G-C3N4/ TiO2 coating with light-control and antibacterial functions and preparation method thereof

A g-c3n4 coating technology, applied in coating, medical science, tissue regeneration, etc., to achieve the effect of dense coating, high bonding strength and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

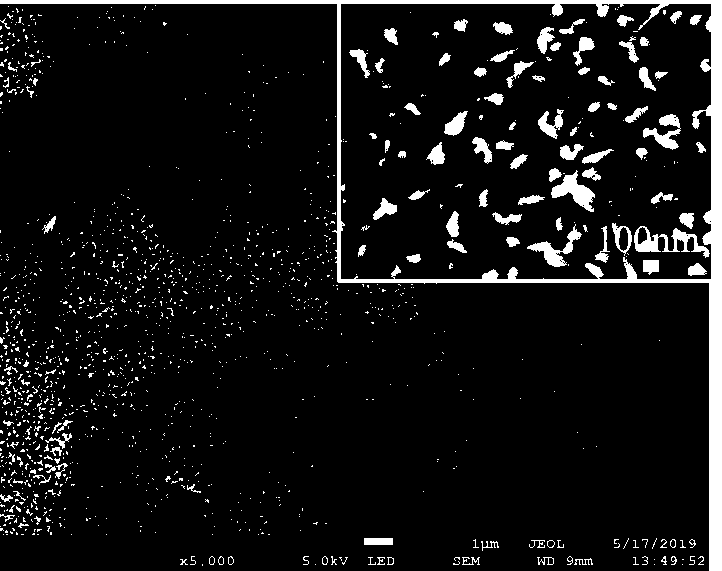

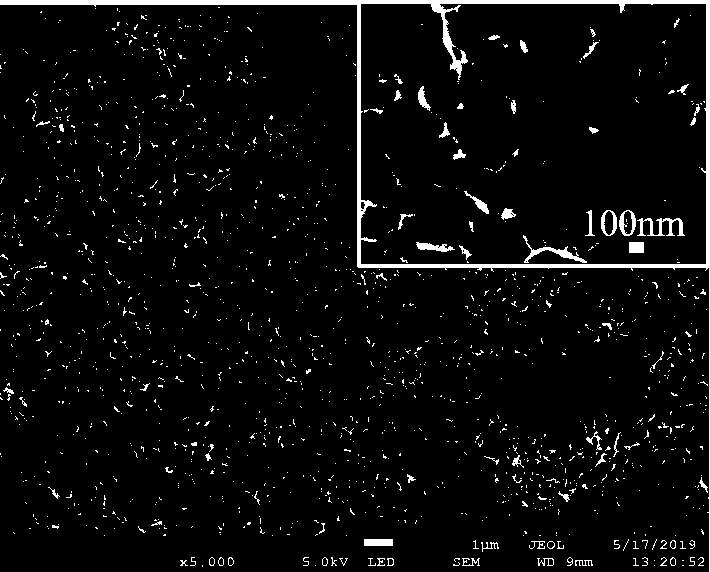

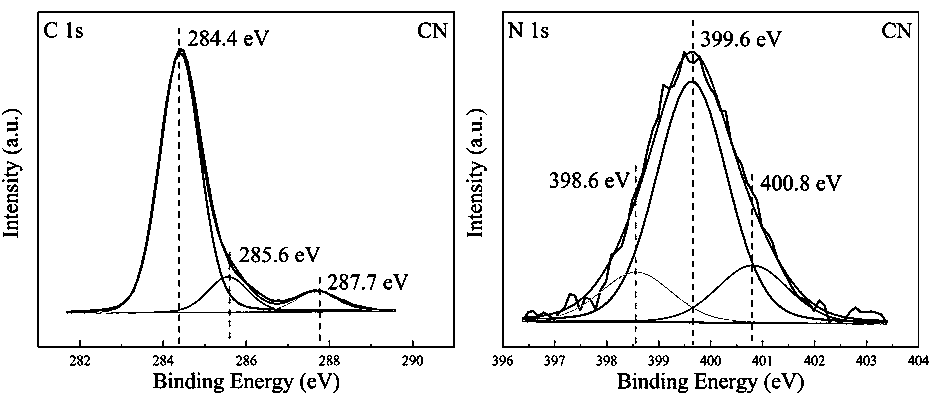

Image

Examples

Embodiment 1

[0030] (1) First select TC4 titanium alloy.

[0031] (2) Pretreatment: The titanium-based alloy implant material is polished and polished step by step with metallographic sandpaper with the labels of 600#, 800#, and 1000# from coarse sand to fine sand, and then with acetone, 70% alcohol, and distilled water Ultrasonic cleaning, dry for use.

[0032] (3) Chemical polishing: prepare 40 ml of polishing solution containing hydrofluoric acid and concentrated nitric acid, the volume ratio is: H 2 O: HF: HNO 3 =5:1:4; put TC4 titanium alloy in chemical polishing solution and polish for 3 min.

[0033] (4) Advanced oxidation: Prepare 5 wt% hydrogen peroxide solution, put the TC4 titanium alloy in the oxidation solution, and irradiate its outer surface with a 254nm ultraviolet lamp, and the oxidation treatment time is 4 h.

[0034] (5) Hydrothermal synthesis treatment: The advanced oxidized TC4 titanium alloy was hydrothermally synthesized with a sodium hydroxide solution with a con...

Embodiment 2

[0038] (1) First select TC4 titanium alloy.

[0039] (2) Pretreatment: The titanium-based alloy implant material is polished and polished step by step with metallographic sandpaper with the labels of 600#, 800#, and 1000# from coarse sand to fine sand, and then with acetone, 70% alcohol, and distilled water Ultrasonic cleaning, dry for use.

[0040] (3) Chemical polishing: prepare 40 ml of polishing solution containing hydrofluoric acid and concentrated nitric acid, the volume ratio is: H 2 O: HF: HNO 3 =5:1:4; put TC4 titanium alloy in chemical polishing solution and polish for 3 min.

[0041] (4) Advanced oxidation: Prepare 5 wt% hydrogen peroxide solution, put the TC4 titanium alloy into the oxidation solution, and irradiate its outer surface with a 254nm ultraviolet lamp, and the oxidation treatment time is 3 h.

[0042] (5) Hydrothermal synthesis treatment: The highly oxidized titanium alloy bone nail was hydrothermally reacted with a sodium hydroxide solution with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com