A kind of anisotropic smco5 type rare earth permanent magnet material and its preparation method

A rare-earth permanent magnet and anisotropic technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of small supercooling, low quenching speed, insufficient supercooling, etc., and achieve high Effects of residual magnetization, easy process control, and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

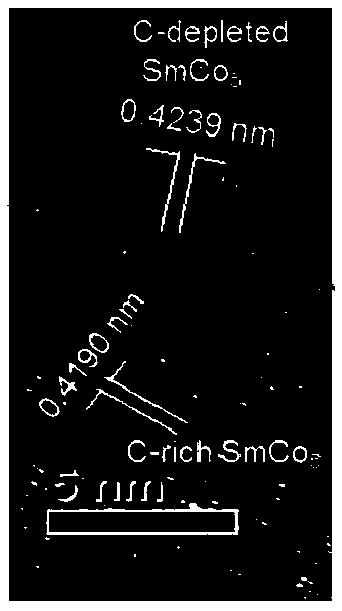

Embodiment 1

[0050] SmCo will be stoichiometrically 4.95 C 0.05 Proportioning, wherein the weight of Sm is increased by 3wt% to make up for the Sm volatilized due to high vapor pressure during the smelting process. Put Sm, Co and graphite with a purity higher than 98% in the crucible of the melting furnace, and evacuate to make the vacuum degree reach 5×10 -2 Pa; pass high-purity argon to make the pressure in the melting furnace 50kPa, and melt it with electricity; and use electromagnetic force to automatically stir the liquid for refining. The temperature of the alloy liquid is 1200-1400 ° C, and keep it warm for 6 minutes; cast the evenly smelted alloy liquid Put it in a water-cooled copper mold for use; then, break the cooled alloy ingot into pieces and put it into a quartz tube with a diameter of 10mm in a vacuum stripping machine. The bottom of the quartz tube has a small hole with a diameter of about 0.5mm as a nozzle; Vacuumize the cavity of the vacuum belt throwing machine until ...

Embodiment 2

[0054] The stoichiometric ratio Sm(Co 0.99 Ti 0.01 ) 4.95 C 0.05 Proportioning, wherein the weight of Sm is increased by 8wt% to make up for the Sm volatilized due to high vapor pressure during the smelting process. Put Sm, Co, TiC and graphite with a purity higher than 98% in the crucible of the melting furnace, and evacuate to make the vacuum degree reach 1×10 -2 Pa; pass high-purity argon gas to make the pressure in the melting furnace 50kPa, and melt it with electricity; and use electromagnetic force to automatically stir the liquid for refining. The temperature of the alloy liquid is 1200-1400 ° C, and keep it warm for 4 minutes; cast the evenly smelted alloy liquid Put it in a water-cooled copper mold for use; then, break the cooled alloy ingot into pieces and put it into a quartz tube with a diameter of 10mm in a vacuum stripping machine. The bottom of the quartz tube has a small hole with a diameter of about 0.5mm as a nozzle; Vacuumize the cavity of the vacuum bel...

Embodiment 3

[0058] The stoichiometric ratio Sm(Co 0.7 Ti 0.3 ) 3 C 2 Proportioning, wherein the weight of Sm is increased by 5wt% to make up for the Sm volatilized due to high vapor pressure during the smelting process. Put Sm, Co, TiC and graphite with a purity higher than 98% in the crucible of the melting furnace, and evacuate to make the vacuum degree reach 1×10 -2 Pa; pass high-purity argon gas to make the pressure in the melting furnace 50kPa, and melt it with electricity; and use electromagnetic force to automatically stir the liquid for refining. The temperature of the alloy liquid is 1200-1400 ° C, and keep it warm for 4 minutes; cast the evenly smelted alloy liquid Put it in a water-cooled copper mold for use; then, break the cooled alloy ingot into pieces and put it into a quartz tube with a diameter of 10mm in a vacuum stripping machine. The bottom of the quartz tube has a small hole with a diameter of about 0.5mm as a nozzle; Vacuumize the cavity of the vacuum belt throwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com