Photocatalytic diclofenac purification membrane and preparation method thereof

A technology of diclofenac and photocatalysis, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of increasing operational complexity and cost, MOFs instability, structural degradation, etc., and achieve strong visible light The effect of inducing redox capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

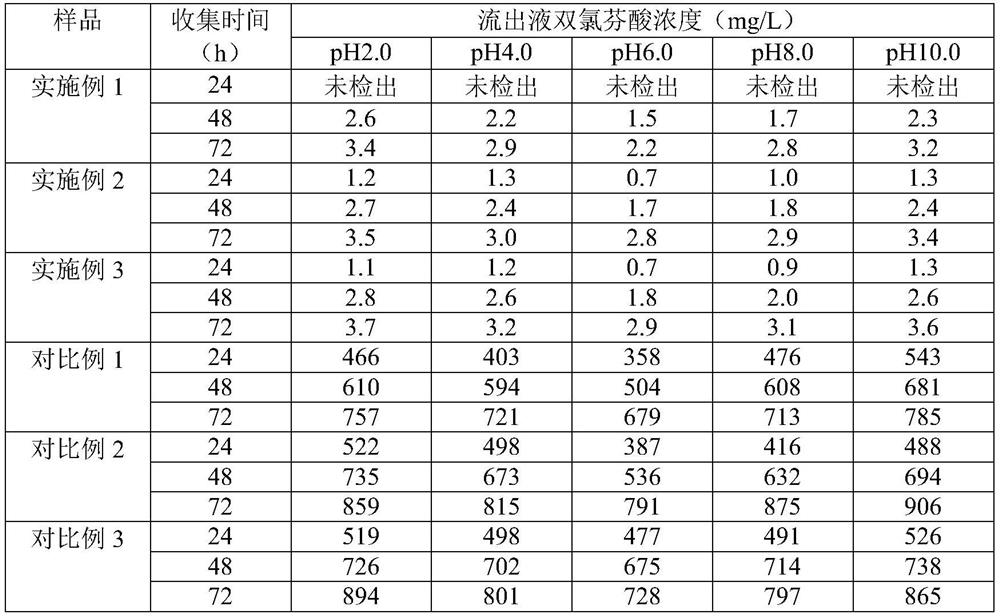

Embodiment 1

[0025] A photocatalytic diclofenac purification membrane and a preparation method thereof, comprising the steps of:

[0026] 1. Fully mix 0.204g of yttrium vanadate and 1.029g of potassium zirconium sulfate trihydrate and calcinate at 1200°C for 20h, then add 1.44g of mellitic acid trianhydride to 25mL of dimethylacetamide and formic acid In a 2:1 mixed solvent, the solution was sonicated until it was completely dissolved to obtain a metal-organic framework material MOFs-YVZr synthesis liquid.

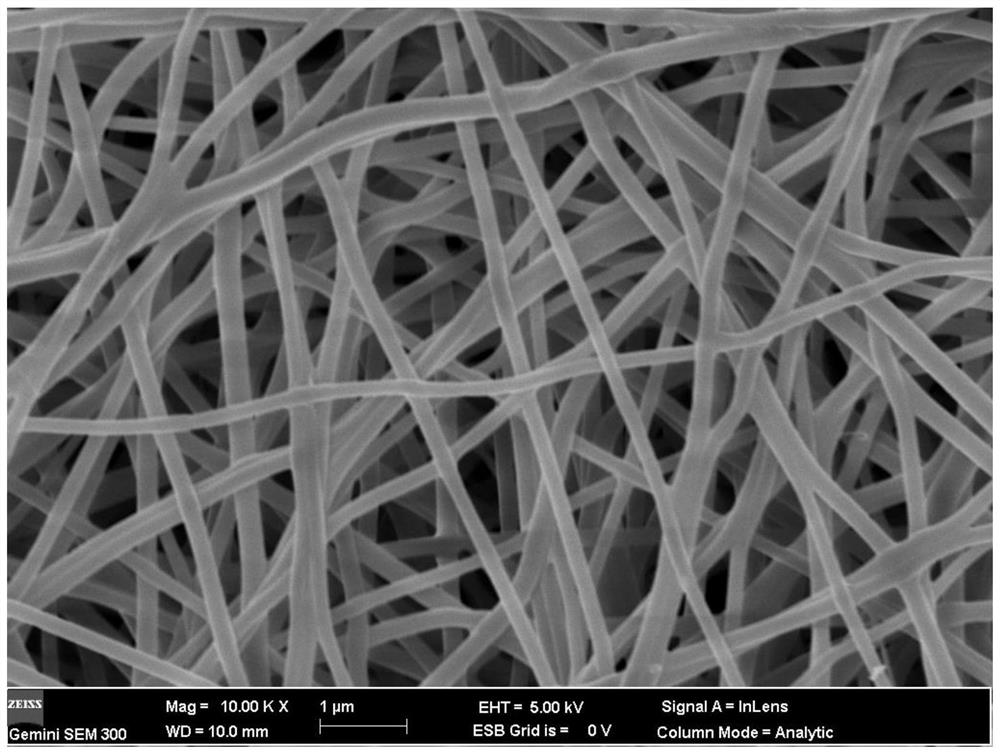

[0027] 2. Add 40g of yttria-stabilized zirconia powder and 160g of thermoplastic polyurethane elastomer into a planetary grinder and grind for 36 hours at 240°C to obtain a melt. After vacuum degassing the melt, spin at a melt temperature of 245°C. Under the conditions of voltage of 22kV, flow rate of 1.2mL / h, receiving distance of 22cm, ambient temperature of 10°C, and relative humidity of 25%, a highly elastic doped polyurethane nanofiber membrane was obtained by melt electrospinning...

Embodiment 2

[0030] A photocatalytic diclofenac purification membrane and a preparation method thereof, comprising the steps of:

[0031] 1. Fully mix 0.163g of yttrium vanadate and 0.823g of potassium zirconium sulfate trihydrate and calcinate at 1100°C for 18h, then add 1.152g of mellitic acid trianhydride to 25mL of dimethylacetamide and formic acid In a 3:1 mixed solvent, the solution was sonicated until it was completely dissolved to obtain a metal-organic framework material MOFs-YVZr synthesis liquid.

[0032] 2. Add 40g of yttria-stabilized zirconia powder and 120g of thermoplastic polyurethane elastomer into a planetary grinder and grind for 24 hours at 230°C to obtain a melt. After vacuum degassing the melt, spin at a melt temperature of 250°C. Under the conditions of a voltage of 20kV, a flow rate of 1.0mL / h, a receiving distance of 20cm, an ambient temperature of 0°C, and a relative humidity of 30%, a highly elastic doped polyurethane nanofiber membrane was obtained by melt elec...

Embodiment 3

[0035] A photocatalytic diclofenac purification membrane and a preparation method thereof, comprising the steps of:

[0036] 1. Fully mix 0.245g of yttrium vanadate and 1.235g of potassium zirconium sulfate trihydrate and calcinate at 1500°C for 24h, then add 1.728g of mellitic acid trianhydride to 25mL of dimethylacetamide and formic acid In a 1:1 mixed solvent, the solution was sonicated until it was completely dissolved to obtain a metal-organic framework material MOFs-YVZr synthesis liquid.

[0037]2. Add 40g of yttria-stabilized zirconia powder and 200g of thermoplastic polyurethane elastomer into a planetary grinder and grind for 48 hours at 250°C to obtain a melt. After vacuum degassing the melt, spin at a melt temperature of 230°C. Under the conditions of voltage of 25kV, flow rate of 1.5mL / h, receiving distance of 25cm, ambient temperature of 15°C, and relative humidity of 20%, a highly elastic doped polyurethane nanofiber membrane was obtained by melt electrospinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com