Sandwich-structured graphene/molybdenum selenide/nitrogen-doped porous graphene composite material and preparation method and application thereof

A porous graphene, sandwich structure technology, applied in structural parts, electrochemical generators, active material electrodes, etc., can solve the problems of weak conductivity, poor cycle performance, poor rate capability, etc., and achieve low cost, excellent performance, The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Graphene / molybdenum selenide / nitrogen-doped porous graphene (NPGRs@MoSe) were synthesized as follows 2 @GRs):

[0056] Steps (1)-(4) adopt the same method as Comparative Example 2.

[0057] (5) Graphene / molybdenum selenide / nitrogen-doped porous graphene (NPGRs@MoSe 2Synthesis of @GRs): Take 100 mg of the product of step (4) and dissolve it in 100 mL of deionized water, add 2.91 mg of hexadecyltrimethylammonium bromide, stir and react for 30 minutes, then add 15 mL of 2 mg / mL The graphene oxide solution was heated to 98°C, and 0.5 mL of hydrazine hydrate was added to react for 6 hours, and the product was washed and dried. After the above drying, put it into a nitrogen tube furnace for pyrolysis. Among them, the pyrolysis process includes: rising from room temperature at 2°C / min to 420°C, constant temperature for 2 hours, then rising to 750°C at 2°C / min, and cooling to room temperature at 5°C / min after constant temperature for 1 hour.

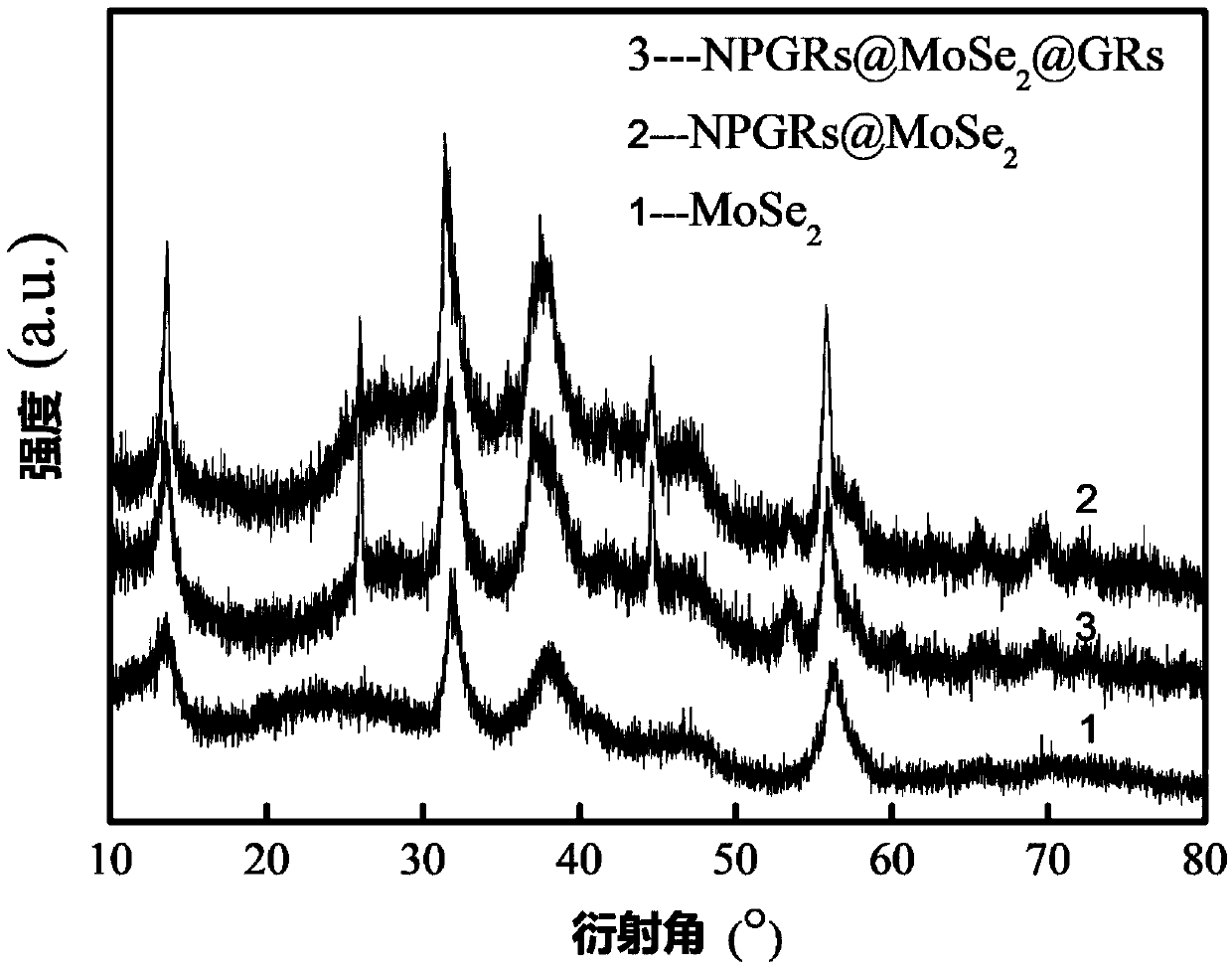

[0058] figure 1 The XRD test ...

Embodiment 2

[0062] Graphene / molybdenum selenide / nitrogen-doped porous graphene (NPGRs@MoSe) were synthesized as follows 2 @GRs):

[0063] Step (1) adopts the same method as Comparative Example 2.

[0064] (2) Preparation of polystyrene (PS): 10g styrene (St) and 0.67g polyvinylpyrrolidone (PVP) were dissolved in 160mL deionized water, then added to a reaction flask with a stirring and condensing device, and Place in an oil bath and start stirring to mix evenly, add 25mL of 20g / L 2,2'-azobisisobutylamidine hydrochloride (AIBA) solution, continue to blow nitrogen, and heat up to 75°C after 90min After reacting for 35 hours, 5 mL was taken and dried in an oven to obtain polystyrene pellets.

[0065] (3) Preparation of nitrogen-doped porous graphene (NPGRs): Add 2 g of PS pellets (ie, 26.5 mL of PS solution) into 500 mL of 0.2 M HCl solution, and start stirring. Add 200mg of graphene oxide into 30mL of deionized water and sonicate for 50min, then add it to the above solution, stir and reac...

Embodiment 3

[0070] Graphene / molybdenum selenide / nitrogen-doped porous graphene (NPGRs@MoSe) were synthesized as follows 2 @GRs):

[0071] Step (1) adopts the same method as Comparative Example 2.

[0072] (2) Preparation of polystyrene (PS): 10g styrene (St) and 2g polyvinylpyrrolidone (PVP) were dissolved in 60mL deionized water, then added to a reaction flask with a stirring and condensing device, and placed side by side Put it in an oil bath and start stirring to make it evenly mixed, add 20mL 10g / L 2,2'-azobisisobutylamidine hydrochloride (AIBA) solution, continue to blow nitrogen, after 40min, raise the temperature to 65°C and react for 15h , take 5mL and place it in an oven to dry to obtain the concentration of the polystyrene solution to be 0.0754g / mL.

[0073] (3) Preparation of nitrogen-doped porous graphene (NPGRs): Add 2 g of PS pellets (ie, 26.5 mL of PS solution) into 500 mL of 0.2 M HCl solution, and start stirring. Add 200mg of graphene oxide into 30mL of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com