Composite material of skutterudite filling substrate and preparation method thereof

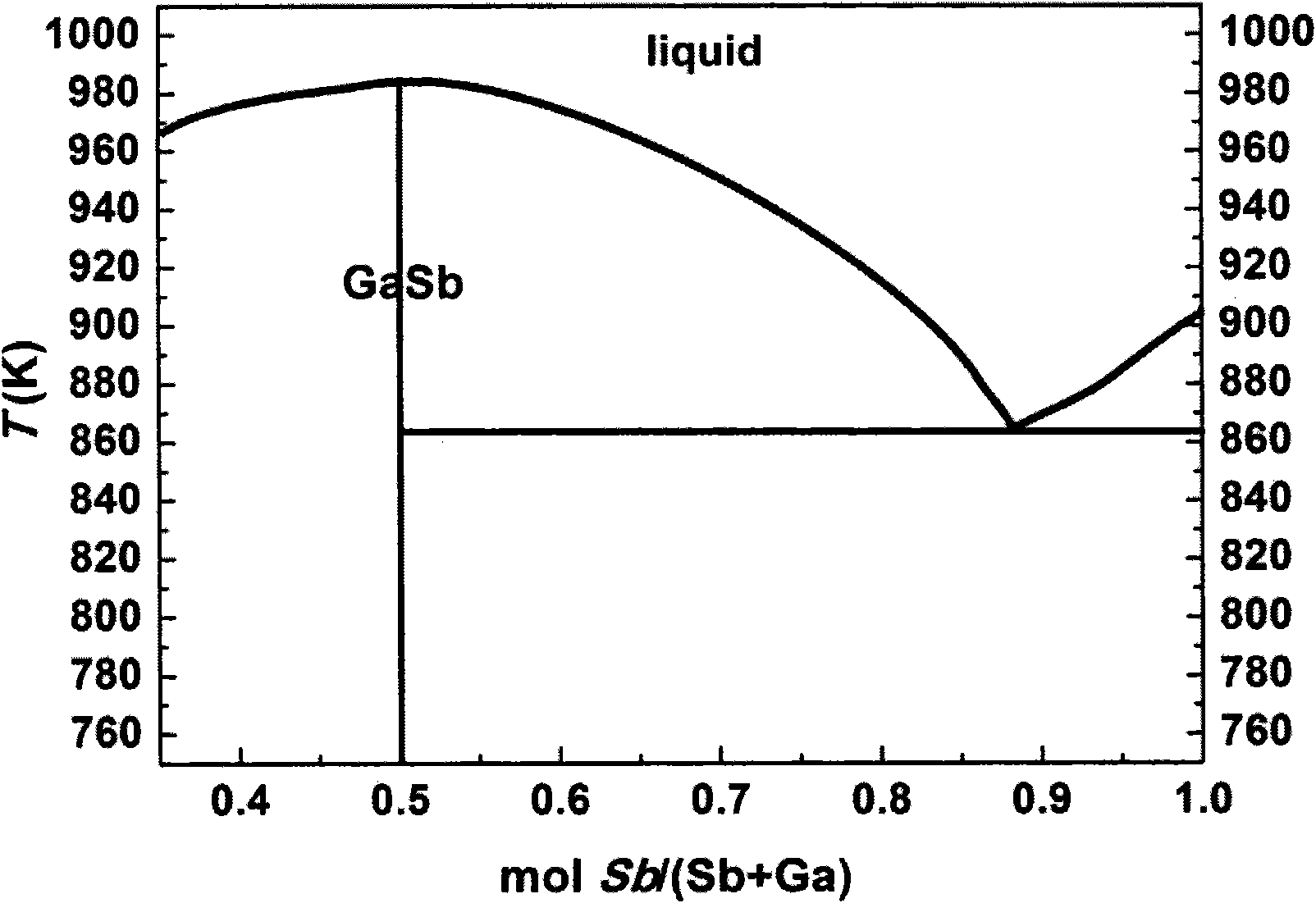

A technology for filling skutterudite and composite materials, which is applied in the direction of cobalt compounds, chemical instruments and methods, and thermoelectric device node lead-out materials, etc. melting point etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

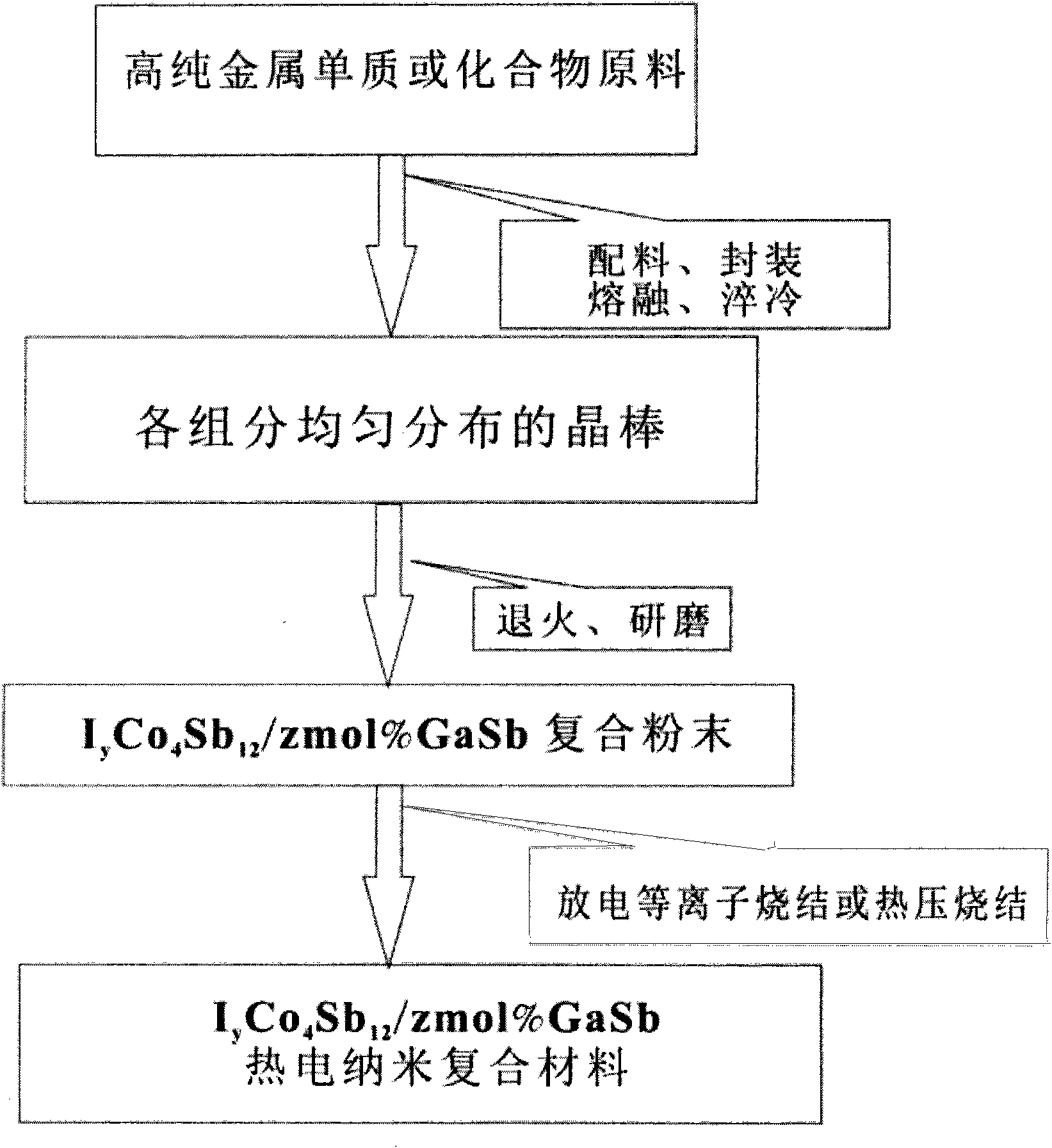

[0116] The preparation method of composite material of the present invention comprises the steps:

[0117] Weighing and packaging I, Co, Sb and Ga, the weighing process is carried out according to the stoichiometric ratio, wherein I is at least one of Yb, Eu, Ce, La, Nd, Ba and Sr,

[0118] obtaining a molten mixture of I, Co, Sb and Ga, wherein I is at least one of Yb, Eu, Ce, La, Nd, Ba and Sr,

[0119] said molten mixture is quenched to form a solid bulk material;

[0120] The solid matrix material is annealed; the annealed solid matrix material is obtained

[0121] The annealed solid matrix material is made into powder;

[0122] The powder is consolidating to form the composite material.

[0123] Specifically, the melting temperature of the molten mixture is 1000-1200°C.

[0124] Specifically, a quenching medium selected from air, water, brine, oil or liquid nitrogen or other quenching methods are used for quenching. Other quenching methods include Melt spinning and t...

Embodiment 1

[0146] The high-purity metal raw materials Yb block, Co block, Sb block, and Ga block are mixed in the glove box according to the molar ratio of 0.26:4:12:0 and 0.26:4:12.2:0.2, respectively, and the raw materials are sealed in the inner wall for evaporation. The carbon-filmed quartz tube is sealed with an argon plasma flame while drawing a vacuum. The packaged quartz tube was heated to 1100°C at a heating rate of 2°C / min and held for 20 hours, then quenched in saturated brine. The quenched ingot and the quartz tube were annealed at 730°C for 240 hours to obtain the composition Yb 0.26 co 4 Sb 12 and Yb 0.26 co 4 Sb 12 / 1.2mol% GaSb bulk. After the block is ground into fine powder, discharge plasma sintering is carried out, the sintering temperature is 600°C, the holding time is 5 minutes, and the pressure is 50MPa. The phase analysis, microstructure and thermoelectric properties of the obtained materials are as follows: Figure 4-9 shown.

Embodiment 2

[0148] The high-purity raw materials Yb block, Co block, Sb block, and Ga block are mixed in a glove box at a molar ratio of 0.26:4:12.3:0.3, and the raw materials are sealed in a quartz tube with a built-in tantalum foil crucible. Encapsulation was performed with an argon plasma flame. The packaged quartz tube was heated to 1200°C at a heating rate of 3°C / min and held for 10 hours, then quenched in saturated brine. The quenched ingot and the quartz tube were annealed at 750°C for 300 hours to obtain a composition of Yb 0.26 co 4 Sb 12 / 1.8mol% GaSb bulk. After the block is ground into fine powder, discharge plasma sintering is carried out, the sintering temperature is 600°C, the holding time is 10 minutes, and the pressure is 60MPa. The maximum ZT value of the obtained composite thermoelectric material is 1.35 (850K).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com