Artificial tooth root with trace element selenium sustained-release function and preparation method thereof

A technology of artificial tooth roots and trace elements, applied in dental preparations, dentistry, dental implants, etc., to achieve the effect of anti-inflammatory and healthy teeth-induced osteogenesis, high bonding strength, and improved immunity of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) First choose pure titanium to process the artificial tooth root;

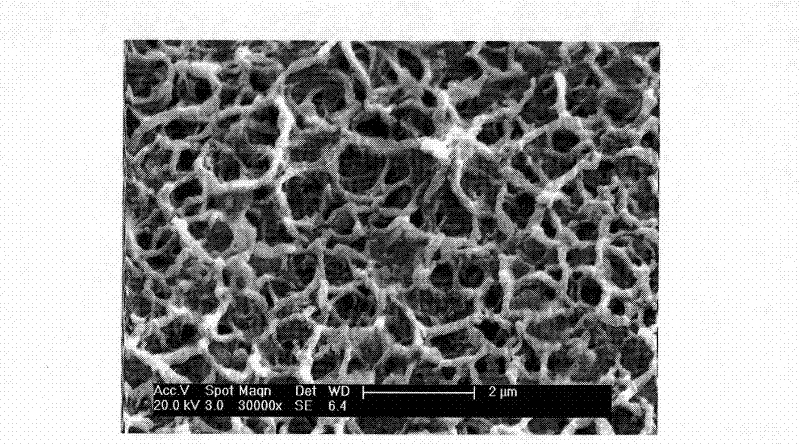

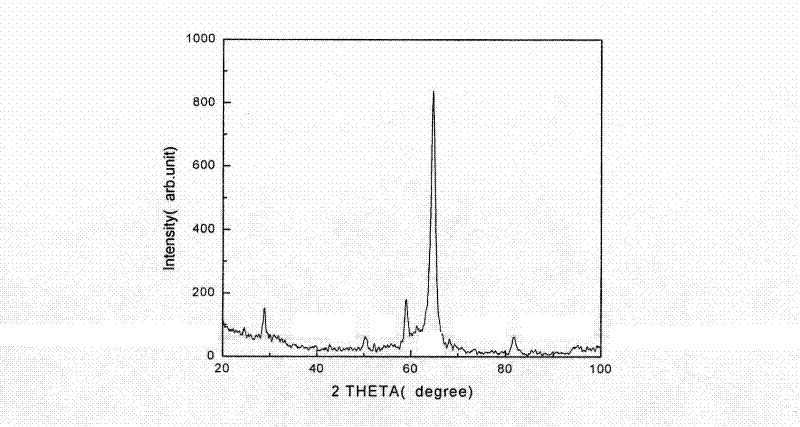

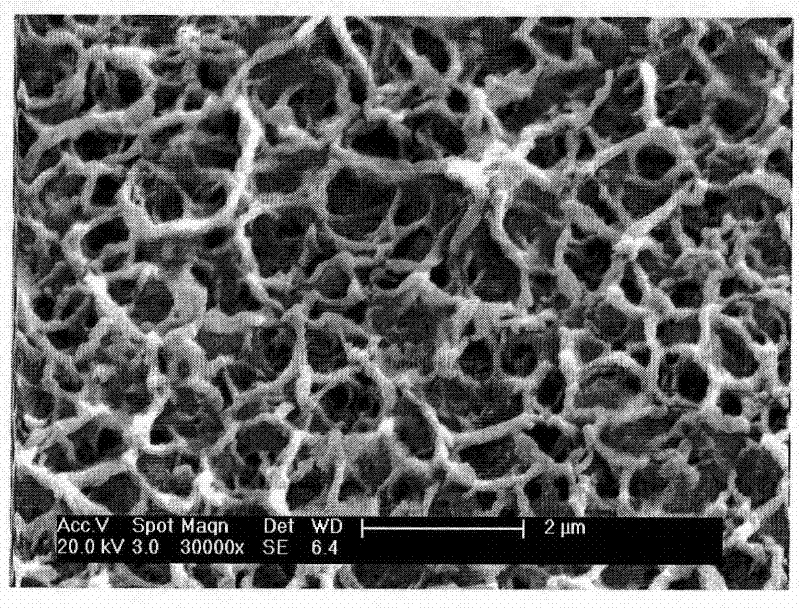

[0025] (2) Hydrothermal treatment of the surface of the artificial tooth root: the artificial tooth root is polished and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. After 6 hours, a sodium titanate bioactive coating with a microporous structure was obtained on the surface of the artificial tooth root, and its SEM photos and XRD spectra are shown in figure 1 and figure 2 ;

[0026] (3) Centrifugal loading treatment of trace amounts of sodium selenite and BMP: fix the artificial tooth root with the sodium titanate bioactive coating with a microporous structure on the surface in a centrifugal cylinder, pour 5 × 10 -3 mol / L sodium selenite, 0.1-50 mg / L bone morphogenetic protein and 0.1 mol / L...

Embodiment 2

[0029] (1) First choose Ti6Al4V alloy to process the artificial tooth root;

[0030] (2) Hydrothermal treatment of the surface of the artificial tooth root: the artificial tooth root is polished and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. The time is 6 hours, and a sodium titanate bioactive coating with a microporous structure is obtained on the surface of the artificial tooth root;

[0031] (3) Centrifugal loading treatment of trace amounts of sodium selenite and BMP: fix the artificial tooth root with the sodium titanate bioactive coating with a microporous structure on the surface in a centrifugal cylinder, pour 5 × 10 -3 mol / L sodium selenite, 0.1-50 mg / L bone morphogenetic protein and 0.1 mol / L phosphate-buffered saline solution, and submerged more than twice...

Embodiment 3

[0034] (1) First choose pure titanium to process the artificial tooth root;

[0035] (2) Hydrothermal treatment of the surface of the artificial tooth root: the artificial tooth root is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 150 degrees Celsius. The time is 72 hours, and a sodium titanate bioactive coating with a microporous structure is obtained on the surface of the artificial tooth root;

[0036] (3) Centrifugal loading treatment of trace amounts of sodium selenite and BMP: fix the artificial tooth root with the sodium titanate bioactive coating with a microporous structure on the surface in a centrifugal cylinder, pour 5 × 10 -3 mol / L sodium selenite, 0.1-50 mg / L bone morphogenetic protein and 0.1 mol / L phosphate-buffered saline solution, and submerge more than twice t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com