Method for extracting tremella polysaccharide from tremella fuciformis

A tremella polysaccharide, tremella polysaccharide technology, applied in the field of extraction of natural active product Tremella polysaccharide, can solve the problems of not suitable for large-scale industrial production application, increase extraction equipment investment and energy consumption, etc., achieve safe and efficient extraction method, reduce extraction preparation Cost, good effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

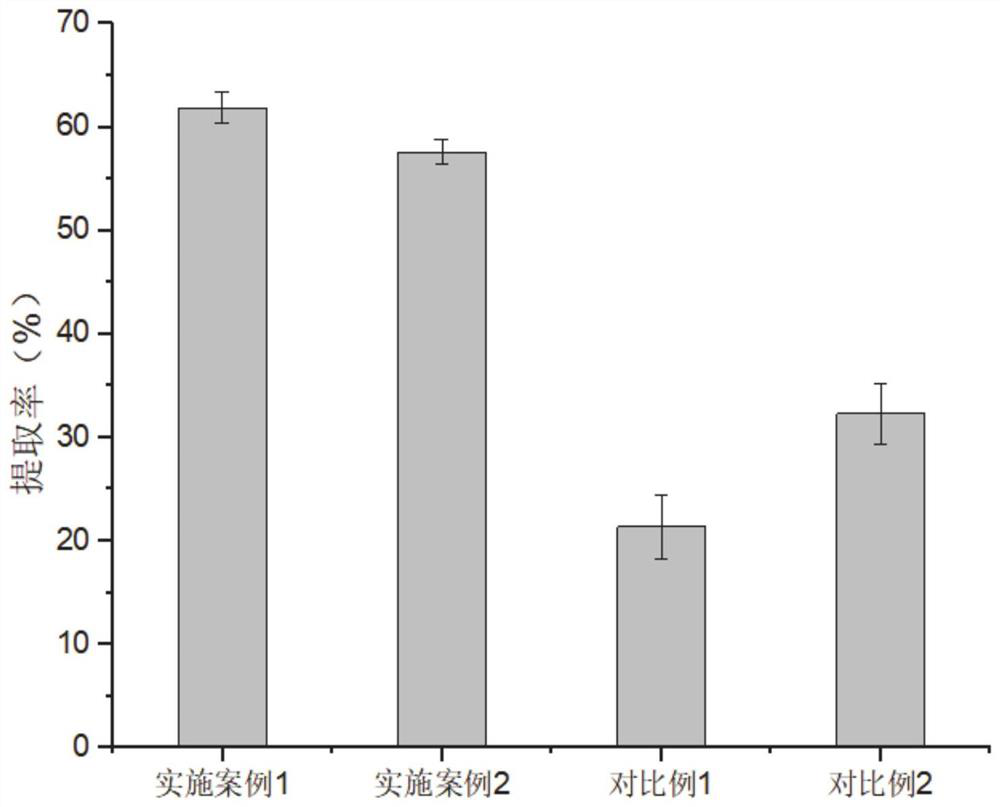

[0041] Crush the white fungus and pass through a 120-mesh sieve to get the white fungus powder. Take the tremella powder after sieving and add 0.4% compound enzyme enzymolysis solution (the compound enzyme ratio is cellulase: pectinase: xylanase=1:0.8:1), the pH of compound enzyme enzymolysis solution= 4.5, make the two fully mixed, enzymatic hydrolysis at 55°C for 1 hour, heat up to inactivate the enzyme after enzymatic hydrolysis, heat up to 100°C for 2 hours, after the extraction is completed, the extract is centrifuged at 5000rpm for 10 minutes to remove the residue, and take it up after centrifugation The polysaccharide was determined by the sulfuric acid phenol method in the serum, and the extraction rate was 61.88%.

Embodiment 2

[0043] Crush the white fungus and pass through a 120-mesh sieve to get the white fungus powder. Take the white fungus powder after sieving and add 0.3% compound enzyme enzymolysis solution (the compound enzyme ratio is cellulase: pectinase: xylanase=1:0.8:1.2), the pH of compound enzyme enzymolysis solution= 4.5, make the two fully mixed, enzymatically hydrolyze at 55°C for 1 hour, heat up to inactivate the enzyme after enzymatic hydrolysis, heat up to 100°C for extraction for 2 hours, after the extraction is completed, the extract is centrifuged at 5000rpm for 10min to remove the residue, and take the supernatant after centrifugation The content of tremella polysaccharide was determined by sulfuric acid phenol method, and the extraction rate was 57.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com