Functionalized artificial joint with selenium-loaded nanotube array surface and preparation method thereof

A nanotube array, artificial joint technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problem of not involving the preparation of the surface of the metal matrix, and improve the immunity of the body, facilitate the load, and increase the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

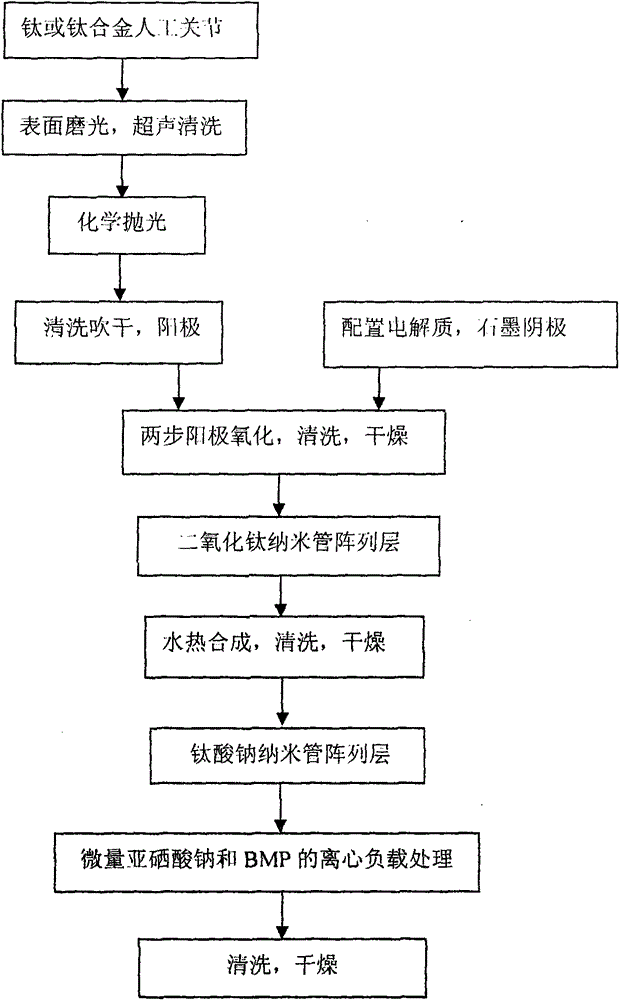

Method used

Image

Examples

Embodiment 1

[0028] (1) First choose pure titanium to process the artificial joint;

[0029] (2) Artificial joint surface pretreatment: After the surface is polished, wash it with acetone, deionized water and absolute ethanol in sequence for 10-30 minutes, and then wash it with HF and HNO 3 and water (volume ratio: 1:4:5) chemically polish for 20-40 seconds, rinse thoroughly with deionized water, and dry for use;

[0030] (3) Preparation of aqueous organic electrolyte solution: using ethylene glycol as a solvent, other active ingredients are: water 2vol% (volume percent), phosphoric acid 4vol% (volume percent), ammonium fluoride 0.3wt% (mass percent);

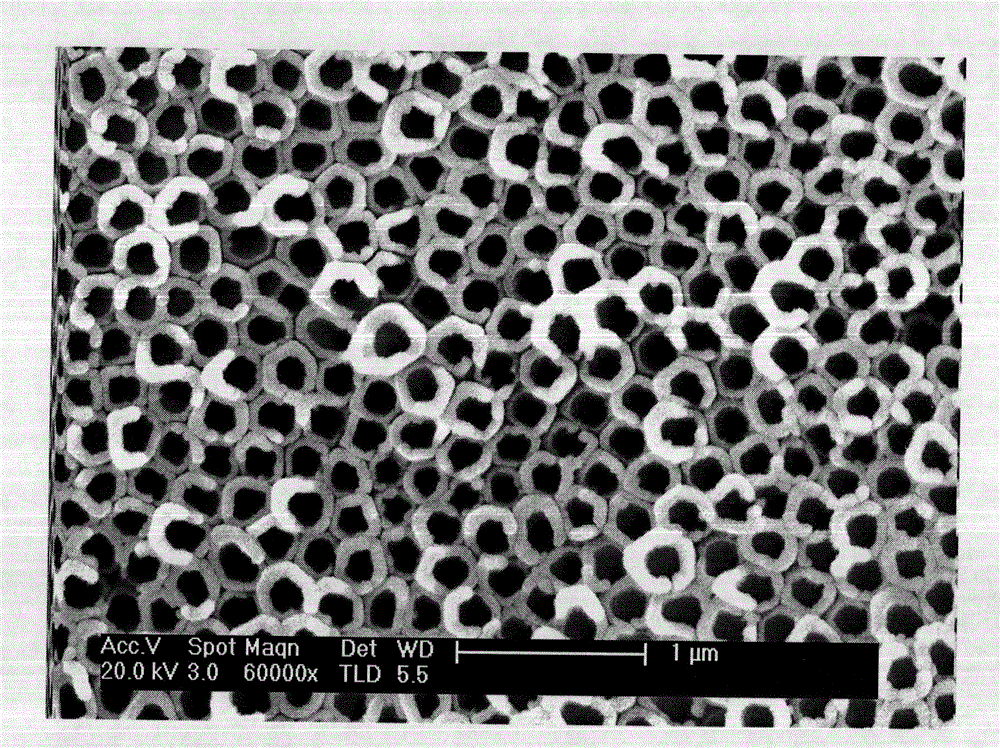

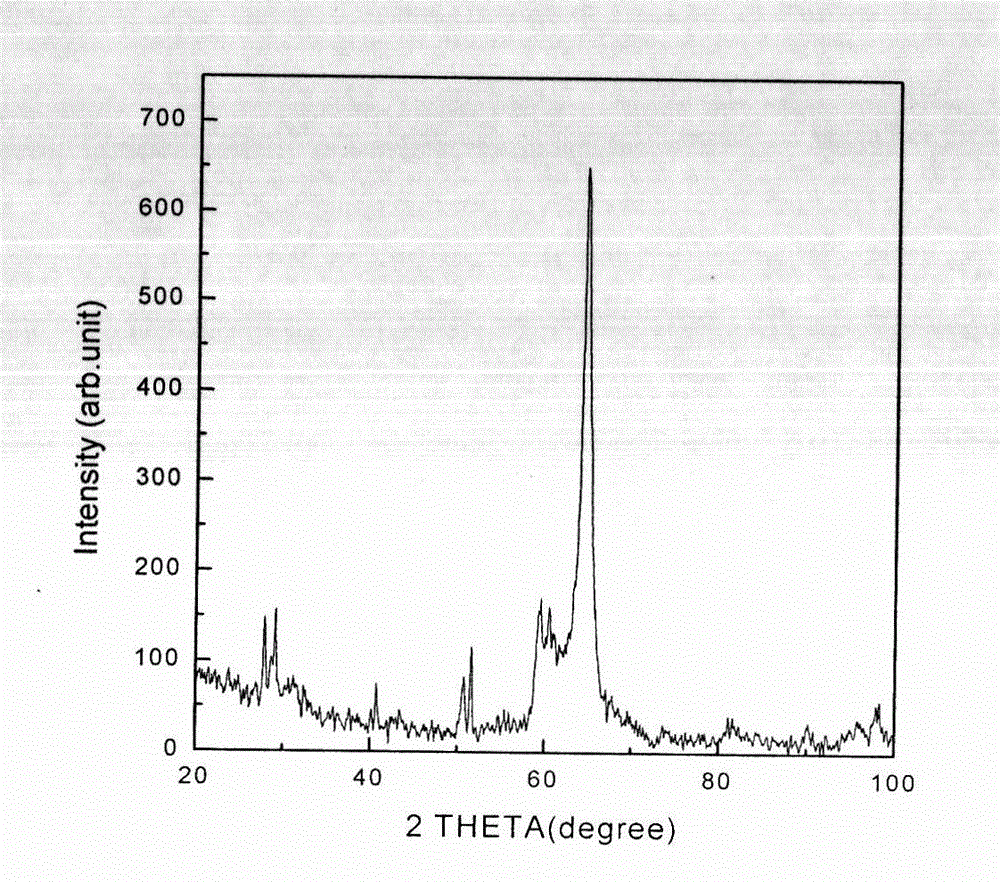

[0031] (4) Preparation of titanium dioxide nanotubes by two-step anodization: the surface pretreated artificial joint is used as the anode, graphite or platinum sheet is used as the cathode, and the first anodization is carried out in an aqueous organic electrolyte solution. The specific anodization parameters are: voltage 60V, the reactio...

Embodiment 2

[0036] (1) First choose titanium to process the artificial joint;

[0037] (2) Artificial joint surface pretreatment: After the surface is polished, wash it with acetone, deionized water and absolute ethanol in sequence for 30-60 minutes, and then wash it with HF and HNO 3 and water (volume ratio: 1:4:5) chemically polish for 40-60 seconds, then rinse thoroughly with deionized water, and blow dry with a hair dryer for use;

[0038] (3) Preparation of aqueous organic electrolyte solution: using ethylene glycol as a solvent, other active ingredients are: water 2vol% (volume percent), phosphoric acid 4vol% (volume percent), ammonium fluoride 0.5wt% (mass percent);

[0039] (4) Preparation of titanium dioxide nanotubes by two-step anodization: the surface pretreated artificial joint is used as the anode, graphite is used as the cathode, and the first anodization is carried out in an aqueous organic electrolyte solution. The specific anodization parameters are: voltage 80V, reactio...

Embodiment 3

[0044] (1) First choose pure titanium to process the artificial joint;

[0045] (2) Artificial joint surface pretreatment: after surface polishing, wash with acetone, deionized water and absolute ethanol in sequence for 60-90 minutes, and then wash with HF and HNO 3 and water (volume ratio: 1:4:5) chemically polish for 60-80 seconds, then rinse thoroughly with deionized water, and blow dry with a hair dryer for use;

[0046] (3) Preparation of aqueous organic electrolyte solution: using ethylene glycol as a solvent, other active ingredients are: water 4vol% (volume percent), phosphoric acid 6vol% (volume percent), ammonium fluoride 0.5wt% (mass percent);

[0047] (4) Preparation of titanium dioxide nanotubes by two-step anodization: the surface pretreated artificial joint is used as the anode, the platinum sheet is used as the cathode, and the first anodization is carried out in an aqueous organic electrolyte solution. The specific anodization parameters are: voltage 40V, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com