High-performance N type argyrodite thermoelectric material and preparation method thereof

A technology of thermoelectric materials and sulfur-argentine ore, which is applied in the direction of thermoelectric device node lead-out materials, chemical instruments and methods, and elemental compounds other than selenium/tellurium, can solve the practical application of limited liquid thermoelectric materials, N Solve the problems such as the slow development of type materials, and achieve the effect of low thermal conductivity, excellent ZT value, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

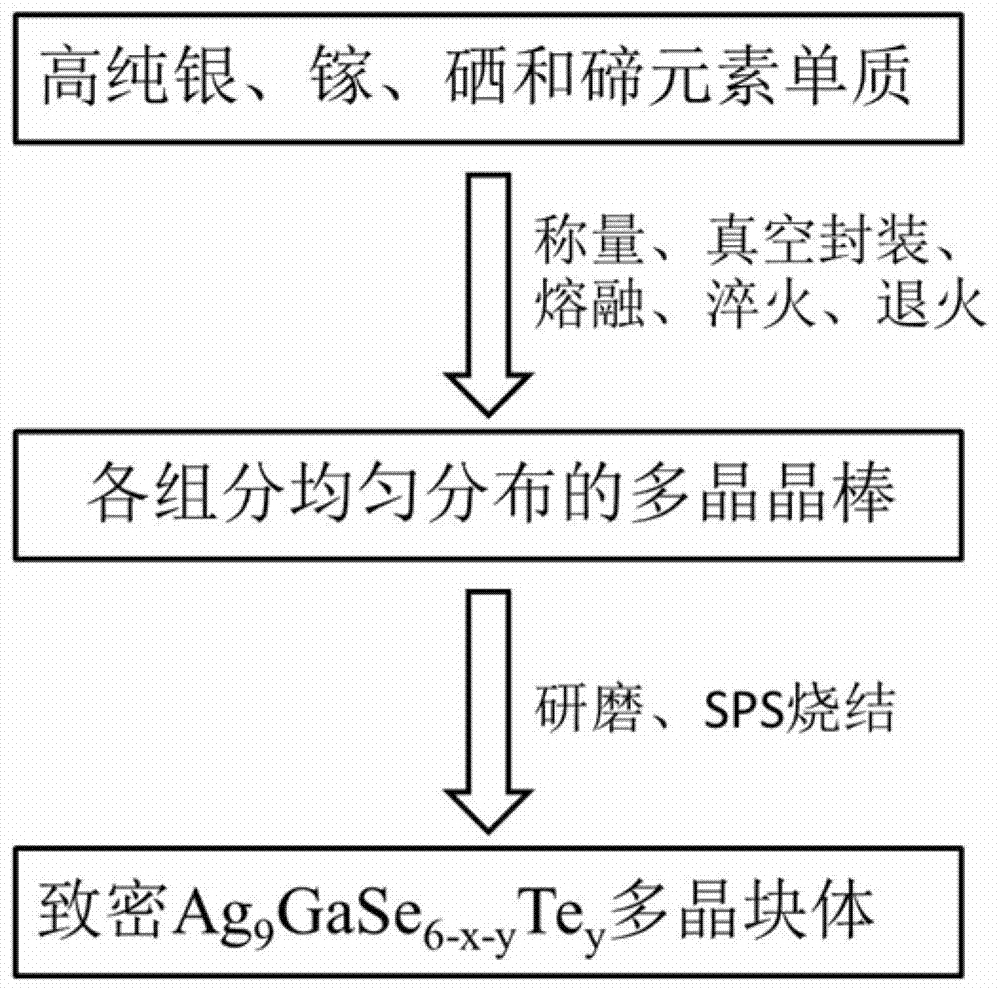

Method used

Image

Examples

Embodiment 1

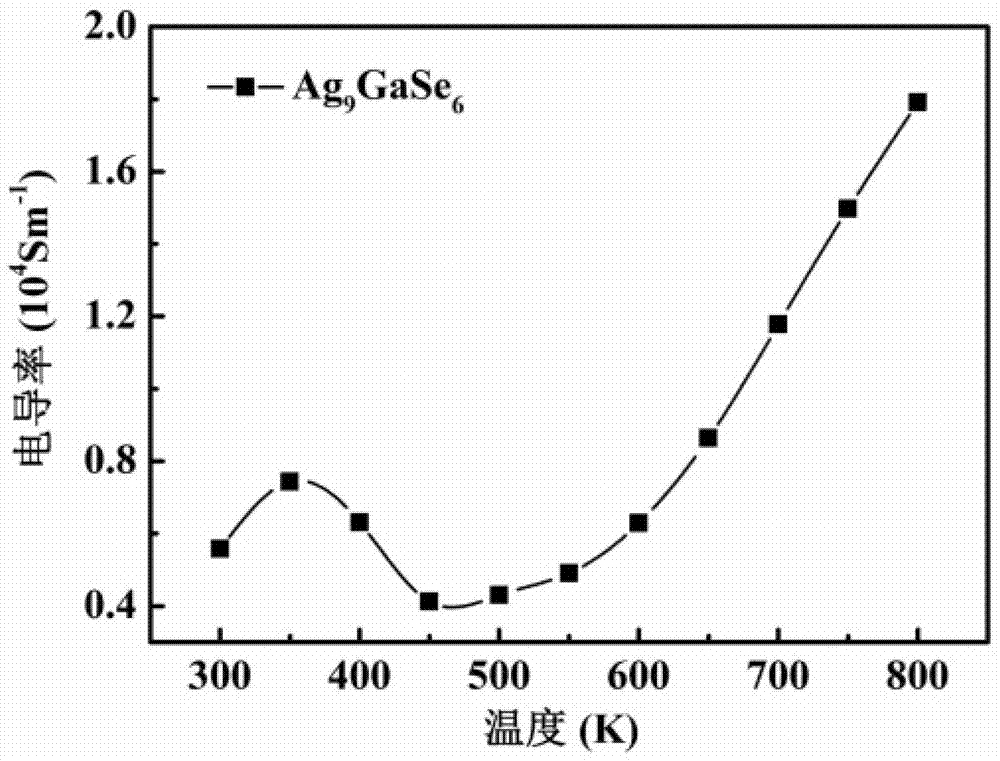

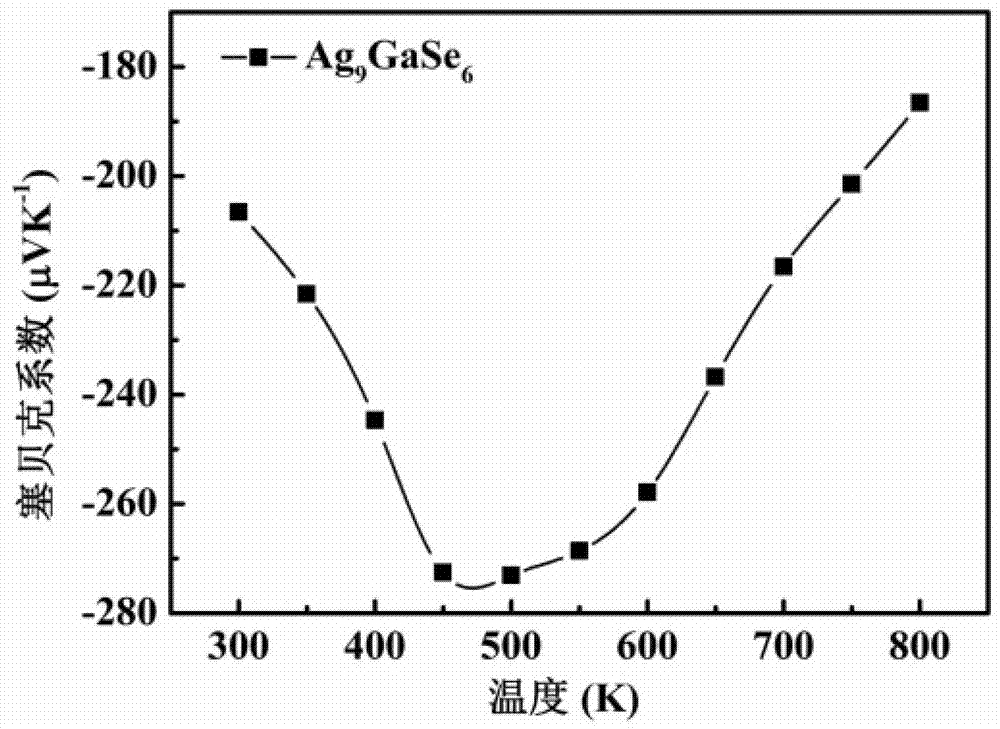

[0054] Example 1: Ag 9 GaSe 6 Polycrystalline bulk of semiconductor material

[0055] The elemental raw materials Ag, Ga and Se were weighed according to the molar ratio of 9:1:6, and then packaged in a quartz tube. The temperature was raised to 800°C at a heating rate of 4°C / min, then to 1100°C at a rate of 2°C / min, melted at this temperature for 12 hours, and then quenched in a mixture of ice and water. Put the quenched quartz tube into a tube furnace for annealing at 550°C for 120 hours, then cool to room temperature with the furnace;

[0056] The product obtained after annealing was ground into powder, and subjected to spark plasma sintering at a sintering temperature of 560° C., a pressure of 40 MPa, and a sintering time of 10 minutes to obtain a dense bulk material.

[0057] Such as Figures 2A-2D As shown, the obtained Ag 9 GaSe 6 The thermoelectric performance measurement of the polycrystalline block shows that in the measured temperature range (300-800K), the ma...

Embodiment 2

[0058] Example 2: Ag 9 GaSe 5.98 Polycrystalline bulk of semiconductor material

[0059] The elemental raw materials Ag, Ga and Se were weighed according to the molar ratio of 9:1:5.98, and then packaged in a quartz tube. The temperature was raised to 800°C at a heating rate of 4°C / min, then to 1100°C at a rate of 2°C / min, melted at this temperature for 12 hours, and then quenched in a mixture of ice and water. Put the quenched quartz tube into a tube furnace for annealing at 550°C for 120 hours, then cool to room temperature with the furnace;

[0060] The product obtained after annealing was ground into powder, and subjected to spark plasma sintering at a sintering temperature of 560° C., a pressure of 40 MPa, and a sintering time of 10 minutes to finally obtain a dense bulk material.

[0061] Such as Figure 3A-3D As shown, the obtained Ag 9 GaSe 5.98 The thermoelectric performance measurement of the polycrystalline block shows that in the measured temperature range (3...

Embodiment 3

[0062] Example 3: Ag 9 GaSe 5.97 Polycrystalline bulk of semiconductor material

[0063] The elemental raw materials Ag, Ga and Se were weighed according to the molar ratio of 9:1:5.97, and then packaged in a quartz tube. The temperature was raised to 800°C at a heating rate of 4°C / min, then to 1100°C at a rate of 2°C / min, melted at this temperature for 12 hours, and then quenched in a mixture of ice and water. Put the quenched quartz tube into a tube furnace for annealing at 550°C for 120 hours, then cool to room temperature with the furnace;

[0064]The product obtained after annealing was ground into powder, and subjected to spark plasma sintering at a sintering temperature of 560° C., a pressure of 40 MPa, and a sintering time of 10 minutes to obtain a dense bulk material.

[0065] Such as Figures 4A-4D As shown, the obtained Ag 9 GaSe 5.97 The thermoelectric performance measurement of the polycrystalline block shows that in the measured temperature range (300-800K)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com