Artificial joint having slow-release function of rare earth element cerium and preparation method thereof

A technology for artificial joints and rare earth elements, which is used in chemical instruments and methods, medical science, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) First choose pure titanium to process the artificial joint;

[0027] (2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. The time is 6 hours, and a sodium titanate bioactive coating with a microporous structure is obtained on the surface of the artificial joint.

[0028] (3) Cerium doping treatment by dipping method: The artificial joint prepared above covered with microporous sodium titanate bioactive layer was immersed in soluble cerium salt (NH 4 ) 2 Ce(NO 3 ) 6 The rare earth element cerium was doped into the aqueous solution by ion exchange, (NH 4 ) 2 Ce(NO 3 ) 6 The concentration of the aqueous solution is 0.05mol L -1 , the liquid level of the solution shou...

Embodiment 2

[0032] (1) First choose Ti6Al4V alloy to process the artificial joint;

[0033](2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. The time is 6 hours, and a sodium titanate bioactive coating with a microporous structure is obtained on the surface of the artificial joint.

[0034] (3) Cerium doping treatment by dipping method: The artificial joint prepared above covered with microporous sodium titanate bioactive layer was immersed in soluble cerium salt Ce(NO 3 ) 4 The rare earth element cerium, Ce(NO 3 ) 4 The concentration of the aqueous solution is 0.05mol L -1 , the liquid level of the solution should be submerged over the artificial joint, and the soaking time should be no ...

Embodiment 3

[0038] (1) First choose pure titanium to process the artificial joint;

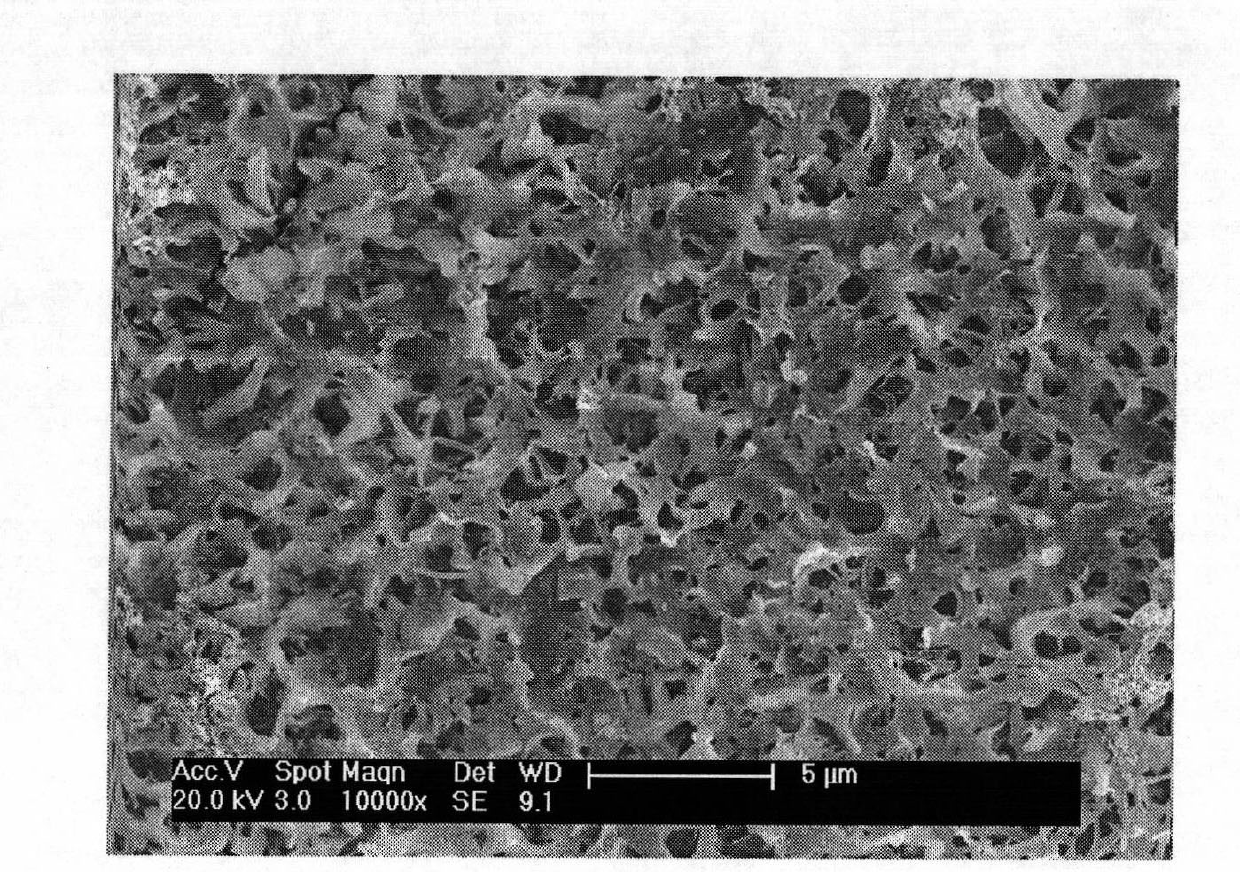

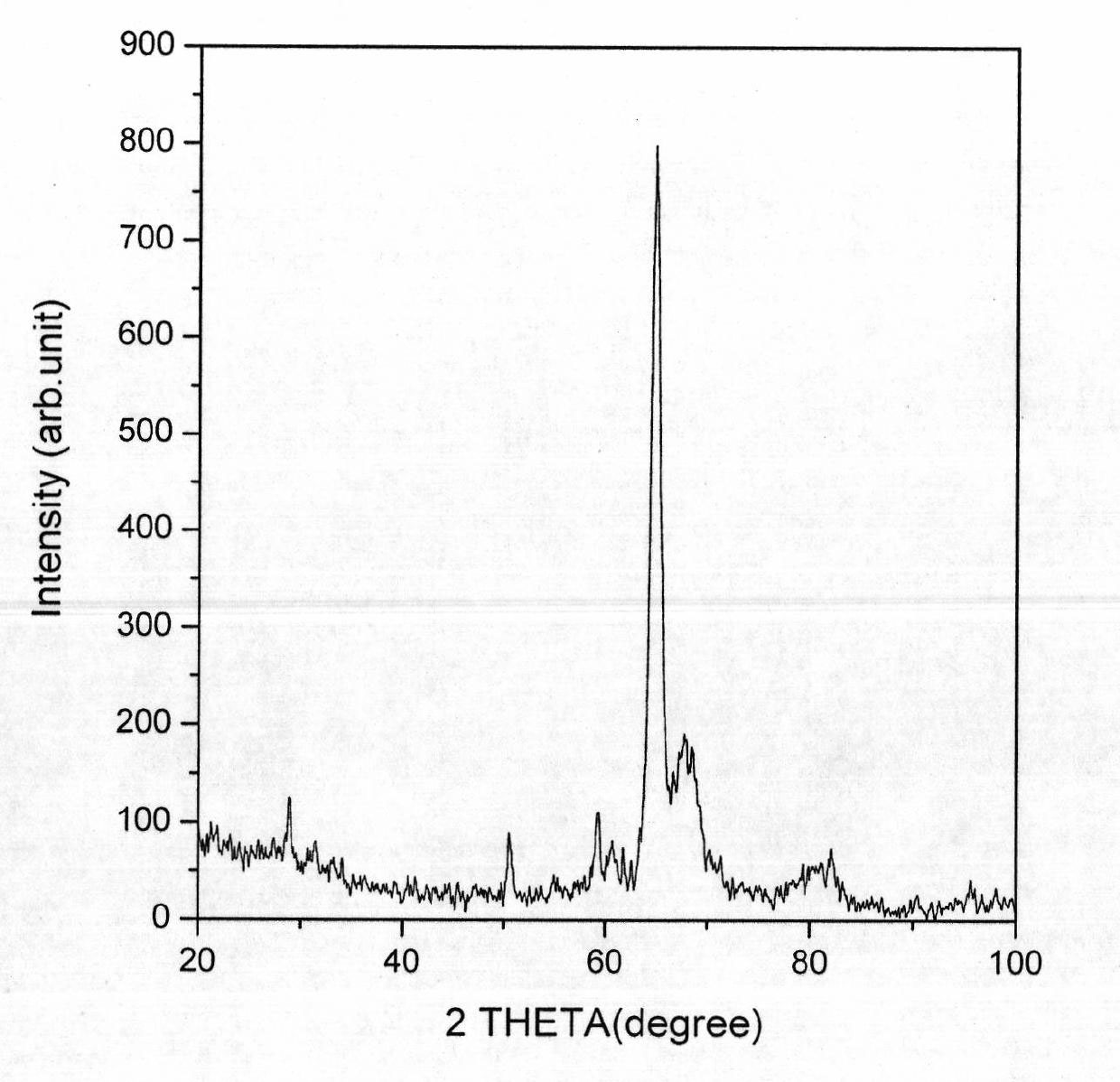

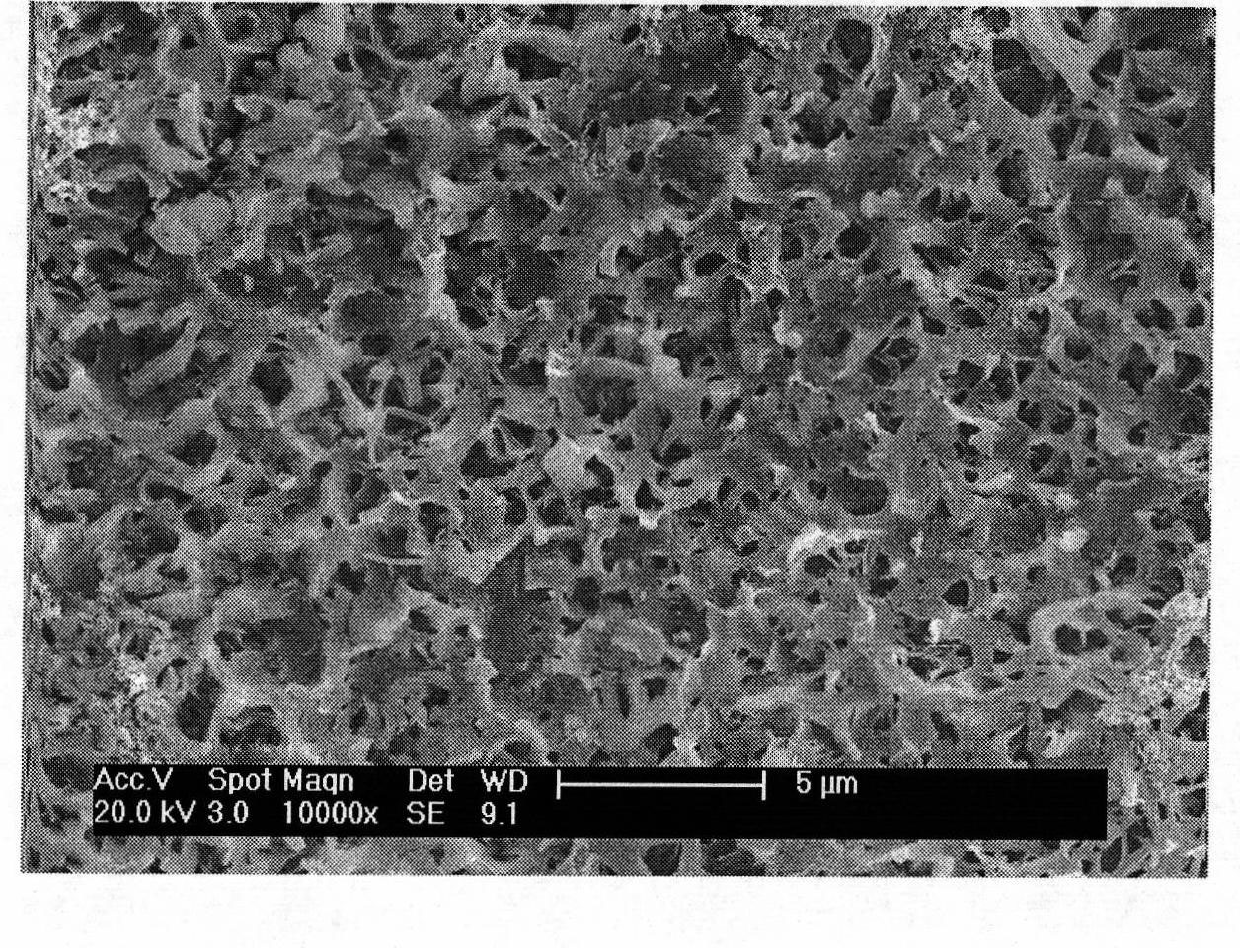

[0039] (2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 150 degrees Celsius. The time is 72 hours, and a sodium titanate bioactive coating with microporous structure is obtained on the surface of the artificial joint, and its SEM photos and XRD spectra are shown in figure 1 and figure 2 .

[0040] (3) Cerium doping treatment by dipping method: The artificial joint prepared above covered with microporous sodium titanate bioactive layer was immersed in soluble cerium salt (NH 4 ) 2 Ce(NO 3 ) 6 The rare earth element cerium was doped into the aqueous solution by ion exchange, (NH 4 ) 2 Ce(NO 3 ) 6 The concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com