Electromagnetic ultrasonic critical refraction longitudinal wave excitation device

A technology of critical refraction and electromagnetic ultrasound, which is applied in the generation of ultrasonic/sonic/infrasonic waves, measuring devices, and the use of sound waves/ultrasonic/infrasonic waves to analyze solids, etc., to achieve the effects of improving detection efficiency, small devices, and simple methods of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

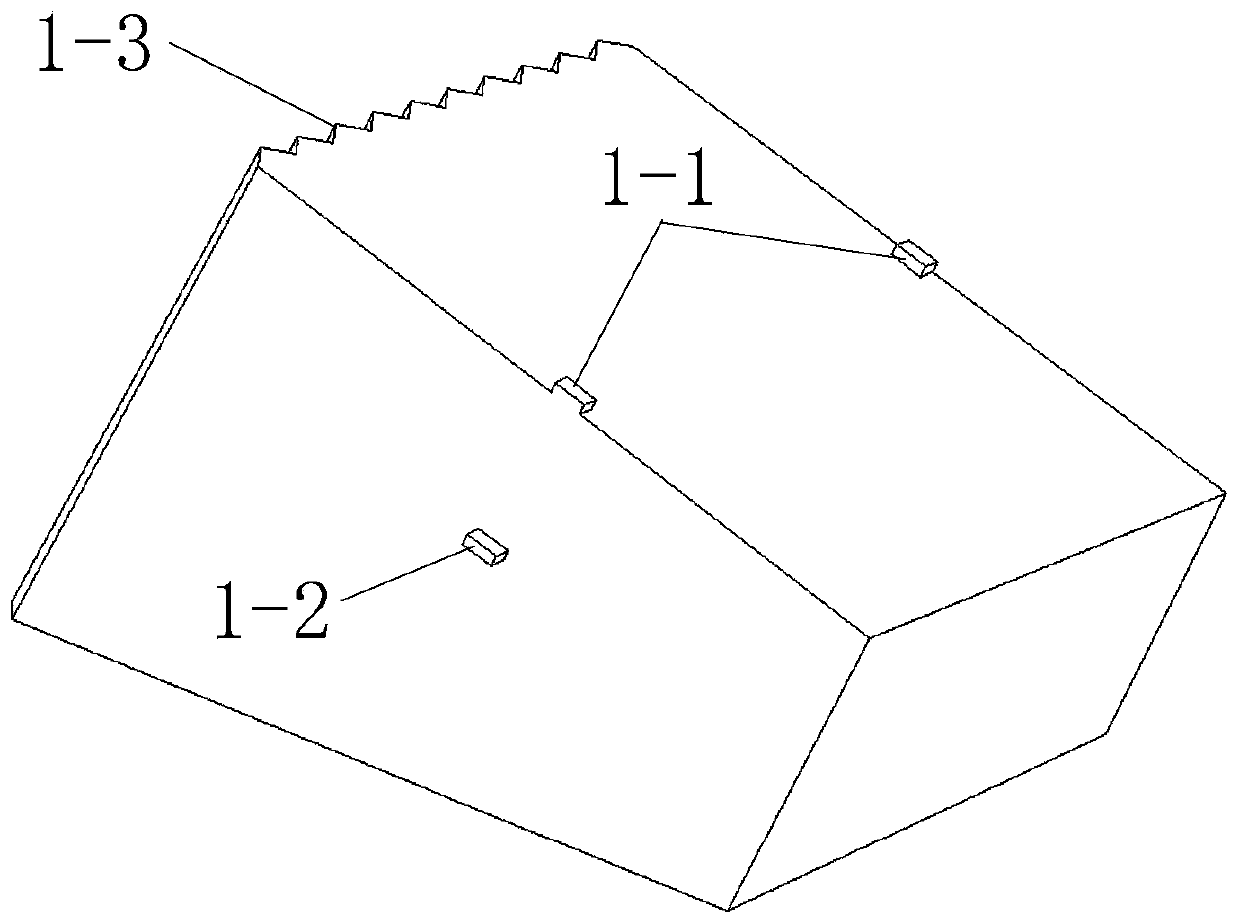

[0035] The wedge 1 is made of acrylic material, with a horizontal length of 30 mm; the setting position of the support block 1-2 is 10 mm from the upper surface of the wedge 1 .

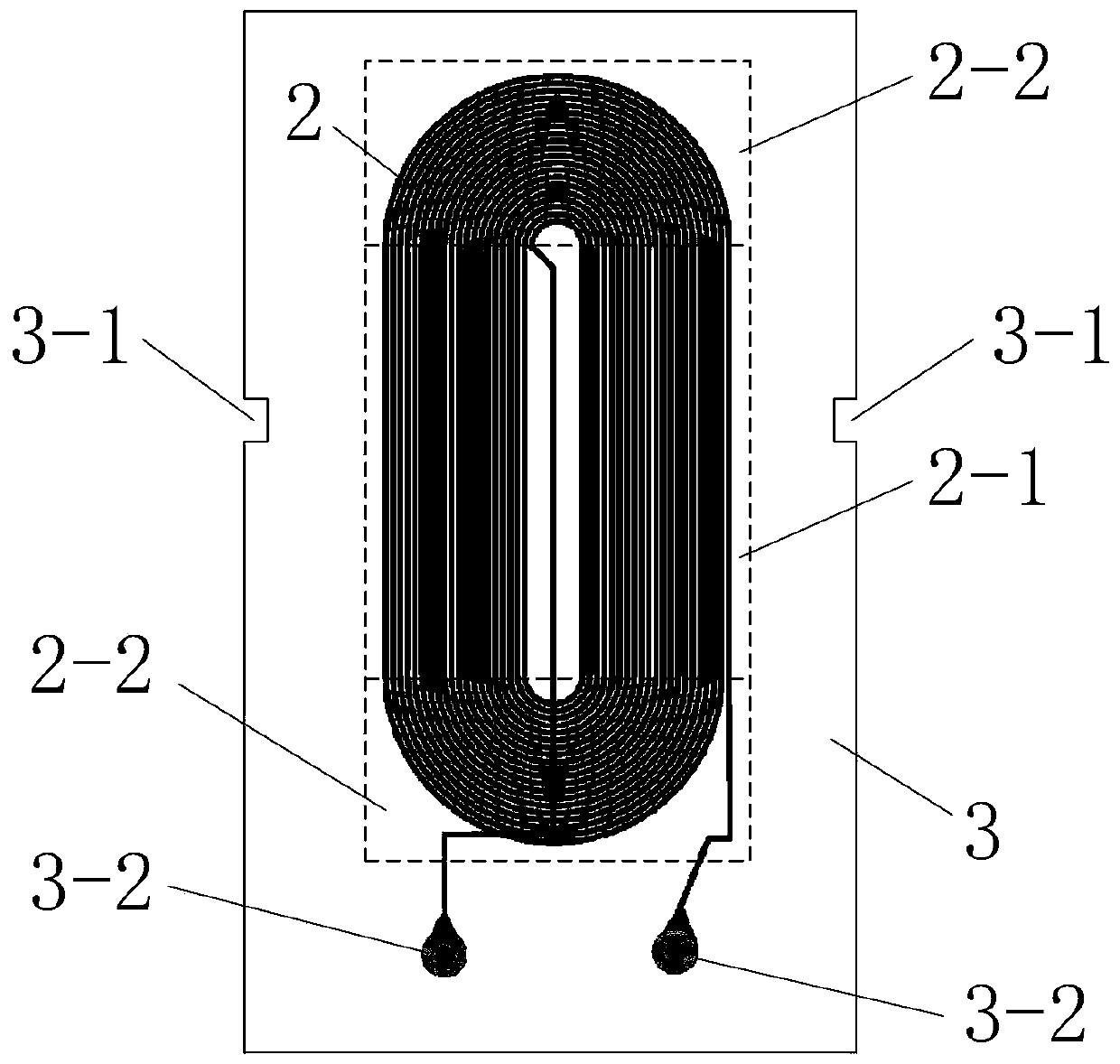

[0036] The excitation coil 2 is oblong, the copper thickness is 0.3mm, the number of turns is 20, the width (horizontal length) of a single coil is 0.4mm, and the distance between the coils is 0.1mm; in order to form a loop, the excitation area 2-1 is divided into two parts: left and right. The two regions are connected through the connecting region 2-2, and the current directions in the two regions are opposite at the same time, the distance between the two regions is 3.6mm, and the length (vertical length) of a single coil is 30mm.

[0037] The dimensions of the printed circuit board 3 are 30×70 mm×0.5 mm. And a 2*4mm fixed opening 3-1 is cut out at the position corresponding to the horizontal center position of the racetrack-shaped excitation coil on both sides of the printed circuit board 3 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com