Cooling block for polycrystalline silicon ingot furnace

A polycrystalline silicon ingot furnace and cooling block technology, which is applied to the growth of polycrystalline materials, crystal growth, single crystal growth, etc., can solve the problems of inability to suppress preferential crystallization, grain growth direction deviation, low photoelectric conversion efficiency, etc. The effect of inhibiting preferential growth, improving quality, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

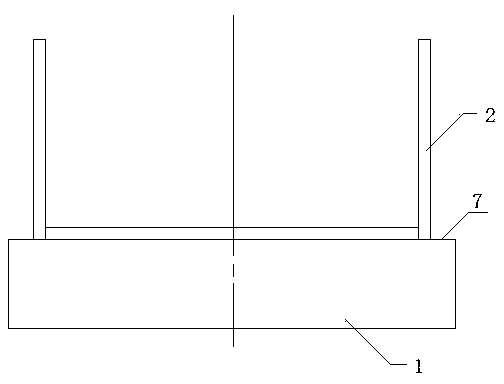

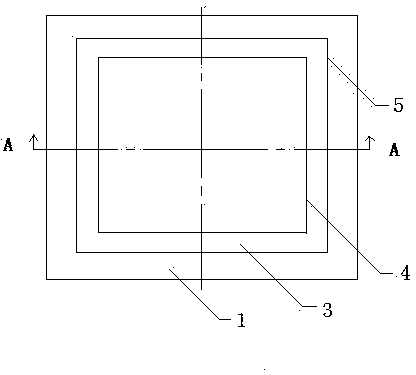

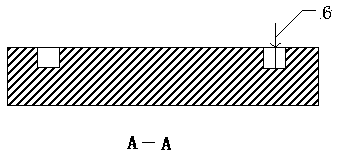

[0019] Embodiment one: see Figure 1-Figure 3 , This embodiment includes a cooling block body 1 , a crucible 2 , a groove 3 , an inner wall 4 , an outer wall 5 , a groove depth 6 and a top surface 7 .

[0020] The cooling block body 1 in this embodiment is in contact with the crucible 2, the crucible 2 is located on the top surface of the cooling block body 1, the top surface 7 of the cooling block body 1 is provided with an annular square groove 3, and the center line of the groove 3 is in line with the The centerlines of the cooling block body 1 coincide with each other, and the crucible 2 is placed on the cooling block body 1 for directional solidification.

[0021] Groove 3 in this implementation comprises inner wall 4 and outer wall 5, and the inner wall 4 sides length of groove 3 is 625mm, and outer wall 5 sides length is 780mm, and the groove width of groove 3 is 103mm, and the groove depth 6 of groove 3 is 5mm , the sides of the inner wall 4 and the outer wall 5 of th...

Embodiment 2

[0025] Embodiment two: see Figure 1-Figure 3 , This embodiment includes a cooling block body 1, a crucible 2, a groove 3, an inner wall 4, an outer wall 5 and a groove depth 6.

[0026] In this embodiment, the cooling block body 1 is in contact with the crucible 2, the crucible 2 is located on the top surface of the cooling block body 1, the top surface 7 of the cooling block body 1 has a groove 3, and the cooling block body 1 is made of graphite.

[0027] In this embodiment, the centerline of the groove 3 is on the same straight line as the centerline of the cooling block body 1. The groove 3 includes an inner wall 4 and an outer wall 5. The groove 3 is an annular square. The inner wall 4 and the outer wall of the groove 3 The sides of 5 and the corresponding sides of the cooling block body 1 are parallel to each other.

[0028] In this embodiment, the inner wall 4 of the groove 3 has a length of 677 mm, the outer wall 5 has a side length of 875 mm, the groove width of the ...

Embodiment 3

[0031] Embodiment three: see Figure 1-Figure 3 , This embodiment includes a cooling block body 1, a crucible 2, a groove 3, an inner wall 4, an outer wall 5 and a groove depth 6.

[0032] In this embodiment, the cooling block body 1 is in contact with the crucible 2, the crucible 2 is located on the top surface of the cooling block body 1, the top surface 7 of the cooling block body 1 has a groove 3, and the cooling block body 1 is made of graphite.

[0033] In this embodiment, the centerline of the groove 3 and the centerline of the cooling block body 1 are on the same straight line, the groove 3 includes 4 and the outer wall 5, and the four sides of the groove 3 correspond to the four sides of the cooling block body 1 in the corresponding direction Parallel to each other, the groove 3 is an annular square.

[0034] In this embodiment, the 4 sides of the inner wall of the groove 3 are 780 mm long, the 5 sides of the outer wall are 935 mm long, the groove width of the groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com