Patents

Literature

32results about How to "Promotes deposition growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver-loaded antibacterial artificial joint and preparation method thereof

InactiveCN101766839ABroad-spectrum antibacterialImprove sterilization efficiencyTitanium compoundsCoatingsSodium titanateTitanium alloy

Owner:江苏广达医材集团有限公司 +1

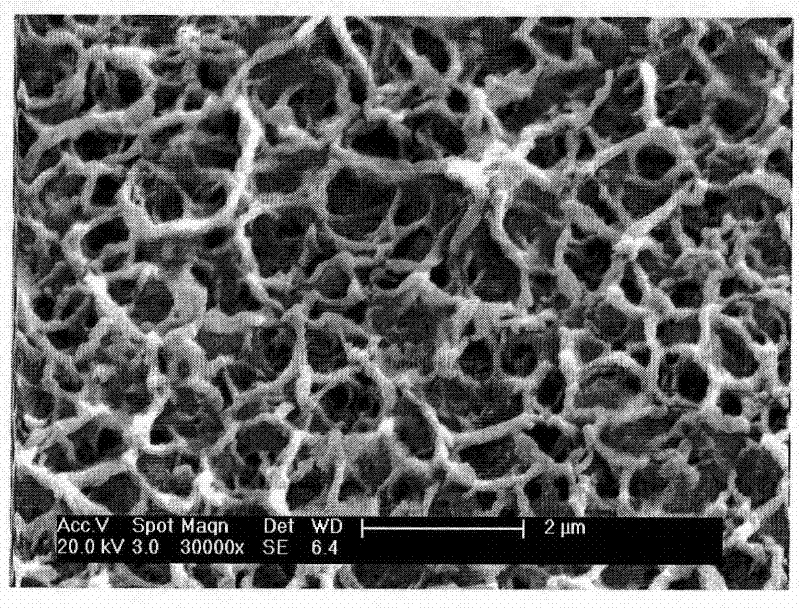

Artificial joint with micro-nano graded topological surface structure and preparation method of artificial joint

ActiveCN102732882ABiological activity hasCapable of regulating cellsElectrolytic inorganic material coatingSurface reaction electrolytic coatingMicro nanoPlasma electrolytic oxidation

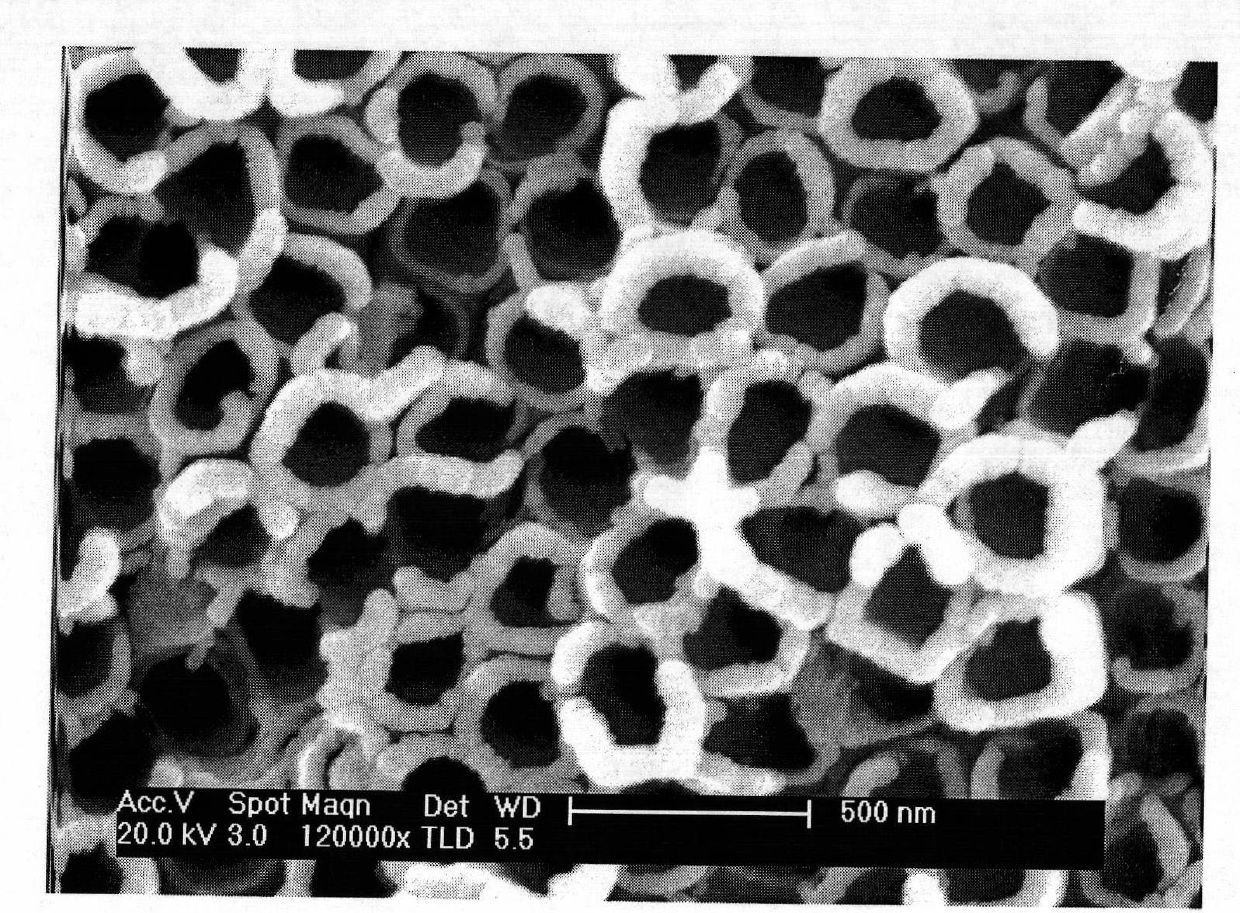

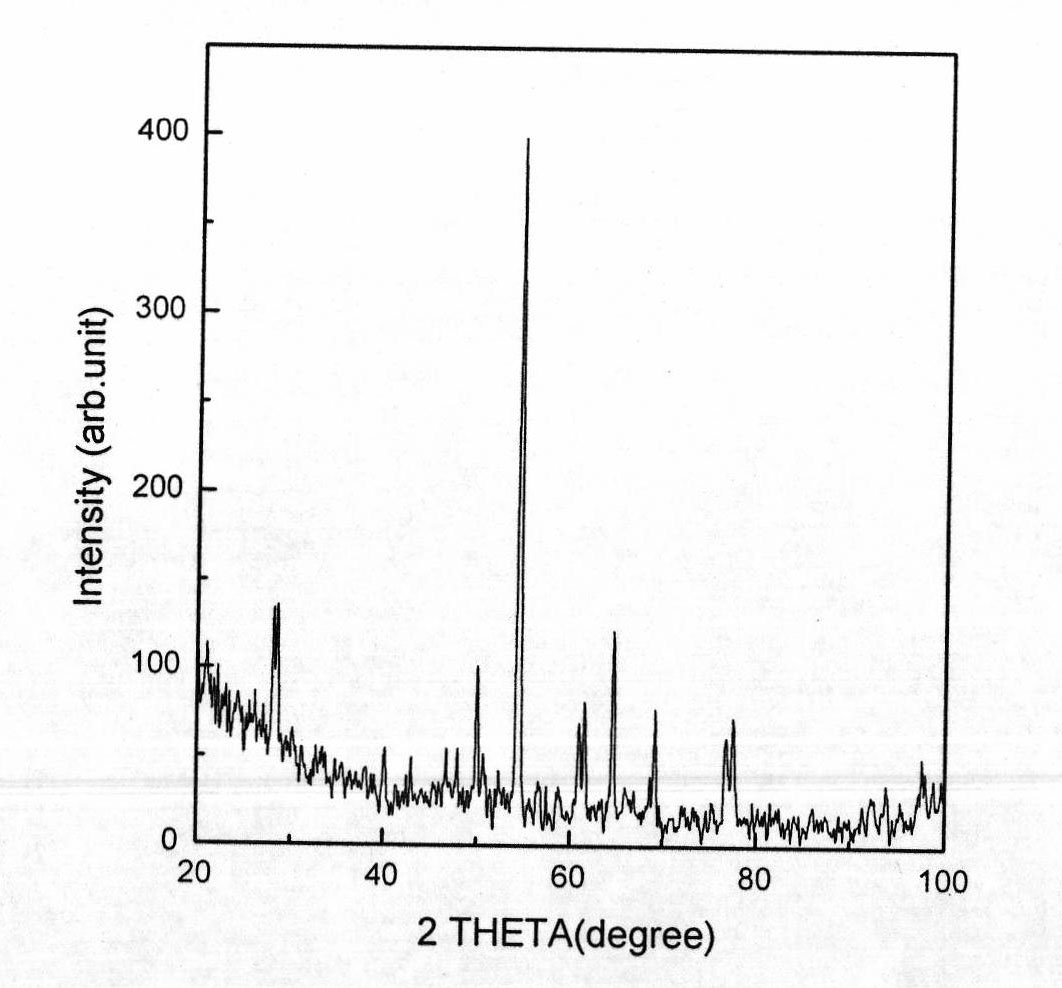

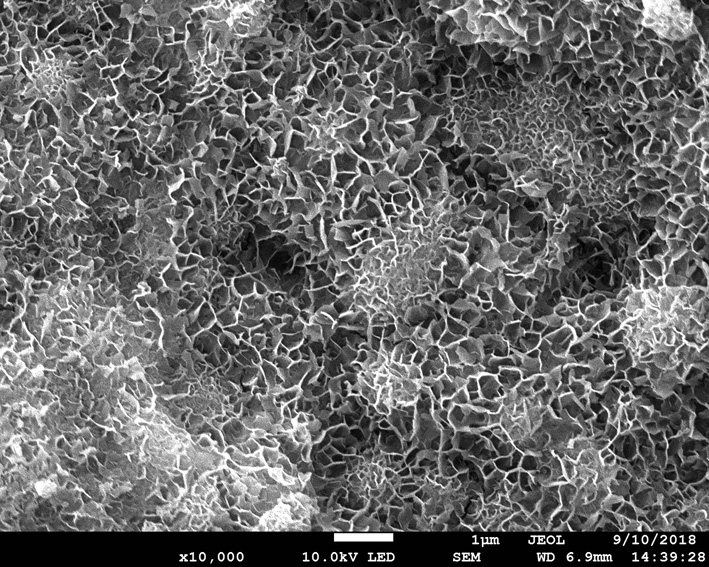

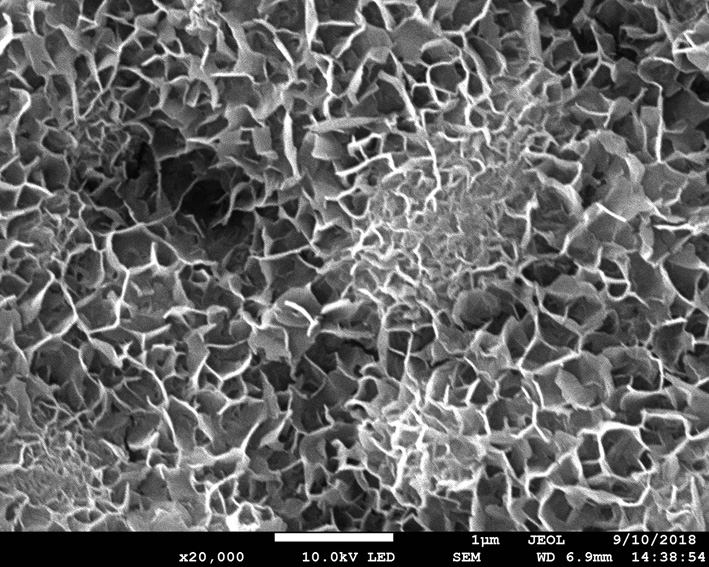

The invention provides an artificial joint with a micro-nano graded topological surface structure and a preparation method of the artificial joint. The artificial joint is formed by compounding a titanium alloy substrate, a micro-porous titanium dioxide surface layer prepared by a micro-arc oxidization method, and a zinc oxide nano rod or a nano taper deposited and grown on the hole wall of the surface, namely the micro-porous titanium dioxide biological activity surface layer is obtained on the surface of an artificial joint titanium substrate through the micro-arc oxidization method; and furthermore, electric depositing parameters are adjusted and a zinc oxide nano rod / taper is deposited and prepared on the titanium dioxide biological activity surface layer, so as to form the artificial joint with the micro-nano graded topological surface structure. The artificial joint can utilize abundant titanium dioxide micron hole structures on the surface and a zinc oxide nano topological structure deposited and grown in the hole wall to enhance the biological effects of adhesion, growth, multiplication and the like of surface osteoblast, and realize the slow release of the element zinc; and therefore, the antibacterial capability, the biological activity, the biocompatibility and the cell regulating and controlling capability of the surface at an implantation initial stage are greatly improved.

Owner:苏州晶俊新材料科技有限公司

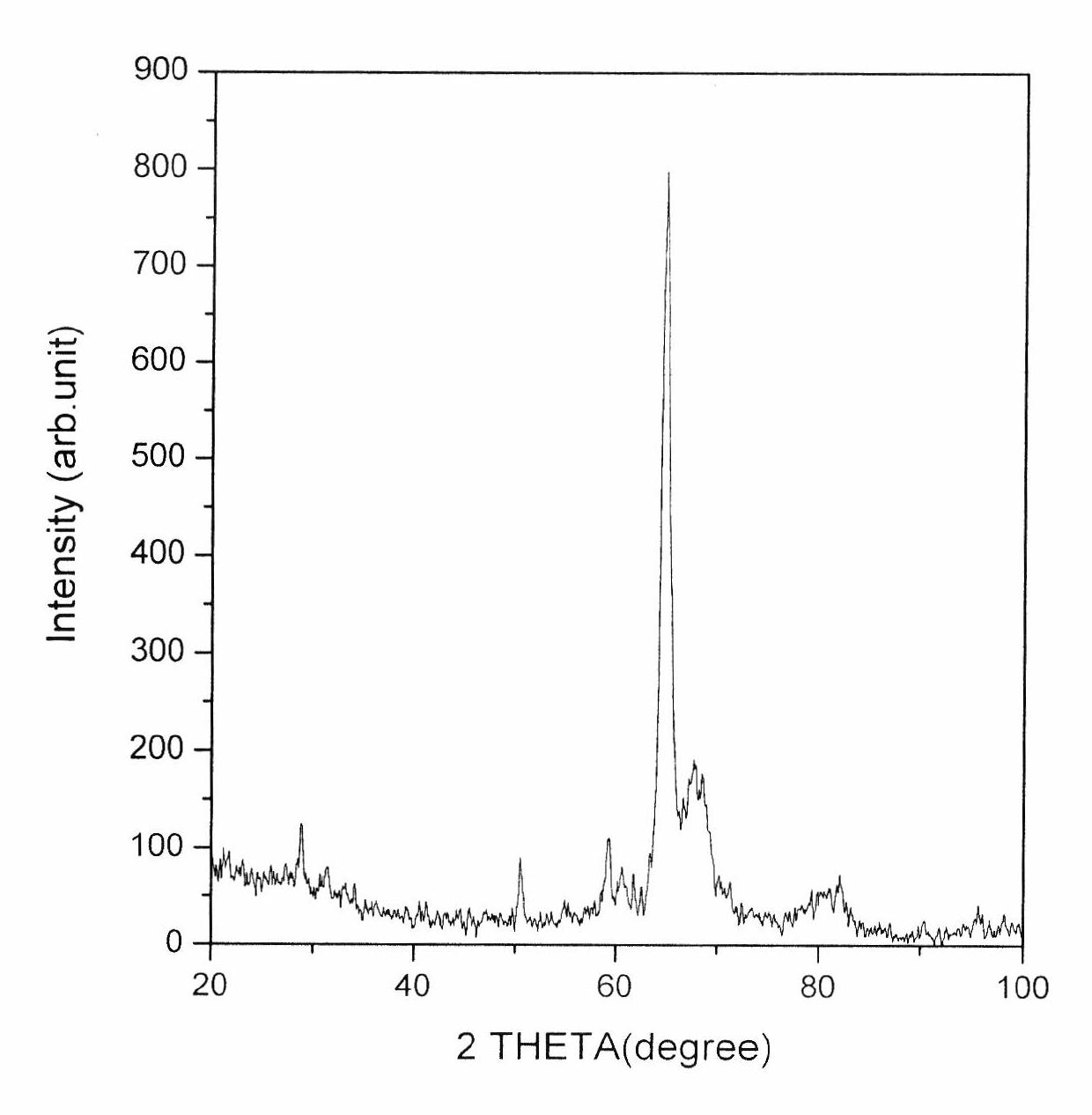

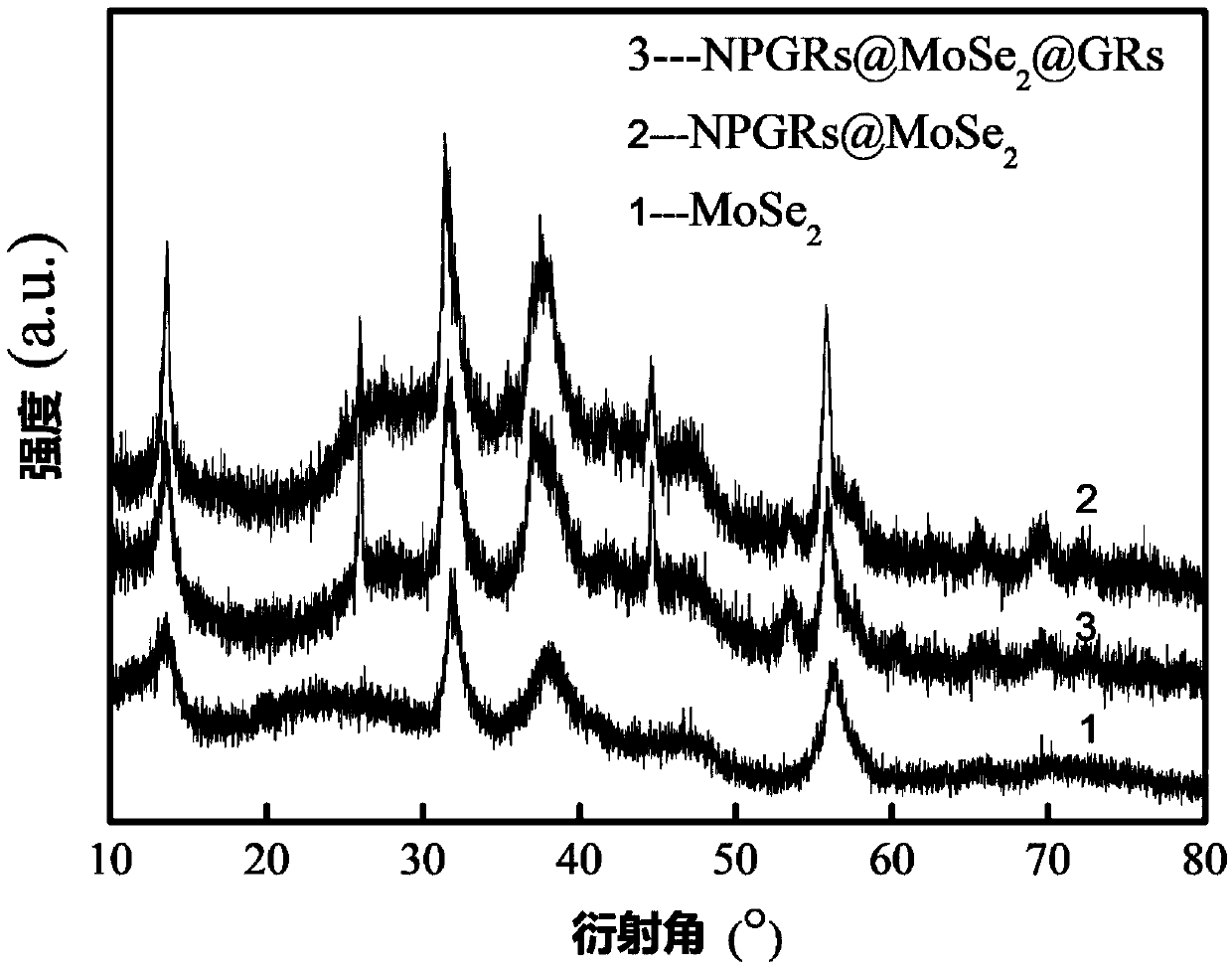

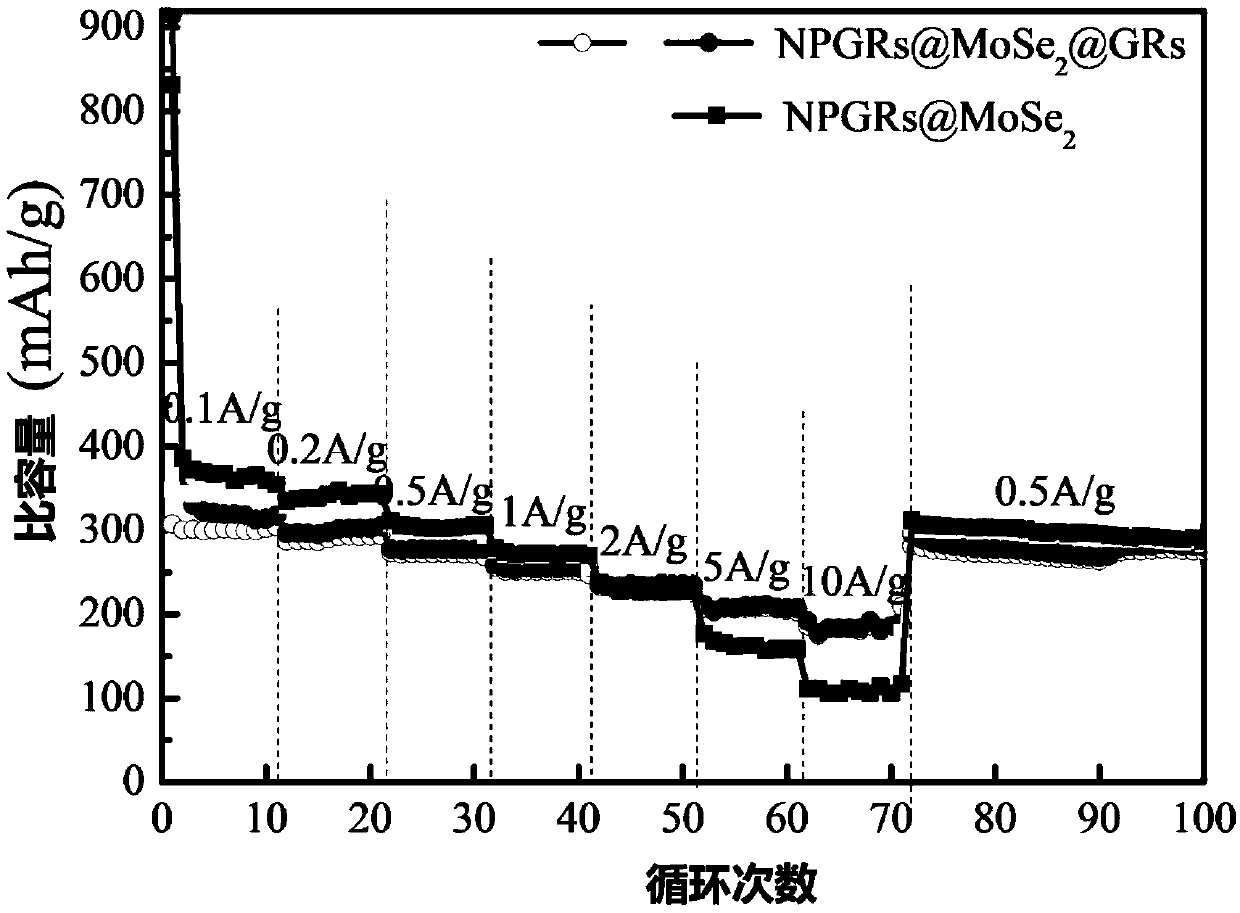

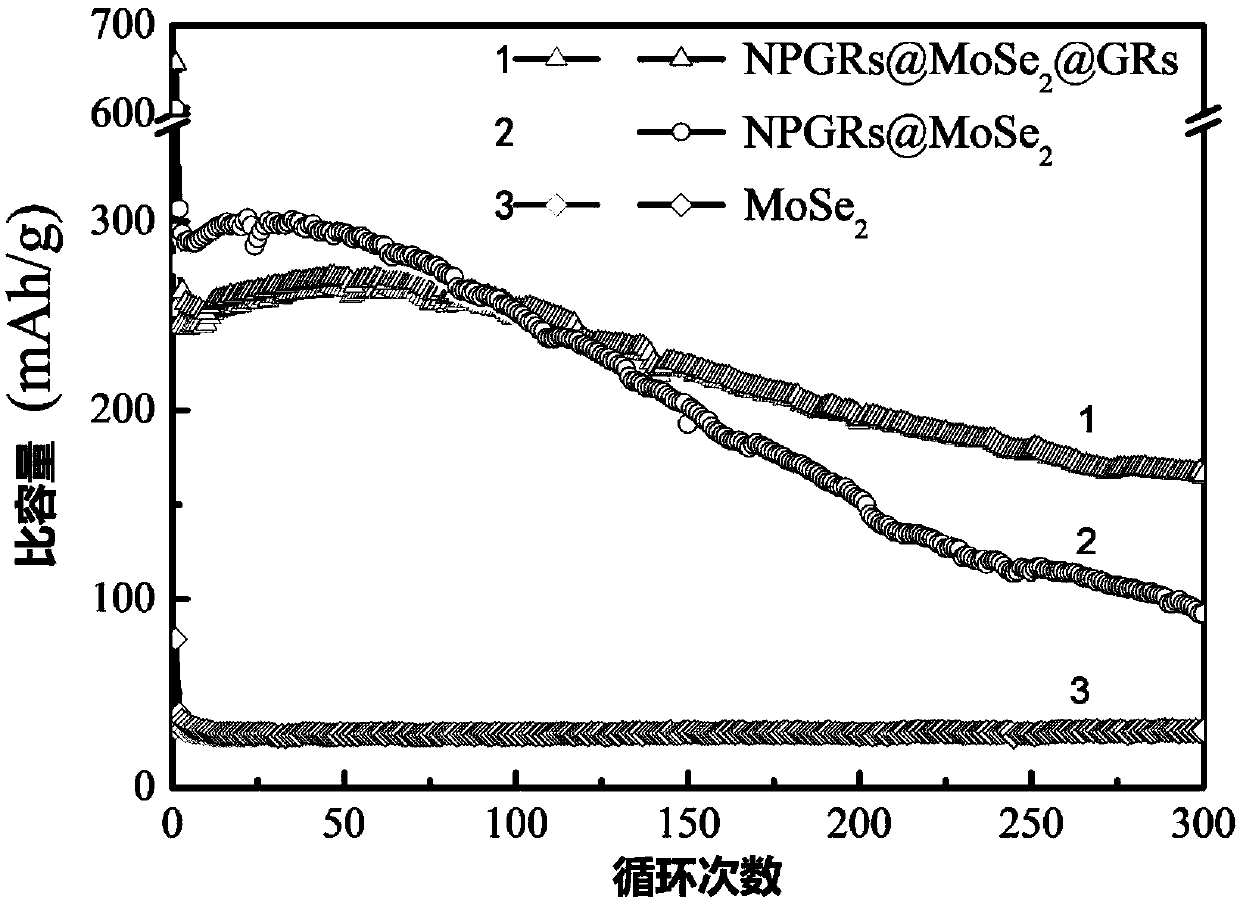

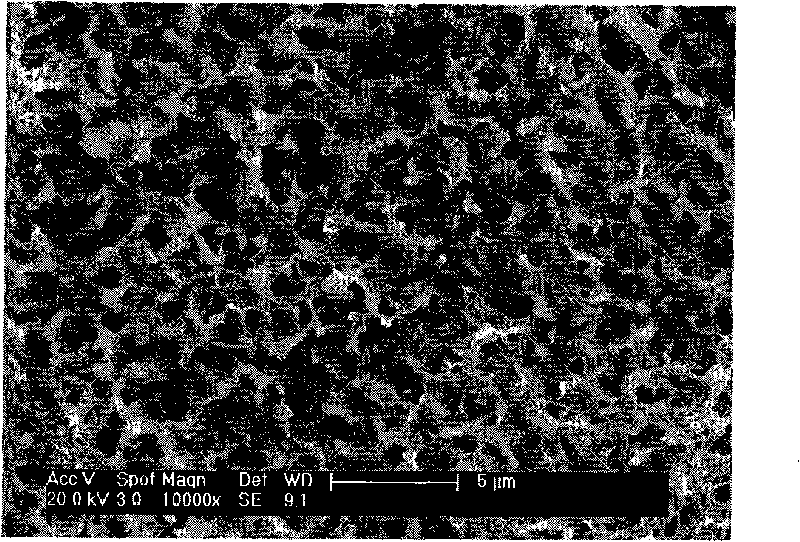

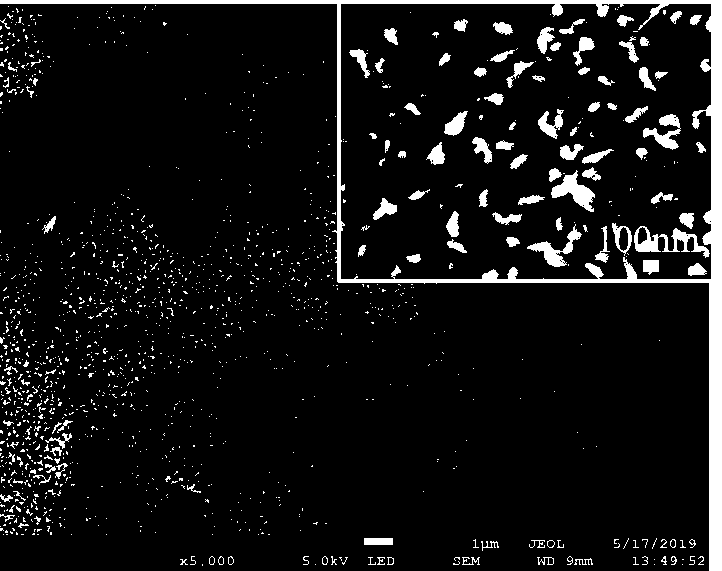

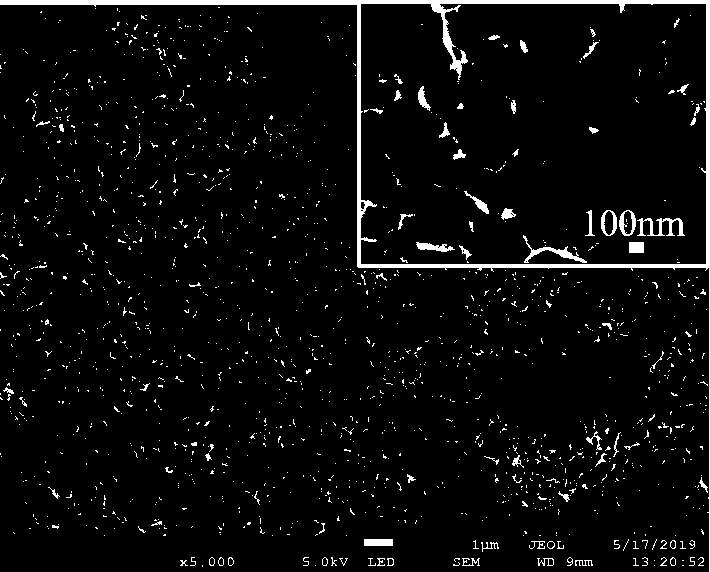

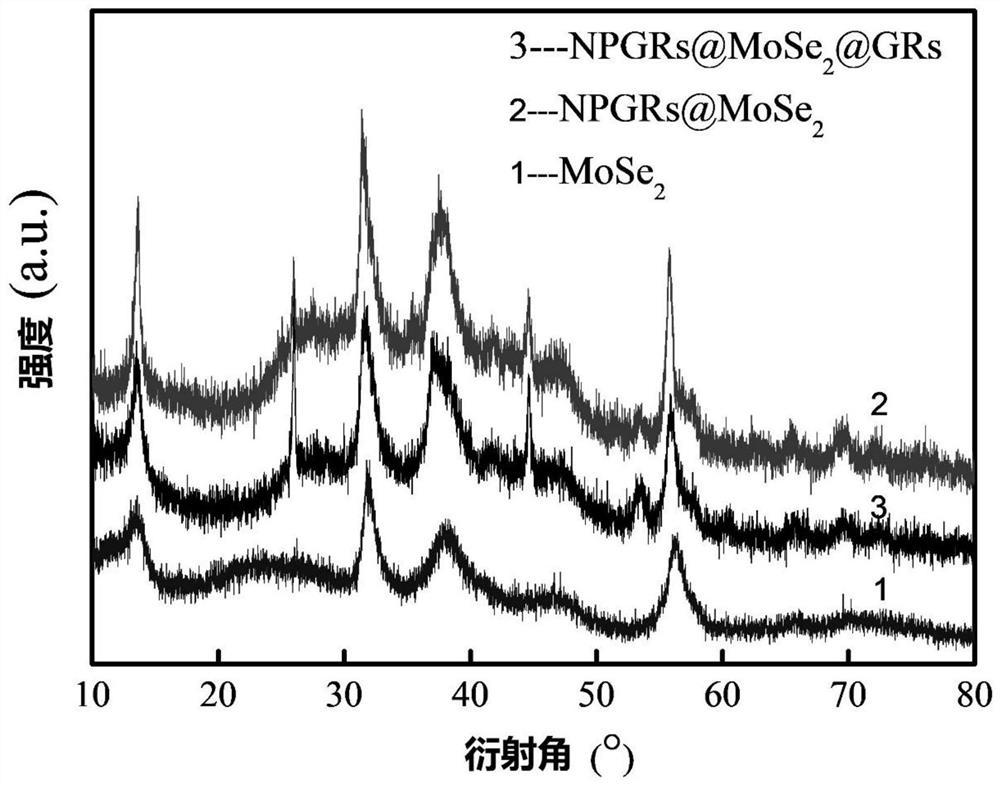

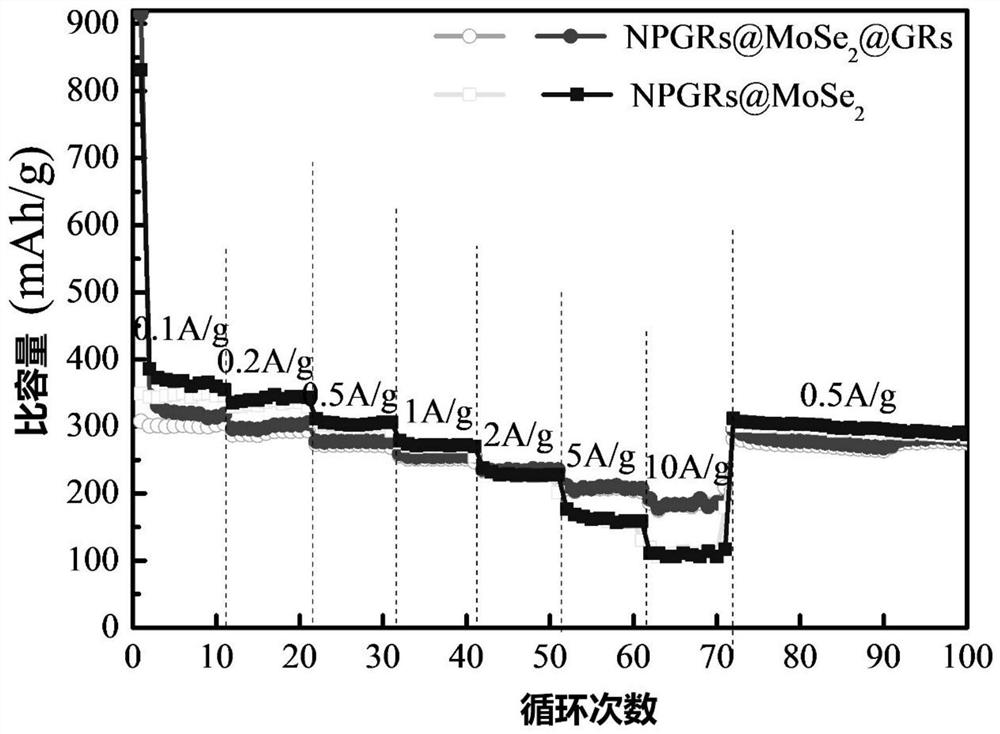

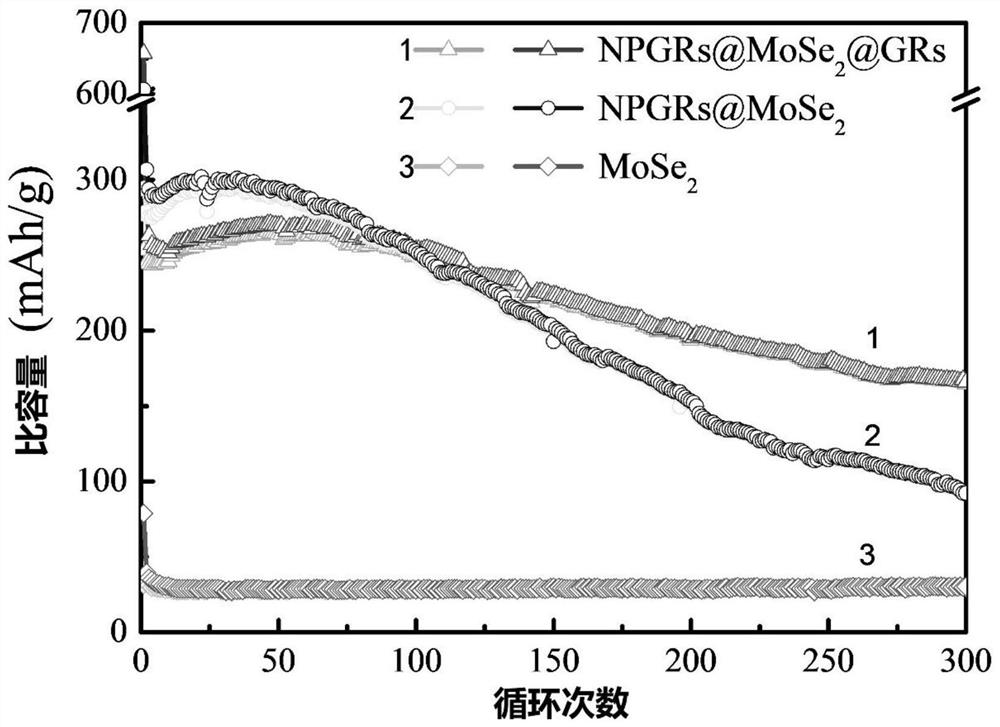

Sandwich-structured graphene/molybdenum selenide/nitrogen-doped porous graphene composite material and preparation method and application thereof

ActiveCN109546133AStable structureLow costSecondary cellsNegative electrodesPorous grapheneDissolution

The invention discloses a sandwich-structured graphene / molybdenum selenide / nitrogen-doped porous graphene composite material and a preparation method and an application thereof. The structure unit includes a nitrogen-doped porous graphene layer of a substrate, a molybdenum selenide layer growing on the substrate, and a graphene layer as an outer protective film on the molybdenum selenide layer. Molybdenum selenide is grown in the middle of two graphene layers by using structural similarity. The inner nitrogen-doped porous graphene has good conductivity and a porous structure, which is conducive to electron transport and electrolyte infiltration. The graphene protective film on the surface can reduce the dissolution and destruction of molybdenum selenide and improve the stability and rate performance of materials. Therefore, technical problems such as serious self-agglomeration, weak conductivity, large volume deformation and low capacity caused by the use of pure molybdenum selenide asa negative material of sodium ion batteries are solved.

Owner:ZHEJIANG SCI-TECH UNIV

Bioactive artificial joint capable of slowly releasing trace element selenium

InactiveCN101732762AImprove immunityGood anti-inflammatory effectCoatingsProsthesisSodium titanateTitanium alloy

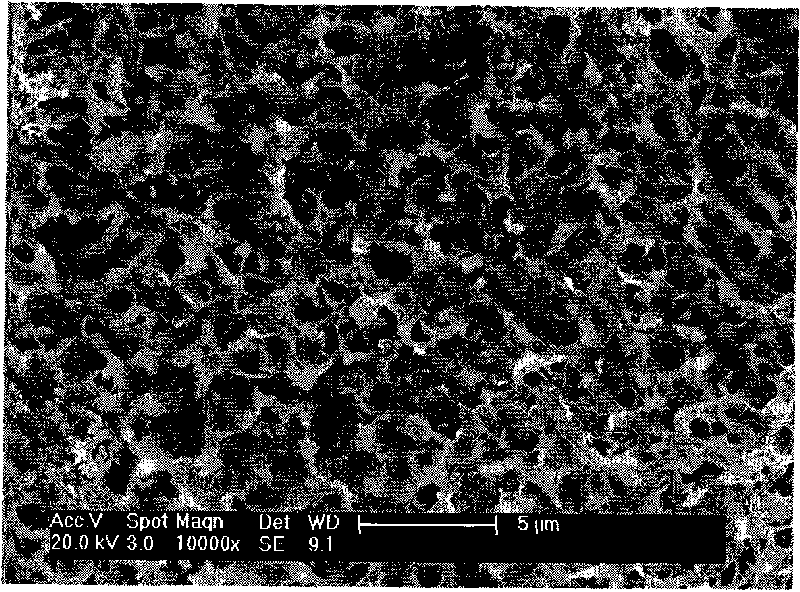

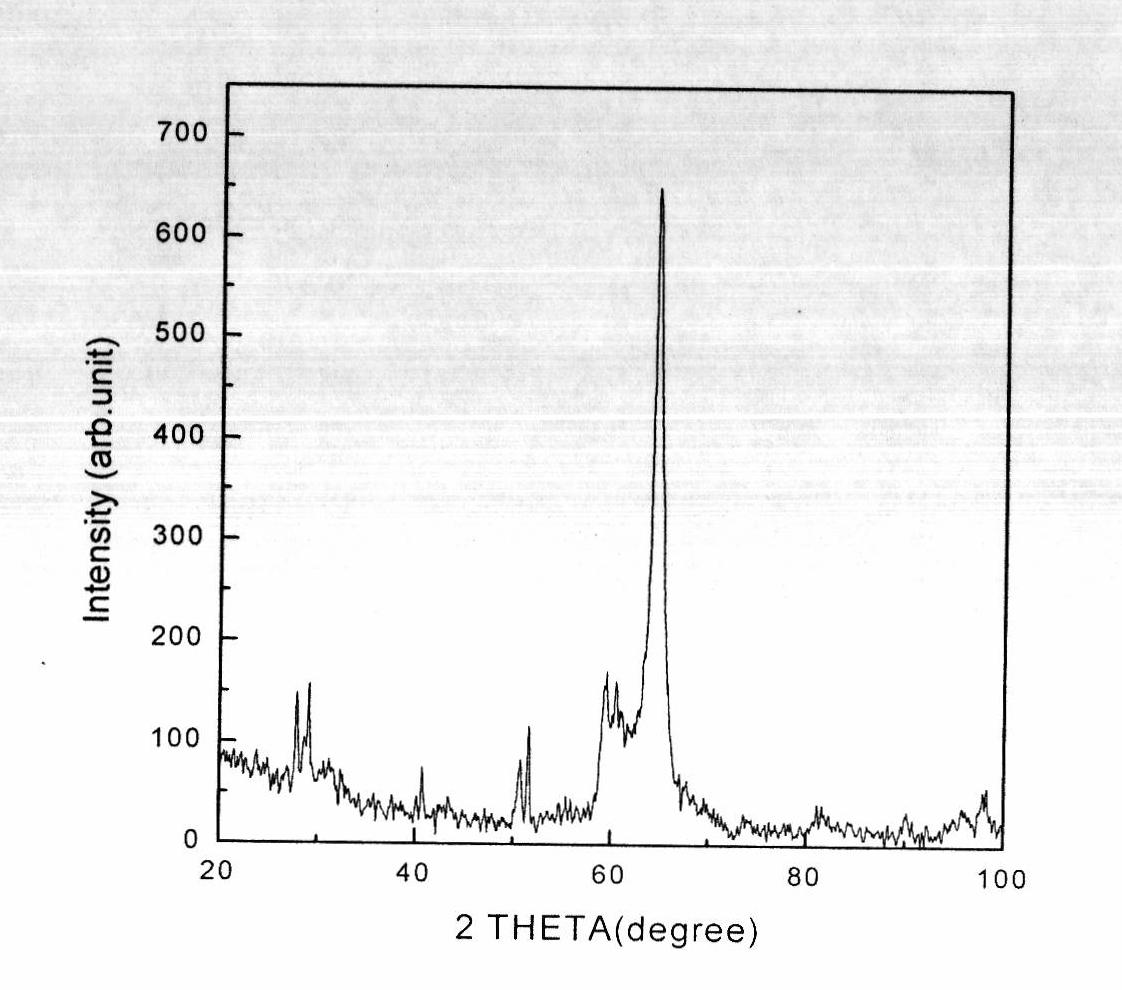

The invention relates to a bioactive artificial joint capable of slowly releasing trace element selenium. The artificial joint consists of a pure titanium or titanium alloy artificial joint matrix and a microporous sodium titanate surface layer loaded with trace sodium selenite and bone morphogenetic protein (BMP), wherein the sodium titanate bioactive layer with microporous structures is combined with the surface of the metal matrix and formed by mutually and alternately stacking the sodium titanate microporous structures generated by carrying out a hydrothermal reaction on the surface of the titanium or titanium alloy matrix and a sodium hydroxide solution, and the trace sodium selenite and the BMP are compounded in the microporous structures through centrifugal force and the effect of capillaries. A preparation method of the bioactive artificial joint comprises the following steps of: firstly, selecting a processed pure titanium or titanium alloy artificial joint; then obtaining the sodium titanate layer with the microporous structures on the surface of the titanium artificial joint by adopting an alkali liquor hydrothermal synthesis technology; and finally, loading the sodium selenite and the BMP in the microporous sodium titanate layer by adopting a centrifugal loading technology.

Owner:江苏广达医材集团有限公司 +1

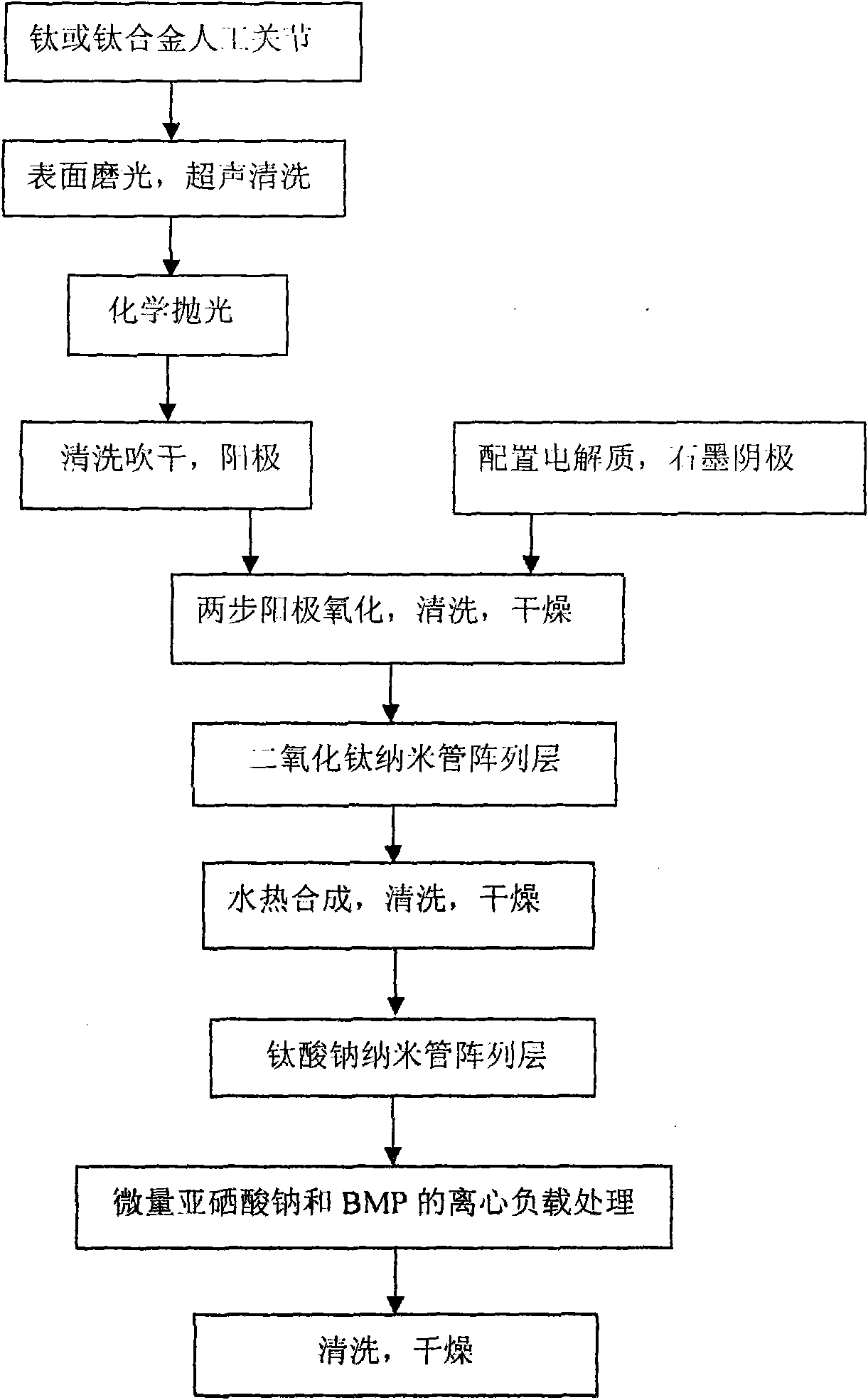

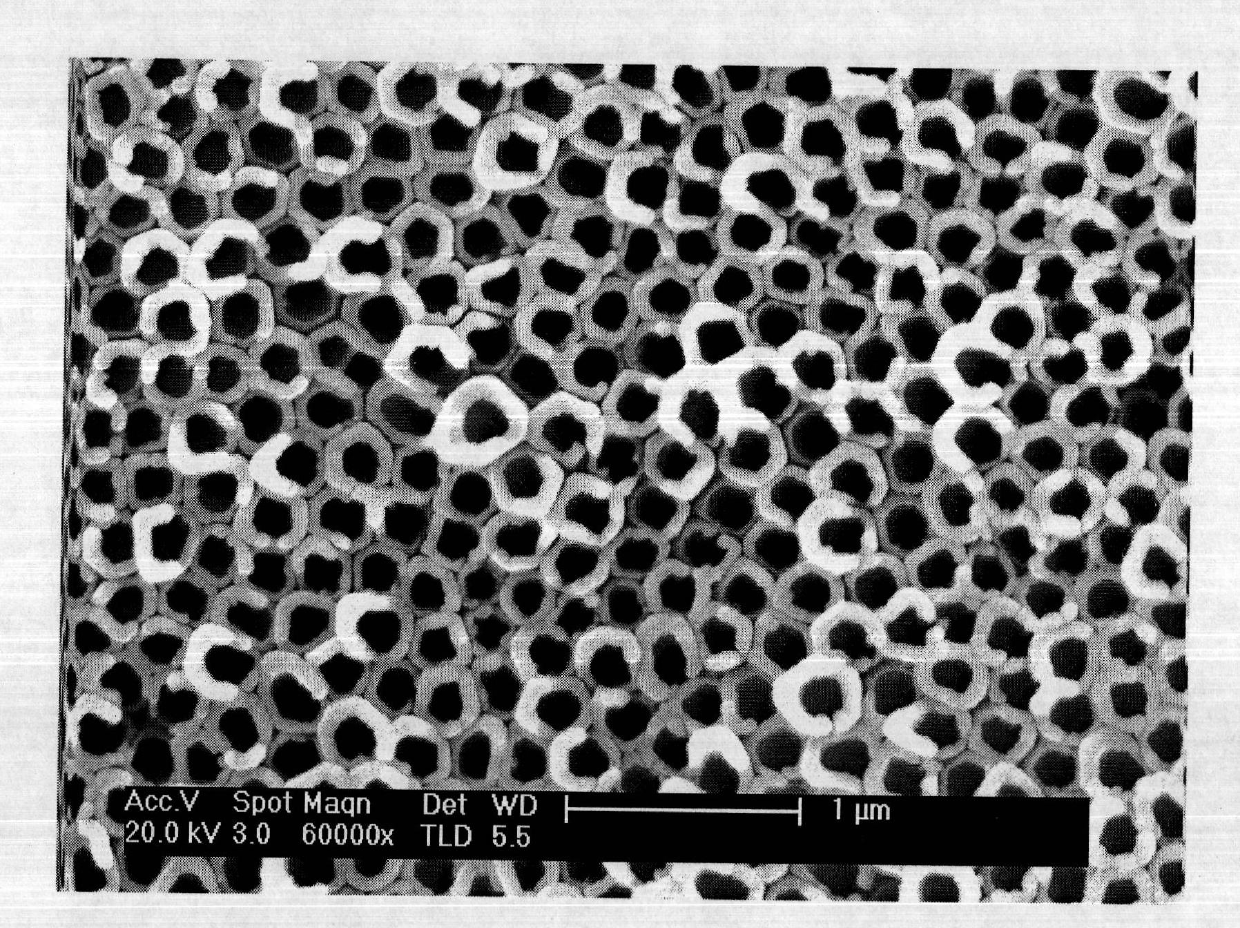

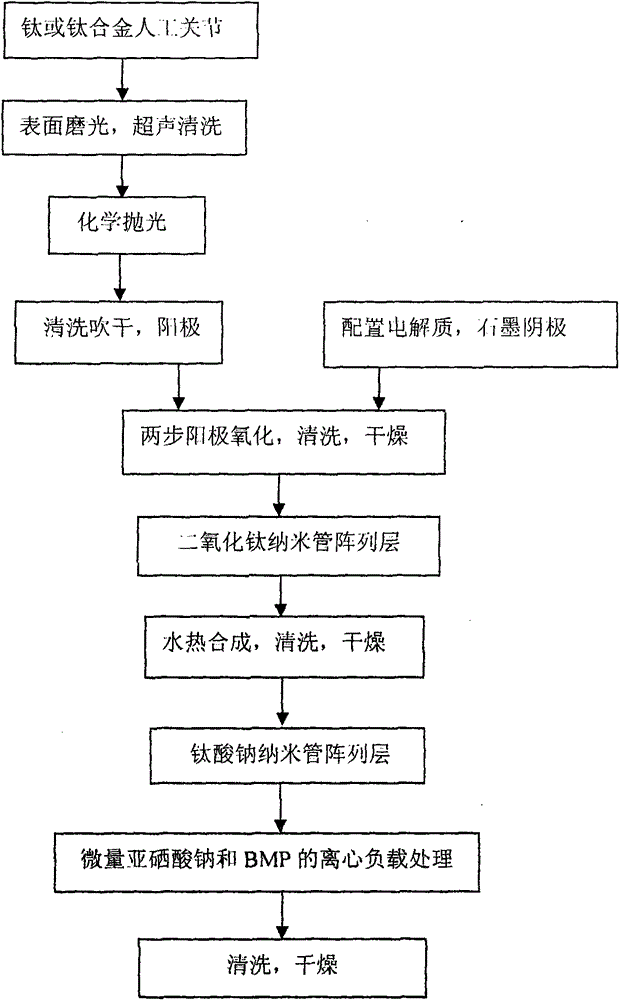

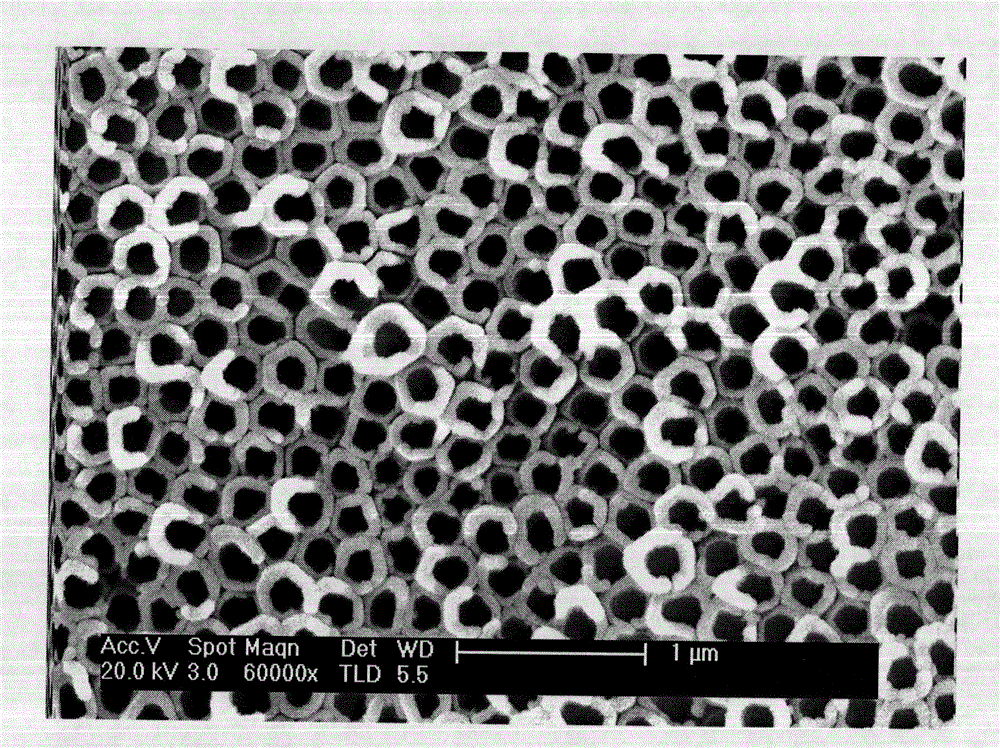

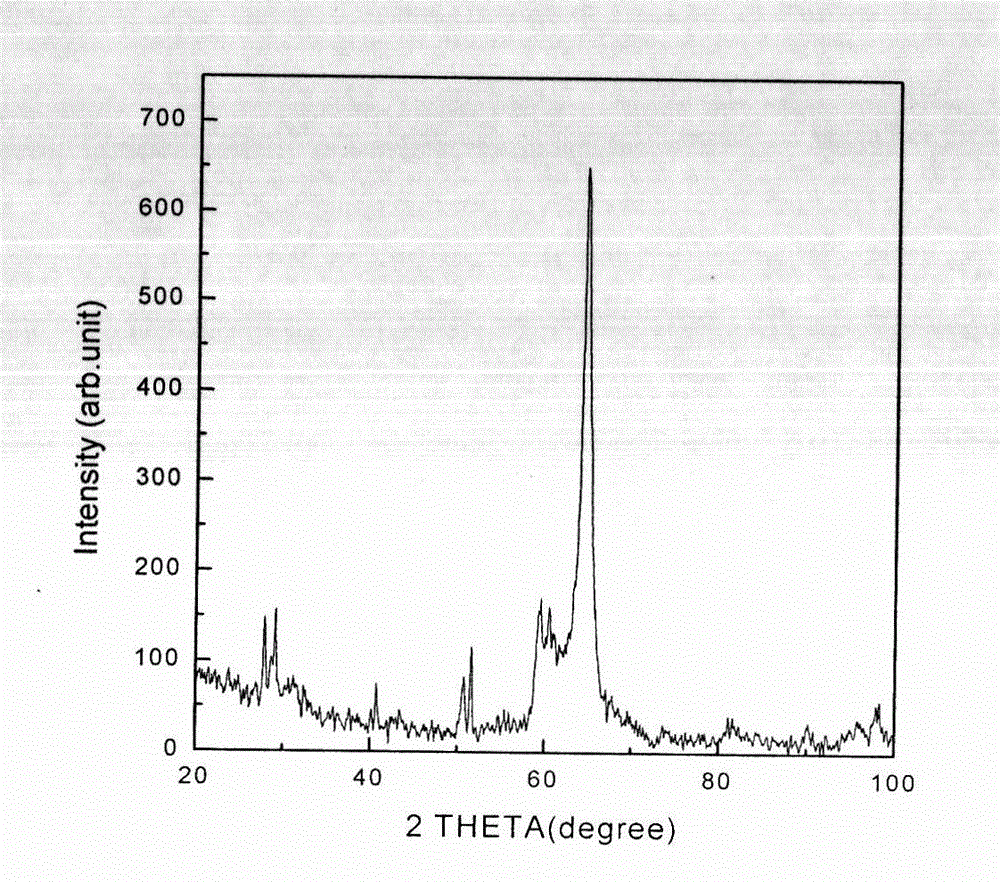

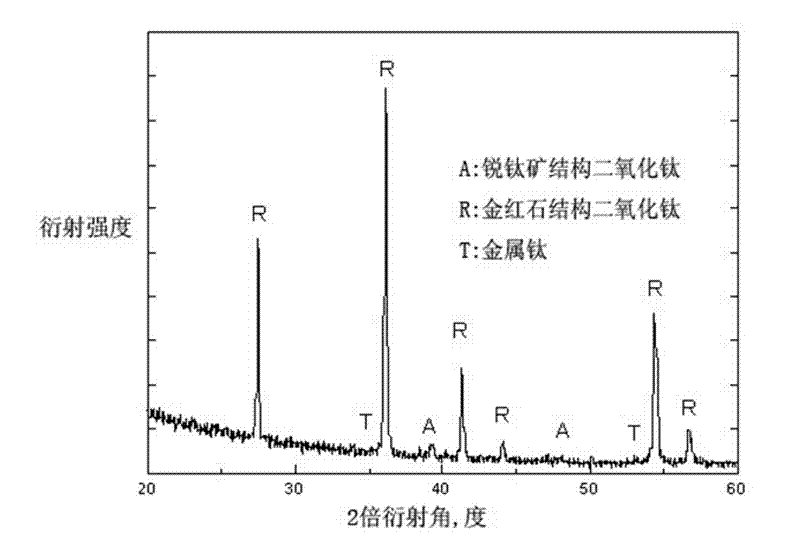

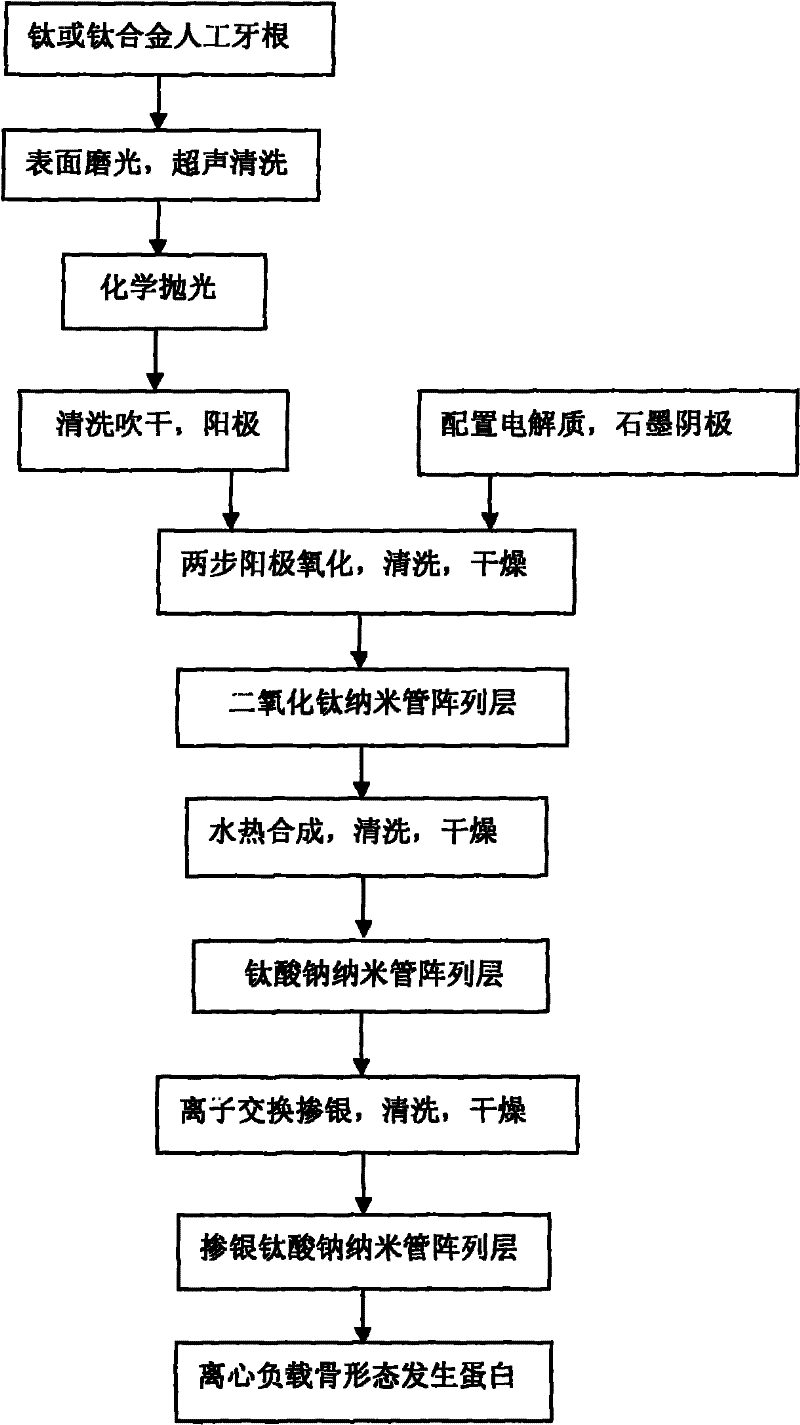

Functionalized artificial joint with selenium-loaded nanotube array surface and preparation method thereof

InactiveCN101766838AImprove immunityGood anti-inflammatory effectSurface reaction electrolytic coatingTitanium compoundsSodium titanateTwo step

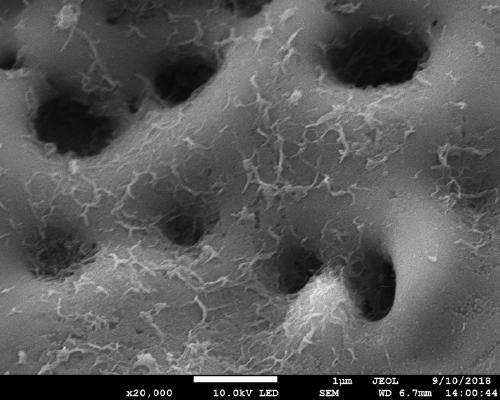

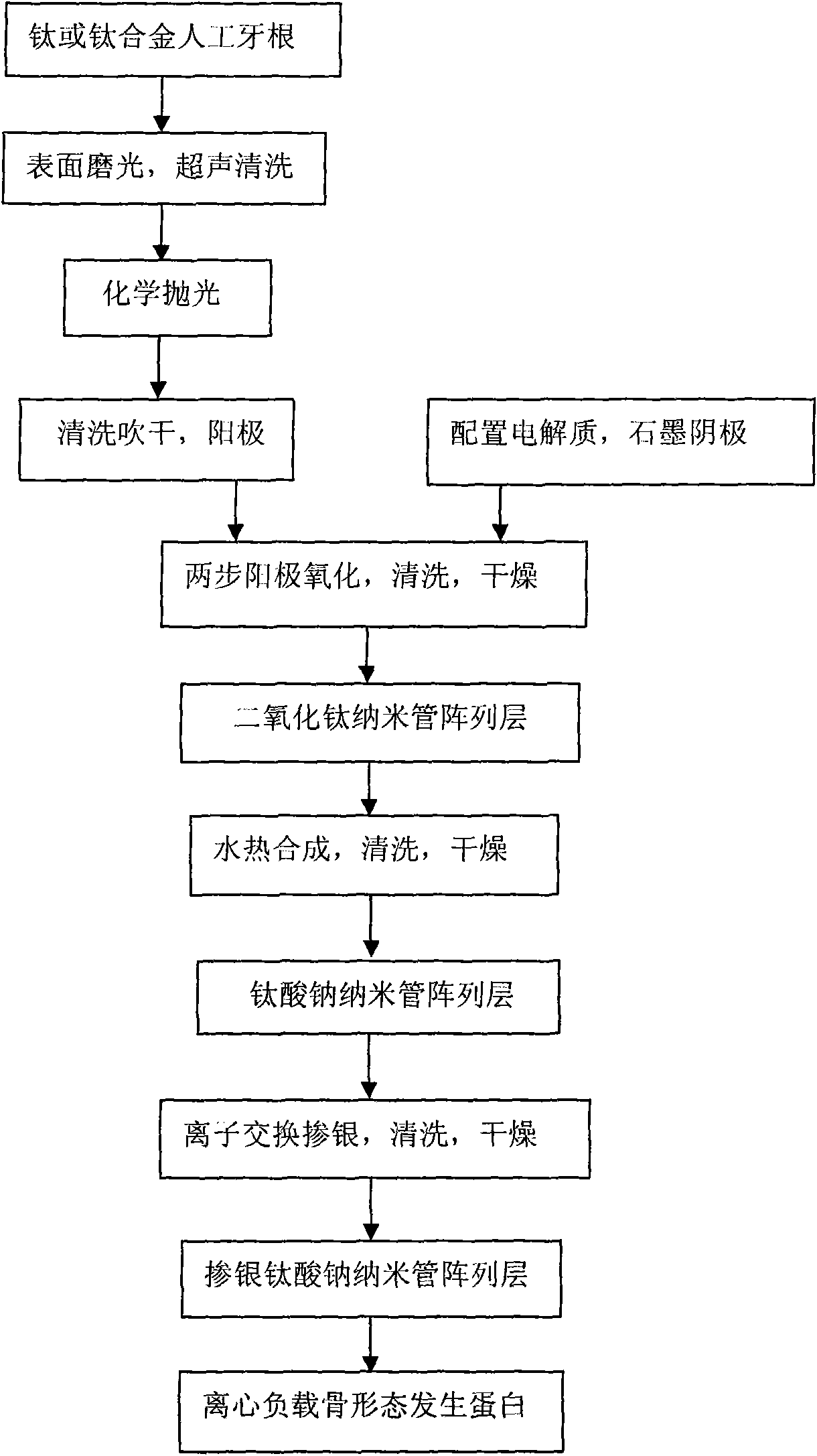

The invention relates to a functionalized artificial joint with a selenium-loaded nanotube array surface. A titanium substrate surface of the artificial joint is provided with a sodium titanate nanotube array layer, and the inside of the sodium titanate nanotube array layer is further loaded with trace sodium selenite and bone morphogenetic protein. The preparation method of the artificial joint with the functionalized selenium-loaded nanotube array surface comprises the following steps: selecting pure titanium or titanium alloy to process the artificial joint; then adopting the two-step anodizing technology to obtain a titanium dioxide nanotube array layer with a tubular structure on the surface of the pure titanium or titanium alloy artificial joint; adopting the alkaline hydrothermal synthesis technology to convert the titanium dioxide nanotube array layer into the sodium titanate nanotube array layer; and finally adopting the centrifugal load technology to load the trace sodium selenite and the bone morphogenetic protein in the sodium titanate nanotube array layer of the surface of the artificial joint.

Owner:江苏广达医材集团有限公司 +1

Nickel-titanium tubular bone internal fixator and preparation method thereof

InactiveCN101791440AGood biocompatibilityAccelerated corrosionSurgeryVacuum evaporation coatingInternal bone fixationBiocompatibility Testing

The invention relates to a nickel-titanium memory alloy tubular bone internal fixator with a Ti / ZrTi(C,N) gradient coating having good biocompatibility on the surface and a preparation method thereof. The surface of a metal matrix of the nickel-titanium memory alloy tubular bone internal fixator is provided with the Ti / ZrTi(C,N) gradient coating with good biocompatibility, wherein the Ti / ZrTi(C,N) gradient coating has a double-layer structure and consists of a Ti intermediate layer which is contacted with the surface of the nickel-titanium tubular bone internal fixator and a ZrTi(C,N) surface layer; the thickness of the Ti intermediate layer is 0.1 to 0.5 mu m; and the thickness of the ZrTi(C,N) surface layer is 1.0 to 5.0 mu m. The preparation method comprises the following steps: 1) processing the tubular bone internal fixator with a nickel-titanium memory alloy; and 2) performing surface pretreatment on the nickel-titanium memory alloy tubular bone internal fixator, and performing two-step magnetron sputtering treatment to obtain the Ti / ZrTi(C,N) gradient coating consisting of the Ti intermediate layer and the ZrTi(C,N) surface layer in sequence on the surface of the tubular bone internal fixator.

Owner:SOUTHEAST UNIV

G-C3N4/ TiO2 coating with light-control and antibacterial functions and preparation method thereof

ActiveCN110327487AGood biological activityHigh bonding strengthTissue regenerationCoatingsHydrothermal synthesisAntibacterial coating

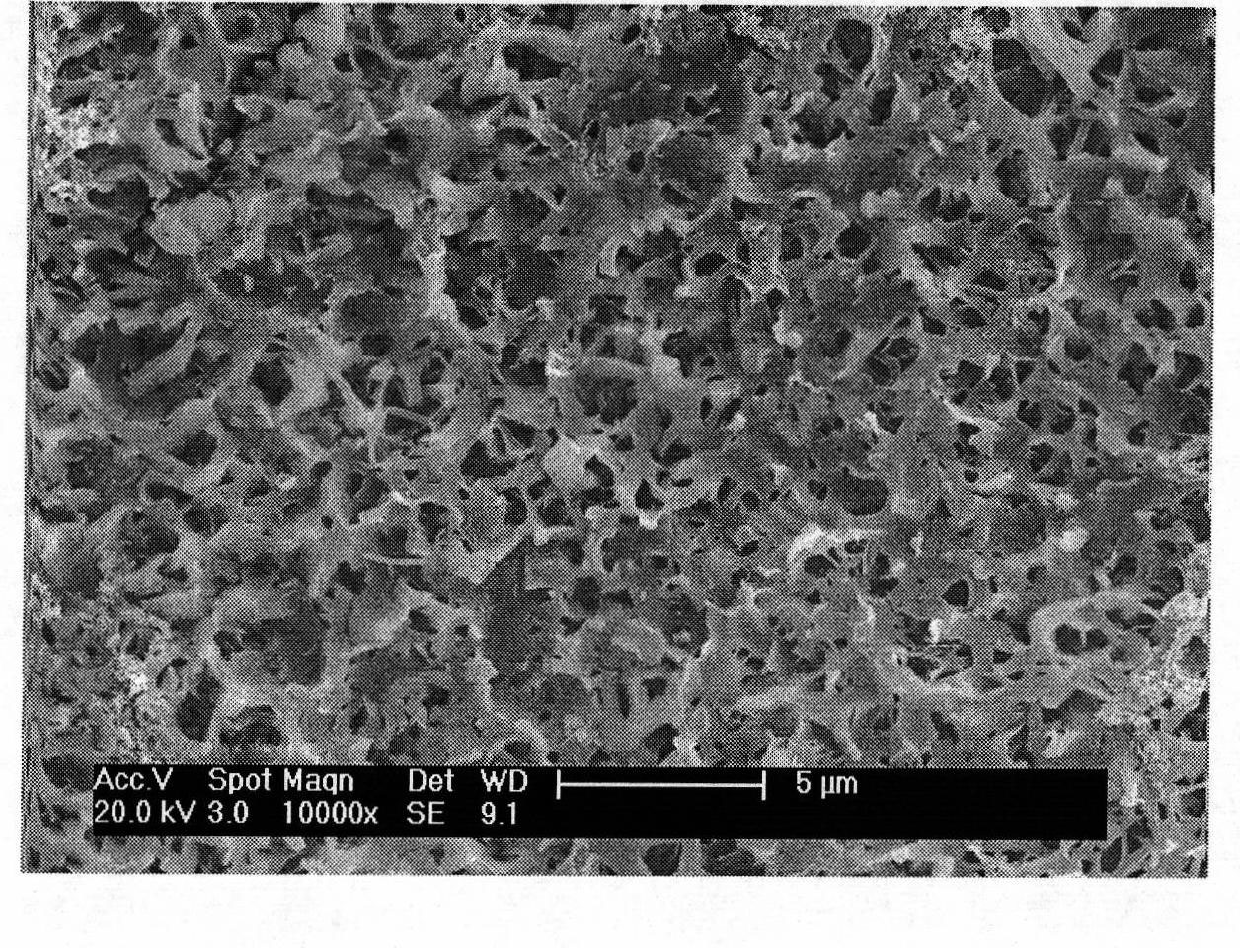

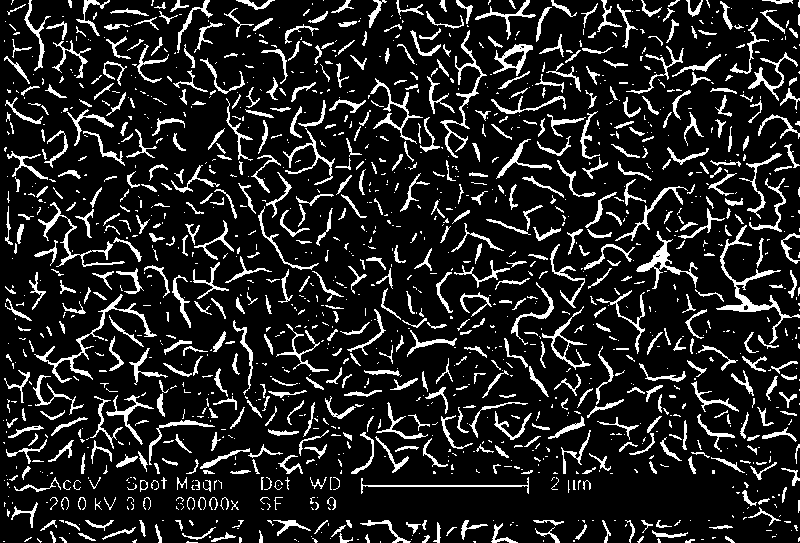

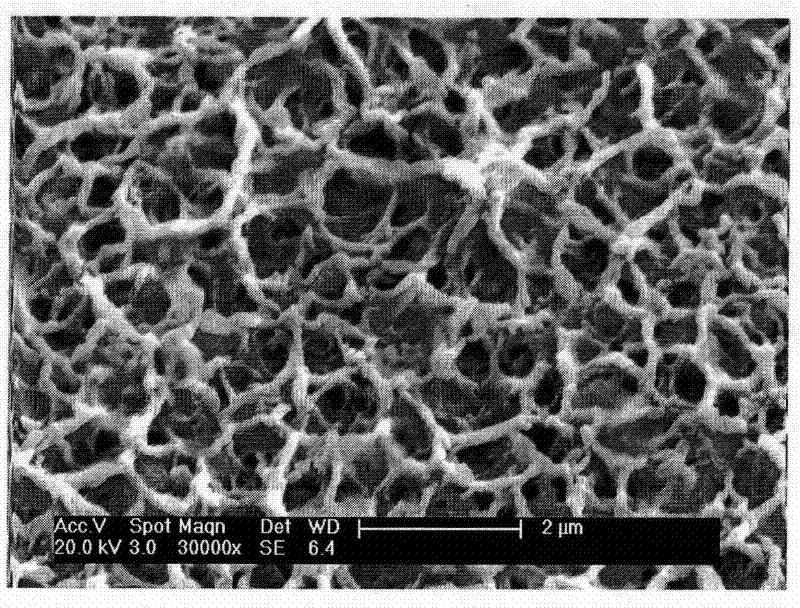

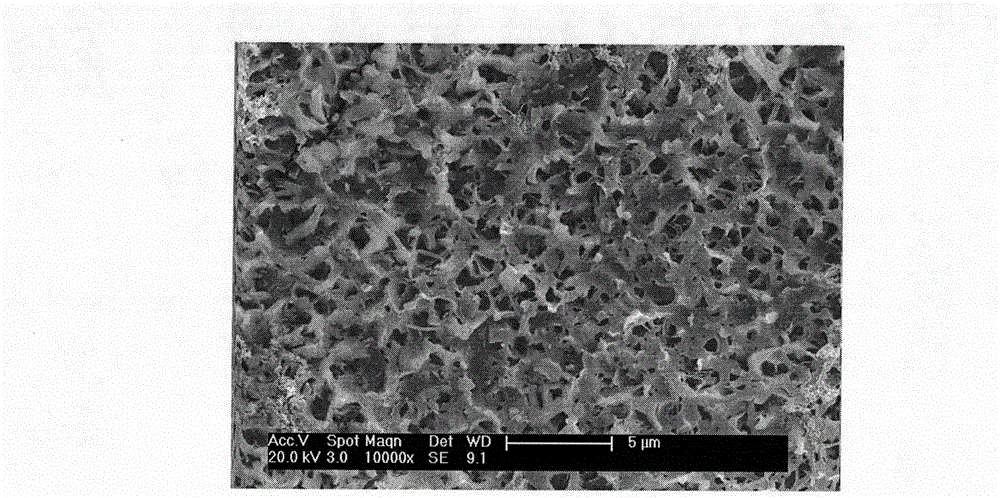

The present invention relates to a g-C3N4 / TiO2 coating with light-control and antibacterial functions and a preparation method thereof. The light-control antibacterial coating consists of TiO2 with athree-dimensional network structure and graphite-like phase carbon nitride (g-C3N4) deposited on the surface of the TiO2. The g-C3N4 / TiO2 coating with a three-dimensional network structure is combined with the surface of a titanium or titanium alloy substrate, rod-shaped nano-array sodium titanate is constructed on the surface of the substrate by a hydrothermal synthesis method, the nano-array sodium titanate is converted into titanium dioxide by a chemical vapor deposition technology, and the g-C3N4 is deposited at the same time. The preparation method comprises the following steps of: firstly, acquiring a rod-shaped nano-array sodium titanate biological coating on the surface of the substrate by adopting a hydrothermal synthesis method; and then converting the coating into titanium dioxide by using a high-temperature annealing technology, taking melamine as a raw material, and depositing g-C3N4 on the surface of the titanium dioxide through a chemical vapor deposition technology soas to finally obtain the g-C3N4 / TiO2 coating with the light-control and antibacterial functions.

Owner:SOUTHWEST UNIVERSITY

Nickel-titanium memory patella claw and preparation method thereof

InactiveCN101791441AGood biocompatibilityAccelerated corrosionSurgeryVacuum evaporation coatingSputteringSurface layer

The invention relates to a nickel-titanium memory patella claw with a Ti / ZrTi(C,N) gradient coating on the surface through magnetron sputtering, in particular to a nickel-titanium memory patella claw with a Ti / ZrTi(C,N) gradient coating having good biocompatibility on the surface and a preparation method thereof. The surface of a metal matrix of the nickel-titanium memory patella claw is provided with the Ti / ZrTi(C,N) gradient coating with good biocompatibility, wherein the Ti / ZrTi(C,N) gradient coating has a double-layer structure and consists of a Ti intermediate layer which is contacted with the surface of the nickel-titanium memory patella claw and a ZrTi(C,N) surface layer; the thickness of the Ti intermediate layer is 0.1 to 0.5 mu m; and the thickness of the ZrTi(C,N) surface layer is 1.0 to 5.0 mu m. The preparation method comprises the following steps: 1) processing the patella claw with a nickel-titanium memory alloy; and 2) performing surface treatment on the nickel-titanium memory patella claw, and performing two-step magnetron sputtering treatment to obtain the Ti / ZrTi(C,N) gradient coating consisting of the Ti intermediate layer and the ZrTi(C,N) surface layer in sequence on the surface of the patella claw.

Owner:SOUTHEAST UNIV

Artificial joint having slow-release function of rare earth element cerium and preparation method thereof

ActiveCN101766841AGrowth inhibitionImprove biological activityTitanium compoundsCoatingsRare-earth elementIon exchange

The invention discloses an artificial joint having a slow-release function of a rare earth element cerium and a preparation method thereof. The artificial joint consists of a pure titanium or titanium alloy artificial joint matrix and a microporous sodium titanate biological activity layer loaded with the rare earth element cerium and bone morphogenetic protein (BMP). The sodium titanate biological activity layer with a microporous structure is combined with the surface of a metal matrix and is formed by alternately stacking sodium titanate microporous structures generated by a hydrothermal reaction performed between the surface of the titanium or the titanium alloy matrix and solution of sodium hydroxide, the cerium and sodium perform cation interchange and are doped into a coating, and the BMP is compounded into the microporous structure through centrifugal force and under the action of a capillary tube. The preparation method comprises the following steps of: firstly, selecting the pure titanium or the titanium alloy to process the artificial joint well; secondly, forming a sodium titanate layer with the microporous structure on the surface of the artificial joint by adopting an alkali liquor hydrothermal synthesis technique; thirdly, doping the rare earth element cerium into the microporous sodium titanate layer through solution impregnation ion exchange; and finally, loading the bone morphogenetic protein into the cerium-doped microporous sodium titanate layer by adopting a centrifugal load technique.

Owner:NANTONG MINGXIN CHEM +1

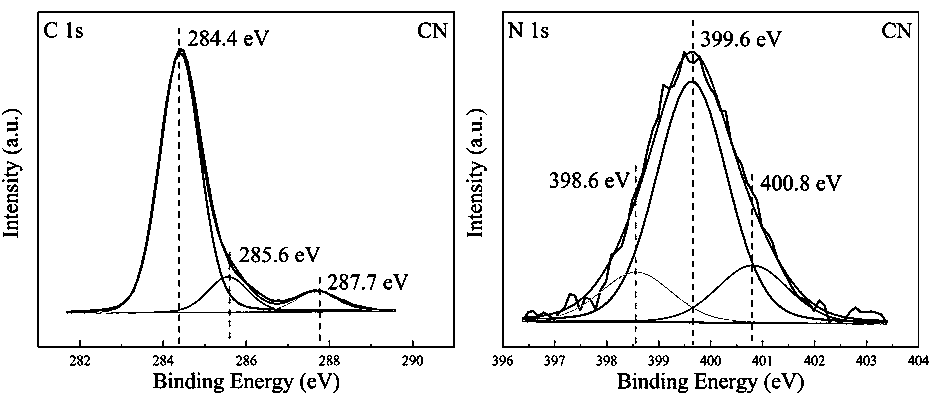

Degradable magnesium alloy bone nail with squamous bionic bone nanostructure coating and preparation method

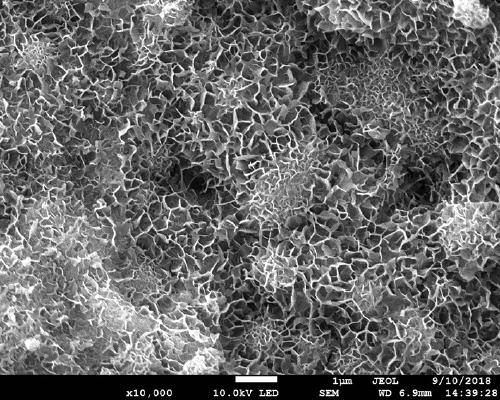

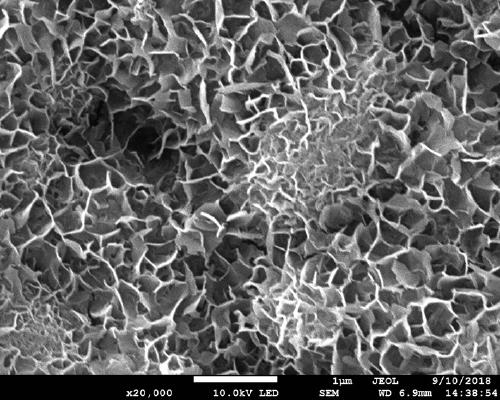

ActiveCN109432514AImprove biological activityImprove antibacterialAnodisationSurgeryOxide ceramicMicro arc oxidation

The invention discloses a degradable magnesium alloy bone nail with a squamous bionic bone nanostructure coating and a preparation method thereof. The degradable bone nail consists of an AZ31B magnesium alloy bone nail matrix and a magnesium oxide bioceramic coating with a squamous bionic bone nanostructure loaded with PLGA-bone morphogenetic protein BMP. The magnesium oxide bioceramic coating with the squamous bionic bone nanostructure is combined with the surface of a metal matrix and the nano-sized squamous nanostructure is constructed on the surface of the matrix by using a micro-arc oxidation technology. The BMP is filled and loaded between magnesium oxide squamous bionic bone nanostructured laminates through centrifugal force and capillary action. The preparation method comprises thefollowing steps: firstly, selecting an AZ31B magnesium alloy and processing into the bone nail; then preparing the magnesium oxide ceramic coating with squamous bionic bone nanostructure characteristics on the surface of the matrix by adopting the micro-arc oxidation technology; finally, loading the PLGA-bone morphogenetic protein between the magnesium oxide squamous bionic bone nanostructured laminates by adopting a centrifugal load technology.

Owner:SOUTHWEST UNIVERSITY

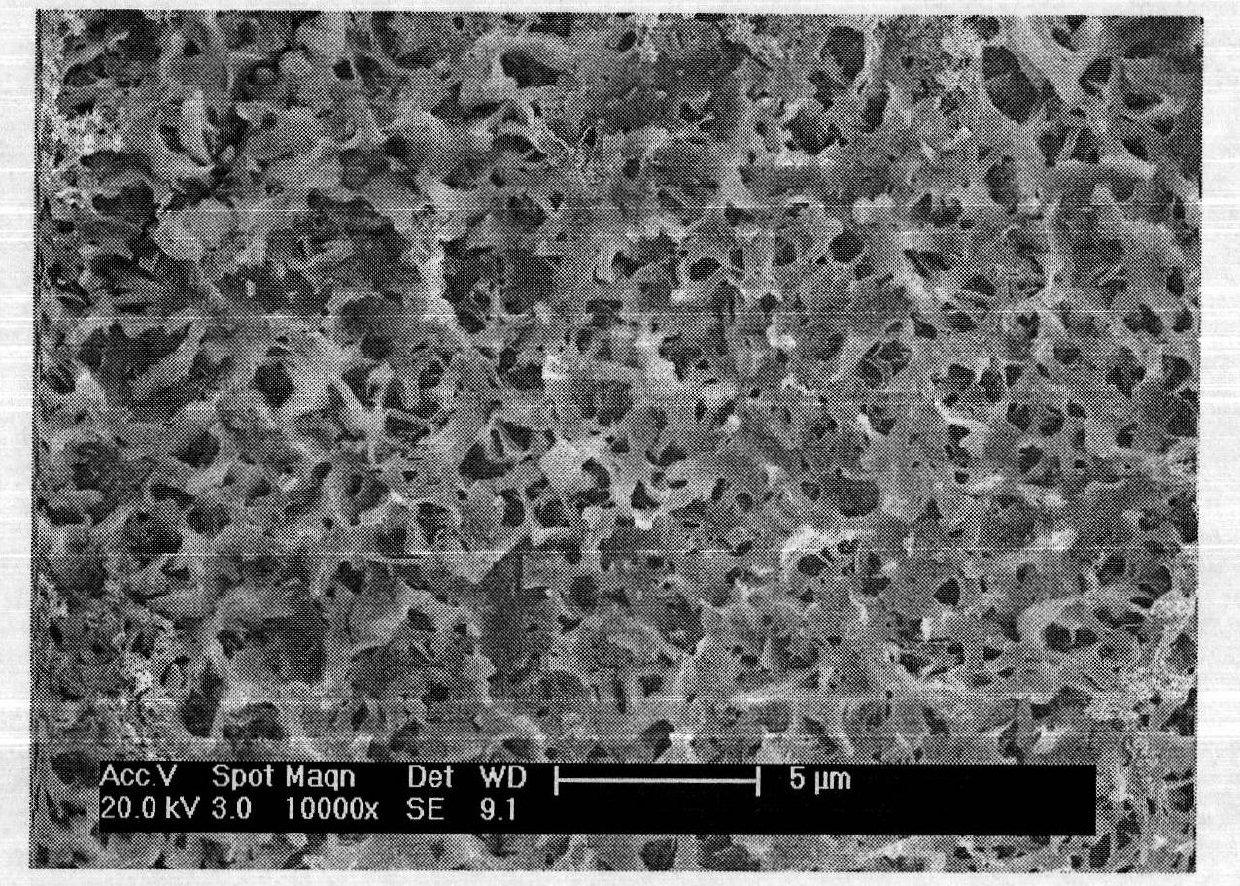

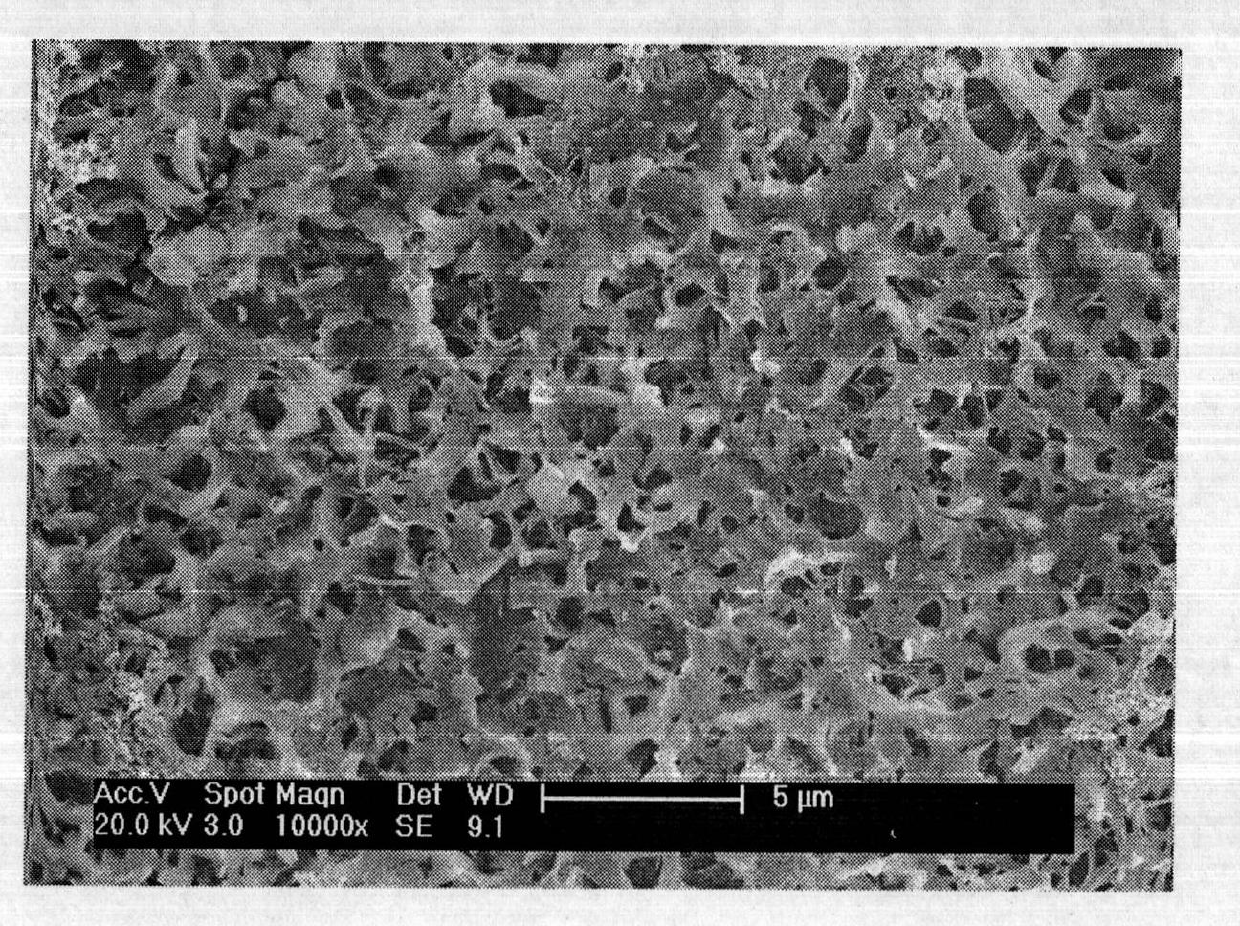

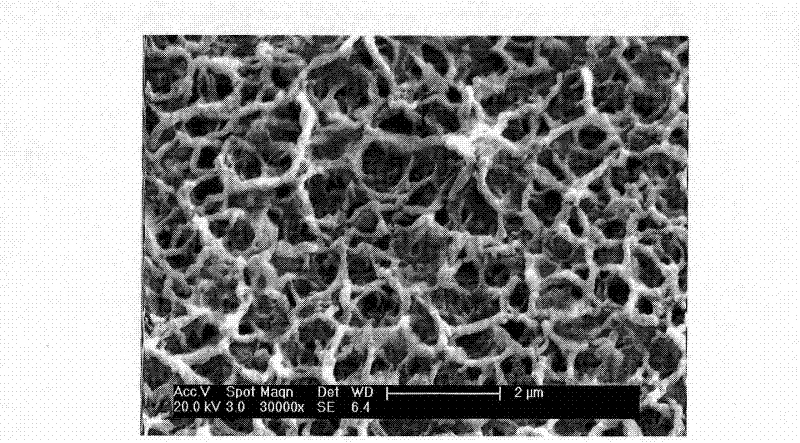

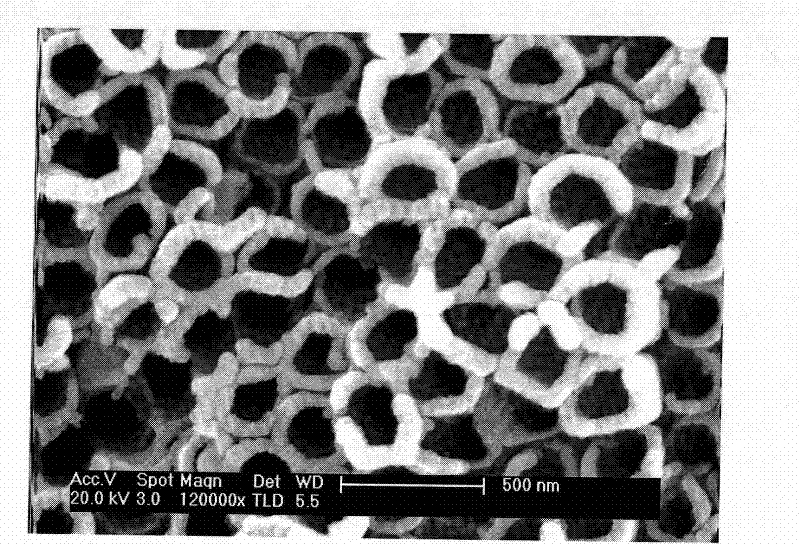

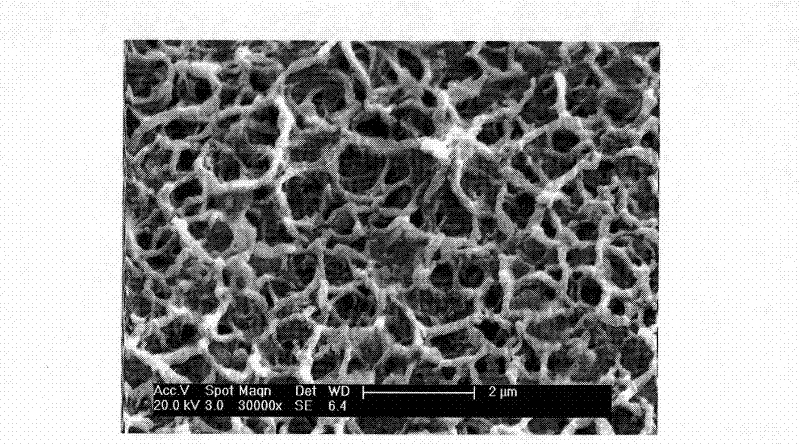

Cancellous bone structure simulating artificial bone having ultra-low elasticity modulus and preparation method of artificial bone

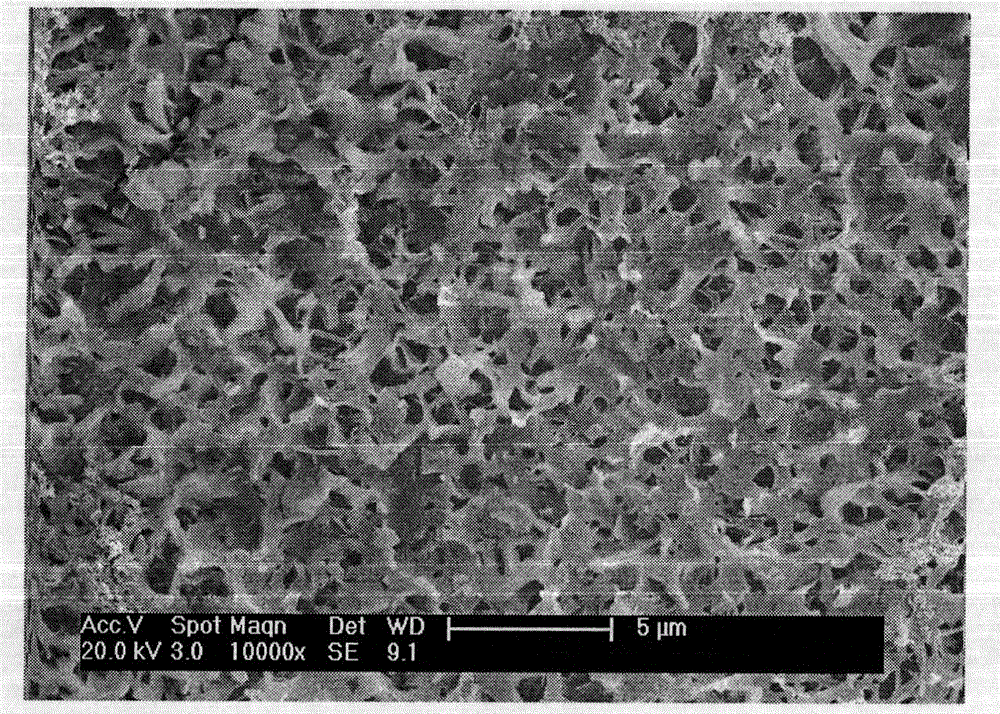

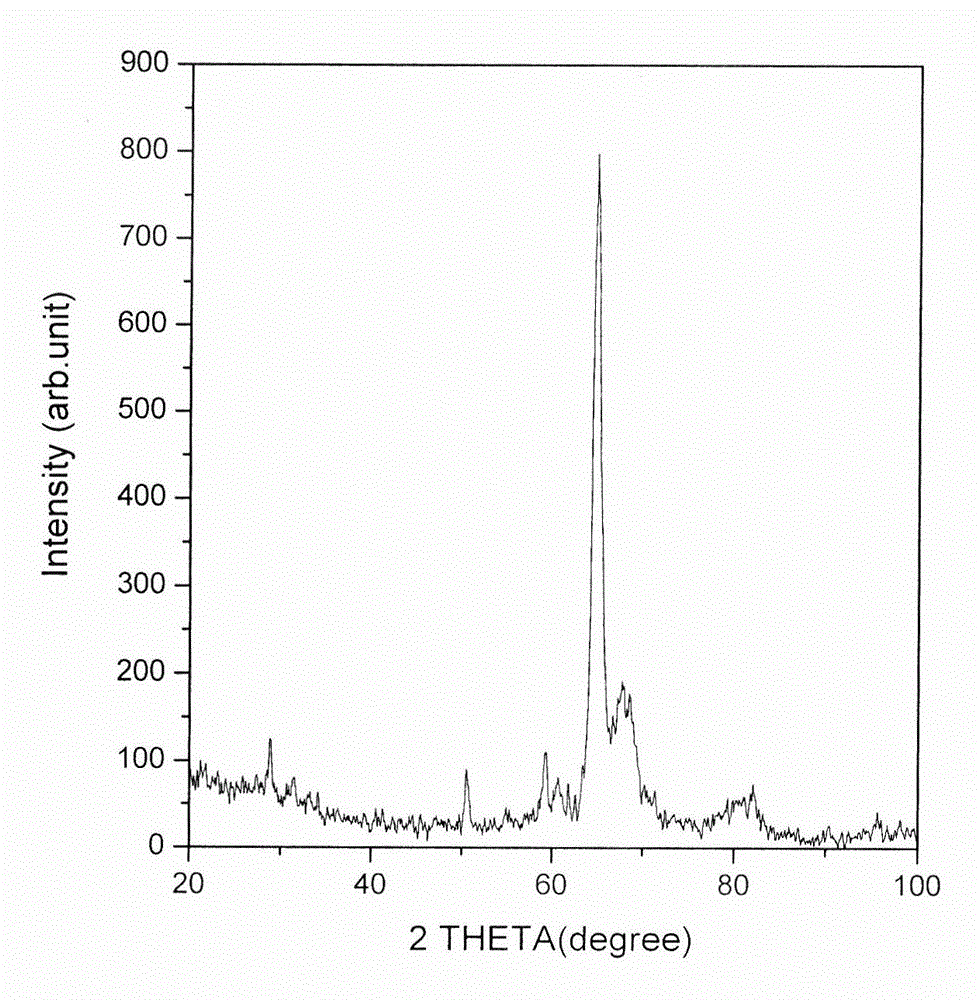

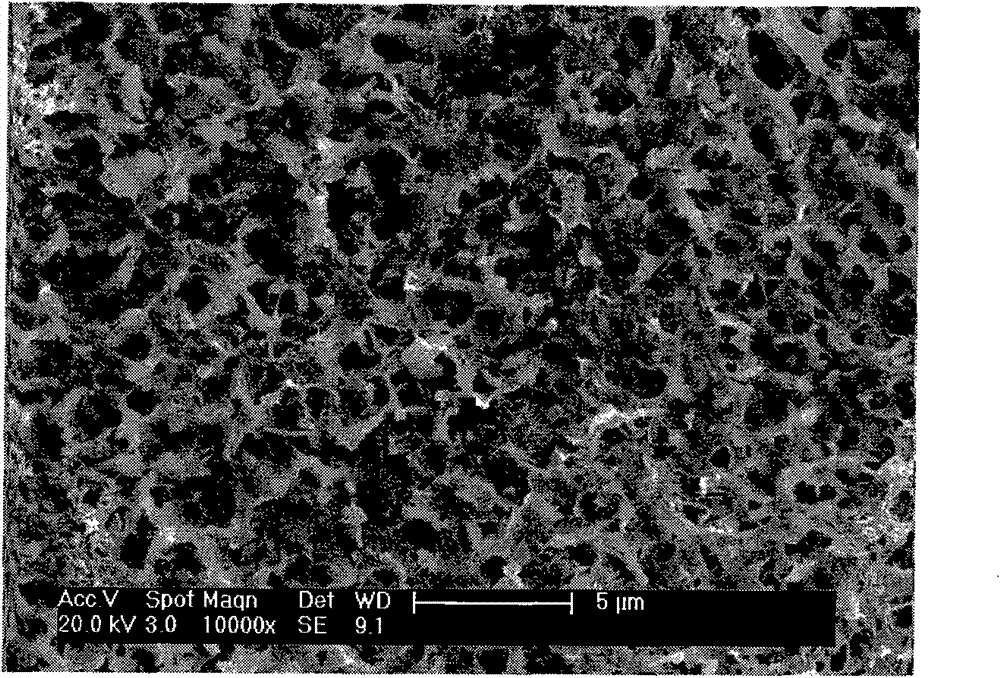

InactiveCN107899070AImprove surface bioactivityImprove biological activityPharmaceutical delivery mechanismTissue regenerationSterile environmentNano structuring

The invention relates to a cancellous bone structure simulating artificial bone having ultra-low elasticity modulus and a preparation method of the artificial bone. The artificial bone is composed of[beta]-phase and [alpha]-phase titanium alloys and a hydroxyapatite-combined sodium titanate surface layer having a porous network nano-structure. The sodium titanate surface layer having the porous network nano-structure is combined with a metal surface and a porous network surface is generated through a hydrothermal reaction between a titanium or titanium alloy surface and a sodium hydroxide solution. The combination of hydroxyapatite is achieved by soaking in simulated body fluid. The preparation method comprises the following steps: firstly, processing compact titanium alloy artificial bone from polymer foams, titanium and other metals; then, synthesizing a sodium titanate layer having the porous network structure by virtue of an alkaline liquid hydrothermal method; soaking the obtained artificial bone in the simulated body fluid; and finally, drip washing the artificial bone by alcohol and de-ionized water, drying and disinfecting the artificial bone, and preserving the artificialbone in an sterile environment for later use.

Owner:SOUTHWEST UNIV

Trace element selenium slow-release type artificial tooth root based on nanometer tube array surface

InactiveCN101766542AImprove immunityGood anti-inflammatory effectImpression capsDentistry preparationsSodium titanateTitanium alloy

The invention relates to a trace element selenium slow-release type artificial tooth root based on a nanometer tube array surface. A layer of sodium titanate nanometer tube array layer is formed on the surface of a metallic titanium base body of the artificial tooth root, and a trace amount of sodium selenite and bone morphogenetic protein are loaded in the sodium titanate nanometer tube array layer. A preparation method of the trace element selenium slow-release type artificial tooth root based on the nanometer tube array surface comprises the following steps: adopting pure titanium or titanium alloy for processing the artificial tooth root; then, adopting the two-step anodic oxidation technology for obtaining a titanium dioxide nanometer tube array layer with the tubular structure on the surface of the pure titanium or titanium alloy artificial tooth root; next, converting the titanium dioxide nanometer tube array layer into the sodium titanate nanometer tube array layer through an alkaline solution hydrothermal synthesis technology; and finally, loading a trace amount of sodium selenite and bone morphogenetic protein into the sodium titanate nanometer tube array layer on the surface of the artificial tooth root by a centrifugal load technology.

Owner:江苏广达医材集团有限公司 +1

Silver-loaded antibacterial artificial joint and preparation method thereof

InactiveCN101766839BBroad-spectrum antibacterialImprove sterilization efficiencyTitanium compoundsCoatingsSodium titanateTitanium alloy

The invention relates to a silver-loaded antibacterial artificial joint and a preparation method thereof. The silver-loaded antibacterial artificial joint consists of a pure titanium or titanium alloy artificial joint substrate and a micropore sodium titanate bioactivity layer loaded with microelement silver and bone morphogenetic protein (BMP). The sodium titanate bioactivity layer with a micropore structure is combined with the metal substrate surface and is formed by mutually alternately stacking the sodium titanate micropore sodium structures generated by the hydro-thermal reaction between the titanium or titanium alloy substrate surface and sodium hydroxide solution. The silver element and sodium carry out cation exchange to dope into a coating. The BMP is compounded in the microporestructures under the action of the centrifugal force and the capillary. The preparation method comprises the following steps: firstly selecting pure titanium or titanium alloy to process the artificial joint; then adopting the alkaline hydrothermal synthesis technology obtain a sodium titanate layer with the micropore structures on the surface of the titanium artificial joint; doping trace silverin the micropore sodium titanate layer by solution impregnation iron exchange; and finally adopting the centrifugal load technology to load the bone morphogenetic protein in the silver-doped micropore sodium titanate layer.

Owner:江苏广达医材集团有限公司 +1

Functionalized artificial joint with selenium-loaded nanotube array surface and preparation method thereof

InactiveCN101766838BImprove immunityGood anti-inflammatory effectSurface reaction electrolytic coatingTitanium compoundsSodium titanateTitanium alloy

The invention relates to a functionalized artificial joint with a selenium-loaded nanotube array surface. A titanium substrate surface of the artificial joint is provided with a sodium titanate nanotube array layer, and the inside of the sodium titanate nanotube array layer is further loaded with trace sodium selenite and bone morphogenetic protein. The preparation method of the artificial joint with the functionalized selenium-loaded nanotube array surface comprises the following steps: selecting pure titanium or titanium alloy to process the artificial joint; then adopting the two-step anodizing technology to obtain a titanium dioxide nanotube array layer with a tubular structure on the surface of the pure titanium or titanium alloy artificial joint; adopting the alkaline hydrothermal synthesis technology to convert the titanium dioxide nanotube array layer into the sodium titanate nanotube array layer; and finally adopting the centrifugal load technology to load the trace sodium selenite and the bone morphogenetic protein in the sodium titanate nanotube array layer of the surface of the artificial joint.

Owner:江苏广达医材集团有限公司 +1

Artificial tooth root or joint material and microarc oxidation preparation method thereof

InactiveCN102090982BImprove surface antibacterial abilityImprove biological activityImpression capsSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

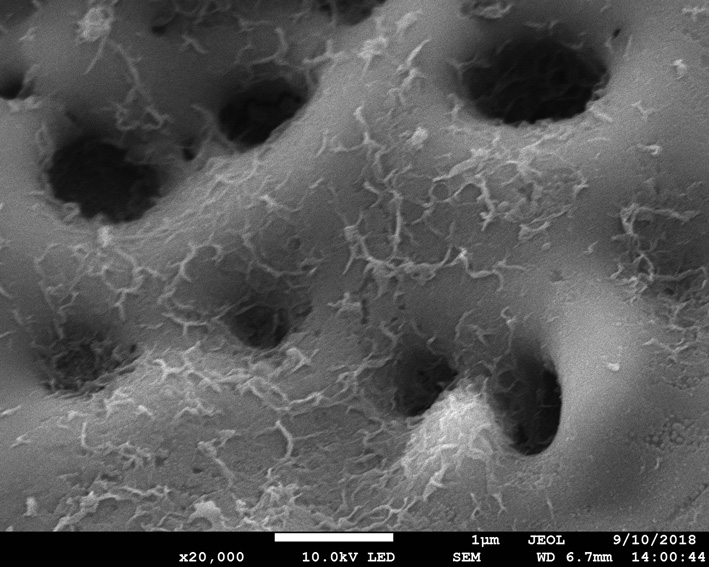

The invention discloses an artificial tooth root or joint material capable of releasing zinc and cerium trace elements and having a nano / micron porous surface structure and a microarc oxidation preparation method thereof. The artificial tooth root or joint is prepared from a pure titanium or titanium alloy matrix and a porous titanium dioxide bioactive surface layer, wherein the porous titanium dioxide bioactive surface layer is obtained on the surface of the pure titanium or titanium alloy matrix by using a microarc oxidization technology and doped with the trace zinc and cerium elements, the pore diameter of the porous titanium dioxide bioactive surface layer is changed between 50nm and 500nm, thus the surface bacteriostatic capacity, the bioactivity and the cell regulation and control capacity of the initial implanted surface can be improved remarkably, and multiple beneficial functions are obtained. The preparation method comprises the steps of: firstly processing the artificial tooth root (joint) by selecting pure titanium or titanium alloy; then obtaining the titanium dioxide bioactive surface layer with the nano-micro porous structure on the surface of the artificial tooth root (joint) by adopting a microarc oxidization technology; meanwhile adding zinc and cerium soluble salts to electrolyte and carrying out synchronous doping by utilizing a microarc oxidization process.

Owner:SOUTHEAST UNIV

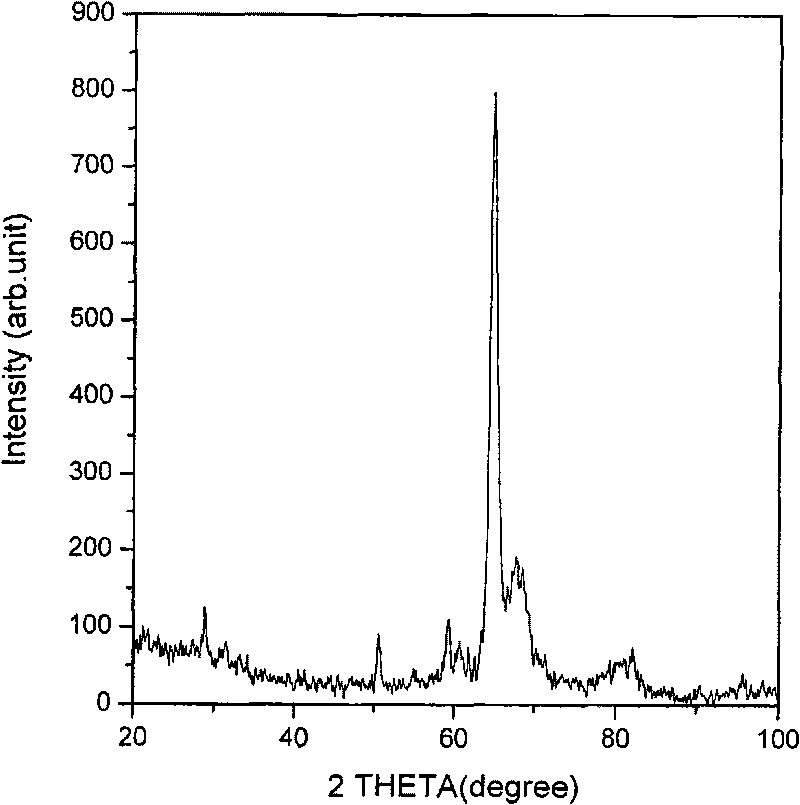

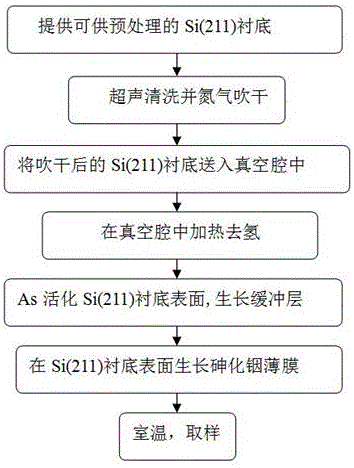

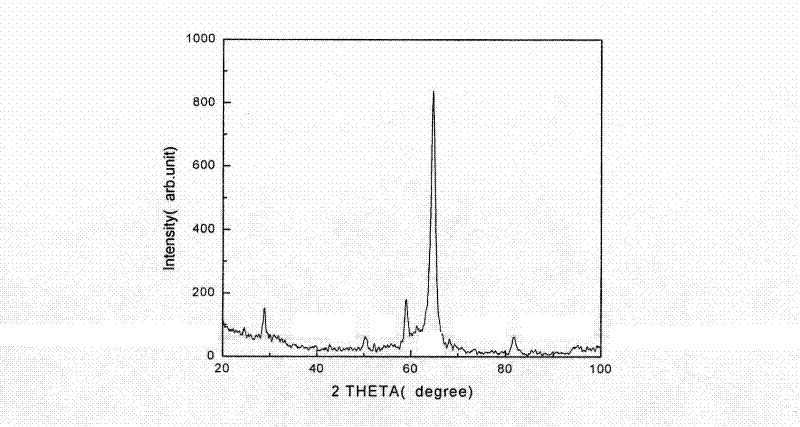

Preparation method and device of indium arsenide thin film material

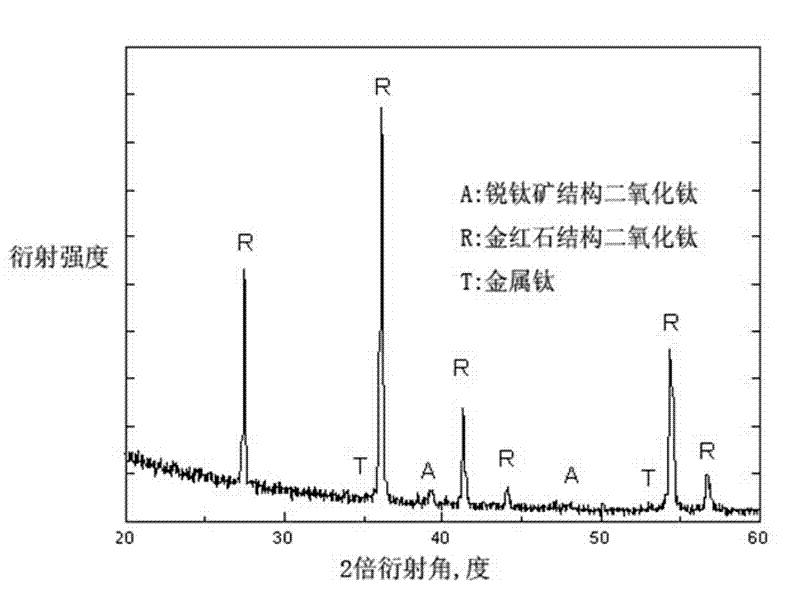

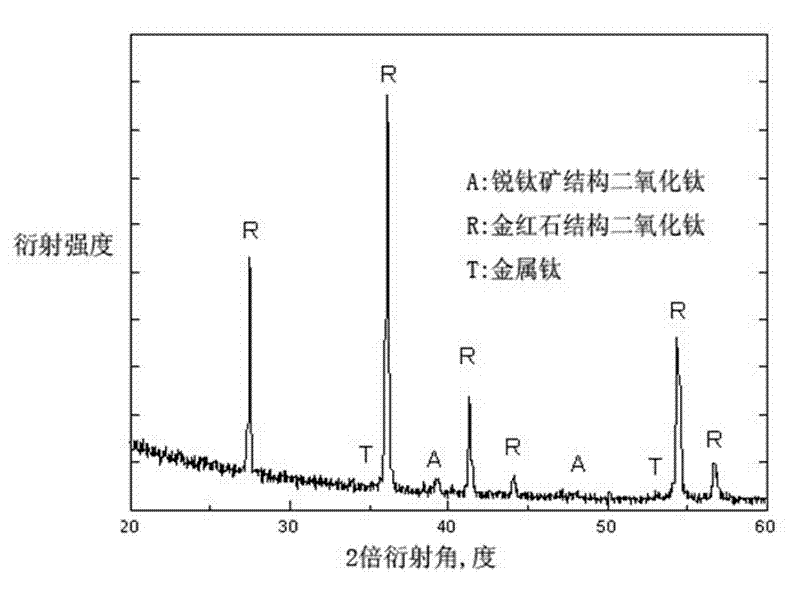

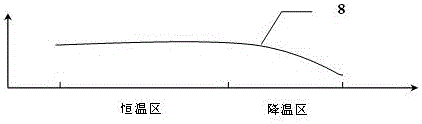

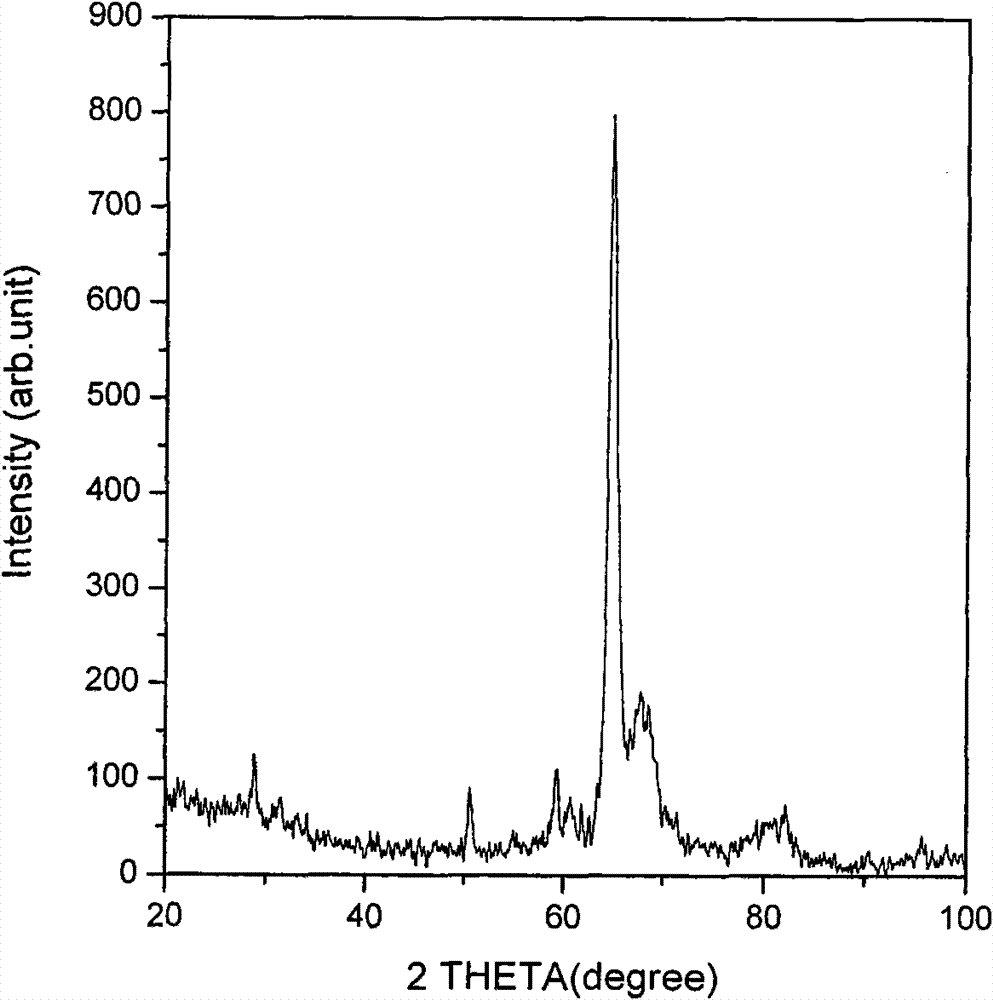

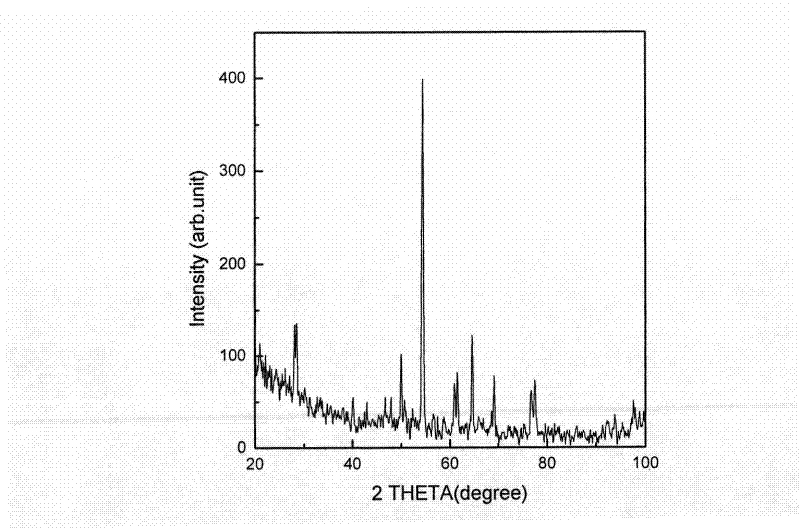

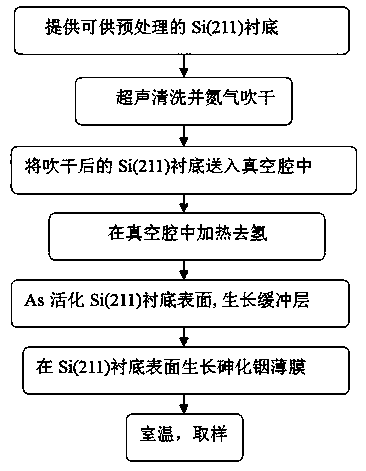

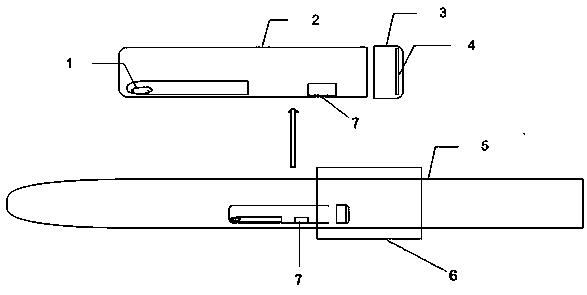

ActiveCN106783549AWon't fall offPromotes deposition growthSemiconductor/solid-state device manufacturingIndium arsenideDehydrogenation

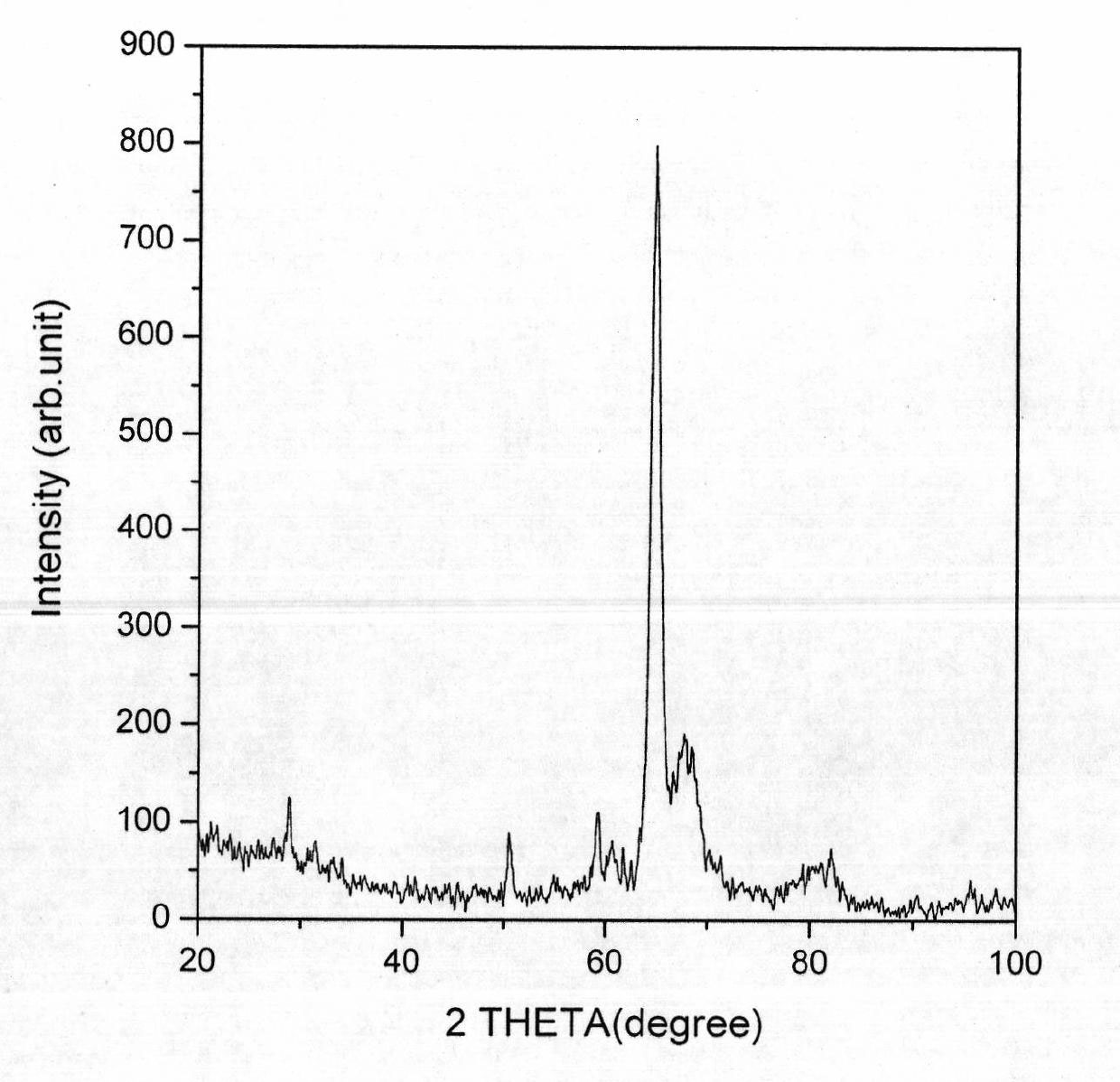

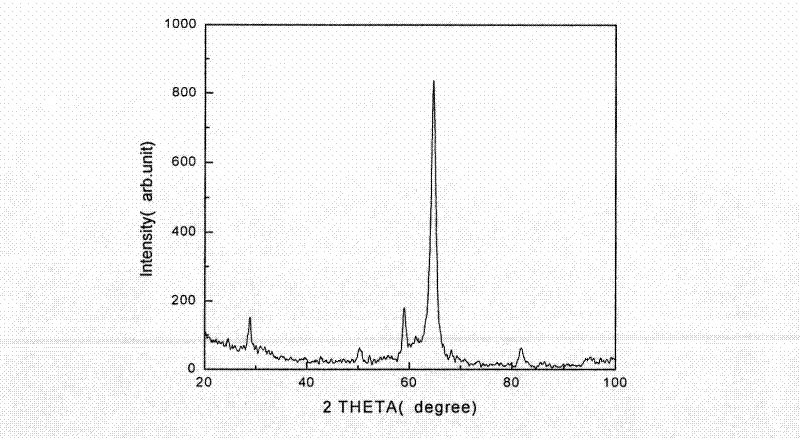

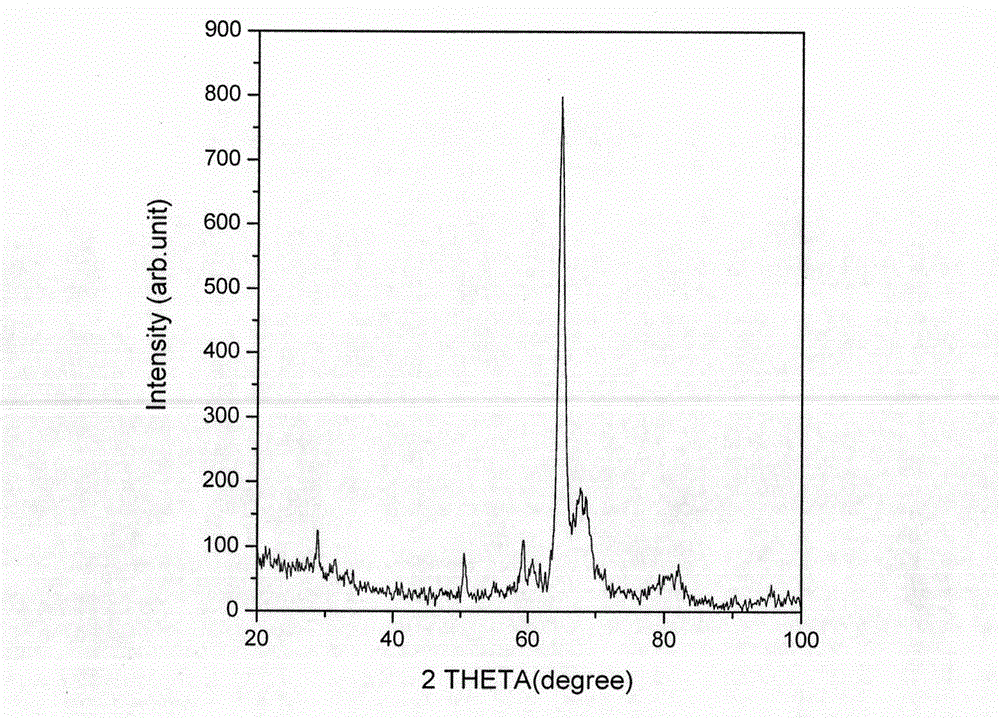

The invention discloses a preparation method and device of an indium arsenide thin film material and belongs to the technical field of semiconductor manufacturing. The method comprises the steps of ultrasonically cleaning a single-side polished mono-crystalline Si substrate and drying, and then feeding the dried mono-crystalline Si substrate into a vacuum chamber for heating and dehydrogenation; heating an arsenic simple substance for volatilization, and driving As air to flow through the surface of the mono-crystalline Si substrate to form an Si-As bond; activating the surface of the mono-crystalline Si substrate, and then growing a buffer layer at a low temperature; growing an indium arsenide thin film on the surface of the mono-crystalline Si substrate; and carrying out furnace cooling to a room temperature, thereby obtaining the indium arsenide thin film material. The method is low in demands on instrument and equipment, low in cost, easy to operate and relatively good in repeatability; and the obtained indium arsenide thin film is uniform and smooth in appearance and surface, preferential growth along (111) orientation is achieved, the thickness is 4.83 microns and the crystal quality is good.

Owner:KUNMING UNIV OF SCI & TECH

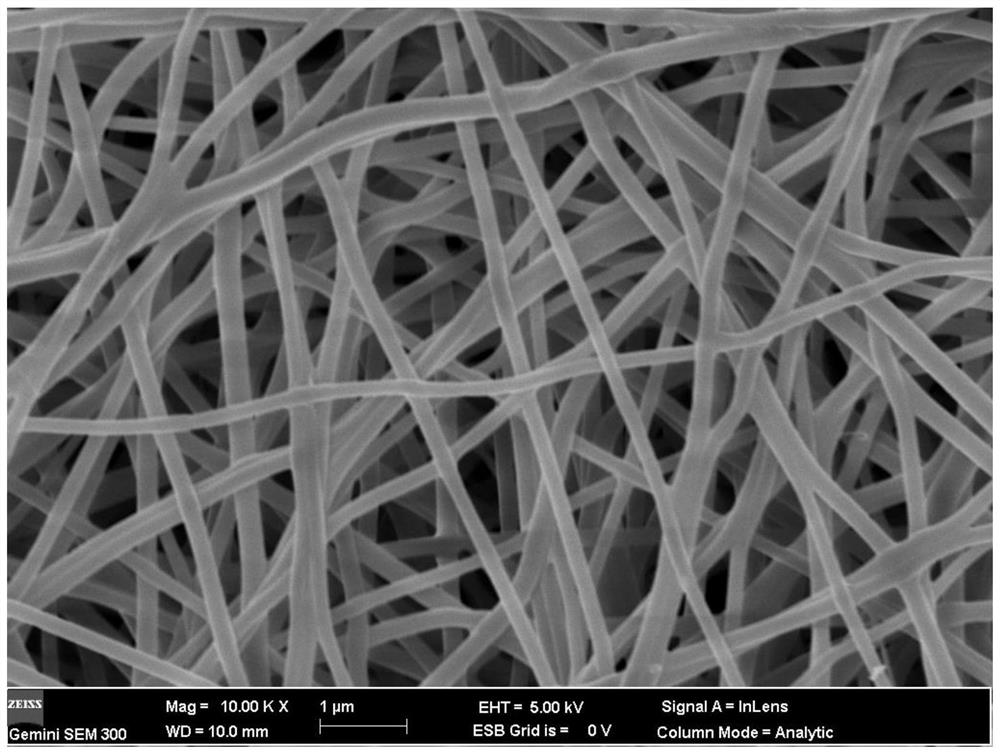

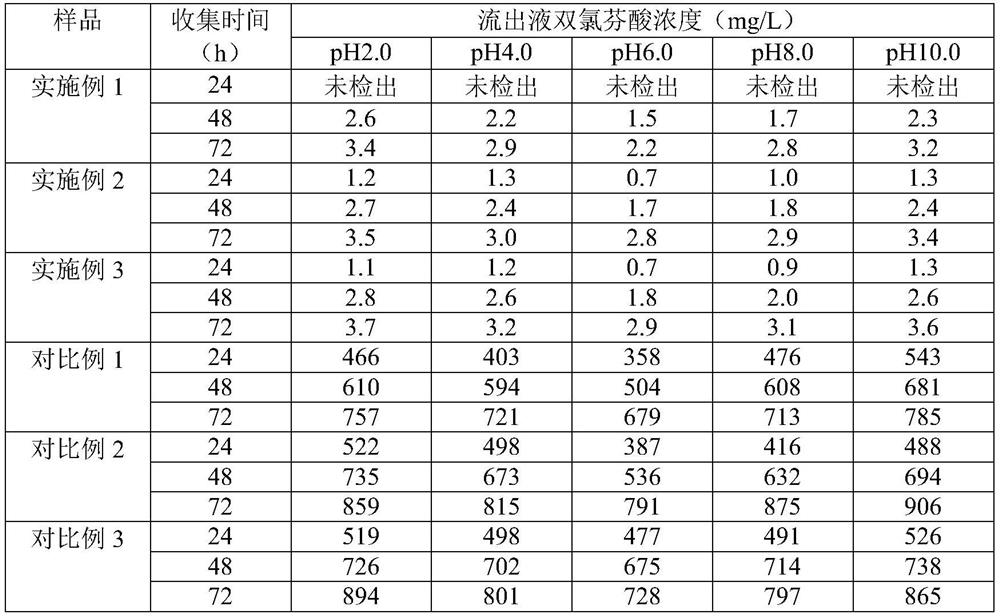

Photocatalytic diclofenac purification membrane and preparation method thereof

ActiveCN113134393APromote excitationIntense visible light-induced redox abilityWater/sewage treatment by irradiationWater treatment compoundsEngineeringMelt electrospinning

The invention belongs to the technical field of sewage treatment, and discloses a photocatalytic diclofenac purification membrane and a preparation method thereof. The preparation method comprises the following steps: preparing a high-elastic polyurethane-doped nanofiber membrane by utilizing melt electrospinning, and depositing a metal-organic framework material MOFs-YVZr on the outer surface to obtain the photodegradation catalytic membrane. The film can efficiently catalyze the degradation of diclofenac in water under the irradiation of visible light, and is suitable for environments with different pH values.

Owner:NANTONG UNIVERSITY

Artificial joint with micro-nano graded topological surface structure and preparation method of artificial joint

ActiveCN102732882BBiological activity hasCapable of regulating cellsElectrolytic inorganic material coatingSurface reaction electrolytic coatingMicro nanoPlasma electrolytic oxidation

The invention provides an artificial joint with a micro-nano graded topological surface structure and a preparation method of the artificial joint. The artificial joint is formed by compounding a titanium alloy substrate, a micro-porous titanium dioxide surface layer prepared by a micro-arc oxidization method, and a zinc oxide nano rod or a nano taper deposited and grown on the hole wall of the surface, namely the micro-porous titanium dioxide biological activity surface layer is obtained on the surface of an artificial joint titanium substrate through the micro-arc oxidization method; and furthermore, electric depositing parameters are adjusted and a zinc oxide nano rod / taper is deposited and prepared on the titanium dioxide biological activity surface layer, so as to form the artificial joint with the micro-nano graded topological surface structure. The artificial joint can utilize abundant titanium dioxide micron hole structures on the surface and a zinc oxide nano topological structure deposited and grown in the hole wall to enhance the biological effects of adhesion, growth, multiplication and the like of surface osteoblast, and realize the slow release of the element zinc; and therefore, the antibacterial capability, the biological activity, the biocompatibility and the cell regulating and controlling capability of the surface at an implantation initial stage are greatly improved.

Owner:苏州晶俊新材料科技有限公司

Bioactive artificial tooth root capable of slowly releasing rare-earth element cerium

InactiveCN101791267BGrowth inhibitionImprove biological activityImpression capsDentistry preparationsRare-earth elementIon exchange

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD +1

Artificial joint having slow-release function of rare earth element cerium and preparation method thereof

ActiveCN101766841BGrowth inhibitionImprove biological activityTitanium compoundsCoatingsRare-earth elementIon exchange

The invention discloses an artificial joint having a slow-release function of a rare earth element cerium and a preparation method thereof. The artificial joint consists of a pure titanium or titanium alloy artificial joint matrix and a microporous sodium titanate biological activity layer loaded with the rare earth element cerium and bone morphogenetic protein (BMP). The sodium titanate biological activity layer with a microporous structure is combined with the surface of a metal matrix and is formed by alternately stacking sodium titanate microporous structures generated by a hydrothermal reaction performed between the surface of the titanium or the titanium alloy matrix and solution of sodium hydroxide, the cerium and sodium perform cation interchange and are doped into a coating, and the BMP is compounded into the microporous structure through centrifugal force and under the action of a capillary tube. The preparation method comprises the following steps of: firstly, selecting thepure titanium or the titanium alloy to process the artificial joint well; secondly, forming a sodium titanate layer with the microporous structure on the surface of the artificial joint by adopting an alkali liquor hydrothermal synthesis technique; thirdly, doping the rare earth element cerium into the microporous sodium titanate layer through solution impregnation ion exchange; and finally, loading the bone morphogenetic protein into the cerium-doped microporous sodium titanate layer by adopting a centrifugal load technique.

Owner:NANTONG MINGXIN CHEM +1

Degradable magnesium alloy bone nail with scaly bone-like nanostructure coating and preparation method thereof

ActiveCN109432514BImprove biological activityImprove antibacterialAnodisationPeptide/protein ingredientsOxide ceramicMicro arc oxidation

The invention relates to a degradable magnesium alloy bone nail with a scaly bone-like nanostructure coating on the surface and a preparation method thereof. The degradable bone nail consists of an AZ31B magnesium alloy bone nail base and PLGA-bone morphogenetic protein BMP loaded Squamous bone-mimicking nanostructures composed of MgO bioceramic coatings. The magnesium oxide bioceramic coating with a scaly bone-like nanostructure is combined with the surface of a metal substrate, and a nanoscale scaly nanostructure is constructed on the surface of the substrate by a micro-arc oxidation technique. BMP fills and loads between magnesium oxide squamous bone-like nanostructure layers through centrifugal force and capillary action. The preparation method is as follows: firstly, the AZ31B magnesium alloy is processed into a bone nail; then, a magnesium oxide ceramic coating with scaly bone-like nanostructure characteristics is obtained on the surface of the substrate by micro-arc oxidation technology; Loading of PLGA‑bone morphogenetic protein between layers of bone nanostructures.

Owner:SOUTHWEST UNIV

Artificial tooth root with micro-nano hierarchical topologic surface structure and preparation method of artificial tooth root

InactiveCN102743789BBiological activity hasCapable of regulating cellsDental implantsImpression capsMicro nanoPlasma electrolytic oxidation

Disclosed are an artificial tooth root with a micro-nano hierarchical topologic surface structure and a preparation method of the artificial tooth root. The artificial tooth root is prepared by compounding a porous titanium dioxide surface layer with a zinc oxide nanorod or nanocone sedimentarily growing on the surface pore wall of the porous titanium dioxide surface layer, wherein the porous titanium dioxide surface layer is prepared with pure titanium or titanium alloy matrix by a microarc oxidation method, namely, the porous titanium dioxide bioactivity surface layer with an adjustable pore size is obtained by adjusting microarc oxidation parameters on the titanium matrix surface of the artificial tooth root, and the zinc oxide nanorod / nanocone is sedimentarily prepared on the titanium dioxide bioactivity surface layer by further adjusting electro-deposition parameters, so that the artificial tooth root with the micro-nano hierarchical topologic surface structure is formed. By the aid of the titanium dioxide micron porous structure with a rich surface and the zinc oxide nano-topologic structure sedimentarily growing on the pore wall of the titanium dioxide micron porous structure, the artificial tooth root can enhance biological effects of adhesion, growth, multiplication and the like of surface osteoblasts, slowly release zinc, and greatly improve antibacterial activity, biological activity, biocompatibility and cell regulation capacity of the surface in the early stage of implantation.

Owner:SOUTHEAST UNIV

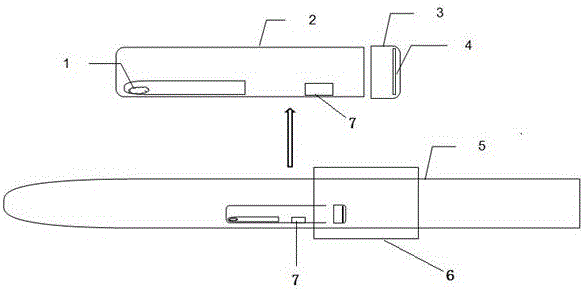

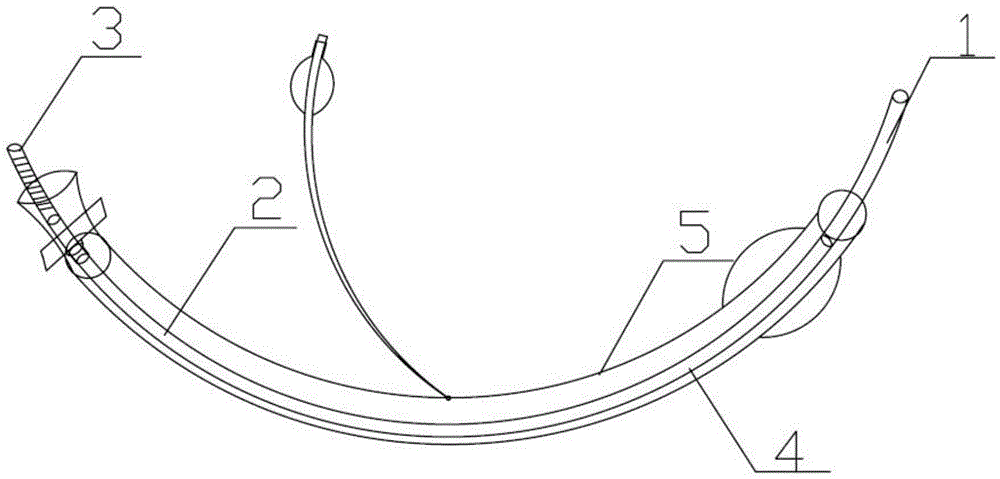

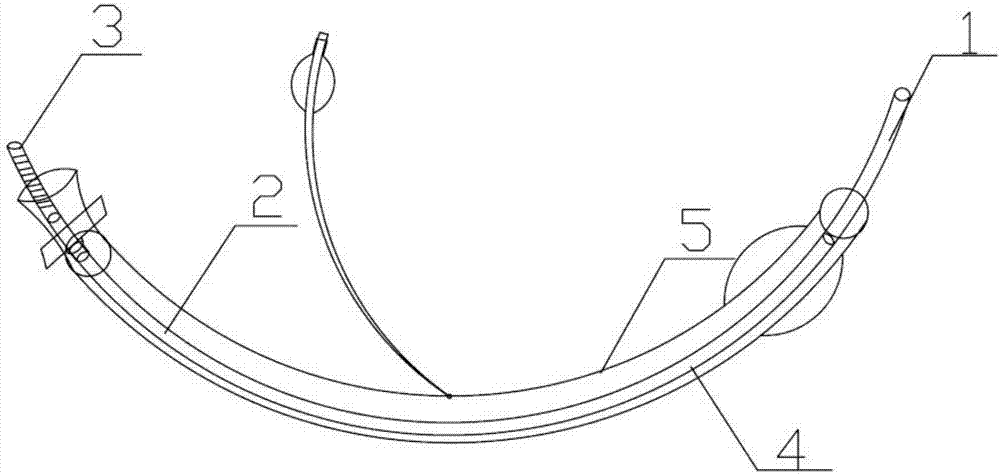

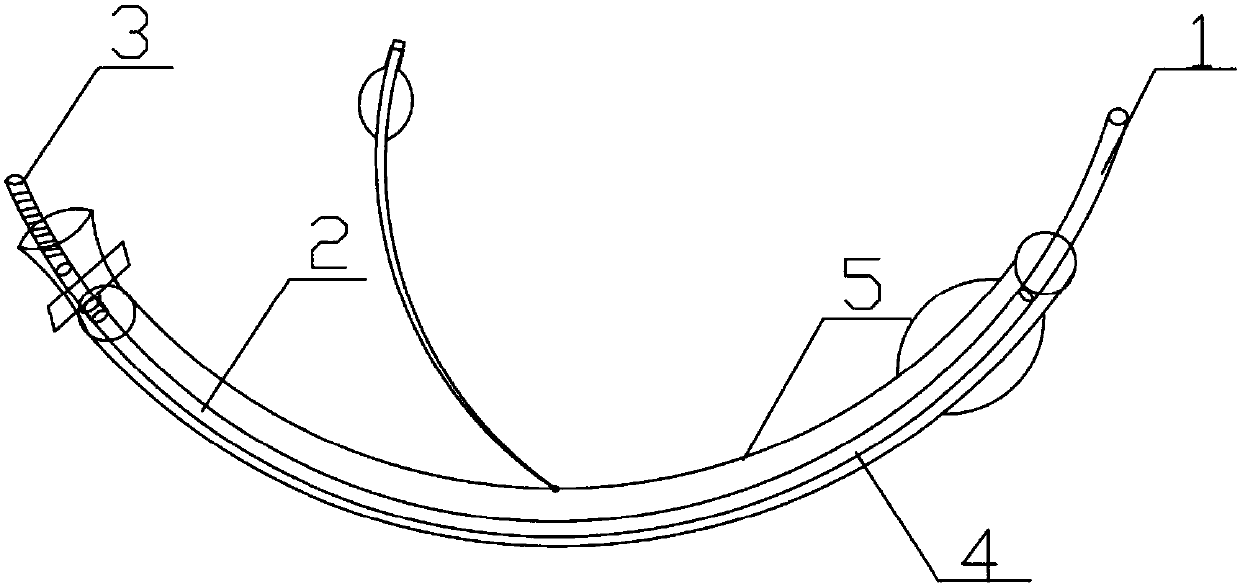

Trachea cannula core and preparation method thereof

ActiveCN105664327AReduce distortionExtended retention timeTracheal tubesMedical devicesIntratracheal intubationTracheal intubation

The invention provides a trachea cannula core and a preparation method thereof. The trachea cannula has the advantages that the operation is simple, the safety is realized, and the efficiency is high. The trachea cannula core comprises a guide tip end and a moulding cannula core, wherein the guide tip end extends outwards from one end of the moulding cannula core; the guide tip end is connected with the moulding cannula core; the outer diameter of the trachea cannula core of a trachea cannula is smaller than the inner diameter of the trachea cannula; the trachea cannula core is arranged in the trachea cannula; the length of the trachea cannula is smaller than the length of the trachea cannula core. The trachea cannula core has the advantages that the guide tip end can replace the trachea cannula, the front end is thinner in the intubation process, and the guide tip end is easily inserted into a trachea; the traditional intubation type is changed, the thinner guide tip end is firstly inserted, and then the trachea cannula is pushed, so that the safety is realized, and the efficiency is high; by combining the moulding cannula core and the guide tip end, while the guide function is guaranteed, the moulding is maintained, the injury to the human body by metal is avoided, more safety is realized, the operation is easy, the price is low, and the manufacturing is convenient.

Owner:车昊

Bioactive artificial joint capable of slowly releasing trace element selenium

InactiveCN101732762BImprove immunityGood anti-inflammatory effectCoatingsProsthesisSodium titanateTitanium alloy

Owner:江苏广达医材集团有限公司 +1

A kind of endotracheal intubation tube core and preparation method thereof

ActiveCN105664327BReduce distortionExtended retention timeTracheal tubesMedical devicesTracheal intubationTrach tube

Owner:车昊

A sandwich-structured graphene/molybdenum selenide/nitrogen-doped porous graphene composite material and its preparation method and application

ActiveCN109546133BStable structureLow costSecondary cellsNegative electrodesPorous grapheneElectrolytic agent

The invention discloses a graphene / molybdenum selenide / nitrogen-doped porous graphene composite material with sandwich structure and its preparation method and application; A molybdenum oxide layer, and a graphene layer on the molybdenum selenide layer as an outer protective film. This method utilizes the similarity in structure to make molybdenum selenide grow in the middle of double-layer graphene, and the nitrogen-doped porous graphene in the inner layer has good conductivity and porous structure, which is beneficial to electron transmission and electrolyte penetration; The graphene protective layer film can reduce the dissolution and destruction of molybdenum selenide, improve the stability and rate performance of the material, and effectively solve the problem of serious self-agglomeration, weak conductivity, large volume deformation, and low capacity when pure molybdenum selenide is used as the negative electrode material of sodium-ion batteries. low technical issues.

Owner:ZHEJIANG SCI-TECH UNIV

Trace element selenium slow-release type artificial tooth root based on nanometer tube array surface

InactiveCN101766542BImprove immunityGood anti-inflammatory effectImpression capsDentistry preparationsSodium titanateTitanium alloy

Owner:江苏广达医材集团有限公司 +1

A preparation method and device for an indium arsenide thin film material

ActiveCN106783549BWon't fall offAvoid mismatchSemiconductor/solid-state device manufacturingIndiumIndium arsenide

The invention discloses a preparation method and device of an indium arsenide thin film material and belongs to the technical field of semiconductor manufacturing. The method comprises the steps of ultrasonically cleaning a single-side polished mono-crystalline Si substrate and drying, and then feeding the dried mono-crystalline Si substrate into a vacuum chamber for heating and dehydrogenation; heating an arsenic simple substance for volatilization, and driving As air to flow through the surface of the mono-crystalline Si substrate to form an Si-As bond; activating the surface of the mono-crystalline Si substrate, and then growing a buffer layer at a low temperature; growing an indium arsenide thin film on the surface of the mono-crystalline Si substrate; and carrying out furnace cooling to a room temperature, thereby obtaining the indium arsenide thin film material. The method is low in demands on instrument and equipment, low in cost, easy to operate and relatively good in repeatability; and the obtained indium arsenide thin film is uniform and smooth in appearance and surface, preferential growth along (111) orientation is achieved, the thickness is 4.83 microns and the crystal quality is good.

Owner:KUNMING UNIV OF SCI & TECH

Trachea cannula core and preparation method thereof

InactiveCN107929902AReduce distortionExtended retention timeTracheal tubesMedical devicesIntratracheal intubationTracheal intubation

The invention provides a safe efficient trachea cannula core with simple operation and a preparation method thereof. The trachea cannula core comprises a guide point and a moulding tube core. The guide point is outwards extended from one end of the moulding tube core. The guide point is connected with the moulding tube core. The outer diameter of the trachea cannula core is less than the inner diameter of a trachea cannula. The trachea cannula core is placed in the trachea cannula. The length of the trachea cannula is less than the length of the trachea cannula core. The trachea cannula can bereplaced by the guide point of the trachea cannula core, so the front end is thinner in an intubation process, and more easily inserted in a trachea. A traditional intubation mode is changed, the thinner guide point is firstly inserted, and the trachea cannula is pushed in, so the process is safe and efficient. The moulding tube core is combined with the guide point, the guide function is guaranteed, and the moulding is kept as well. A human body is prevented from injuring by a metal. The process is safer, the operation is easy through the combination, the price is cheap, and the manufacturing is convenient.

Owner:周中南

Artificial tooth root with trace element selenium sustained-release function and preparation method thereof

InactiveCN101744666BImprove biological activityGood for anti-inflammatory and healthy teethDental implantsImpression capsAlloySodium titanate

The invention relates to a functional artificial tooth root with trace element selenium slow release and a preparation method thereof. The artificial tooth root is composed of a pure titanium or titanium alloy artificial tooth root base and a micro-sodium selenite and bone morphogenetic protein (BMP)-loaded artificial tooth root. The composition of the microporous sodium titanate surface layer. The bioactive coating of the sodium titanate layer with the microporous structure mentioned above is combined with the surface of the metal substrate, and the microporous structures of sodium titanate generated by the hydrothermal reaction between the surface of the titanium or titanium alloy substrate and the sodium hydroxide solution are alternately stacked and formed. In this way, trace amounts of sodium selenite and BMP are compounded in the microporous structure by centrifugal force and capillary action. The preparation method is as follows: firstly select pure titanium or titanium alloy to process the artificial tooth root; then use the alkaline solution hydrothermal synthesis technology to obtain a sodium titanate layer with a microporous structure on the surface of the titanium artificial tooth root; Sodium selenite and bone morphogenetic protein are loaded in the sodium layer.

Owner:江苏广达医材集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com