Preparation method of hydroxyapatite nanosheets

A technology of hydroxyapatite and nanosheets, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high synthesis temperature, influence on purity, complex process, etc., and achieve reduced production costs, easy production process, require simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, a preparation method of hydroxyapatite nanosheets, the steps are as follows: shell powder or egg shells are used as calcium source, ammonium phosphate is used as phosphorus source, and water is used as solvent. The reaction is made.

Embodiment 2

[0024] Embodiment 2, a preparation method of hydroxyapatite nanosheets, the specific steps are as follows:

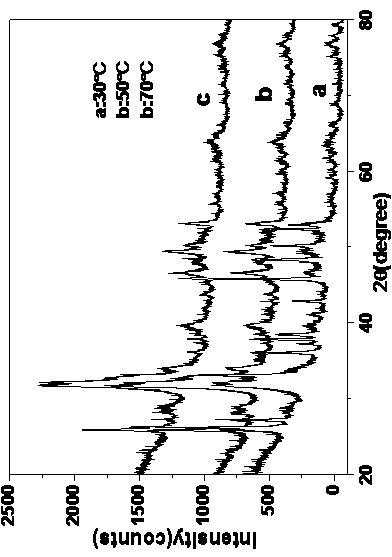

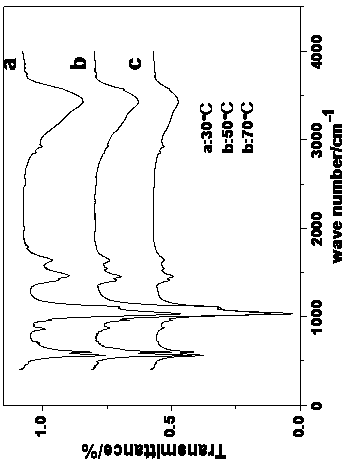

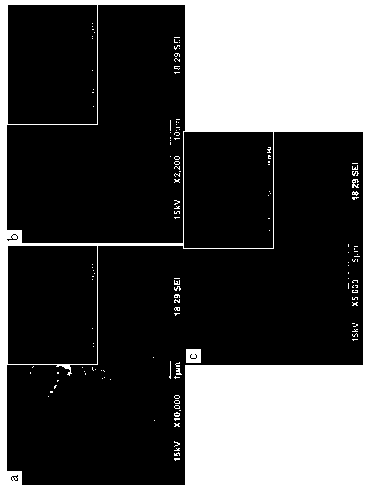

[0025] (1) Weigh the calcium source and chemically pure ammonium phosphate according to the mass ratio of 2:1, then add distilled water with a volume-to-mass ratio of 500mL: 2g of shell powder and mix them, mix them evenly with a magnetic stirrer, and pour them into the reaction vessel , and then placed in a constant temperature water bath at 30°C for 30 h;

[0026] (2) After the reaction, centrifuge to obtain a white precipitate, wash with distilled water and absolute ethanol to remove impurities, and finally put it into a constant temperature drying oven at 55 °C to dry to obtain hydroxyapatite nanosheets.

Embodiment 3

[0027] Embodiment 3, a kind of preparation method of hydroxyapatite nanosheet, its specific steps are as follows:

[0028] (1) Weigh the calcium source and chemically pure ammonium phosphate according to the mass ratio of 4:1, then add distilled water with a volume-to-mass ratio of 1000mL: 4g of shell powder and mix them, mix them evenly with a magnetic stirrer, and pour them into the reaction vessel , and then placed in a constant temperature water bath at 70 °C for 18 h;

[0029] (2) After the reaction, centrifuge to obtain a white precipitate, wash with distilled water and absolute ethanol to remove impurities, and finally put it into a constant temperature drying oven at 65 °C to dry to obtain hydroxyapatite nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com