A kind of preparation method and product of magnesium alloy with good room temperature plasticity

A magnesium alloy, room temperature technology, applied in the field of alloy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

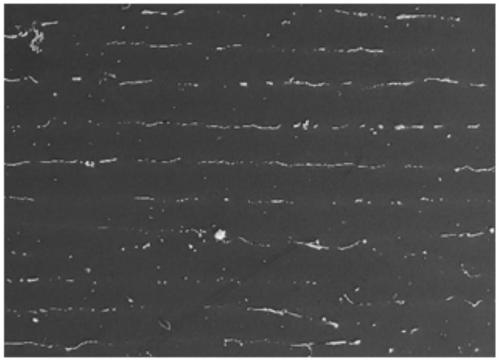

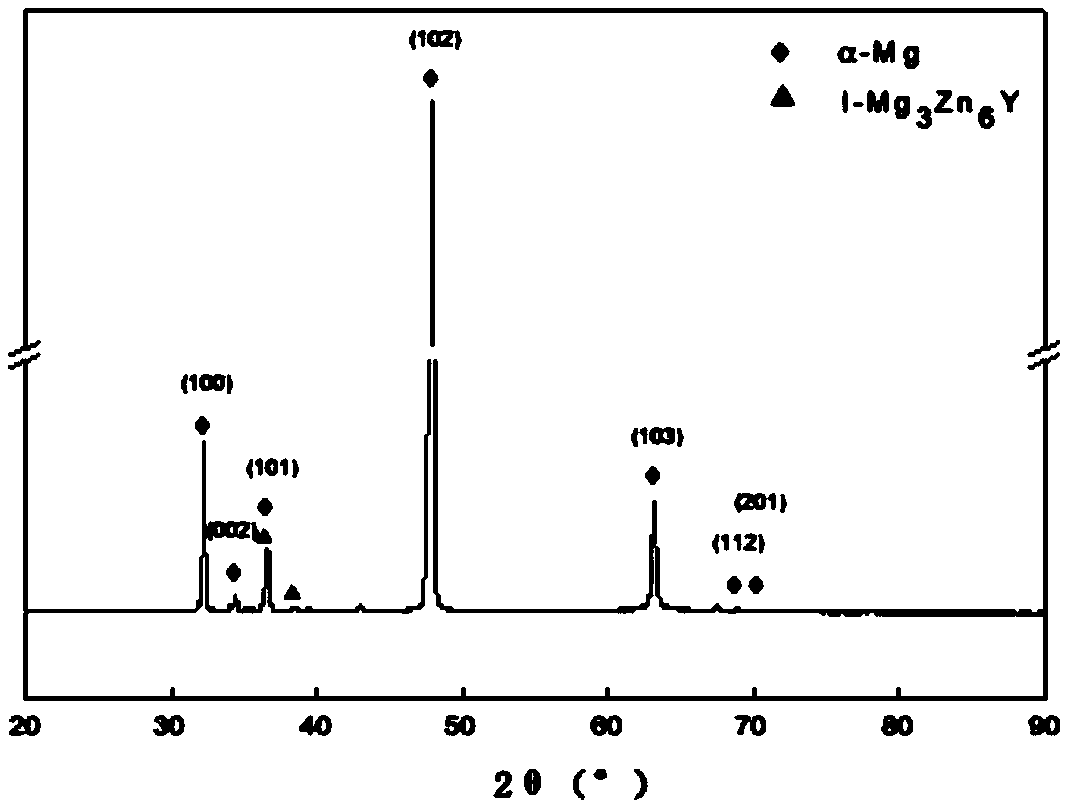

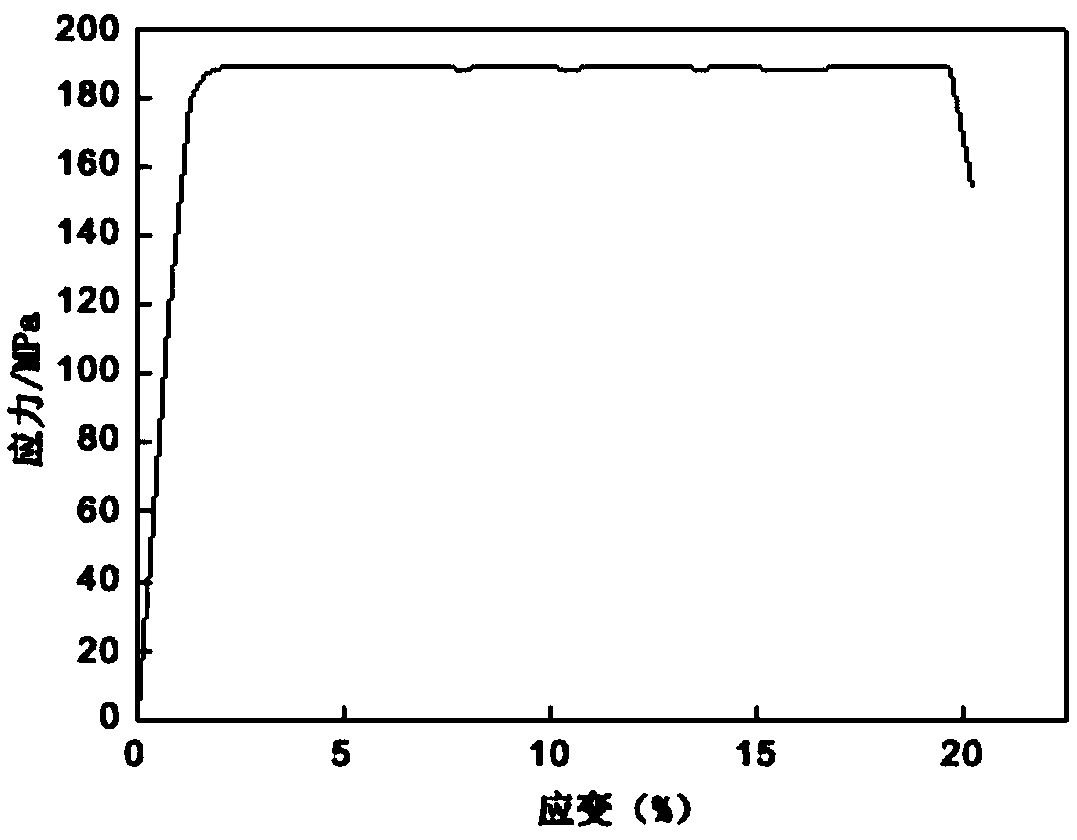

[0060] A method for preparing a magnesium alloy with good room temperature plasticity, comprising the following steps: in parts by weight, taking 94.8 parts of Mg ingots with a purity of 99.9wt.%, 4.1 parts of Zn ingots with a purity of 99.9wt.%, Mg- 1.0 parts of 30Y master alloy and 0.2 parts of Mg-30Zr master alloy were put into a crucible for melting to obtain alloy liquid; then the casting temperature was controlled at 750°C, and the alloy liquid was cast into the graphite mold of the vacuum directional solidification equipment, and the insulation cover was kept warm. The temperature of the insulation jacket is kept consistent with the casting temperature; then the pull-down is performed by controlling the pulling speed of the pull-down system to 5mm / min, and the water-cooling system maintains a constant temperature of 5°C. The crystal face grows, and finally solidifies to obtain a magnesium alloy with good room temperature plasticity. According to the mass percentage, the...

Embodiment 2

[0062] A method for preparing a magnesium alloy with good room temperature plasticity, comprising the following steps: in parts by weight, taking 91.3 parts of Mg ingots with a purity of 99.9wt.%, 6.1 parts of Zn ingots with a purity of 99.9wt.%, Mg- 2.0 parts of 30Y master alloy and 0.7 parts of Mg-30Zr master alloy, take Mg ingot with a purity of 99.9wt.%, Zn ingot with a purity of 99.9wt.%, Mg-30Y master alloy and Mg-Zr master alloy, and put them into a crucible Melting is carried out to obtain alloy liquid; then the casting temperature is controlled at 850°C, and the alloy liquid is cast into the graphite mold of the vacuum directional solidification equipment, and the insulation cover is kept warm, and the temperature of the insulation cover is consistent with the casting temperature; Pull down at a speed of 25mm / min. The water cooling system maintains a constant temperature of 5°C. The water cooling system and the temperature of the alloy liquid form a temperature gradien...

Embodiment 3

[0064] A method for preparing a magnesium alloy with good room temperature plasticity, comprising the following steps: in parts by weight, taking 93.4 parts of Mg ingots with a purity of 99.9wt.%, 4.9 parts of Zn ingots with a purity of 99.9wt.%, Mg- 1.5 parts of 30Y master alloy and 0.3 parts of Mg-30Zr master alloy, take Mg ingot with a purity of 99.9wt.%, Zn ingot with a purity of 99.9wt.%, Mg-30Y master alloy and Mg-Zr master alloy, and put them into a crucible Melting is carried out to obtain alloy liquid; then the casting temperature is controlled to 780°C, and the alloy liquid is cast into the graphite mold of the vacuum directional solidification equipment, and the insulation cover is kept warm, and the temperature of the insulation cover is consistent with the casting temperature; Pull down at a speed of 10mm / min. The water cooling system maintains a constant temperature of 5°C. The water cooling system and the temperature of the alloy liquid form a temperature gradien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com