Metal-doped tungsten disulfide thermoelectric material and preparation method

A technology of thermoelectric material and tungsten disulfide, which is applied in the direction of lead wire material of thermoelectric device and the manufacture/processing of thermoelectric device, etc. The effect of easy mass preparation, improved ZT value, and high Seebeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

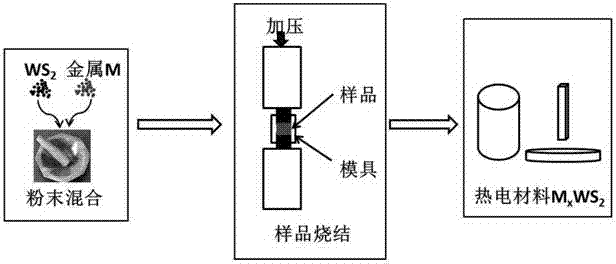

[0036] Ti-doped Ti x WS 2 , the specific preparation method is as follows:

[0037] (1) Solid mixing: when x=0.1, according to Ti and WS 2 Weigh Ti and WS at a molar ratio of 0.1 2 Powder, the Ti powder is 325 mesh (45 μm), the total mass of the powder is 10g, and then the two are put into an agate mortar, and mechanically ground for 90min with a grinder at 90rpm to mix the two evenly.

[0038] (2) Sample sintering: Put the uniformly mixed solid into a graphite mold with an inner diameter of 13.1mm, then put the mold into the furnace body of the SPS sintering instrument, pressurize to 50MPa, and then evacuate, when the vacuum reaches 5Pa , start sintering, gradually increase the current, raise the temperature to 1500°C after 30 minutes, keep it for 10 minutes, then start to cool down, close the sintering program, remove the pressure, adjust the current to 0, and let the sample cool down naturally.

Embodiment 2

[0040] V doped V x WS 2 , the preparation method is as follows:

[0041] (1) Solid mixing: when x=0.2, press V and WS 2 Weigh V and WS at a molar ratio of 0.2 2 Powder, the size of the V powder is 100-200 mesh, and then the powder is put into an agate mortar, the total mass of the powder is 10g, and the grinder is used for mechanical grinding at 90rpm for 90min to mix the two evenly.

[0042] (2) Sample sintering: Put 10g of solids mixed uniformly into a graphite mold with an outer diameter of 40mm and an inner diameter of 13.1mm, then put the mold into the sintering furnace body, apply a pressure of 6.3KN to make the pressure reach 50MPa, and then Start to raise the temperature, raise the temperature to 1500°C after 40 minutes, keep the temperature for 10 minutes, then start to lower the temperature, close the sintering program, release the pressure, and let the sample cool down naturally.

Embodiment 3

[0044] Ta doped Ta x WS 2 , the preparation method is as follows:

[0045] (1) Solid mixing: when x=0.05, according to Ta and WS 2 Weigh Ta and WS at a molar ratio of 0.05 2 Powder, the size of the Ta powder used here is 325 mesh, and the total powder mass is 10g. The weighed solid is put into a mortar, and mechanically ground for 90min with a grinder at 90rpm to mix the two evenly.

[0046] (2) Sample sintering: Put 10g of solids mixed evenly into a graphite mold, then put the mold into the sintering furnace body, apply a pressure of 6.3KN, make the pressure reach 50MPa, vacuumize to 5Pa, then start to heat up, after 30min Raise the temperature to 1500°C, keep the temperature constant for 10 minutes, then start to cool down, close the sintering program, release the pressure, and let the sample cool down naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com