Cancellous bone structure simulating artificial bone having ultra-low elasticity modulus and preparation method of artificial bone

A technology of elastic modulus and cancellous bone, which is applied in the fields of pharmaceutical formulation, medical science, tissue regeneration, etc., can solve the problems of poor direct bonding ability, achieve dense coating, induce osteogenesis effect, and promote deposition and growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) First select 10mm×10mm×10mm polymer foam, 70 g titanium, 25 g niobium, 20 g zirconium, 40 g water, 5 g gelatin and vacuum ball mill for 5 hours;

[0033] (2) The scaffold is first treated at 300°C for 3 hours; then sintered at 1350°C in vacuum for 3 hours to obtain artificial bones, such as figure 1 shown;

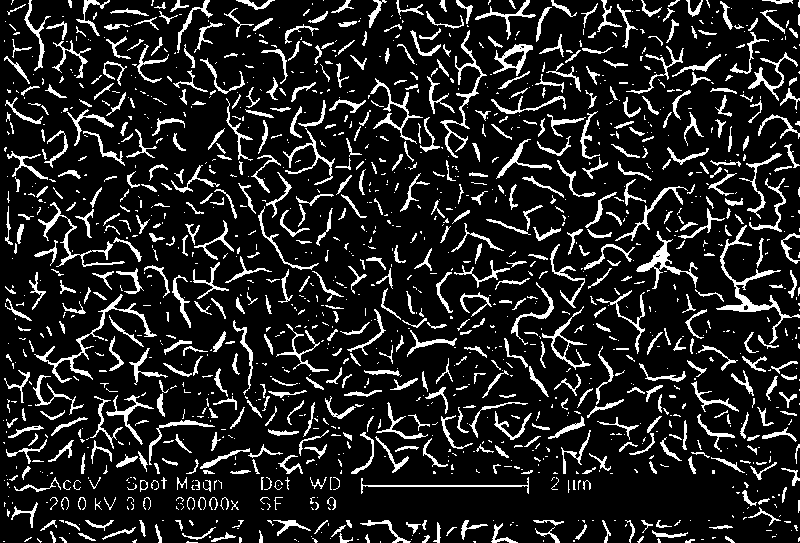

[0034] (3) Use sodium hydroxide aqueous solution with a concentration of 5mol / L to carry out hydrothermal reaction, the working temperature is 100°C, and the treatment time is 12 hours to obtain an artificial bone with a porous sodium titanate coating, such as figure 2 and image 3 shown;

[0035] (4) Soak the obtained artificial bone in simulated body fluid, the temperature is controlled at 37±0.5°C, and the soaking time is 30 days to obtain the artificial bone coated with hydroxyapatite composite sodium titanate, such as Figure 4 shown;

[0036] (5) Take out the above-mentioned artificial bone, wash it with alcohol and deionized water, dry it, store it a...

Embodiment 2

[0038] (1) First select 10mm×10mm×10mm polymer foam, 70 g titanium, 25 g niobium, 20 g zirconium, 40 g water, 5 g gelatin and vacuum ball mill for 5 hours;

[0039] (2) The scaffold is first treated at 400°C for 3 hours; then sintered at 1300°C in vacuum for 3 hours to obtain an artificial bone;

[0040] (3) Using a sodium hydroxide aqueous solution with a concentration of 5mol / L for hydrothermal reaction, the working temperature is 100°C, and the treatment time is 12h, and the artificial bone is coated with porous sodium titanate;

[0041] (4) Soak the obtained artificial bone in simulated body fluid, the temperature is controlled at 37±0.5°C, and the soaking time is 40 days to obtain the artificial bone coated with hydroxyapatite composite sodium titanate;

[0042](5) Take out the above-mentioned artificial bone, wash it with alcohol and deionized water, dry it, store it aseptically after disinfection, and keep it for later use, then the artificial bone with imitation cancel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com