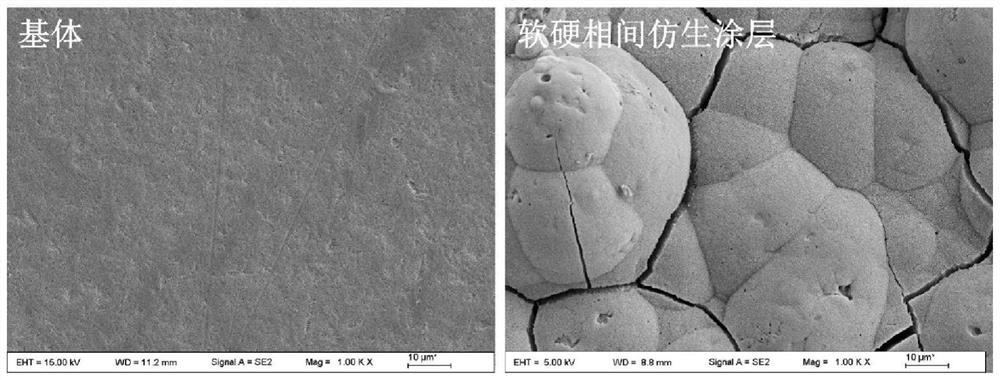

Method for preparing soft and hard alternate bionic coating on surface of medical titanium alloy by utilizing composite treatment of micro-arc oxidation and laser nitridation

A technology of micro-arc oxidation and laser nitriding, applied in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc. performance improvement effect and other issues, to achieve the effect of improving surface biological activity, adjusting friction performance, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Pre-treatment of the titanium alloy, including sandpaper step by step grinding to 2000#, cleaning and drying.

[0031] 2) Configure the electrolyte: the electrolyte composition is: C 4 h 6 CaO 4 8g / L, Na 2 HPO 4 4.3g / L, NaOH 2g / L, AgNO 3 1g / L, the solvent is deionized water;

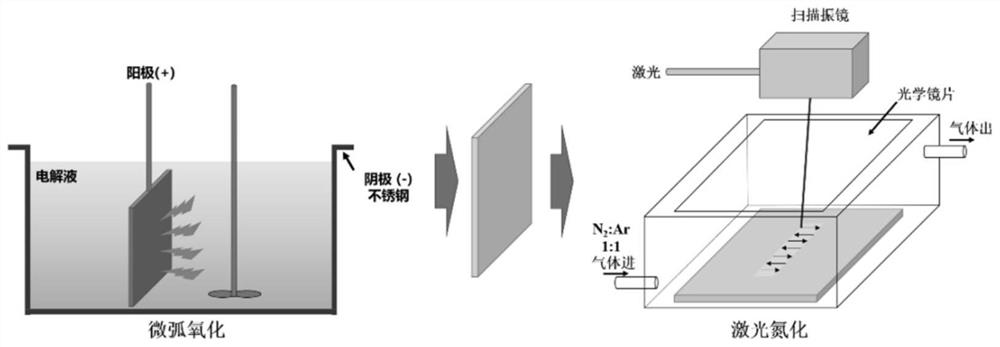

[0032] 3) Set the micro-arc oxidation process: pulse power supply current density 5A / dm 2 , The pulse frequency is 250Hz, the duty cycle is 10%, the processing time is set to 20min, and the micro-arc oxidation treatment is carried out;

[0033] 4) Put the sample after micro-arc oxidation into the atmosphere protection box, set the flow ratio of nitrogen and argon to 0.3:1, and the total flow of the mixed gas to 20L / min;

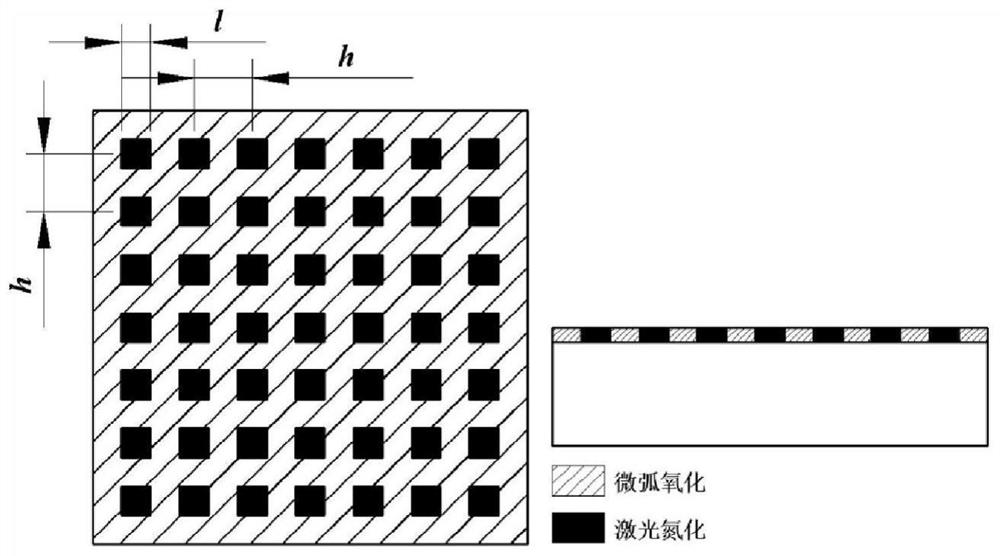

[0034] 5) Set the side length of the square laser nitriding treatment area as l=1mm, and the interval between adjacent squares is h=2mm;

[0035] 6) Set the laser nitriding process: laser power 300W, scanning speed 500mm / s, scanning distance 0.06mm, for nitriding pro...

Embodiment 2

[0038] 1) Pre-treatment of the titanium alloy, including sandpaper step by step grinding to 2000#, cleaning and drying.

[0039] 2) Configure the electrolyte: the electrolyte composition is: C 4 h 6 CaO 4 8g / L, Na 2 HPO 4 4.3g / L, NaOH 2g / L, AgNO 3 1g / L, the solvent is deionized water;

[0040] 3) Set the micro-arc oxidation process: pulse power supply current density 5A / dm 2 , The pulse frequency is 250Hz, the duty cycle is 10%, the processing time is set to 20min, and the micro-arc oxidation treatment is carried out;

[0041] 4) Put the sample after micro-arc oxidation into the atmosphere protection box, set the flow ratio of nitrogen and argon to 0.3:1, and the total flow of the mixed gas to 20L / min;

[0042] 5) Set the side length of the square laser nitriding treatment area as l=3mm, and the interval between adjacent squares is h=8mm;

[0043] 6) Set the laser nitriding process: laser power 300W, scanning speed 500mm / s, scanning distance 0.06mm, for nitriding pro...

Embodiment 3

[0046] 1) Pre-treatment of the titanium alloy, including sandpaper step by step grinding to 2000#, cleaning and drying.

[0047] 2) Configure the electrolyte: the electrolyte composition is: C 4 h 6 CaO 4 16g / L, Na 2 HPO 4 8.50g / L, NaOH 3g / L, AgNO 3 2g / L, the solvent is deionized water;

[0048] 3) Set the micro-arc oxidation process: pulse power supply current density 9A / dm 2 , The pulse frequency is 250Hz, the duty cycle is 30%, the processing time is set to 15min, and the micro-arc oxidation treatment is carried out;

[0049] 4) Put the sample after micro-arc oxidation into the atmosphere protection box, set the flow ratio of nitrogen and argon to 1:1, and the total flow of the mixed gas to 35L / min;

[0050] 5) Set the side length of the square laser nitriding treatment area as l=2mm, and the interval between adjacent squares is h=4mm;

[0051] 6) Set the laser nitriding process: laser power 500W, scanning speed 1000mm / s, scanning distance 0.08mm, for nitriding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com