Silver-loaded antibacterial artificial joint and preparation method thereof

An artificial joint, silver-loaded antibacterial technology, which is applied in the field of replacing silver and achieves the effects of high sterilization efficiency, promotion of deposition growth, and resistance to drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) First choose Ti6Al4V alloy to process the artificial joint;

[0026] (2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. The time is 6 hours, and a sodium titanate bioactive coating with a microporous structure is obtained on the surface of the artificial joint.

[0027] (3) Silver doping treatment by immersion method: immerse the surface hydrothermally treated artificial joint at a concentration of 5×10 -2 mol / L AgNO 3 In solution, AgNO with an operating temperature of 60°C 3 The solution was kept constant using a water bath method. Stir with a magnetic stirrer, take out after soaking for 2 to 12 hours, ultrasonically clean with distilled water, and dry at room temper...

Embodiment 2

[0031] (1) First choose Ti6Al4V alloy to process the artificial joint;

[0032] (2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 120 degrees Celsius. The time is 6 hours.

[0033] (3) Silver doping treatment by immersion method: immerse the surface hydrothermally treated artificial joint at a concentration of 2×10 -1 mol / L AgNO 3 In solution, AgNO with an operating temperature of 60°C 3The solution was kept constant using a water bath method. Stir with a magnetic stirrer, take out after soaking for 2 to 12 hours, ultrasonically clean with distilled water, and dry at room temperature.

[0034] (4) Centrifugal load treatment of BMP: fix the artificial joint with silver-doped sodium titanate bioacti...

Embodiment 3

[0037] (1) First choose Ti6Al4V alloy to process the artificial joint;

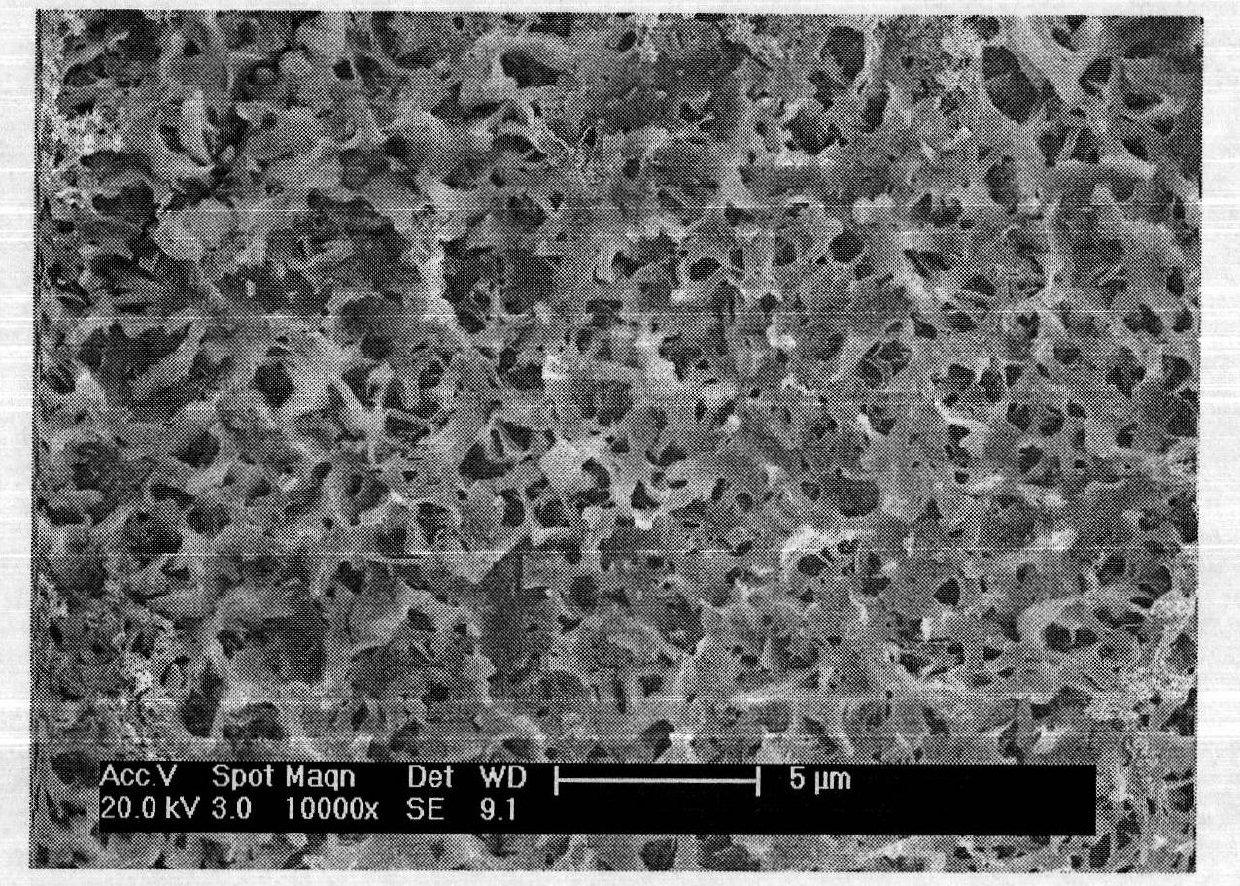

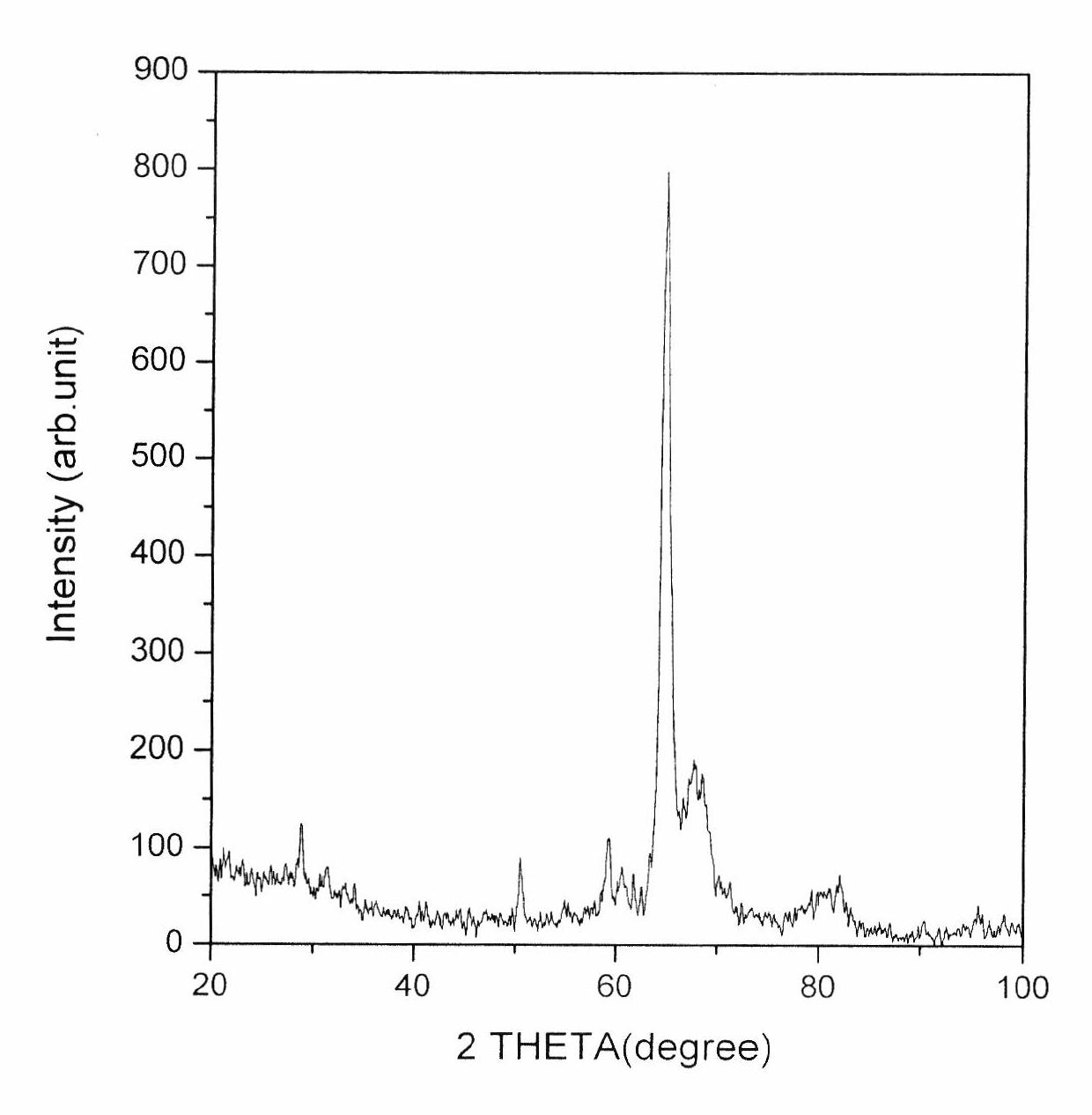

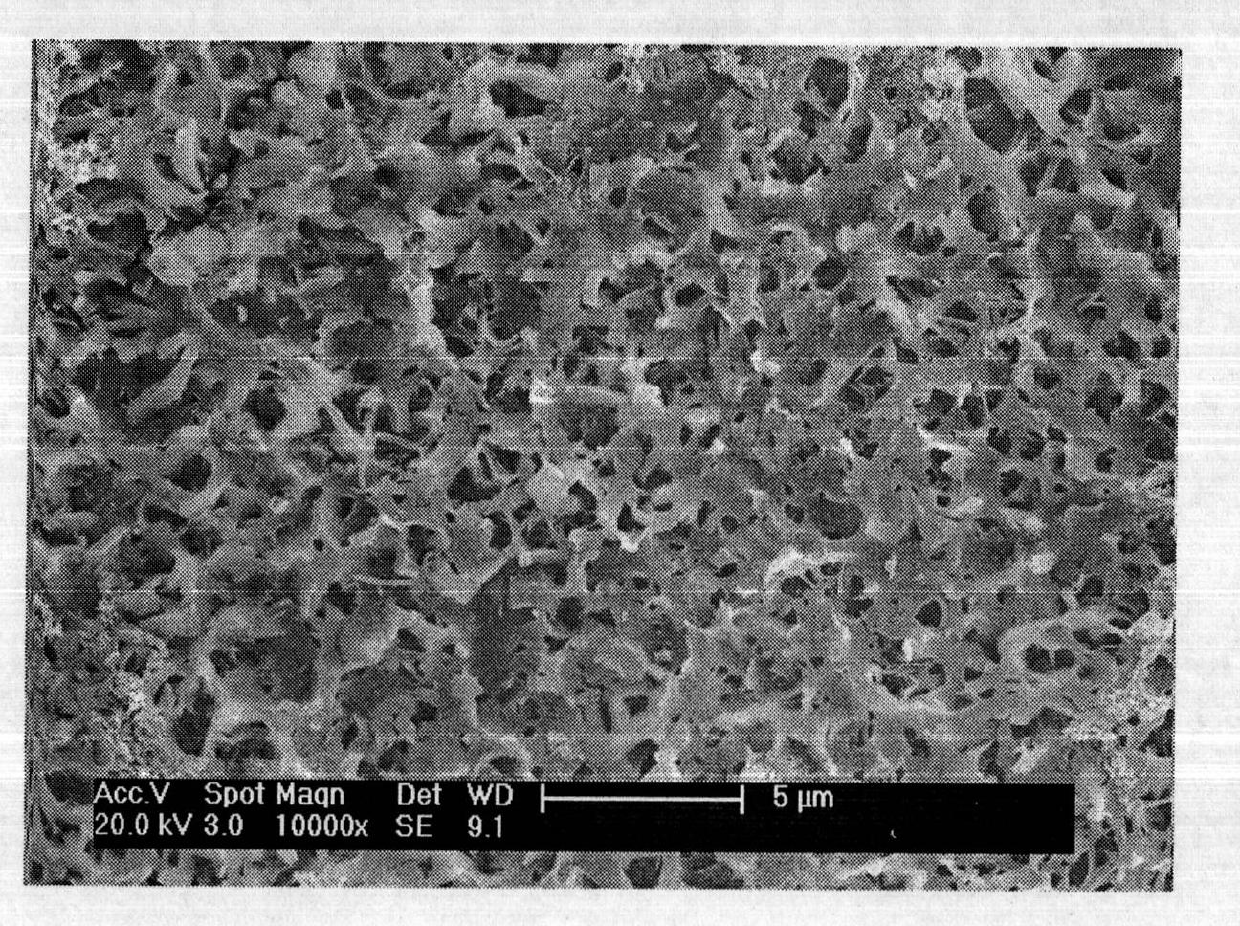

[0038] (2) Hydrothermal treatment of the artificial joint surface: the artificial joint is ground and polished, then ultrasonically cleaned with acetone, 70% alcohol, and distilled water, and the hydrothermal reaction is carried out with a sodium hydroxide aqueous solution with a concentration of 10mol / L, and the working temperature is 150 degrees Celsius. The time is 72 hours, and a sodium titanate bioactive coating with microporous structure is obtained on the surface of the artificial joint, and its SEM photos and XRD spectra are shown in figure 1 with figure 2 .

[0039] (3) Silver doping treatment by immersion method: immerse the surface hydrothermally treated artificial joint at a concentration of 5×10 -2 mol / L AgNO 3 In solution, AgNO with an operating temperature of 60°C 3 The solution was kept constant using a water bath method. Stir with a magnetic stirrer, take out after soaking for 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com