TiNb2O7 material with preferential growth of (010) crystal face and preparation method and application of TiNb2O7 material

A technology of crystal plane and solvent, applied in the field of TiNb2O7 material and its preparation, can solve the problems of short lithium ion migration distance, difficult mass production, complicated process, etc., and achieve low cost, high compaction density and volume energy density, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 7.986g TiO 2 Dissolve in 50mL water, stir well, then weigh 35.588g Nb(OH) 5 Added to the above solution and vigorously stirred for 1 hour, and the obtained suspension was air-dried at 150° C. for 12 hours to obtain a precursor powder. The obtained dry precursor powder is placed in a vibrating sieve, and the powder passing through the vibrating sieve is collected for future use.

[0039] (2) The obtained powder was placed in a muffle furnace, under a pure oxygen atmosphere, the temperature was gradually raised to 1000° C. at 5° C. / min and kept for 10 hours.

[0040] (3) Subsequently, the temperature is lowered from 1000°C to 300°C at a cooling rate of 0.5°C / min, and then naturally cooled to room temperature to obtain TiNb grown on the (010) crystal plane 2 o 7 .

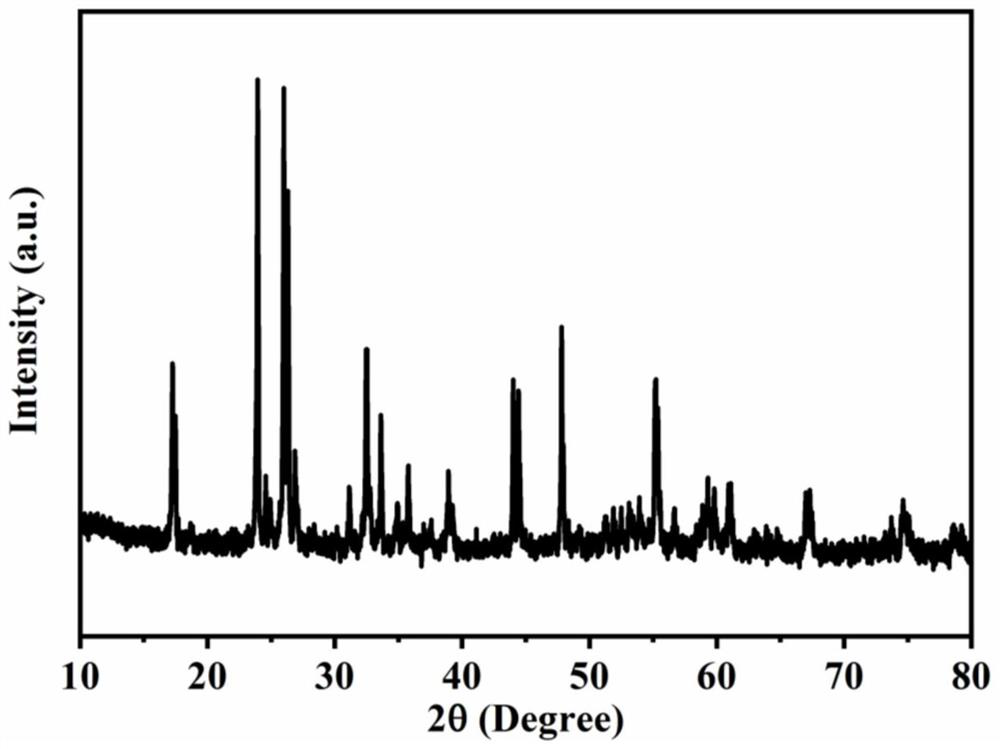

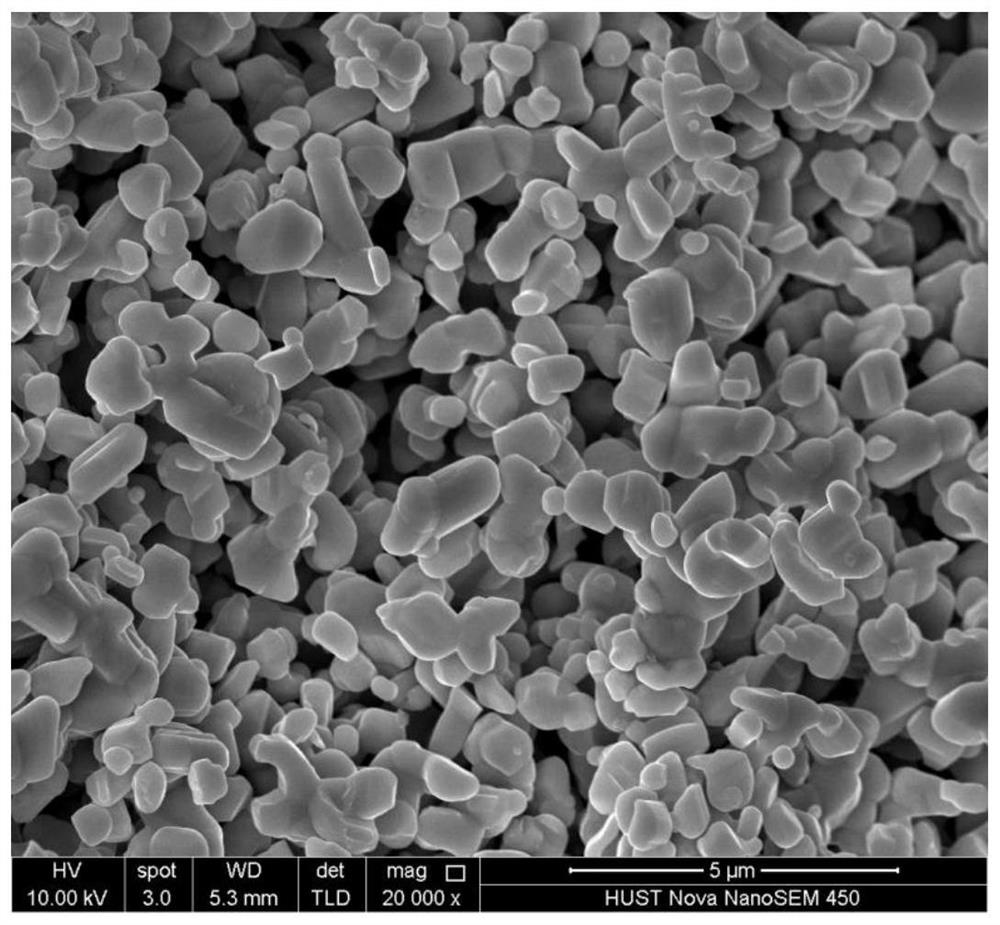

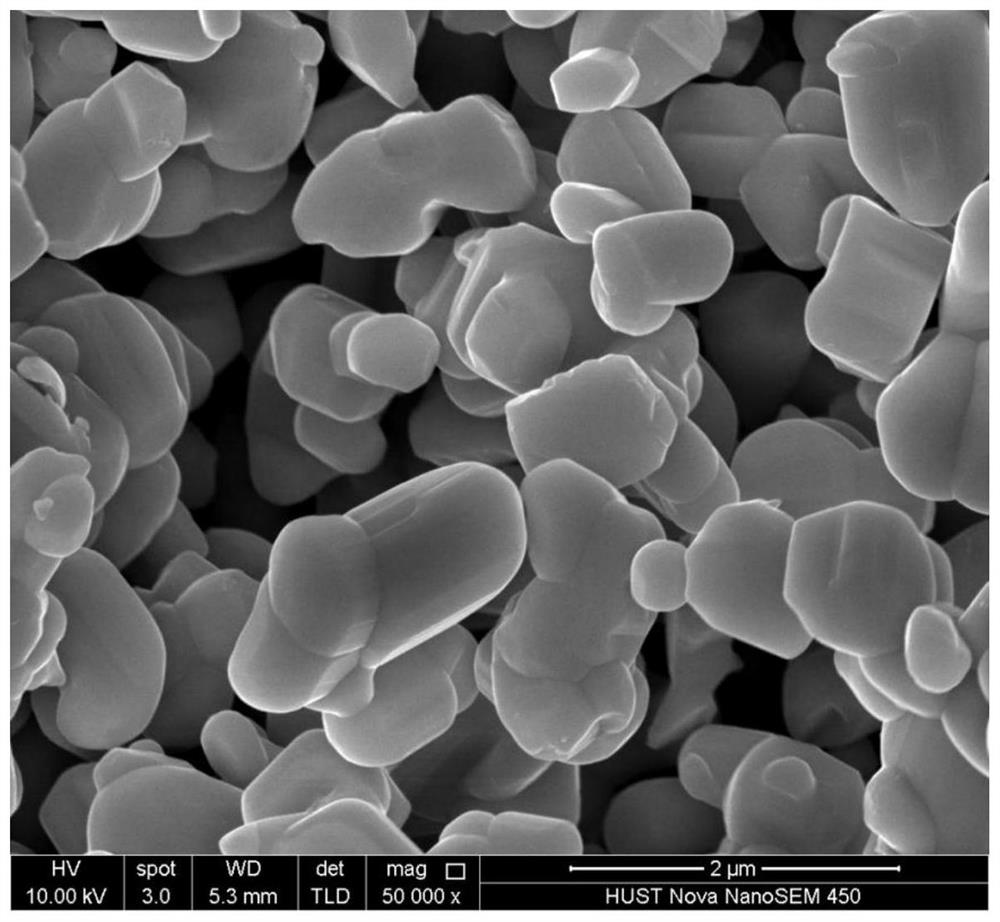

[0041] figure 1 It is the TiNb prepared in Example 1 2 o 7 X-ray diffraction pattern of . From figure 1 It can be seen that the diffraction characteristic peaks appearing in the sample are al...

Embodiment 2

[0048] (1) Weigh 79.86g TiO 2 Place in 100mL absolute ethanol, then weigh 265.81g Nb 2 o 5 Add to the above mixture and stir evenly, then planetary ball mill for 10 hours, freeze-dry the obtained mixture for 24 hours to obtain precursor powder, solid-phase ball mill the obtained dry precursor powder for 1 hour again, and collect the powder for later use.

[0049] (2) The obtained powder was placed in a muffle furnace, under a 50% oxygen atmosphere, the temperature was gradually raised to 1300° C. at 3° C. / min and kept for 24 hours.

[0050] (3) Subsequently, the temperature is lowered from 1300°C to 600°C at a cooling rate of 5°C / min, and then naturally cooled to room temperature to obtain TiNb dominated by crystallographic (010) crystal planes 2 o 7 .

[0051] Figure 7 Is the TiNb prepared in Example 2 2 o 7 The rate performance diagram of the coin full battery test prepared as the negative electrode active material and the commercial lithium iron phosphate pole piece...

Embodiment 3

[0053] (1) Weigh 39.93g TiO 2 Placed in 50mL absolute ethanol, then weighed 132.91g Nb 2 o 5 Add to the above mixture and stir evenly, then planetary ball mill for 5 hours, freeze-dry the obtained mixture for 24 hours to obtain precursor powder, solid phase ball mill the obtained dry precursor powder for 1 hour again, collect the powder for later use.

[0054] (2) The obtained powder was placed in a muffle furnace, under a 50% oxygen atmosphere, the temperature was gradually raised to 1100° C. at 3° C. / min and kept for 24 hours.

[0055] (3) Subsequently, the temperature was lowered from 1100°C to 500°C at a cooling rate of 2°C / min, and then naturally cooled to room temperature to obtain TiNb dominated by crystallographic (010) crystal planes 2 o 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com