A kind of spherical nano iridium oxide dna extraction magnetic powder and its production method

A technology of iridium oxide powder and production method, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., and can solve problems such as insufficient surface biological activity, low chemical stability, and poor biocompatibility , to achieve rapid and thorough solid-liquid separation, chemical stability, not easy to oxidize, and good surface biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

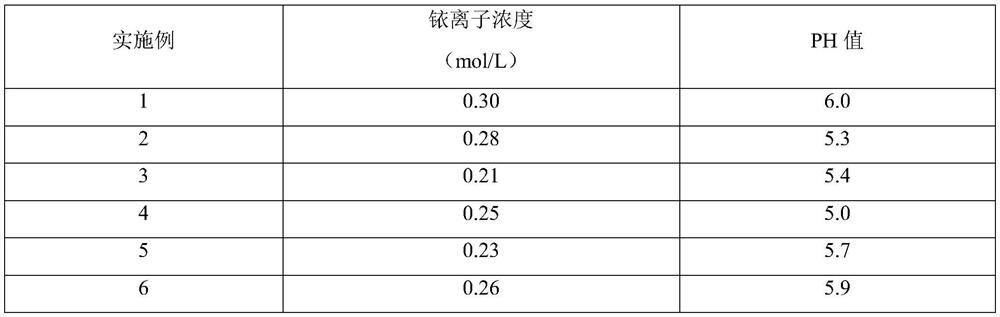

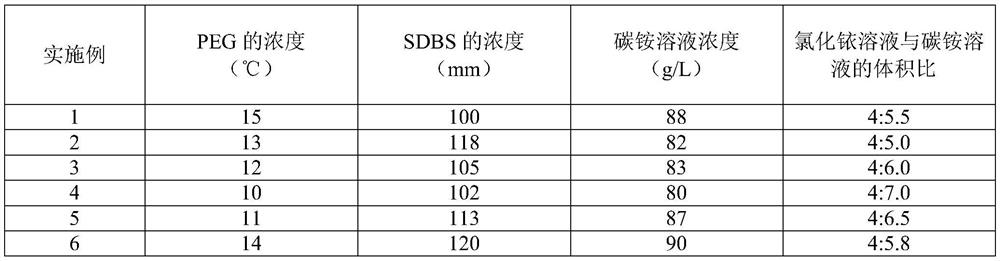

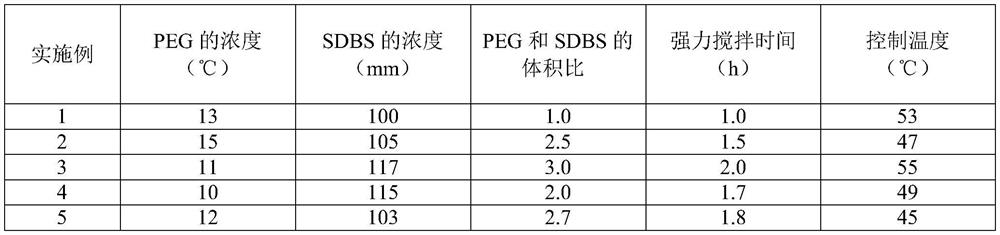

[0026] 4) Preparation of iridium carbonate foam: After filtering and washing all the iridium ion precipitates in the previous step, add PEG (10-15g / L) and SDBS (100-120g / L) at a volume ratio of 1-3:5 into the filter cake of the iridium ion precipitate, and then vigorously stir it for 1 to 2 hours, and control the temperature between 45 and 55°C until the formation of iridium carbonate precipitate foam.

[0027] 5) Preparation of spherical nano-iridium oxide powder: place the prepared iridium carbonate precipitation foam in a muffle furnace and dry at 100-120°C for 20-24 hours, and then keep 1-3L / s air in the tube furnace Flow rate, and calcine at 800-850°C for 2-3 hours, and finally obtain spherical nano-iridium oxide powder.

[0028] 2. Ultrasonic-laser surface roughening of spherical nano-iridium oxide DNA extraction magnetic powder:

[0029] 1) Ultrasound for extracting magnetic powder with spherical nano-iridium oxide DNA: Dissolve the prepared spherical nano-iridium oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com