for reticulating the base component in the even mixture with the metallic powder distributed in a homogeneous way.

Owner:ECOMETAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com