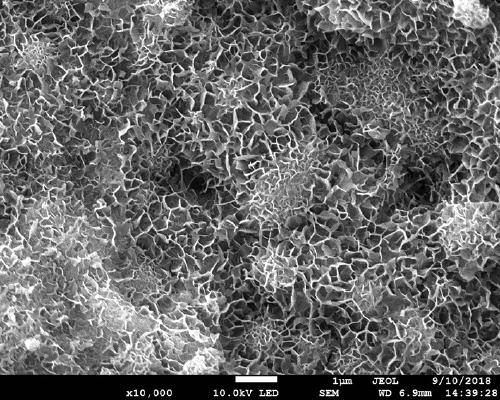

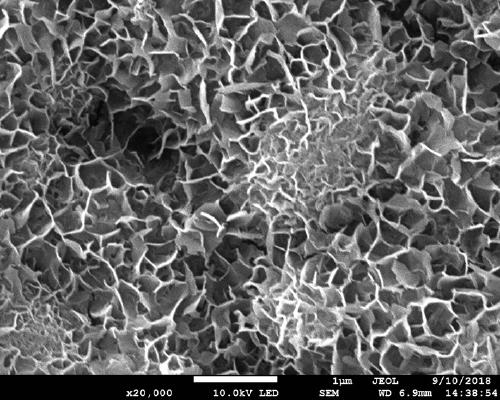

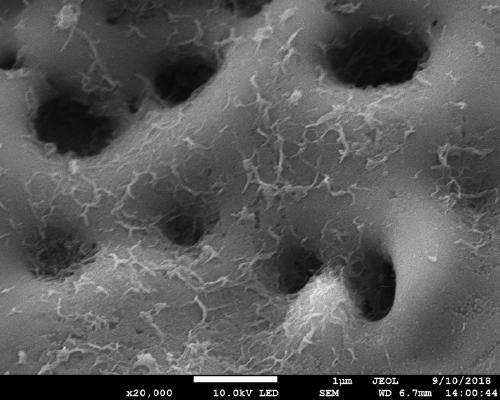

Degradable magnesium alloy bone nail with squamous bionic bone nanostructure coating and preparation method

A nanostructure, magnesium alloy technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., to achieve the effect of improving bone formation ability, dense coating, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) First, choose AZ31B magnesium alloy to process the bone nail;

[0028] (2) Bone nail pretreatment: AZ31B magnesium alloy bone nails are polished and polished step by step with metallographic sandpaper with labels of 600#, 800#, and 1000# from coarse sand to fine sand, and then use acetone, 70% alcohol, Ultrasonic cleaning with distilled water and drying for later use.

[0029] (3) Configuration of electrolyte solution: use sodium phosphate solution system, prepare 10L of sodium phosphate solution with a concentration of 5g / L and sodium hydroxide solution with a concentration of 2g / L, for use;

[0030] (4) Micro-arc oxidation of bone nails: place the AZ31B magnesium alloy bone nails in the electrolytic cell of the bipolar pulse micro-arc oxidation equipment and add the prepared electrolyte solution, use the AZ31B magnesium alloy bone screws as the anode, and the stainless steel electrolytic cell as Cathode, adjust process parameters to carry out micro-arc oxidation ...

Embodiment 2

[0035] (1) First, choose AZ31B magnesium alloy to process the bone nail;

[0036] (2) Bone nail pretreatment: AZ31B magnesium alloy bone nails are polished and polished step by step with metallographic sandpaper with labels of 600#, 800#, and 1000# from coarse sand to fine sand, and then use acetone, 70% alcohol, Ultrasonic cleaning with distilled water and drying for later use.

[0037] (3) Configuration of electrolyte solution: use sodium phosphate solution system, configure 10L sodium phosphate solution with a concentration of 10g / L and sodium hydroxide solution with a concentration of 1g / L for use;

[0038] (4) Micro-arc oxidation of bone nails: place the AZ31B magnesium alloy bone nails in the electrolytic cell of the bipolar pulse micro-arc oxidation equipment and add the prepared electrolyte solution, use the AZ31B magnesium alloy bone screws as the anode, and the stainless steel electrolytic cell as Cathode, adjust process parameters to carry out micro-arc oxidation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com