Patents

Literature

88results about How to "Reduce conductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrosurgical instrument and method of use

ActiveUS7087054B2Reduce conductancePrevent any substantial dehydrationElectrotherapySurgical instruments for heatingEngineeringMedical device

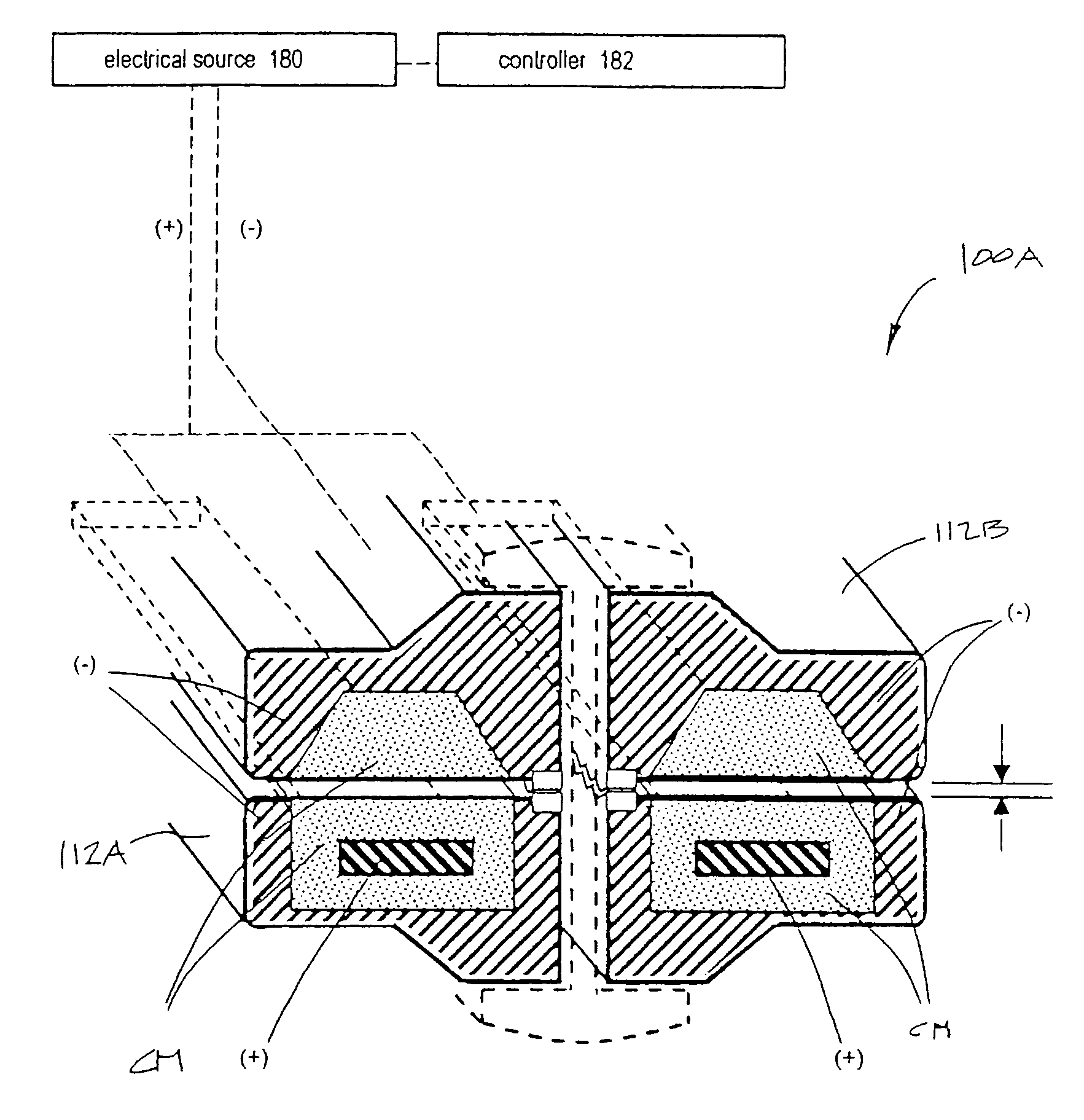

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane that carries a recessed central portion. In another embodiment, the controller coupled to the Rf source is adapted to switch from a power control operational mode to a voltage controlled operational mode at a selected transition impedance level.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

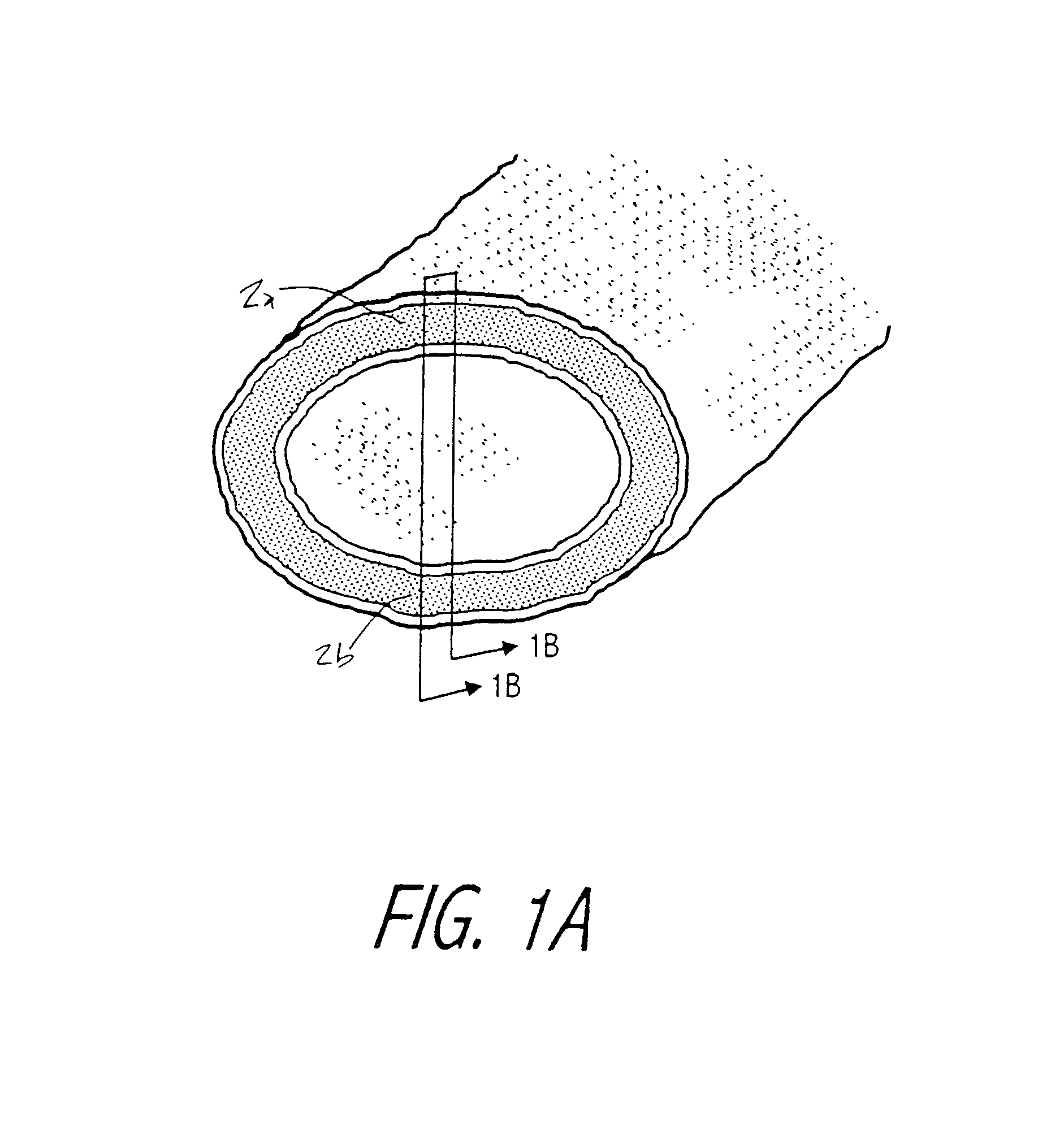

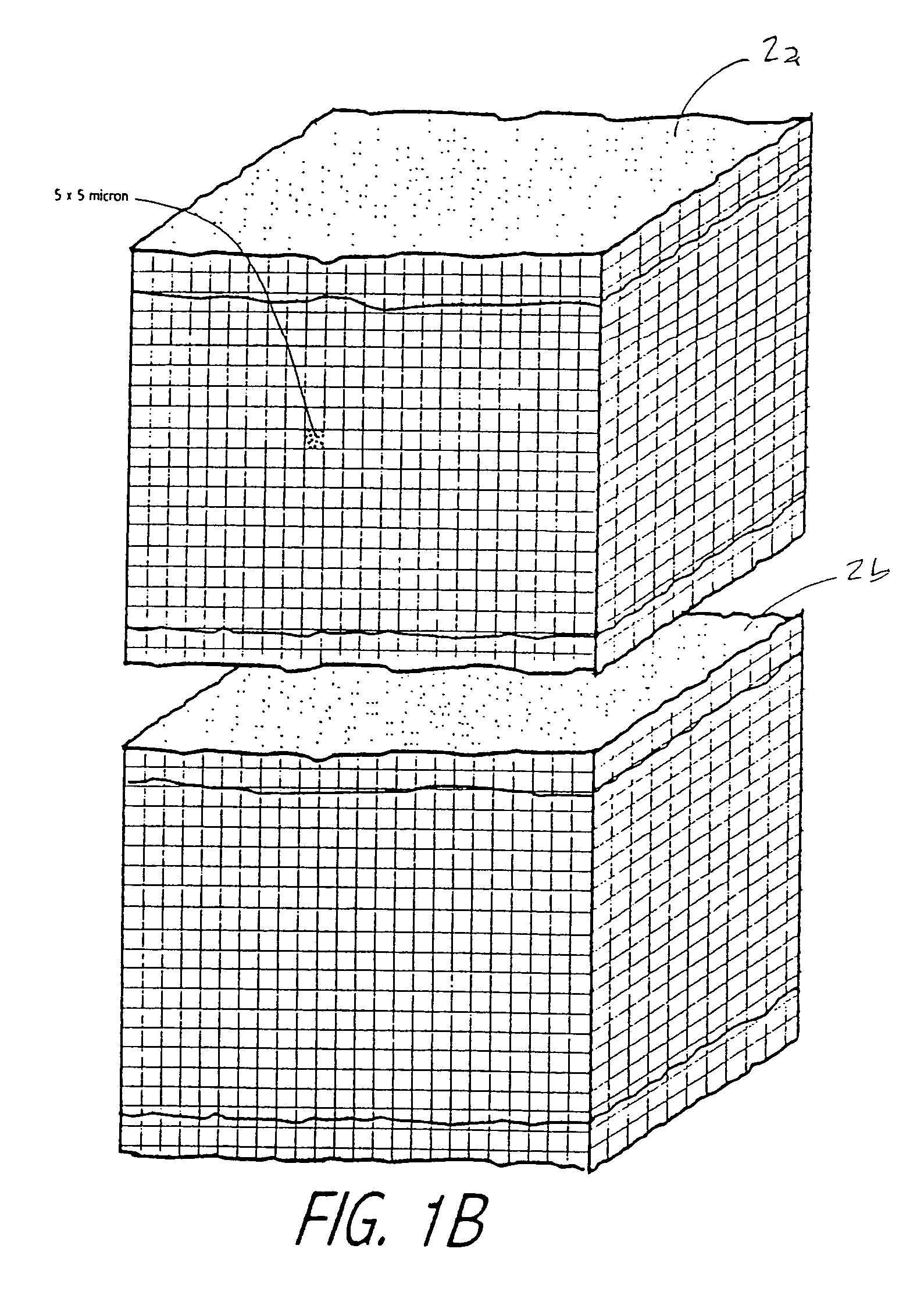

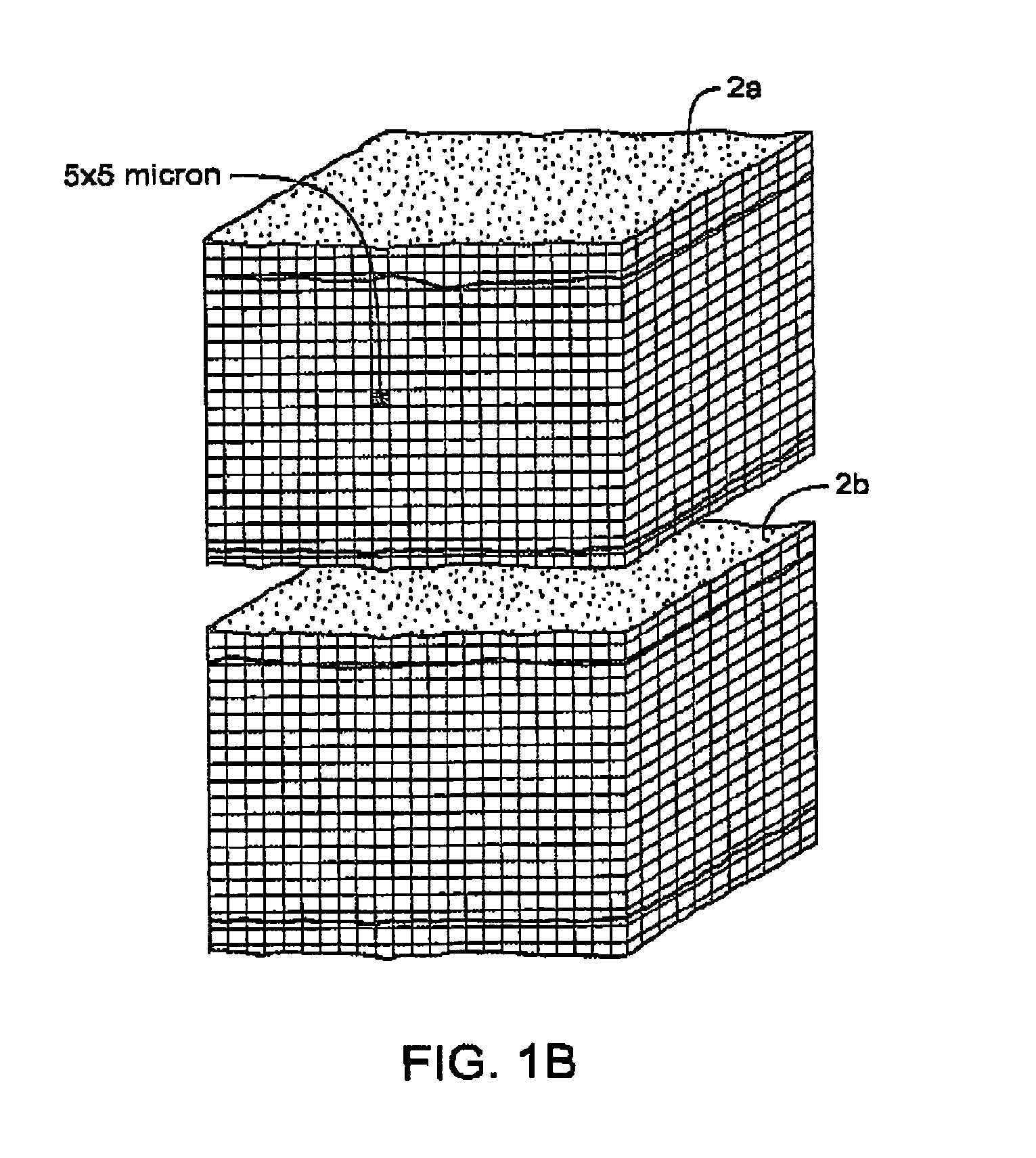

InactiveUS7083619B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

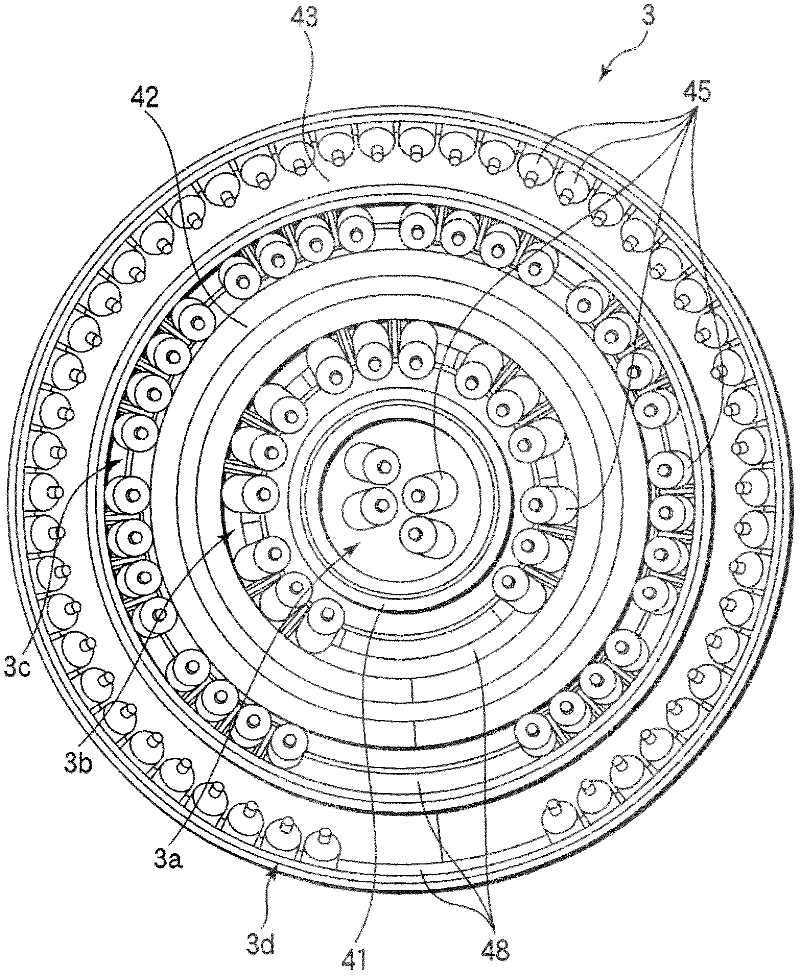

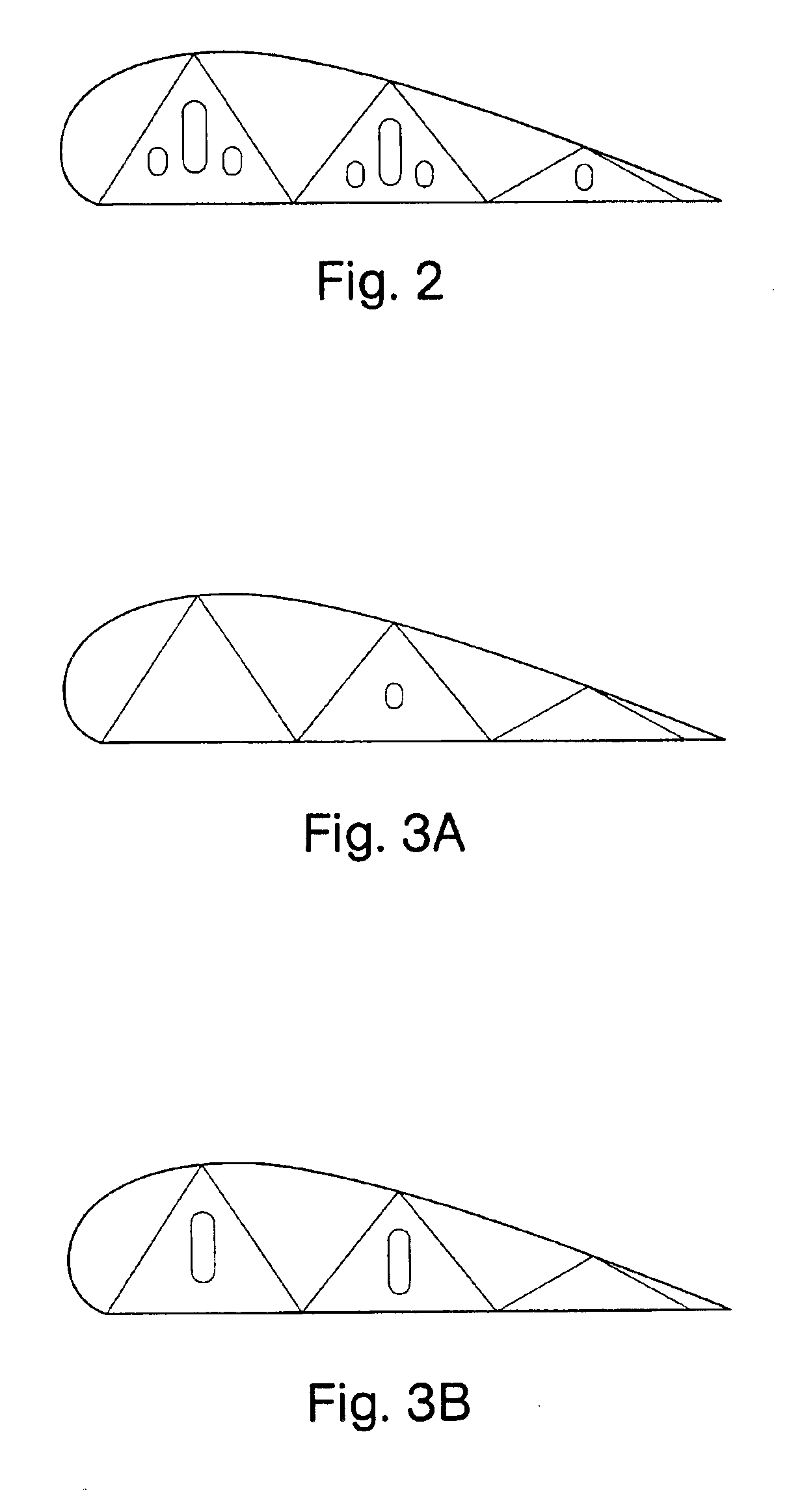

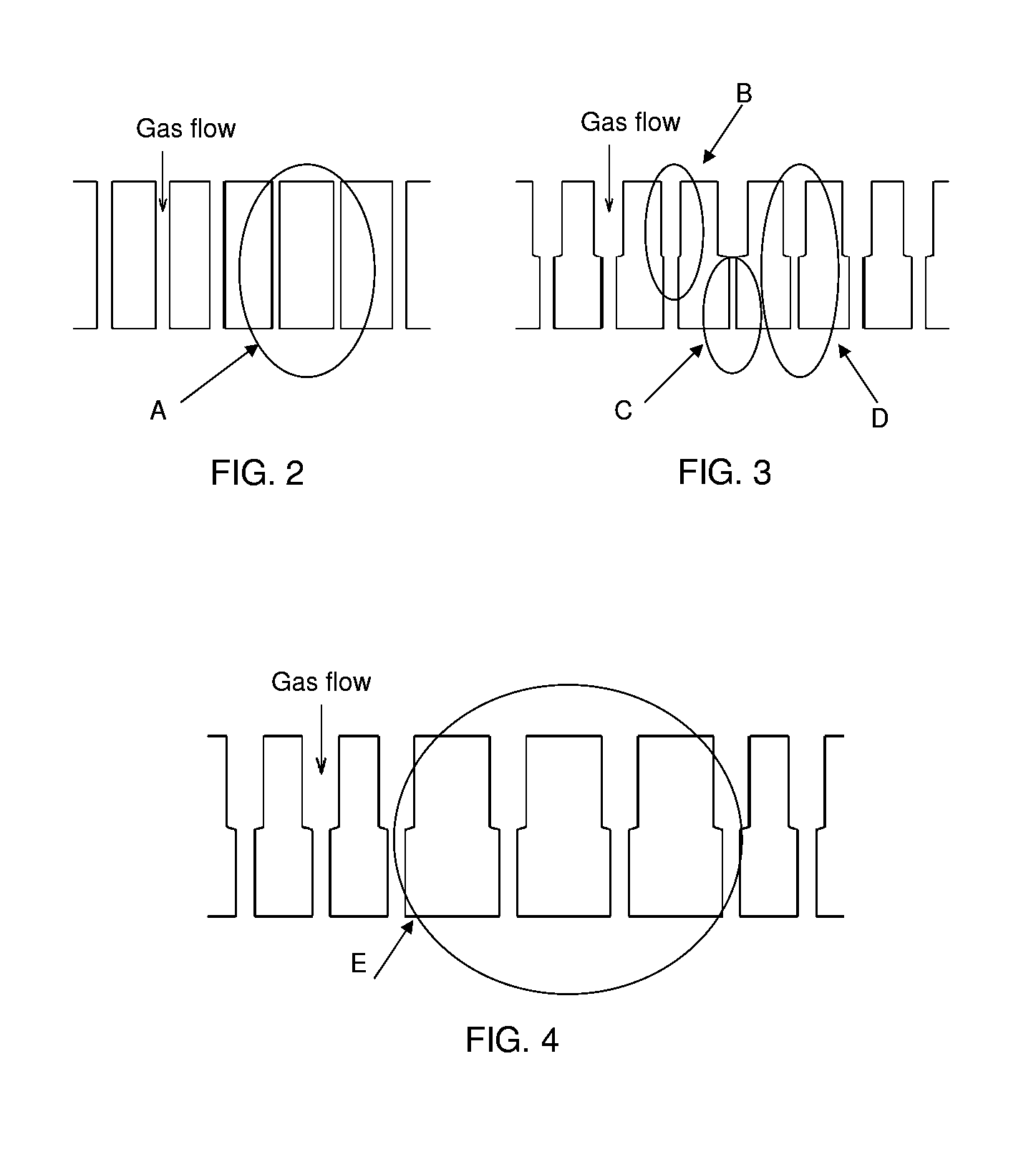

Shower plate having different aperture dimensions and/or distributions

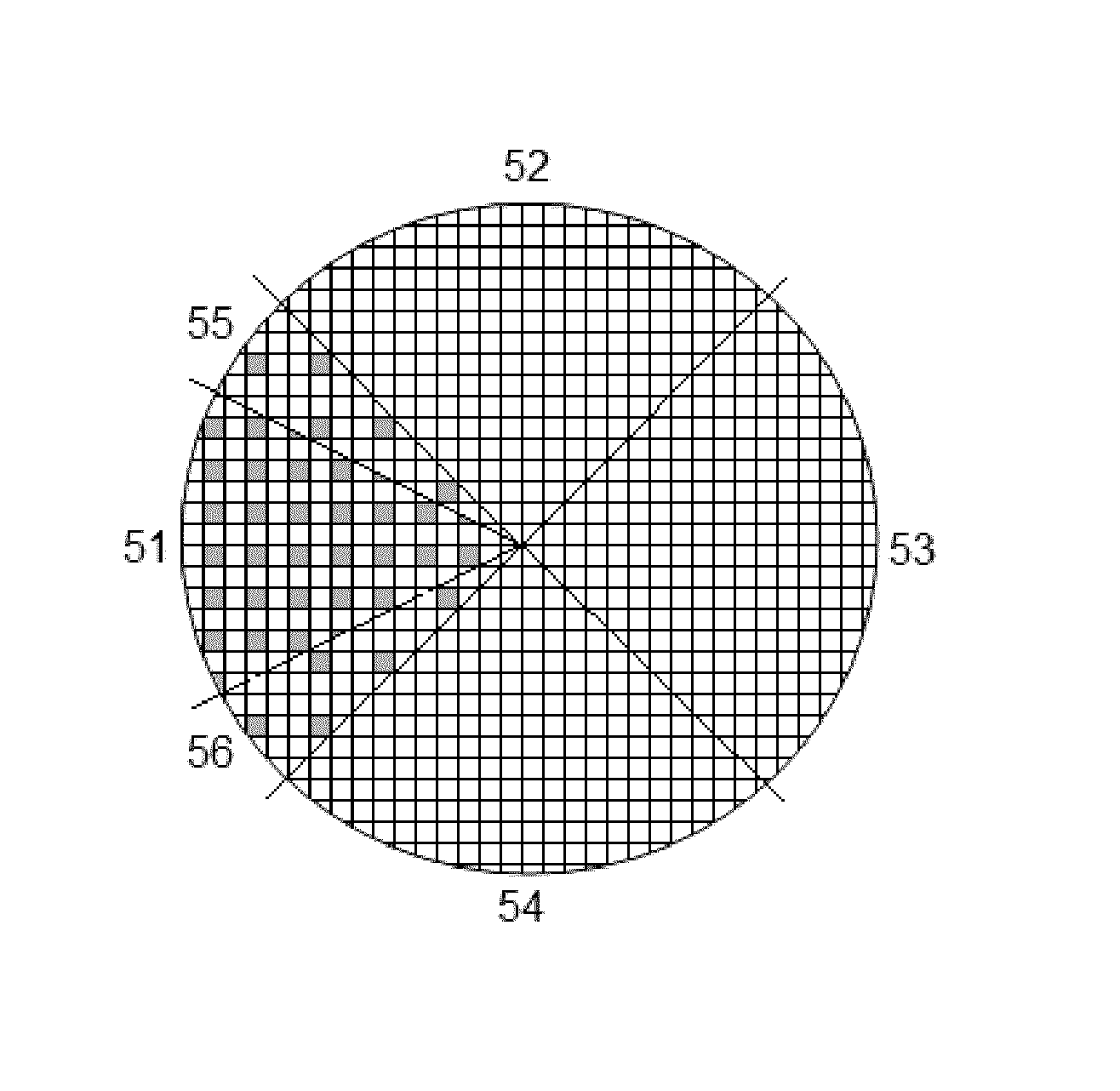

ActiveUS8845806B2Improve uniformityUniform propertyElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

Electrosurgical instrument and method

InactiveUS7517349B2Lower base resistanceRule out the possibilityDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceVaricose veins

Owner:TYCO HEALTHCARE GRP LP

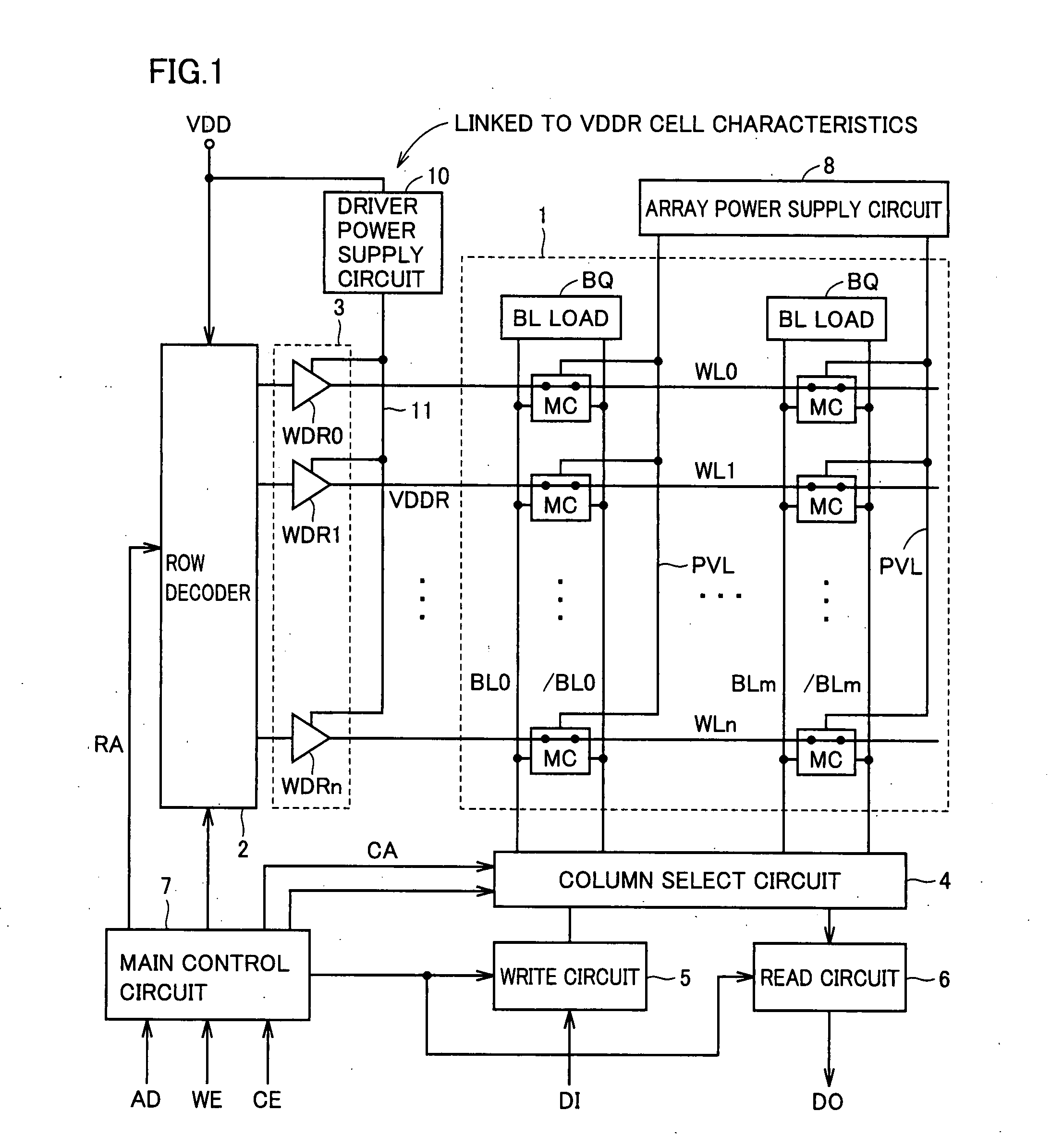

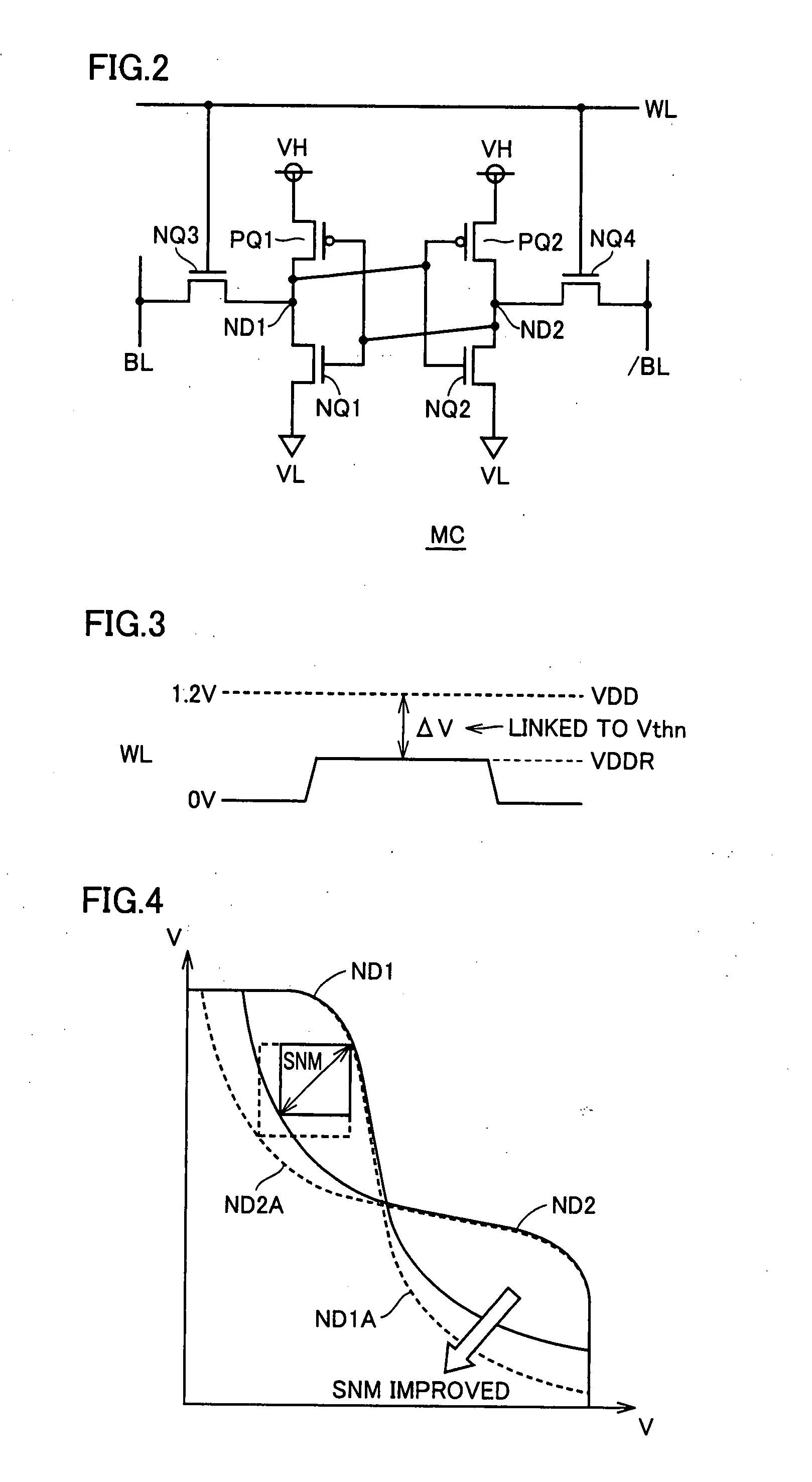

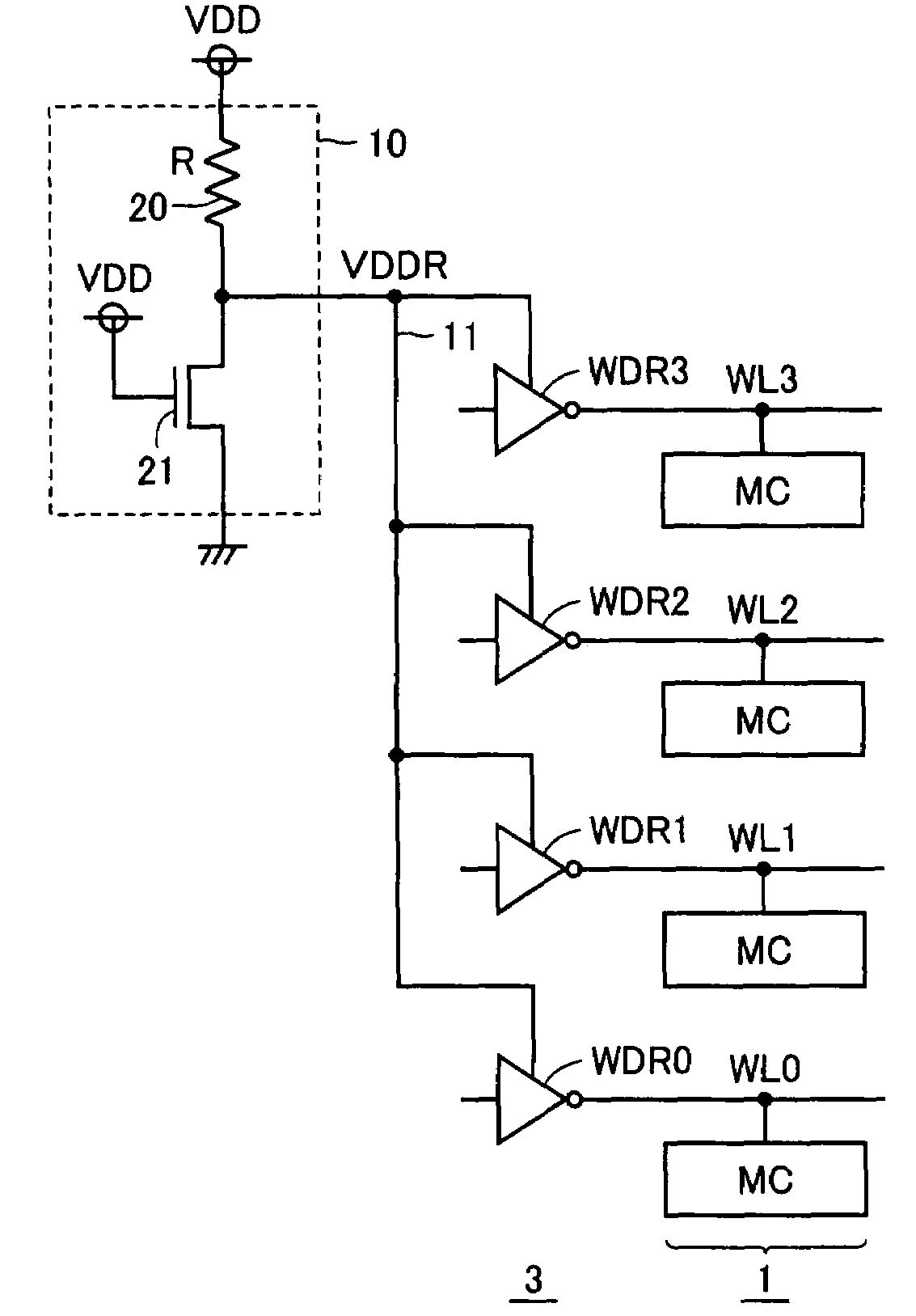

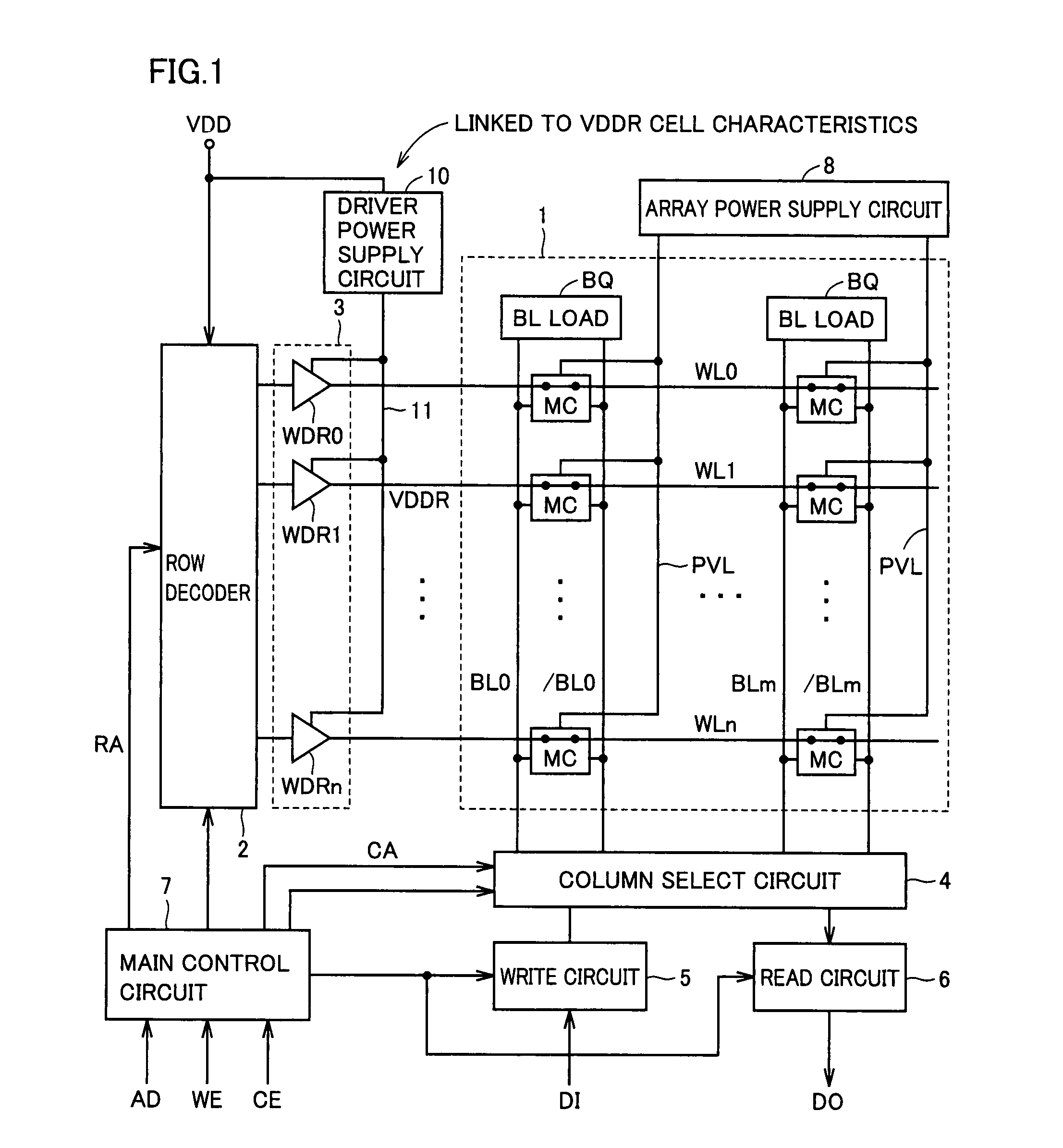

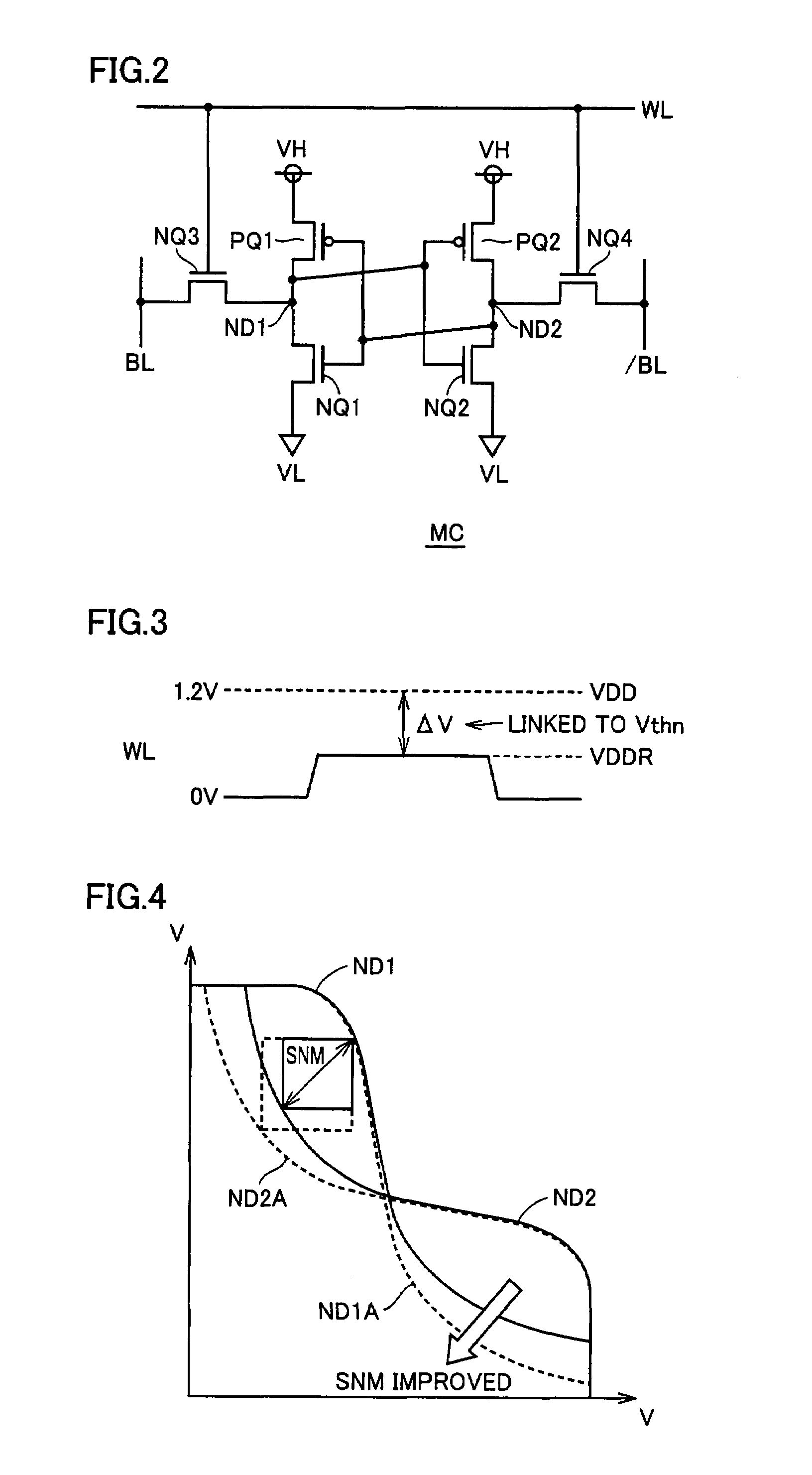

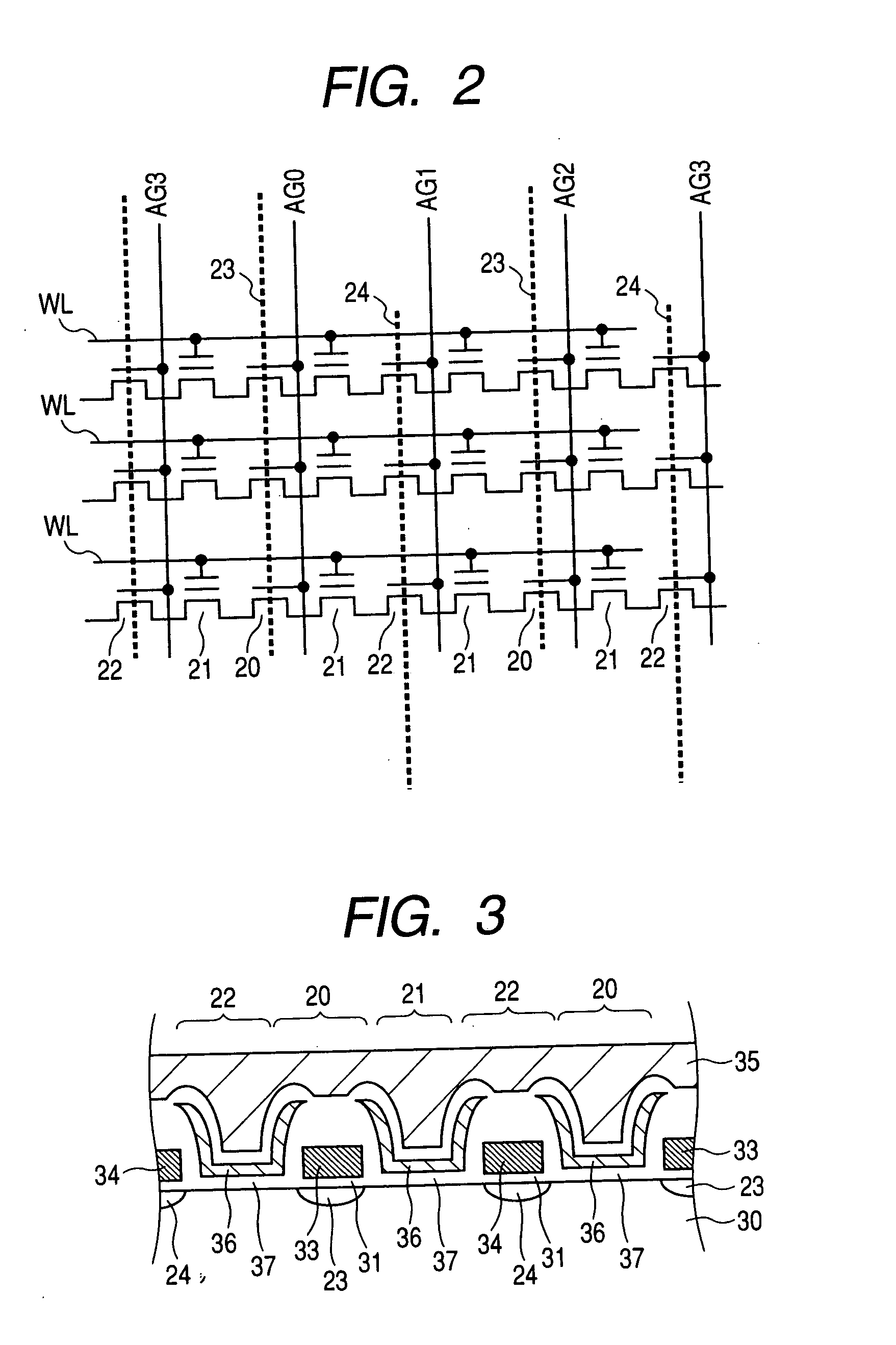

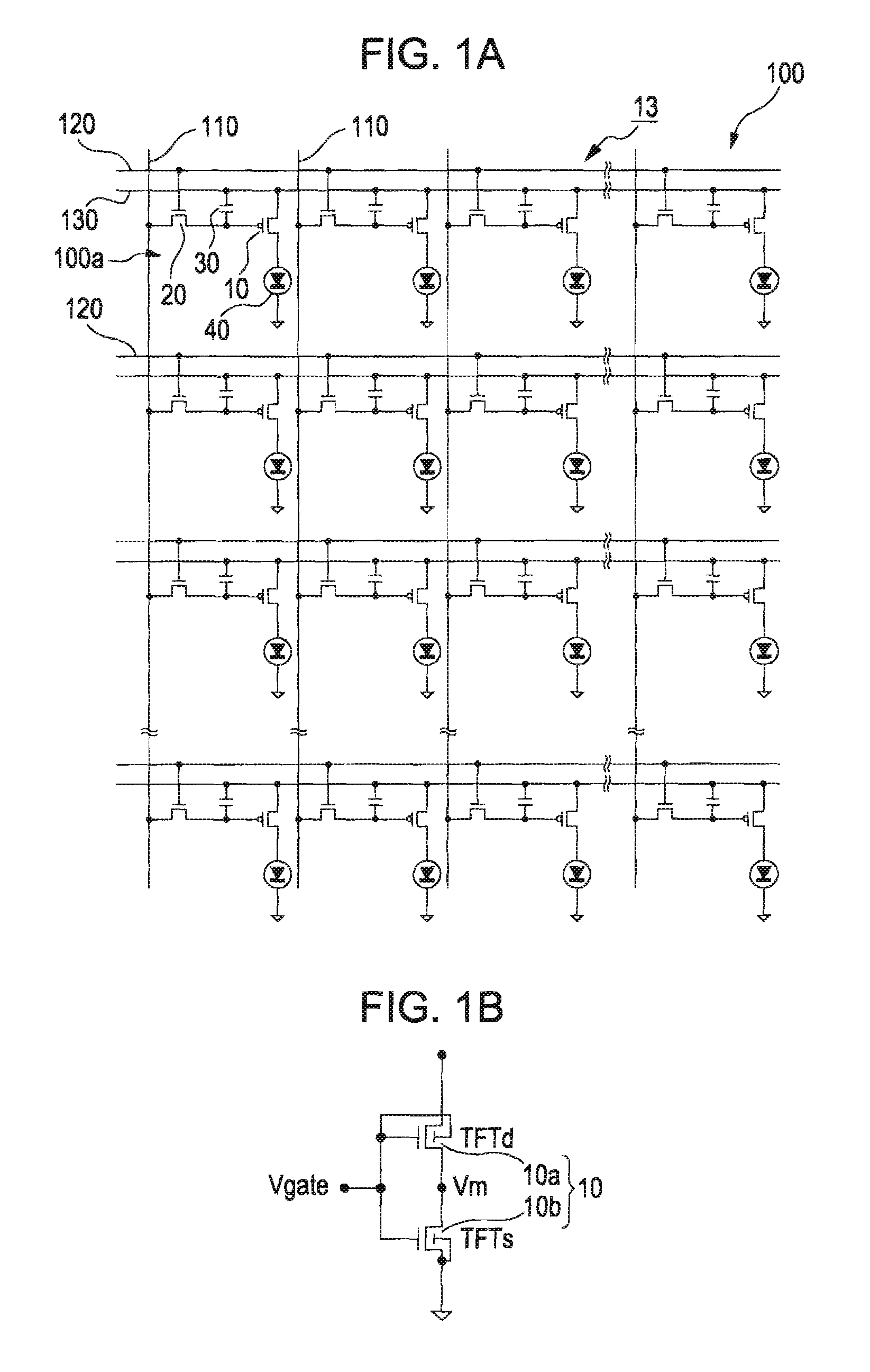

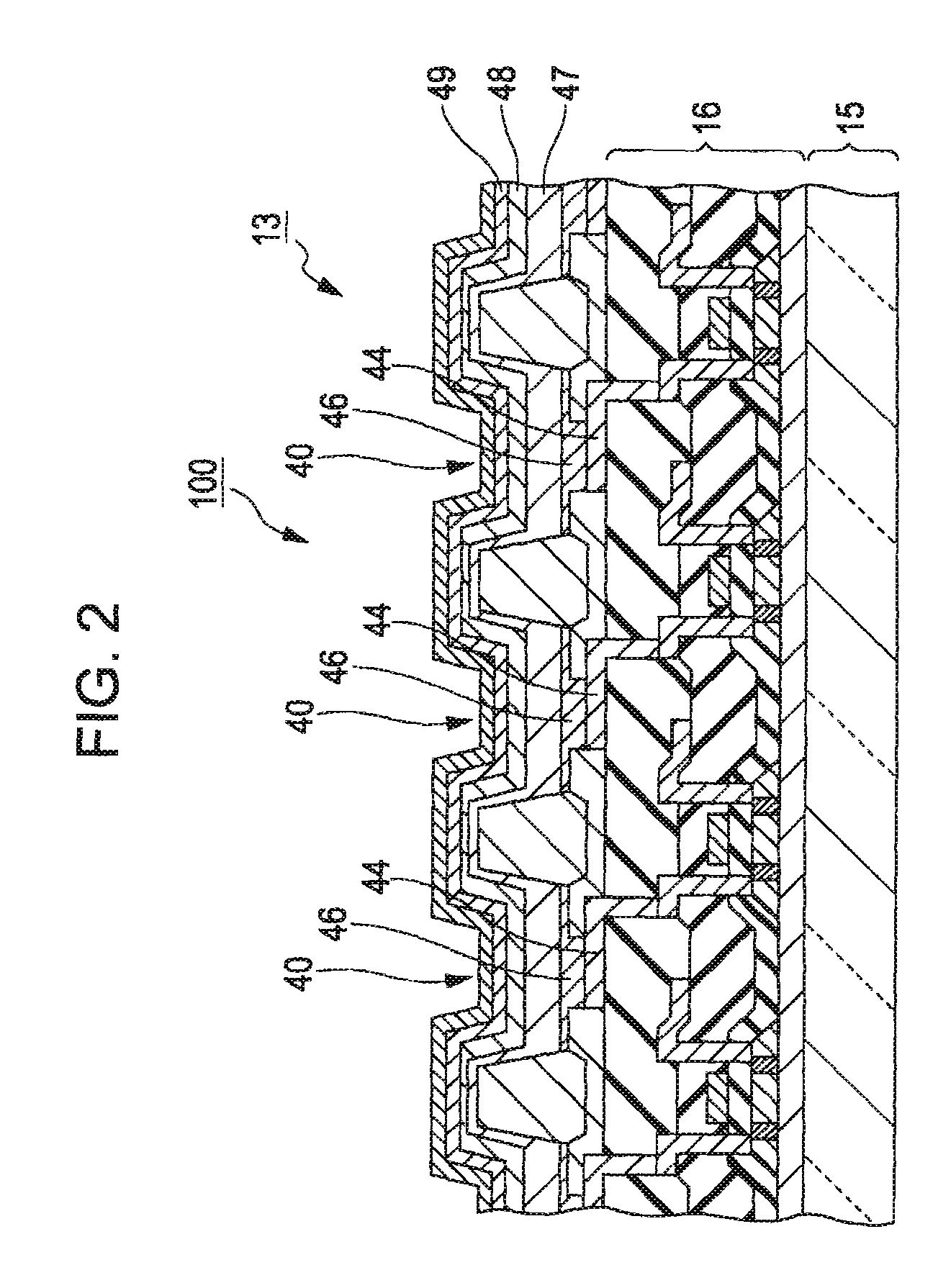

Semiconductor memory device comprising a plurality of static memory cells

ActiveUS20080037358A1Simple circuit structureStable writing and reading of dataDigital storageHemt circuitsLine driver

A driver power supply circuit stepping down a power supply voltage is arranged at a power supply node of a word line driver. The driver power supply circuit includes a non-silicide resistance element of N+ doped polycrystalline silicon, and a pull-down circuit lowering a voltage level of the driver power supply node. The pull-down circuit includes a pull-down transistor having the same threshold voltage characteristics as a memory cell transistor pulling down a voltage level of the driver power supply node, and a gate control circuit adjusting at least a gate voltage of the pull-down transistor. The gate control circuit corrects the gate potential of the pull-down transistor in a manner linked to variations in threshold voltage of the memory cell transistor.

Owner:RENESAS ELECTRONICS CORP

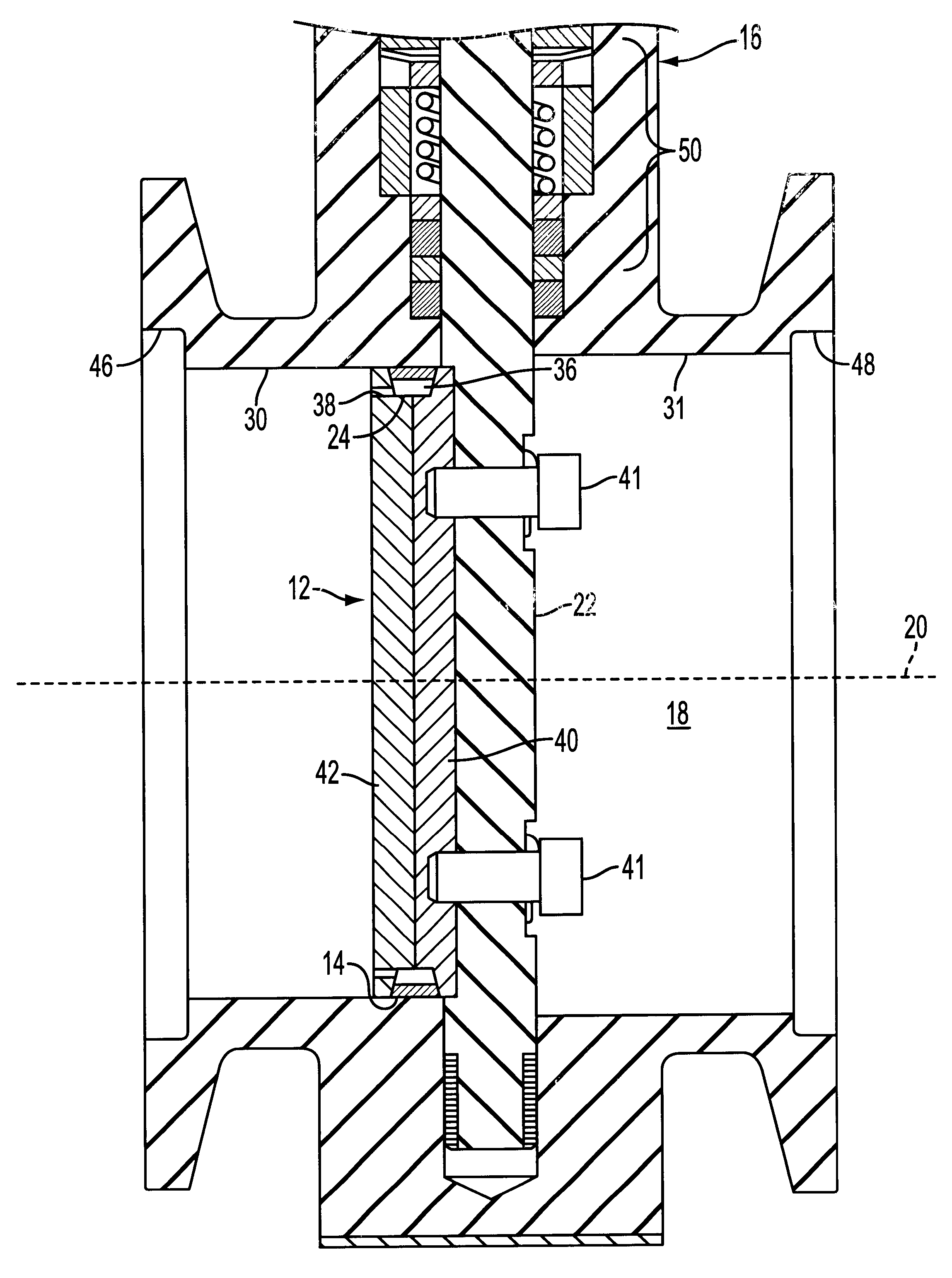

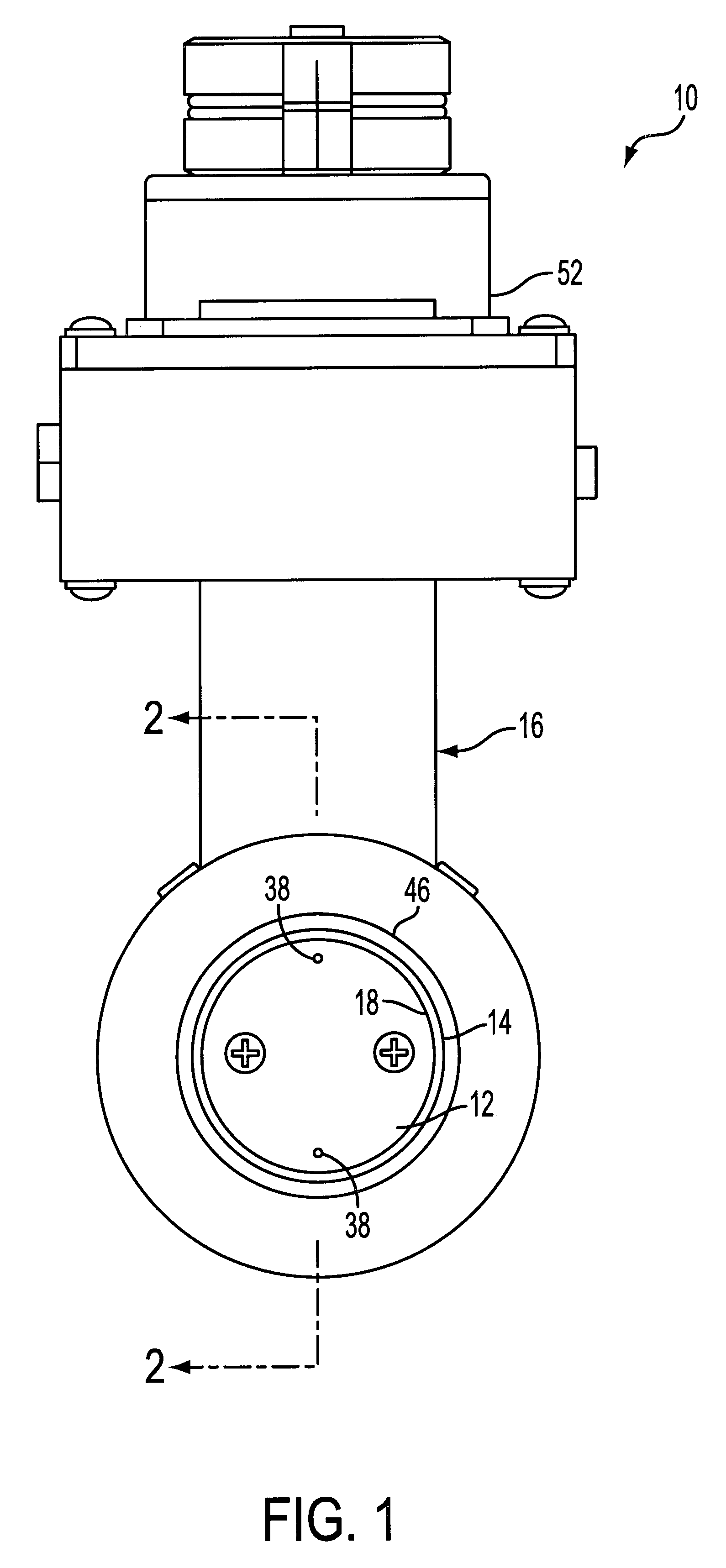

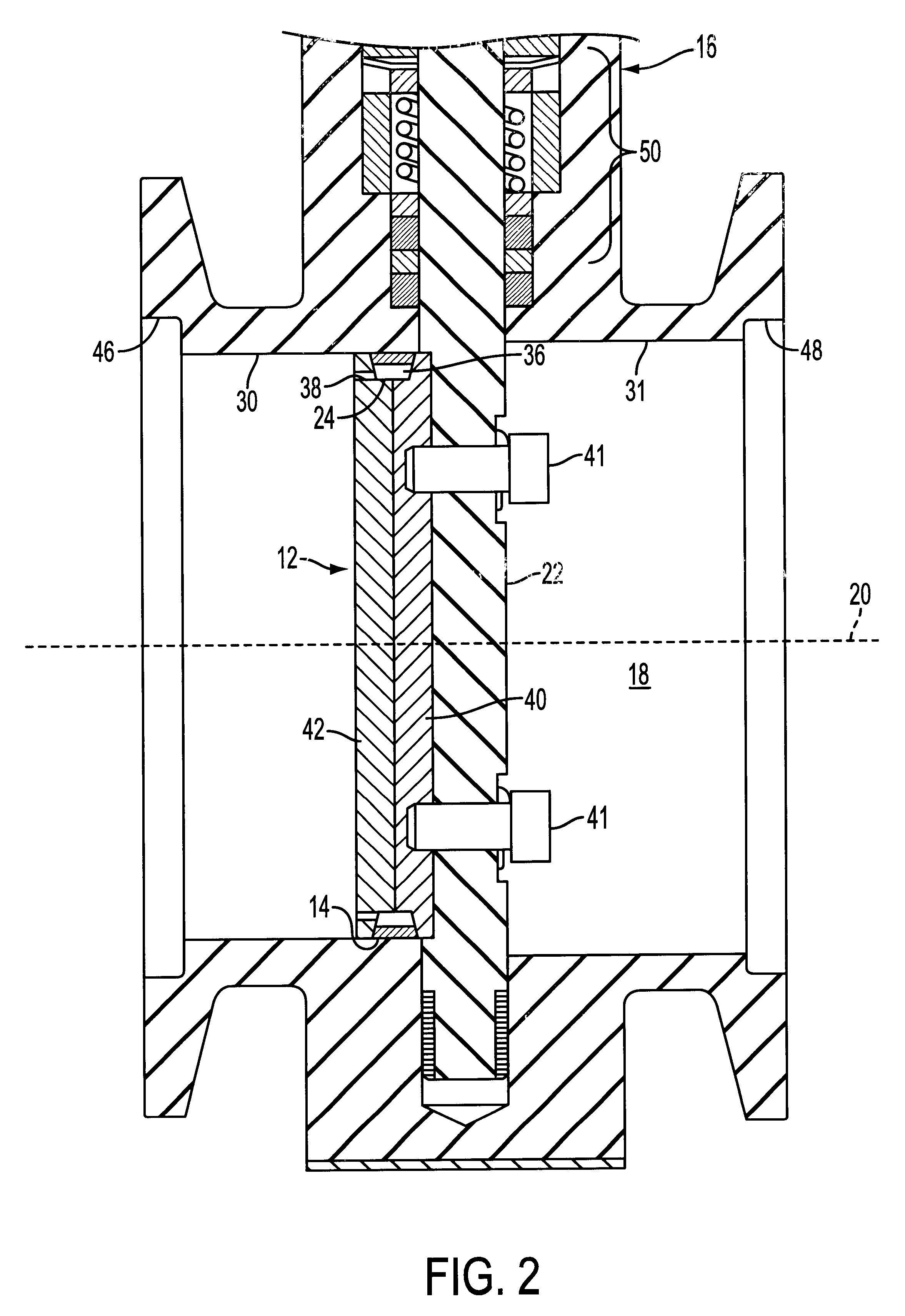

Valve flapper with dynamic circumference seal

A valve assembly including a body defining a passageway having a longitudinal axis, a rotatable shaft extending into the passageway, generally perpendicular to the axis of the passageway, and a flapper secured to the shaft within the passageway and movable upon rotation of the shaft between an opened position and a closed position. The flapper includes a groove in an outer circumference, and a seal is received in the groove. The seal has an outer circumference greater than the outer circumference of the flapper so the entire outer circumference of the seal contacts a wall of the passageway when the flapper is moved to the closed position. The seal also has an inner circumference greater than an inner circumference of the groove of the flapper such that an enclosed space is defined between the seal and the groove. An aperture provides fluid communication between the enclosed space and the passageway.

Owner:MKS INSTR INC

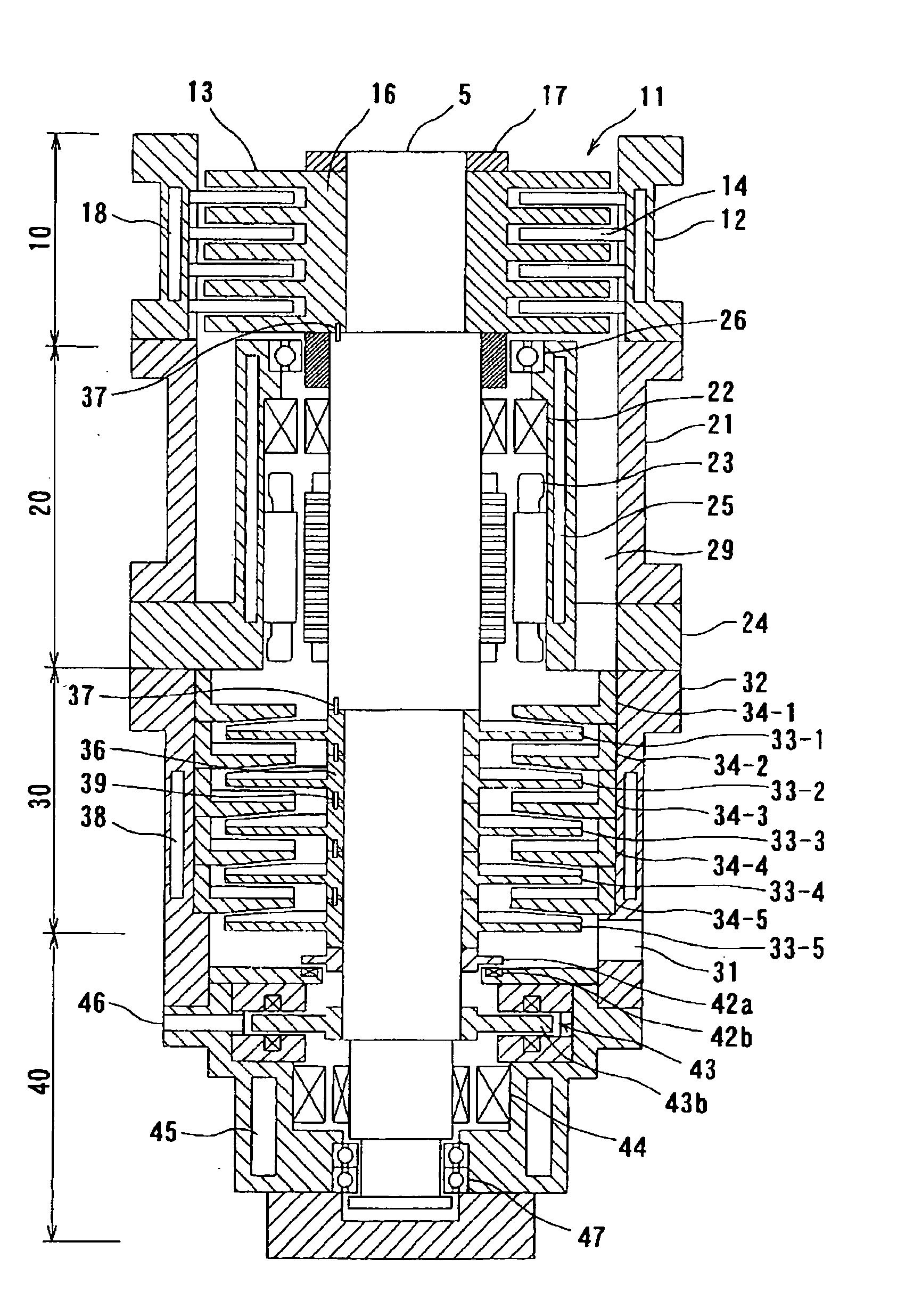

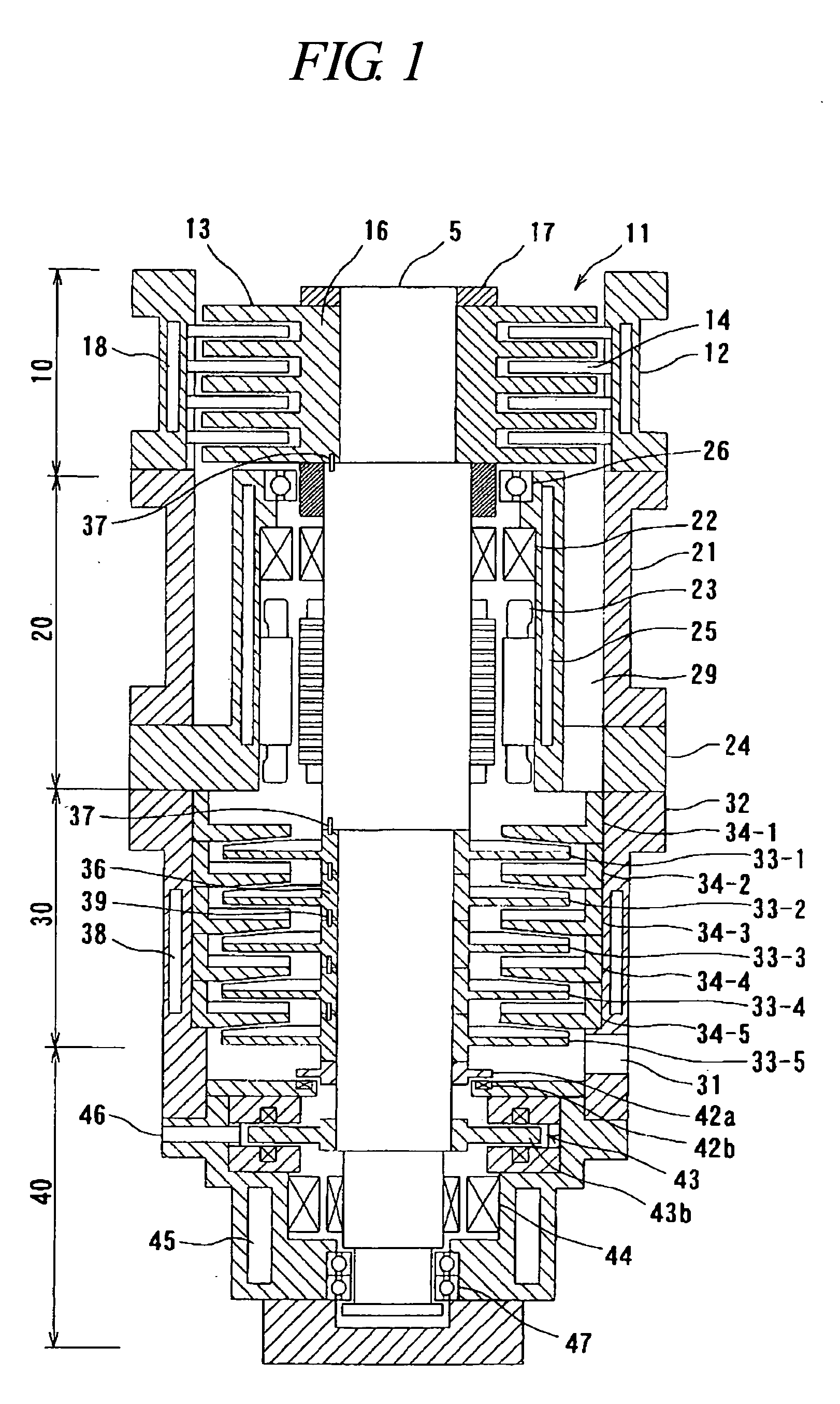

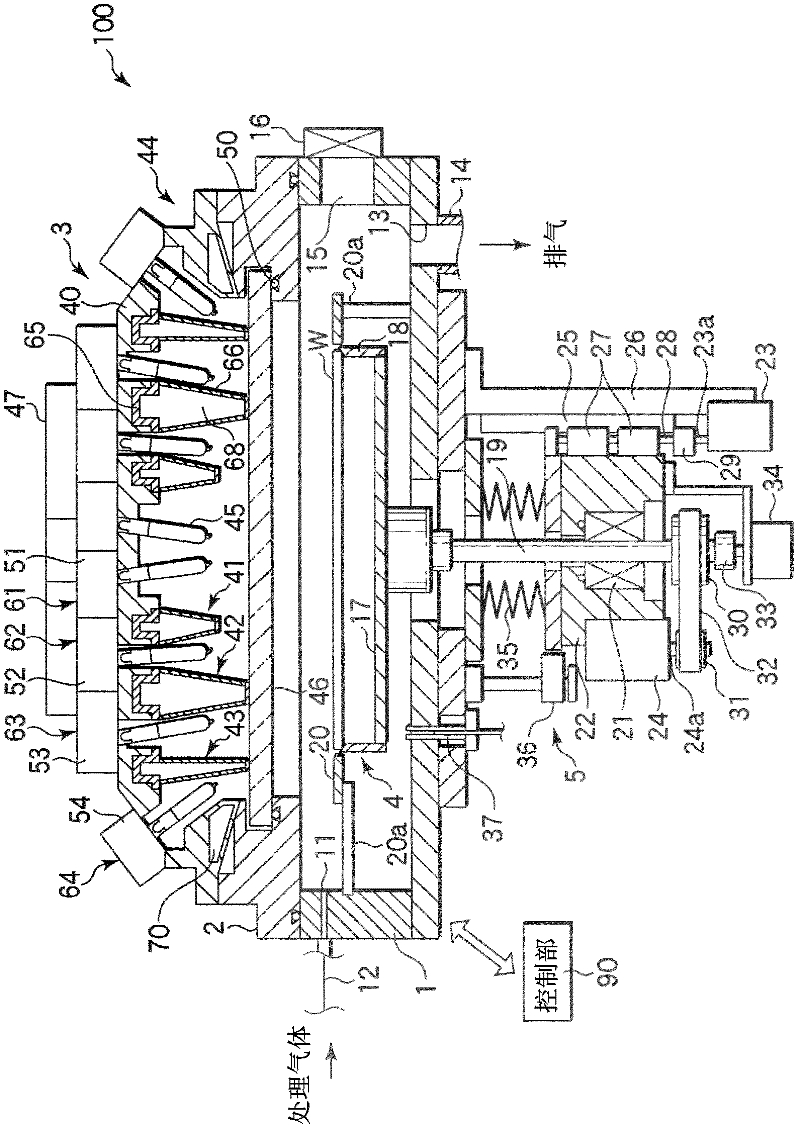

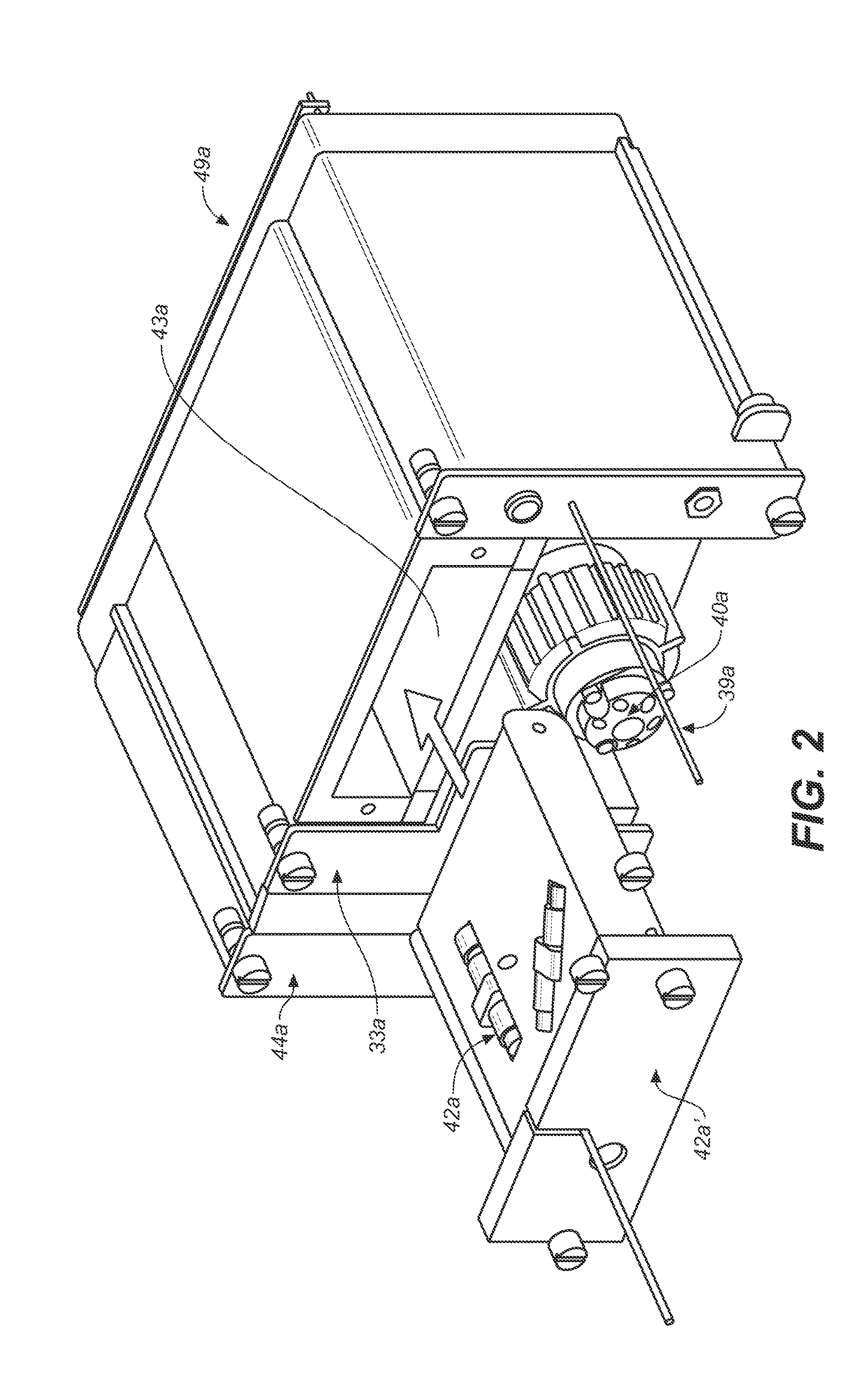

Vacuum pump and semiconductor manufacturing apparatus

InactiveUS20050025640A1Improve the exhaust effectIncreased durabilityPump componentsRotary non-positive displacement pumpsOil freeAtmospheric pressure

To provide a vacuum pump capable of evacuating in pressure ranges from an atmospheric pressure to a high vacuum, capable of rotating at a high speed to be downsized and improved in pumping performance, and capable of producing a completely oil-free vacuum. A vacuum pump for exhausting a gas comprises: a main shaft 5 rotatably supported by a bearing 22; a motor 23 for driving the main shaft 5 for rotation; a first exhaust section 10 having a first rotary vane 13 attached to the main shaft 5, a first fixed vane 14 fixed in a first casing 12, and an intake port 11; and a second exhaust section 30 having a second rotary vane 33 attached to the main shaft 5, a second fixed vane 34 fixed in a second casing 32, and an exhaust port 31. The intake port 11 is located in the vicinity of an end of the main shaft 5, and the first exhaust section 10, the bearing 22 and the second exhaust section 30 are arranged in this order axially along the main shaft 5.

Owner:EBARA CORP

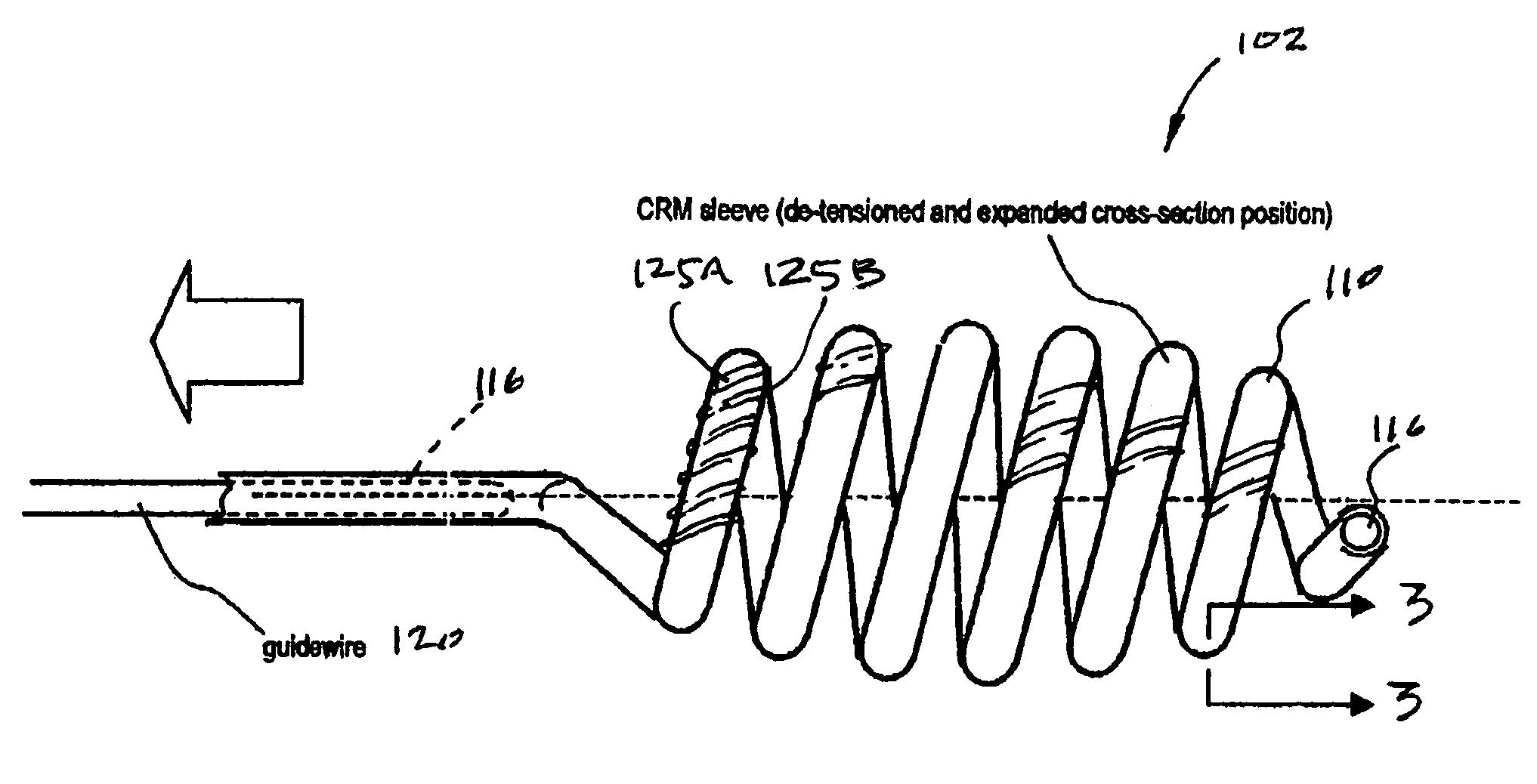

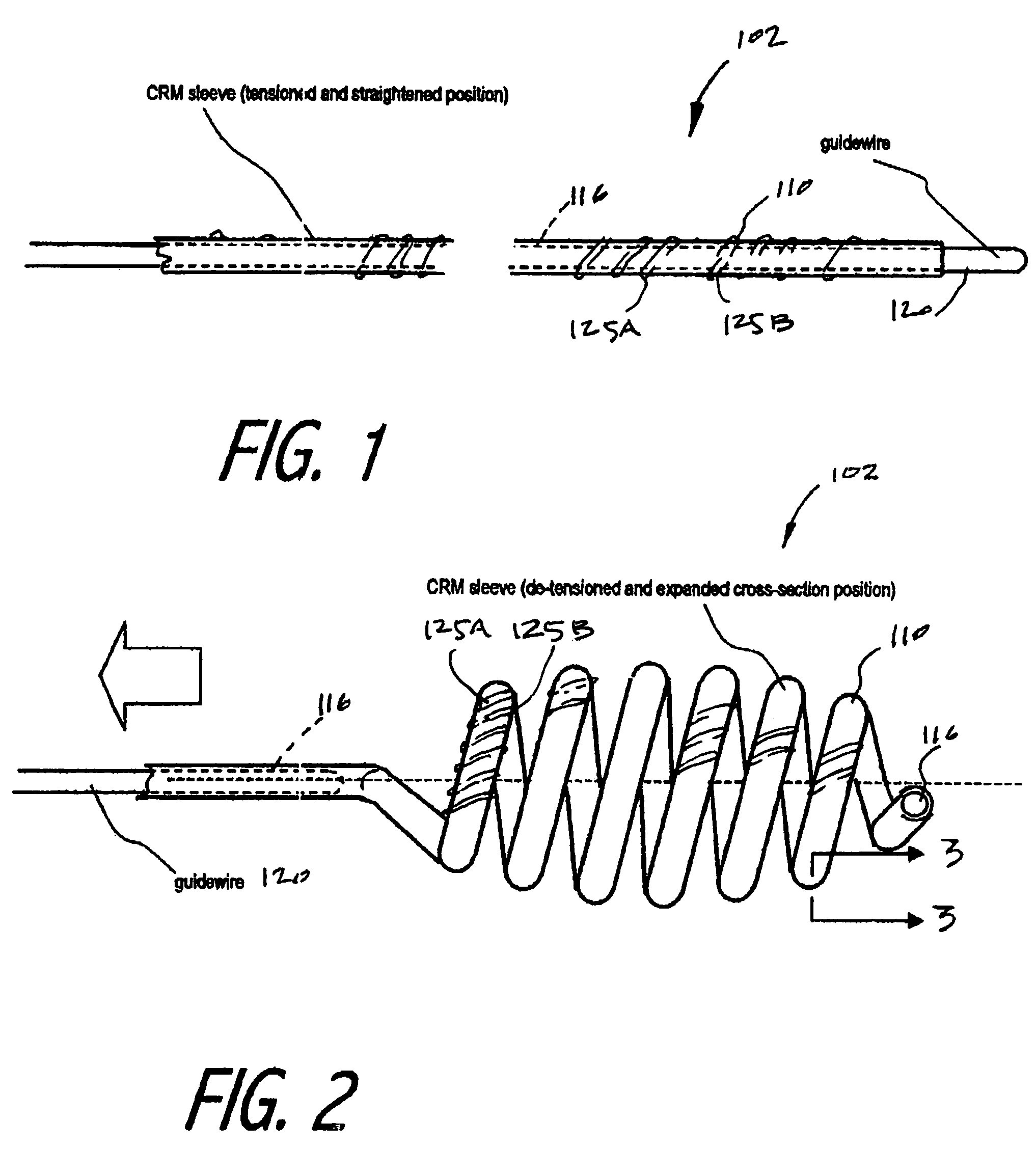

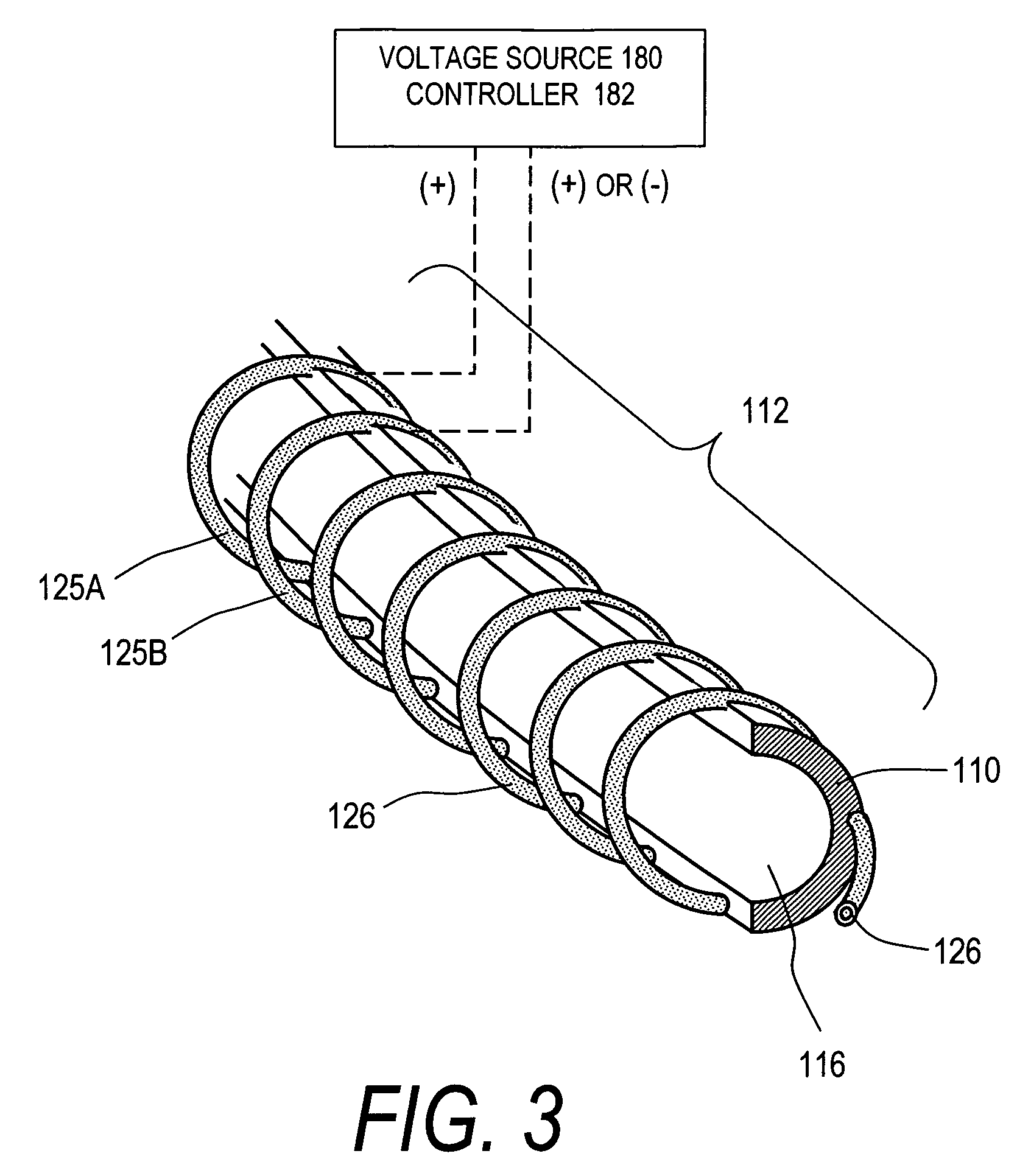

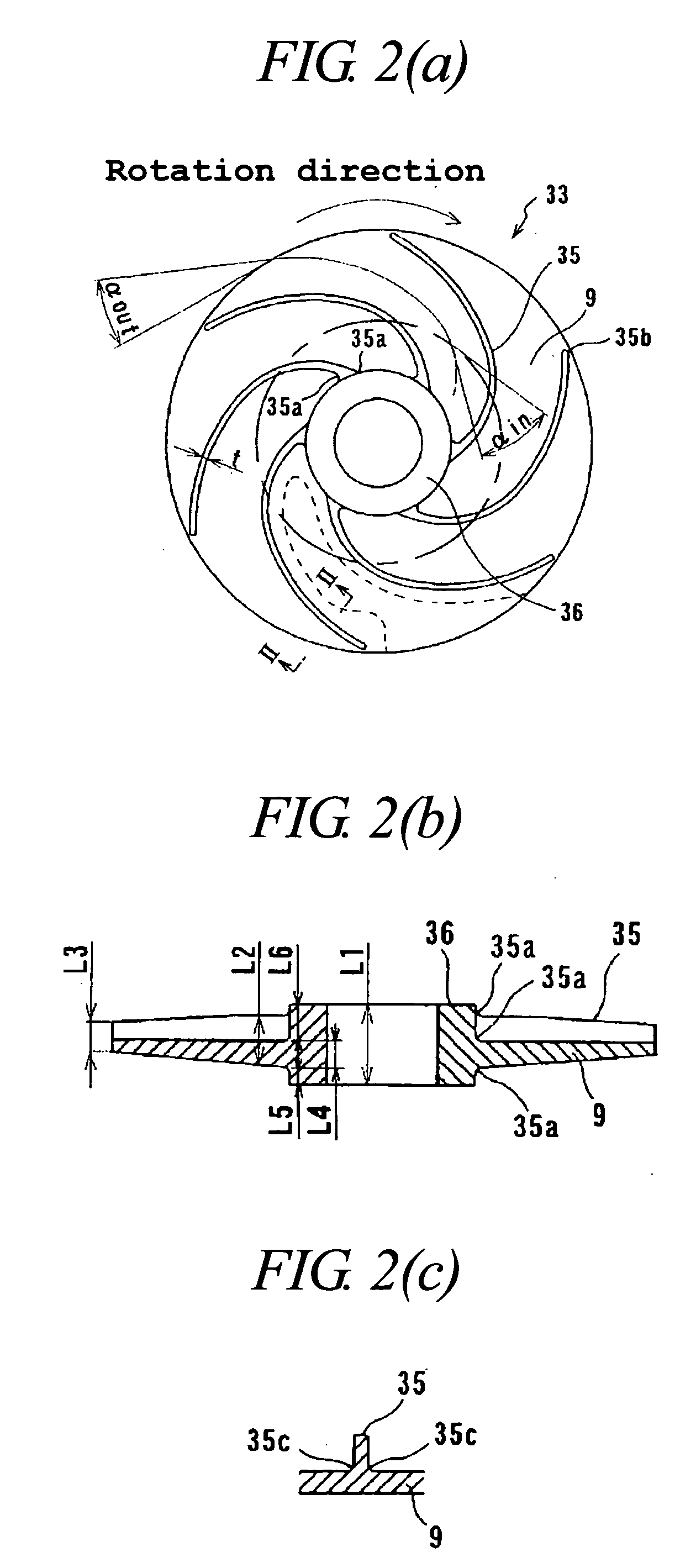

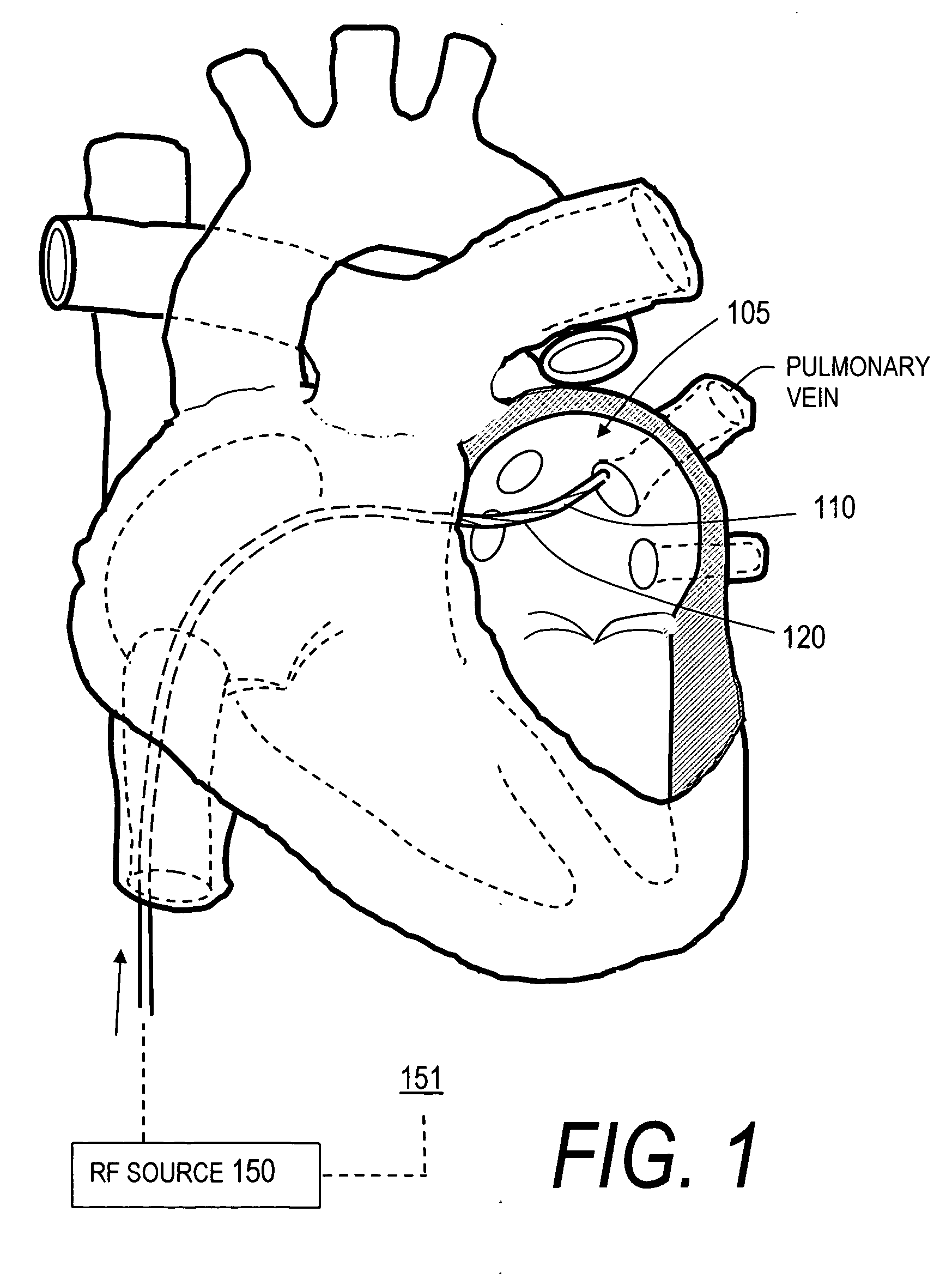

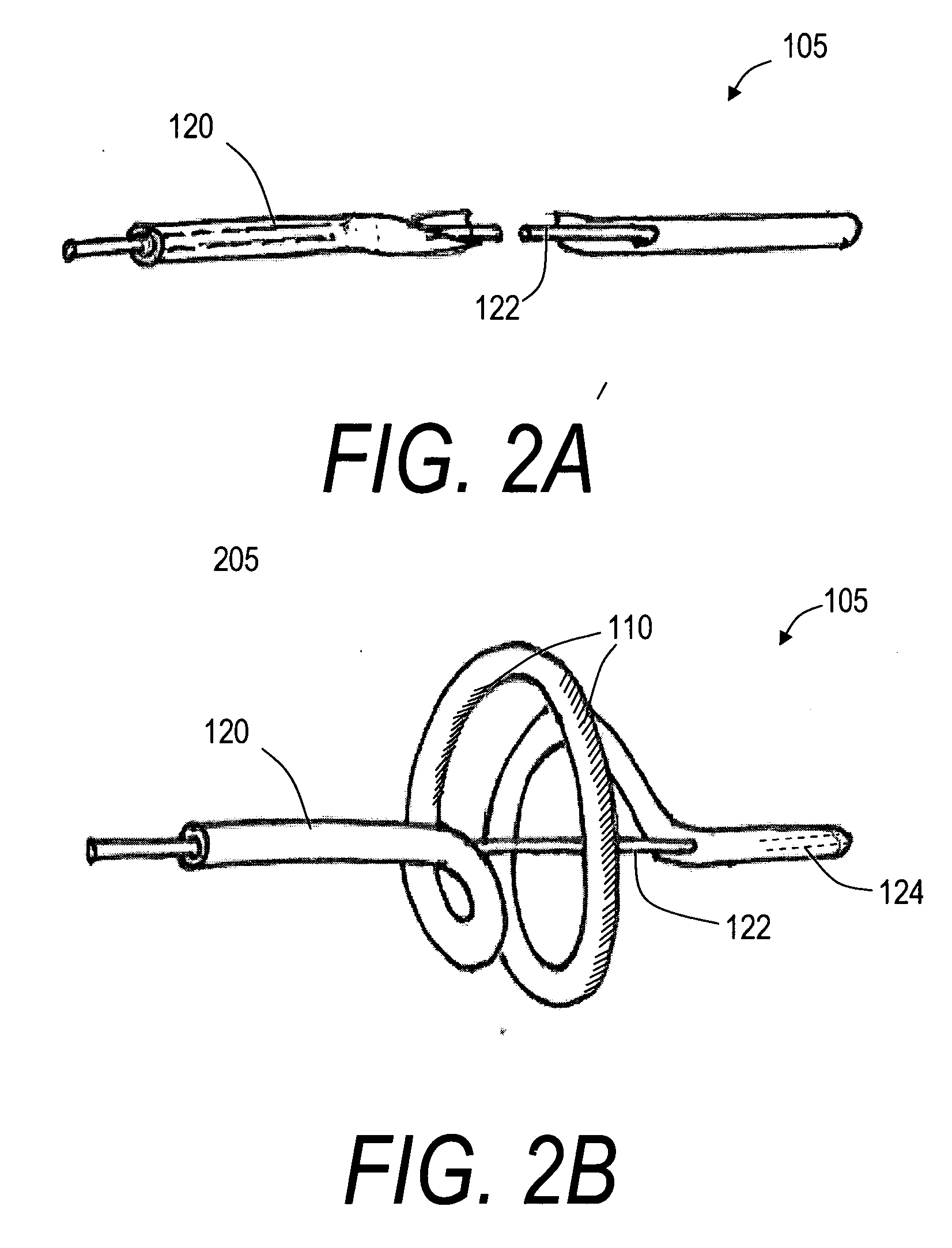

Endovascular catheter and method of use

InactiveUS20060084969A1Inhibit migrationReduce conductanceDiagnosticsSurgical instruments for heatingSurgical departmentIntravascular catheter

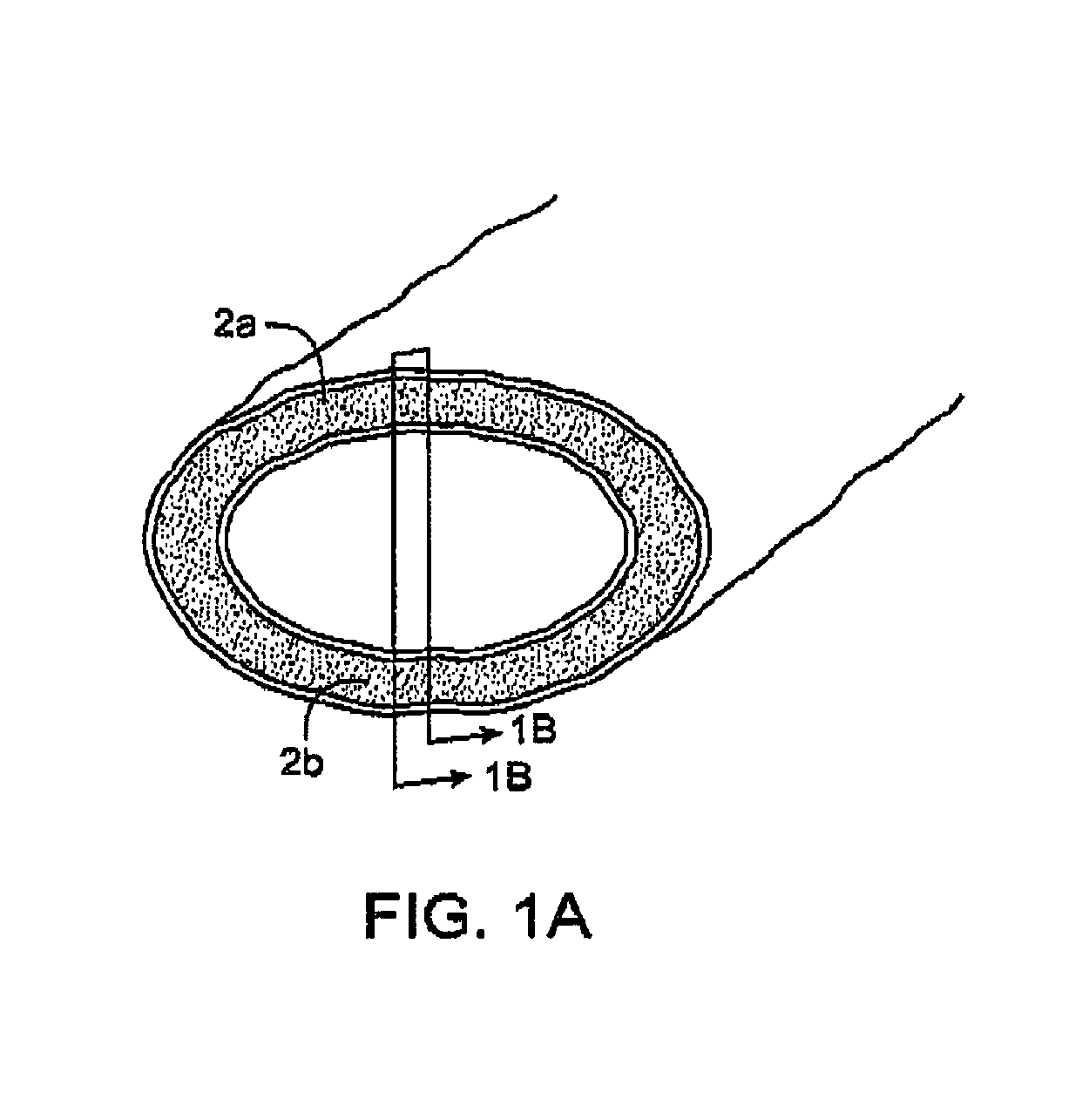

An electrosurgical medical device and method for treating cardiac arrhythmias. In one embodiment, an elongate catheter has a distal shaft end or balloon that carries an electrosurgical energy delivery surface comprising at least one electrode with a positive temperature coefficient of resistance (PTCR) surface and / or an electrode with a pressure sensitive variable resistance to provide a smart surface for controlling Rf current flow at the interface of electrosurgical surface and the tissue. The electrosurgical surface then can limit or modulate Rf energy delivery through the surface in response to the temperature of the tissue or the engagement pressure of the surface against the engaged tissue. In operation, the smart electrosurgical surface can prevent arcing at the electrode-tissue interface, and thus control ohmic heating to prevent tissue desiccation, charring and emboli formation.

Owner:TRUCKAI CSABA +1

Semiconductor memory device comprising a plurality of static memory cells

ActiveUS7602654B2Simple circuit structureStable writing and reading of dataDigital storageHemt circuitsEngineering

A driver power supply circuit stepping down a power supply voltage is arranged at a power supply node of a word line driver. The driver power supply circuit includes a non-silicide resistance element of N+ doped polycrystalline silicon, and a pull-down circuit lowering a voltage level of the driver power supply node. The pull-down circuit includes a pull-down transistor having the same threshold voltage characteristics as a memory cell transistor pulling down a voltage level of the driver power supply node, and a gate control circuit adjusting at least a gate voltage of the pull-down transistor. The gate control circuit corrects the gate potential of the pull-down transistor in a manner linked to variations in threshold voltage of the memory cell transistor.

Owner:RENESAS ELECTRONICS CORP

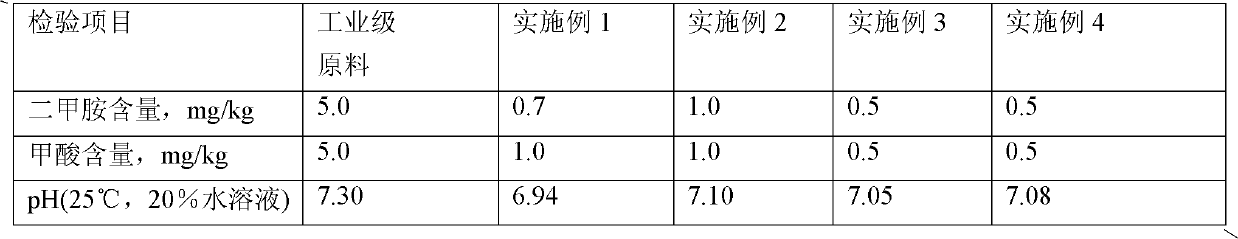

Preparation technique of isosorbide

The invention relates to a preparation technique of isosorbide, belonging to the technical field of pharmacy. In the preparation technique, solid sorbitol is used as the raw material, a mixture of perfluoro-sulfonic acid resin and palladium on carbon is used as the catalyst, and hydrogen is used as an anti-carbonation agent to prepare the non-carbonized light-colored isosorbide reaction liquid; and low-temperature concentration and solvent crystallization are utilized to substitute the original high-temperature distillation. The preparation technique comprises the following steps: dehydration reaction, neutralization decolorization, electrodialysis desalination, water removal by concentration, extraction crystallization, freeze-drying, and quality inspection and packaging (after the product is qualified in inspection, packaging, and warehousing as the finished product). The invention can prevent carbonization and prevent the reaction liquid from becoming dark, thereby enhancing the utilization ratio of the raw material; most calcium salts are precipitated due to low solubility, and the electric conductivity of the reaction liquid is low, thereby being beneficial to subsequent extraction; and the invention overcomes the defect of high energy consumption in the high-temperature distillation technique, and the quality of the prepared isosorbide is more excellent.

Owner:SHANDONG FUTASTE

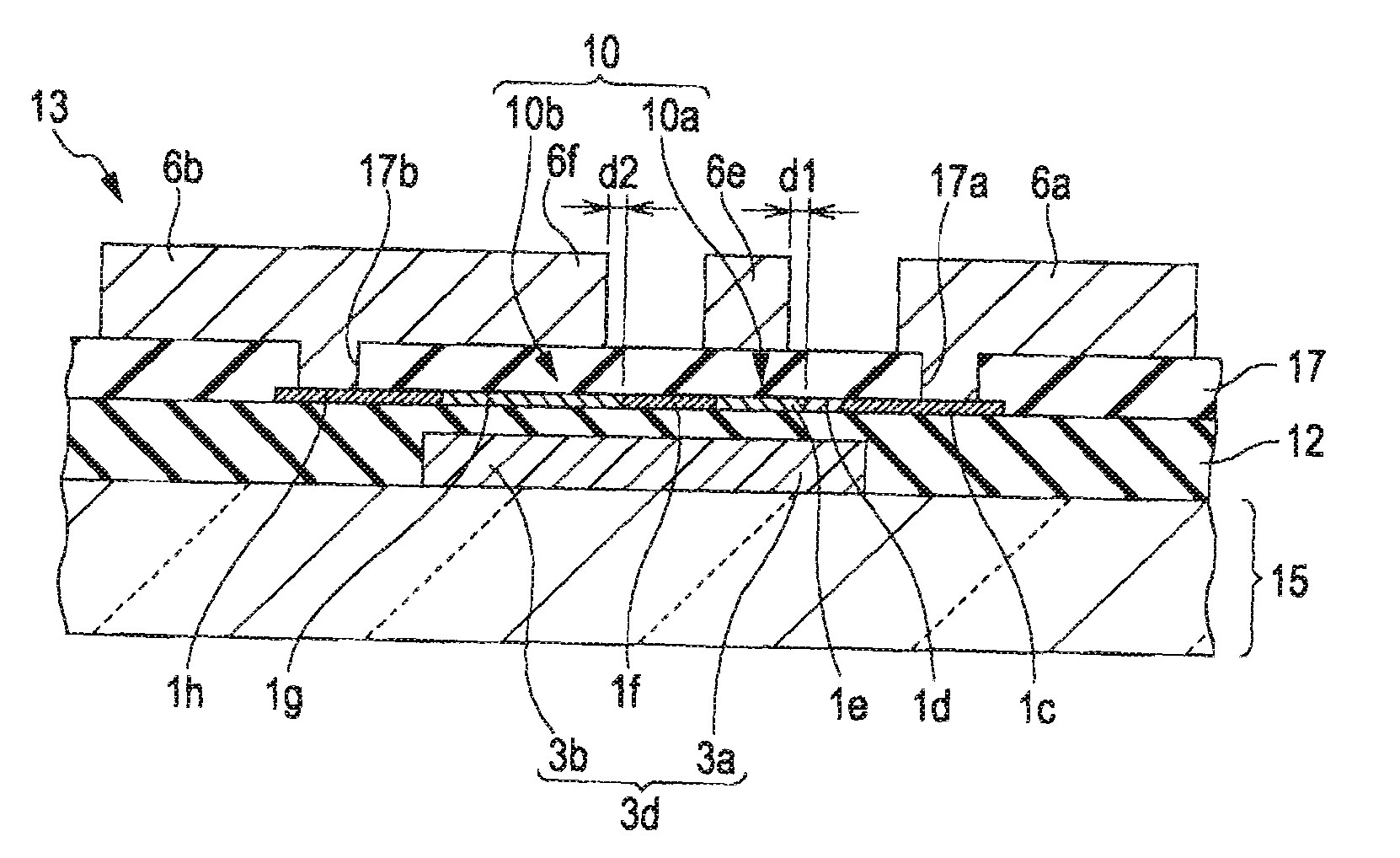

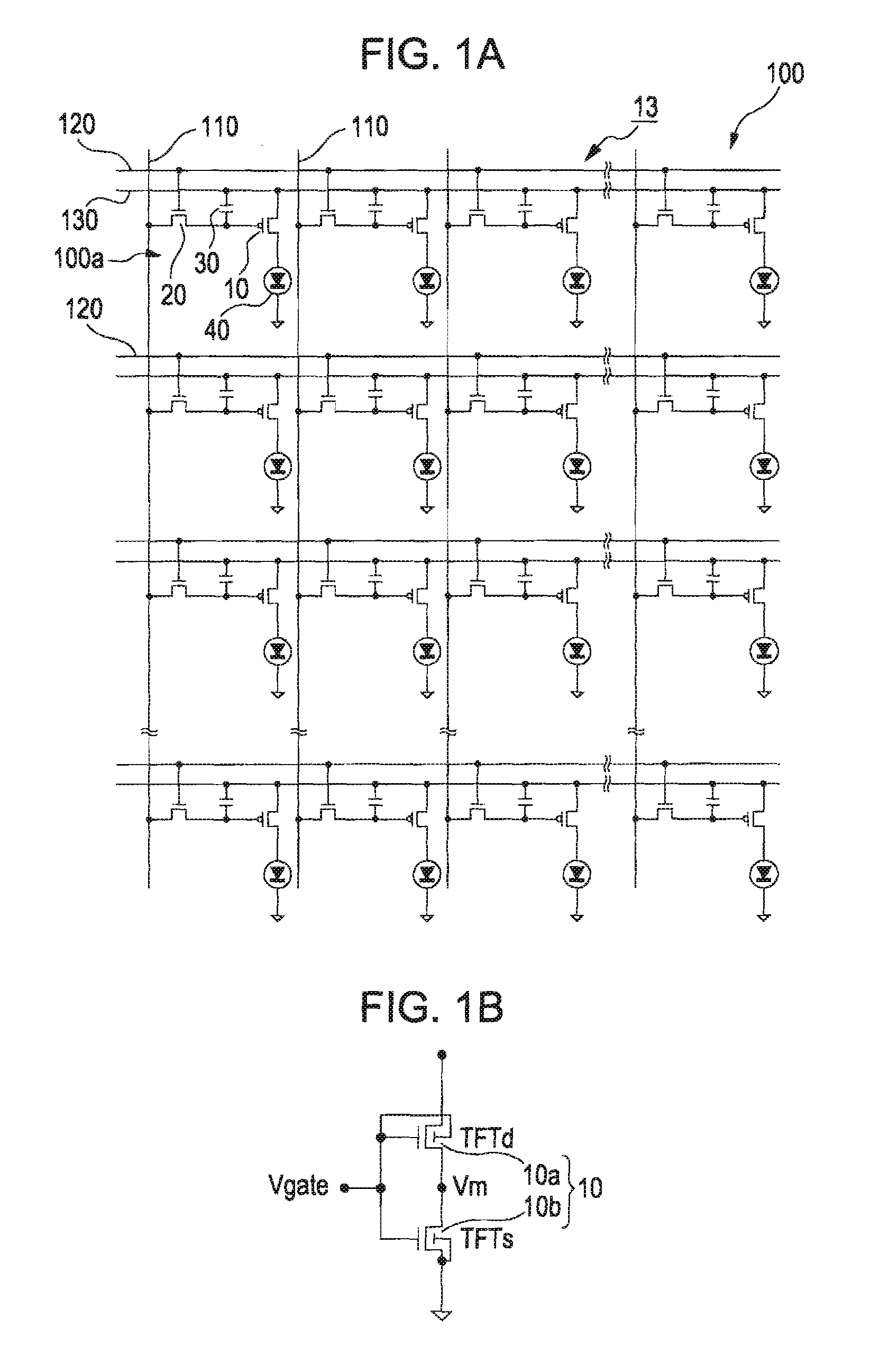

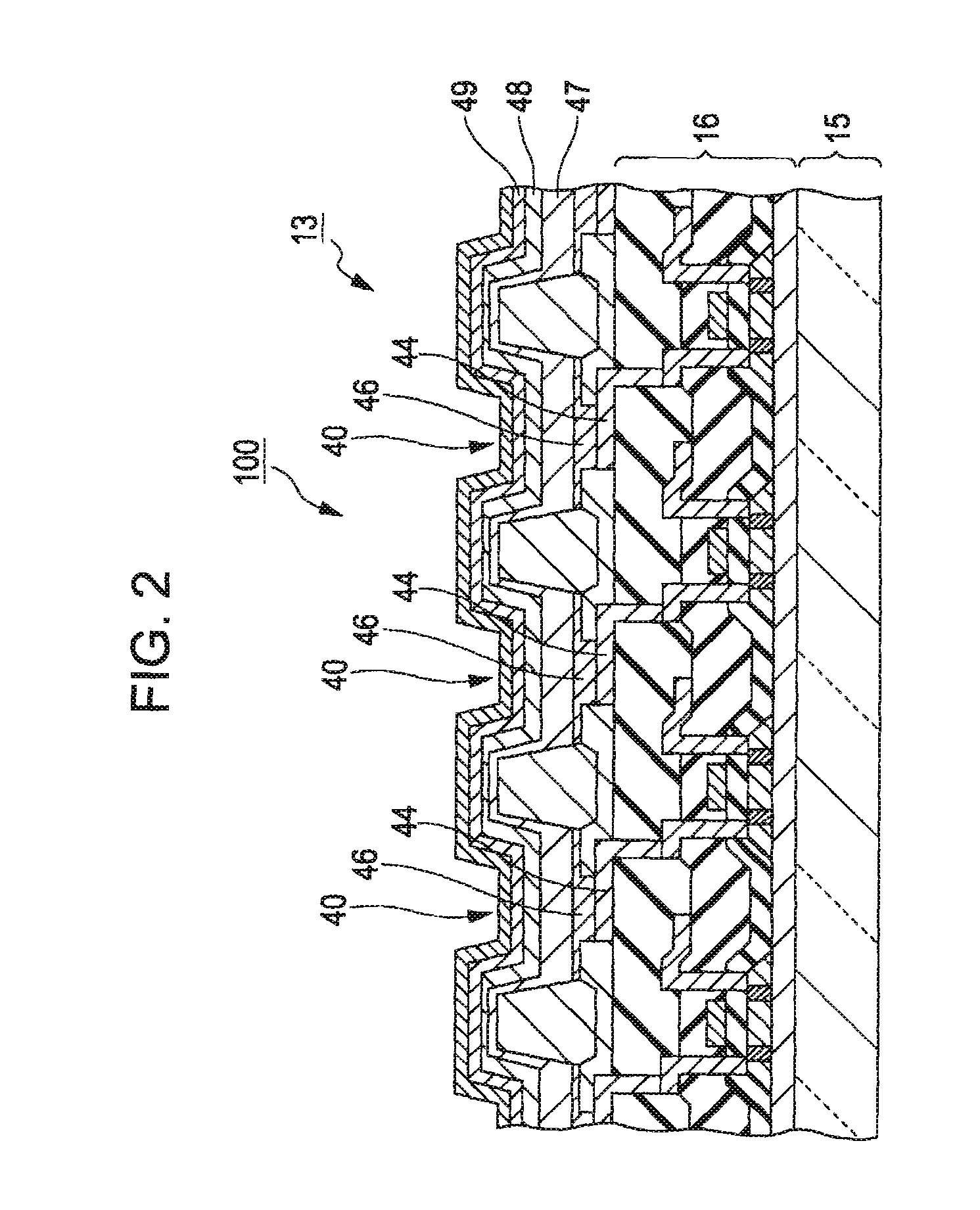

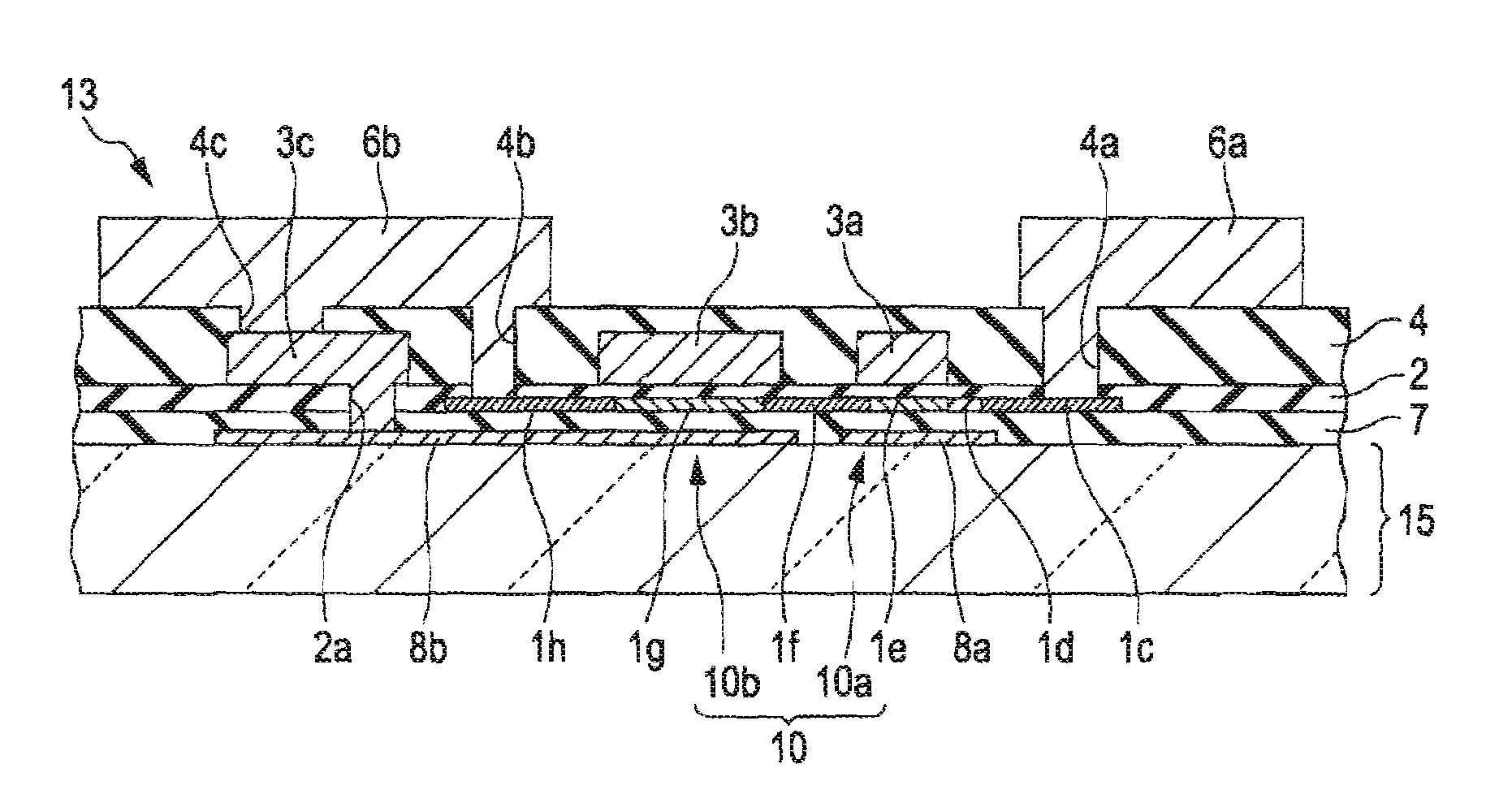

Semiconductor device and electro-optical device

ActiveUS20080128705A1Reduce leakage currentIncrease contrastLiquid crystal compositionsSemiconductor/solid-state device detailsDrain currentActive layer

A semiconductor device and an electro-optical device that ensures a stable output are provided even when there is a change in a source-drain current in a saturated operation region of a thin film transistor due to kink effects. The thin film transistor has a multi-gate structure with a polycrystalline silicon film as an active layer, and a source-side first thin film transistor portion and a drain-side second thin film transistor portion connected in series. The first thin film transistor portion has a drain-side back gate electrode that is connected with a first front gate electrode. The second thin film transistor portion has a source-side back gate electrode that is connected with a second front gate electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

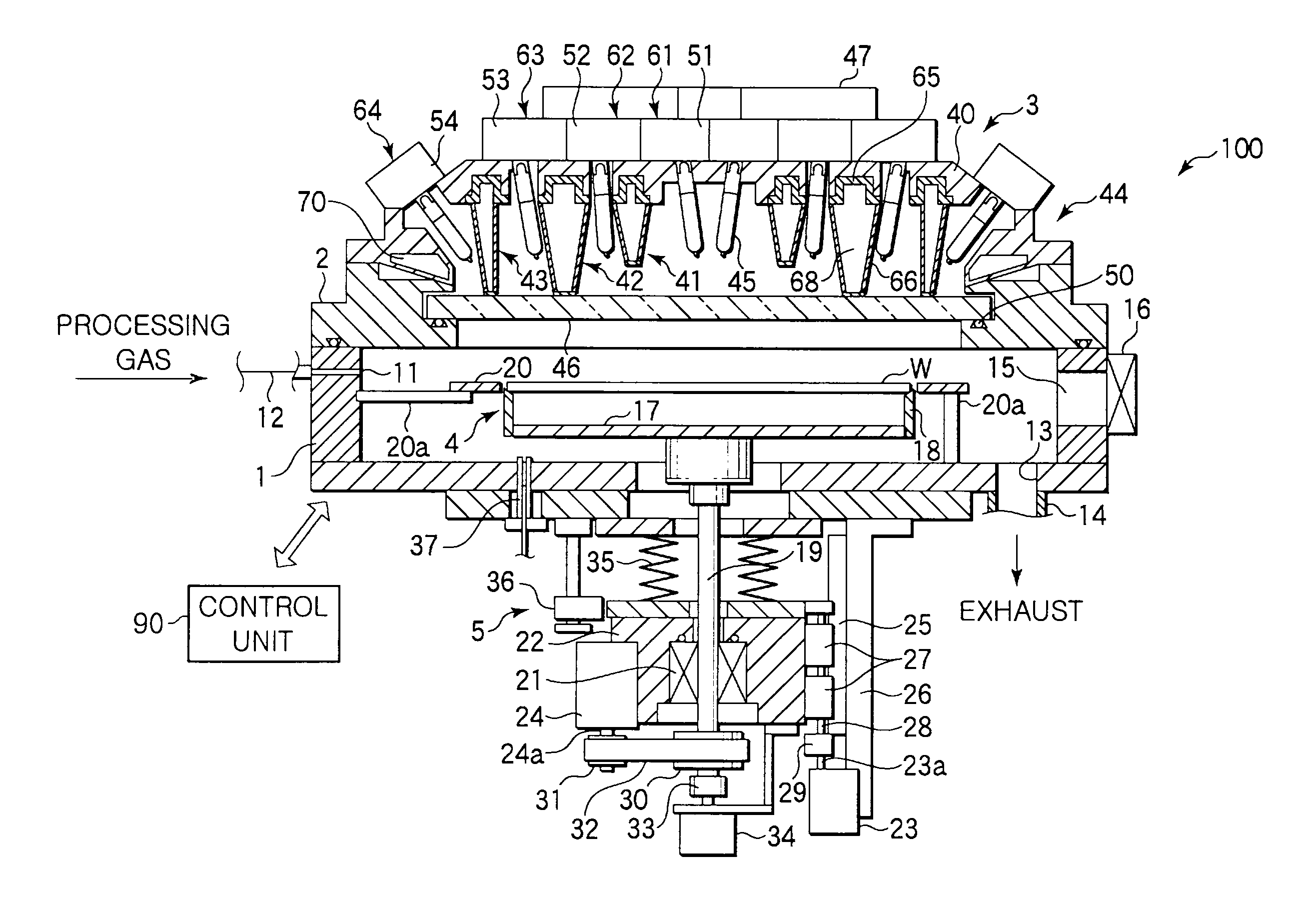

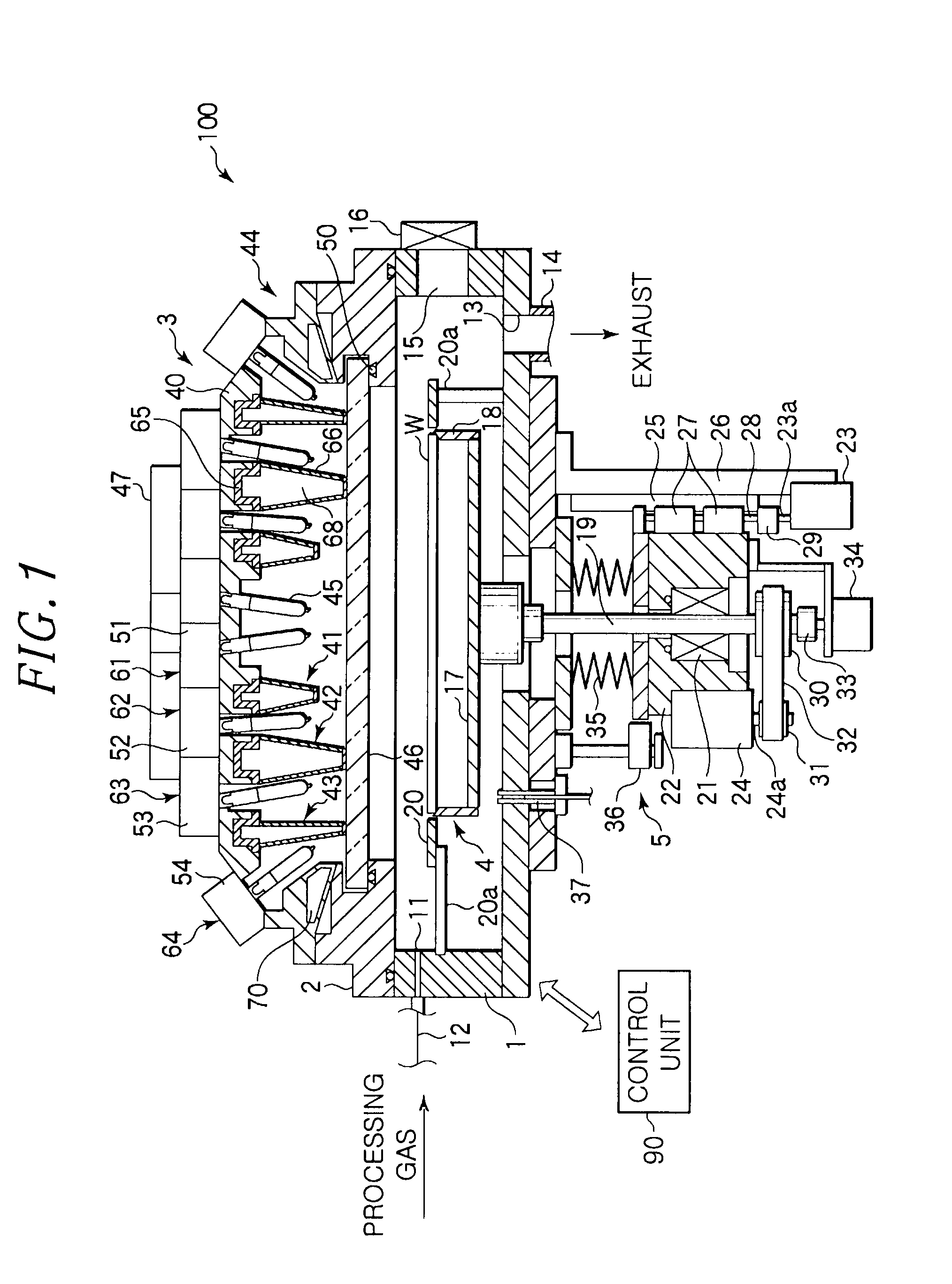

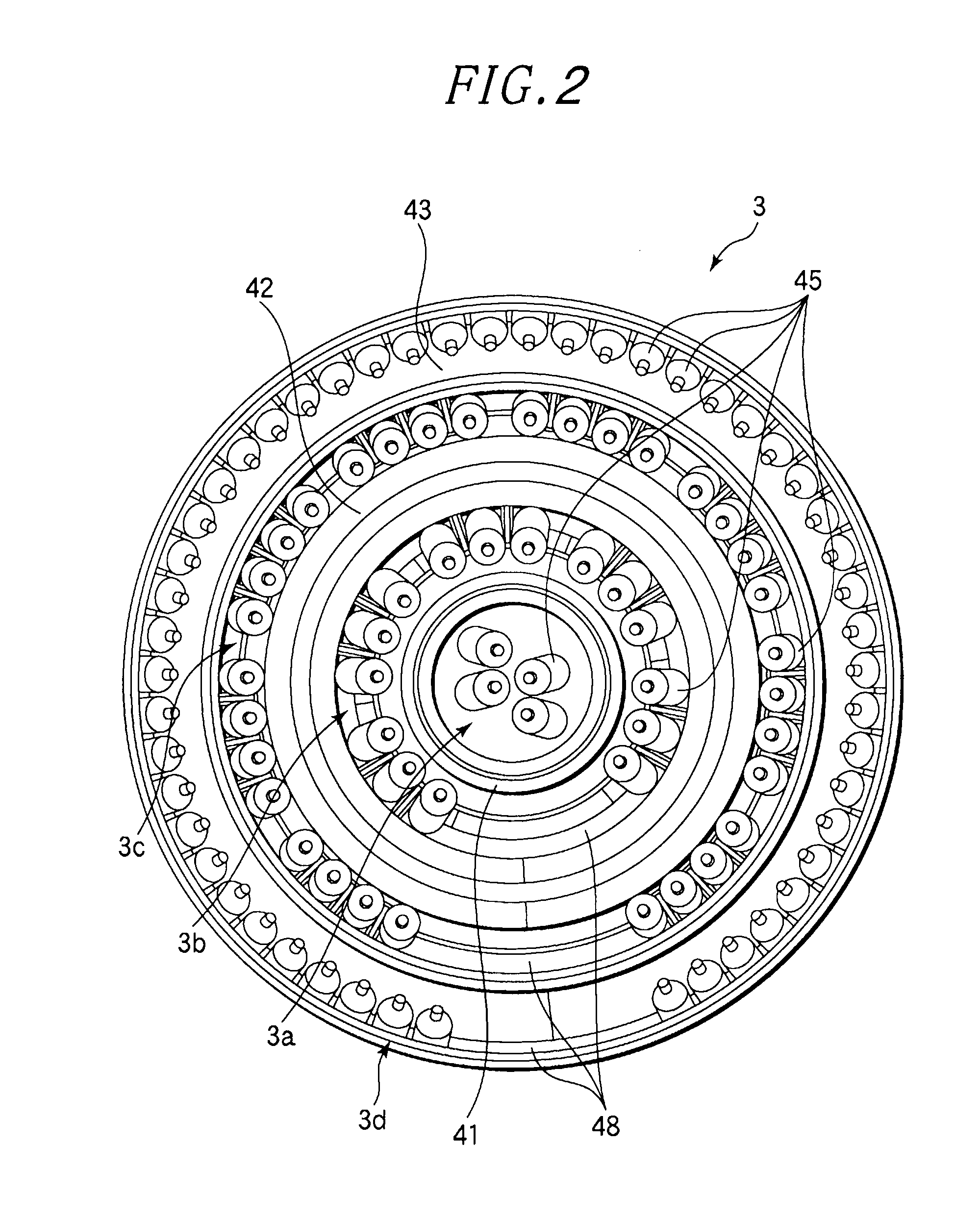

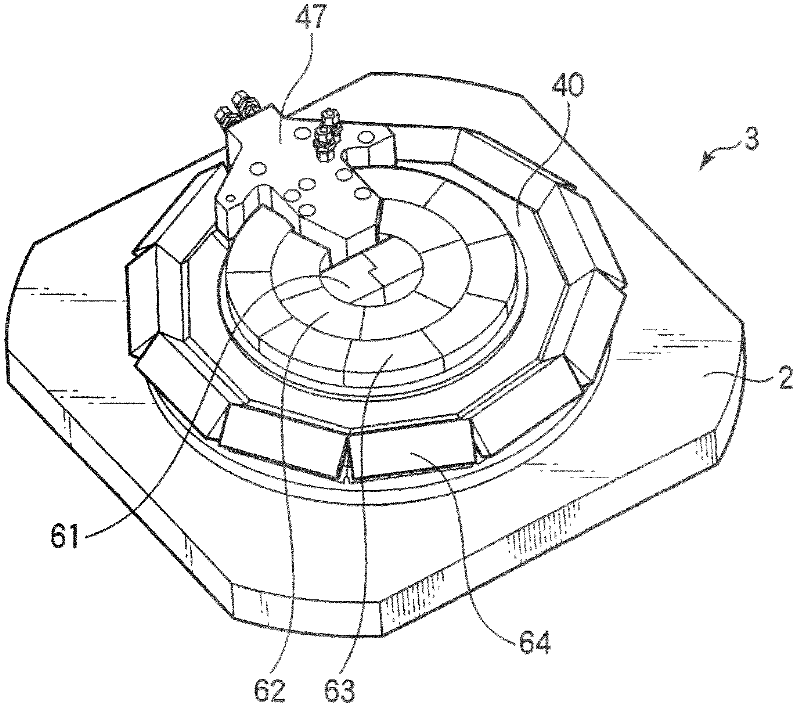

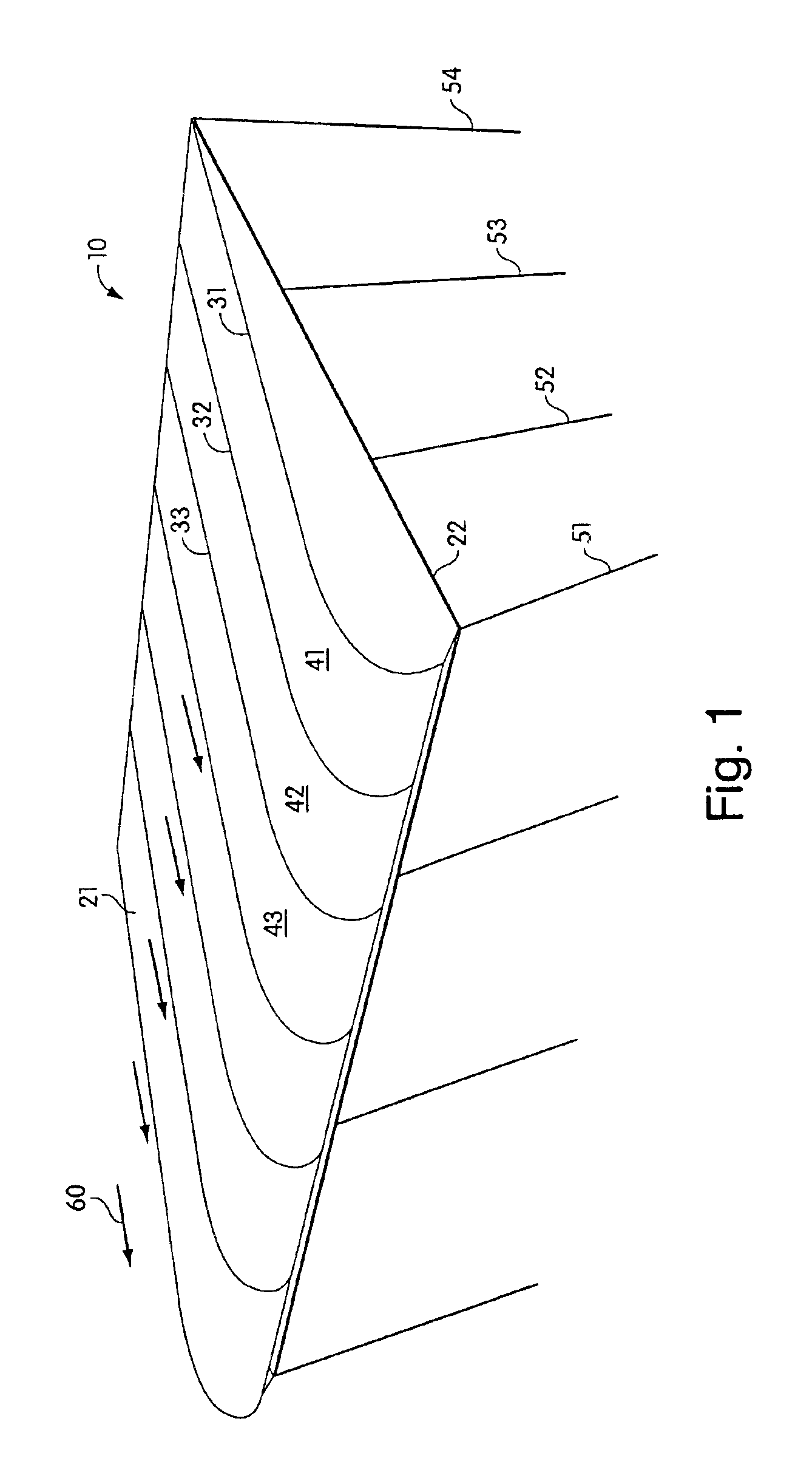

Heat treatment apparatus

InactiveUS20120145697A1Improve cooling effectImprove energy efficiencySemiconductor/solid-state device manufacturingElectric heating for furnacesInterior spaceEngineering

A heat treatment apparatus is configured to include: a treatment chamber for accommodating therein a wafer; a substrate supporting unit for horizontally supporting the wafer in the treatment chamber; and a lamp unit provided above the treatment chamber. The lamp unit includes: a base member; a plurality of lamps provided on the lower surface of the base member whose front ends face downwardly; a plurality of ring-shaped reflectors concentrically provided on the lower surface of the base member to protrude downward; and a cooling head for supplying a cooling medium into the reflectors. At least some of the lamps are arranged along the reflectors, and cooling medium channels, each inner space of which is formed as a ring-shaped space, are respectively provided within the reflectors in the extending directions of the reflectors.

Owner:TOKYO ELECTRON LTD

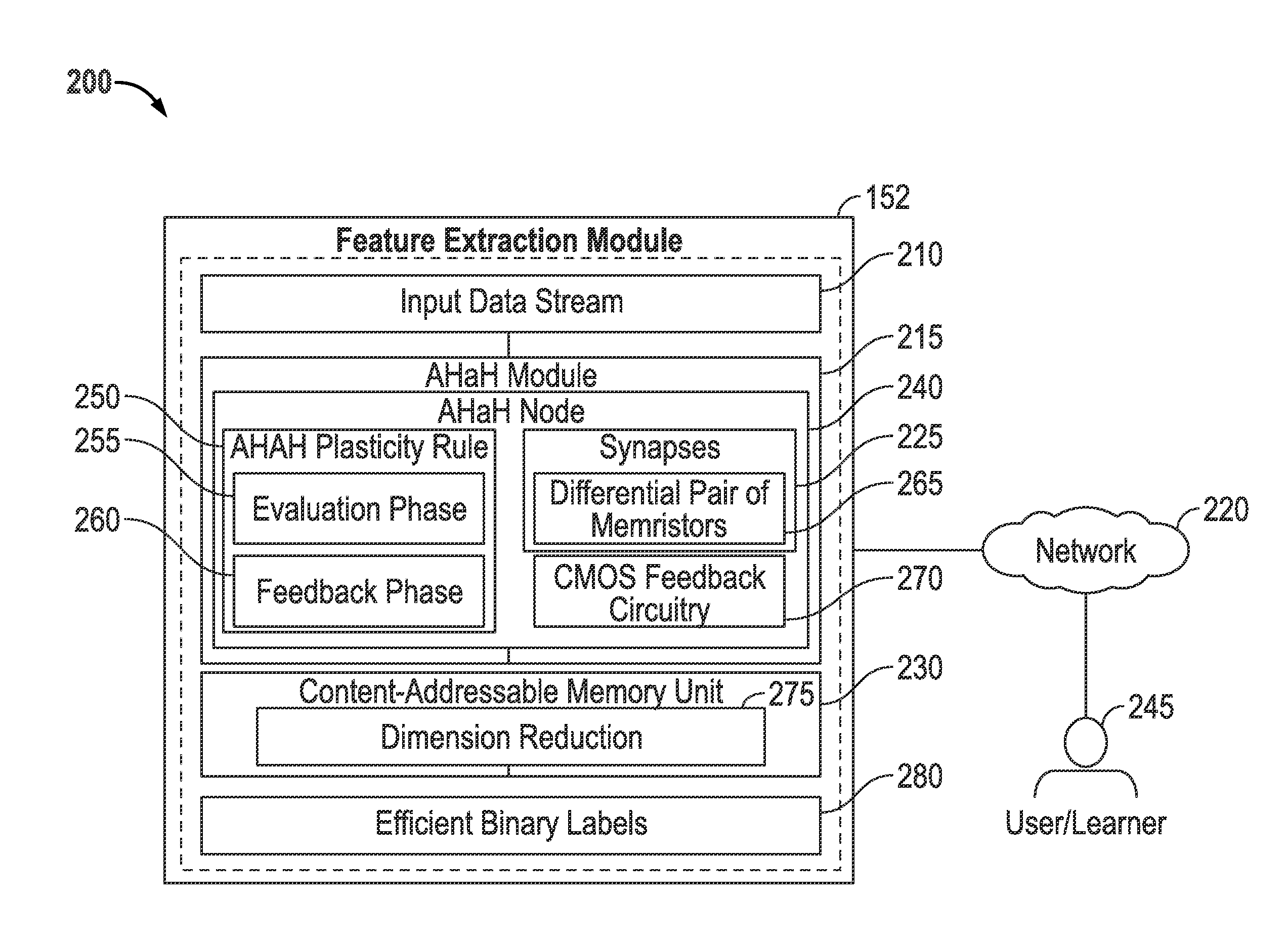

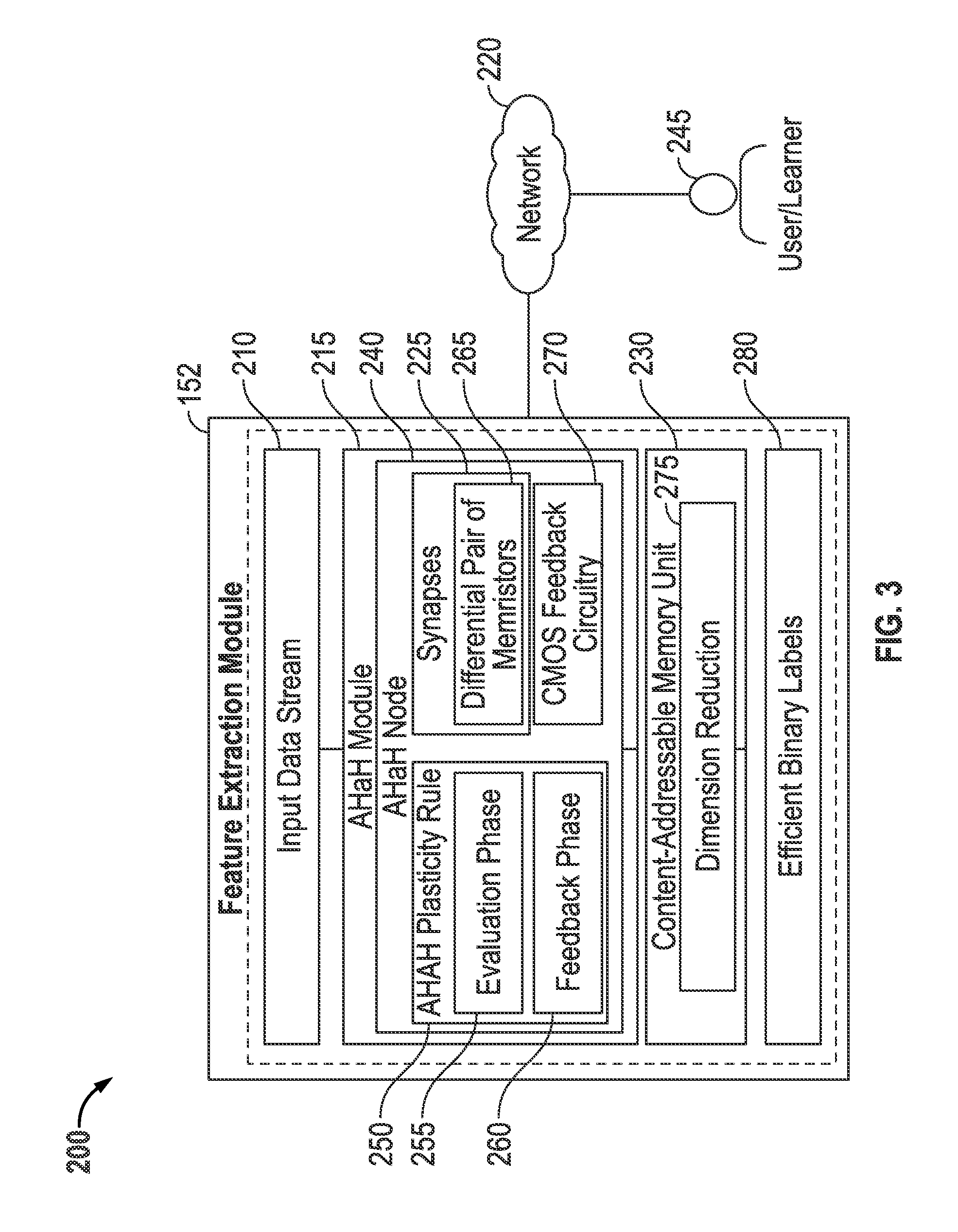

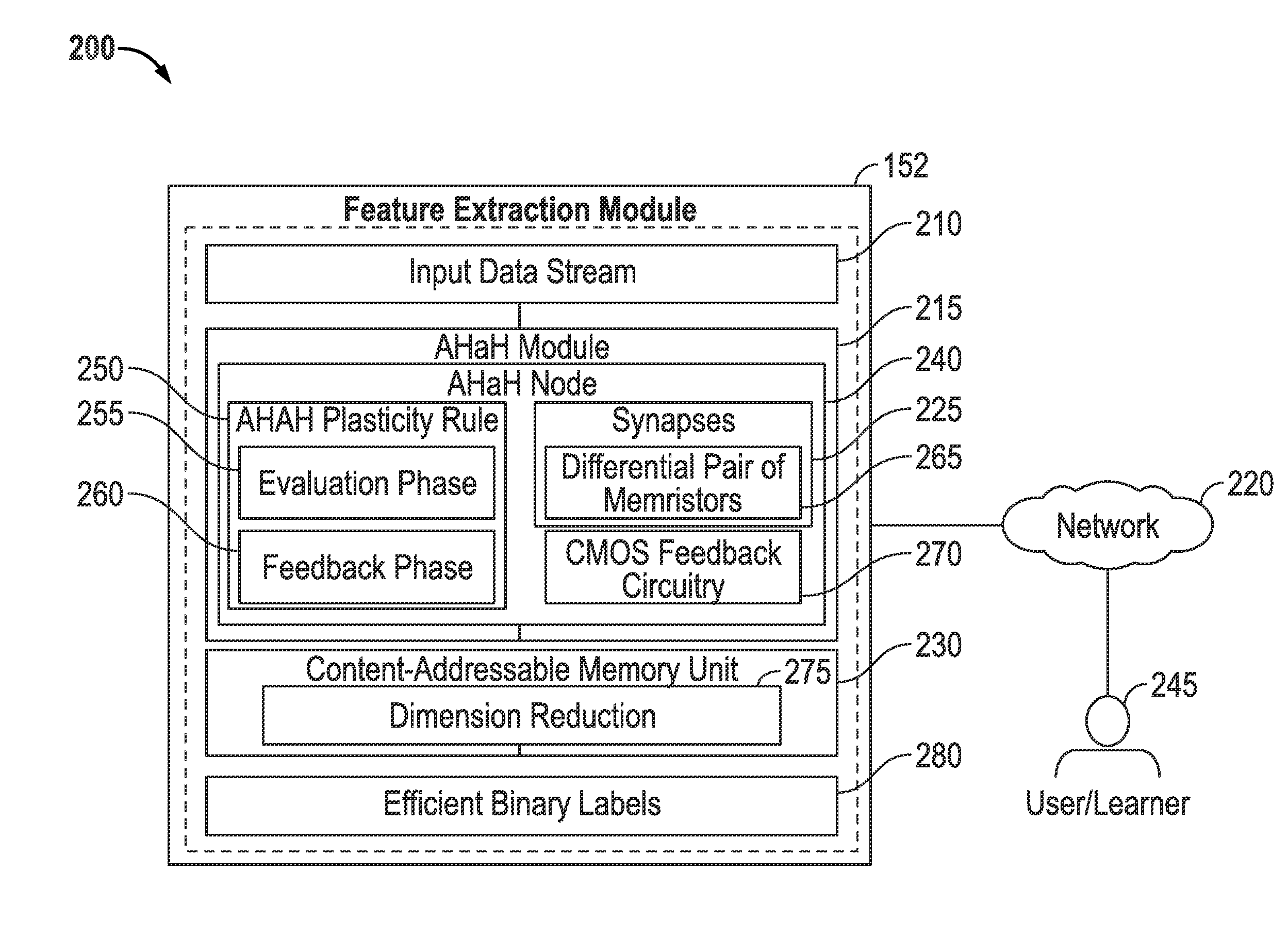

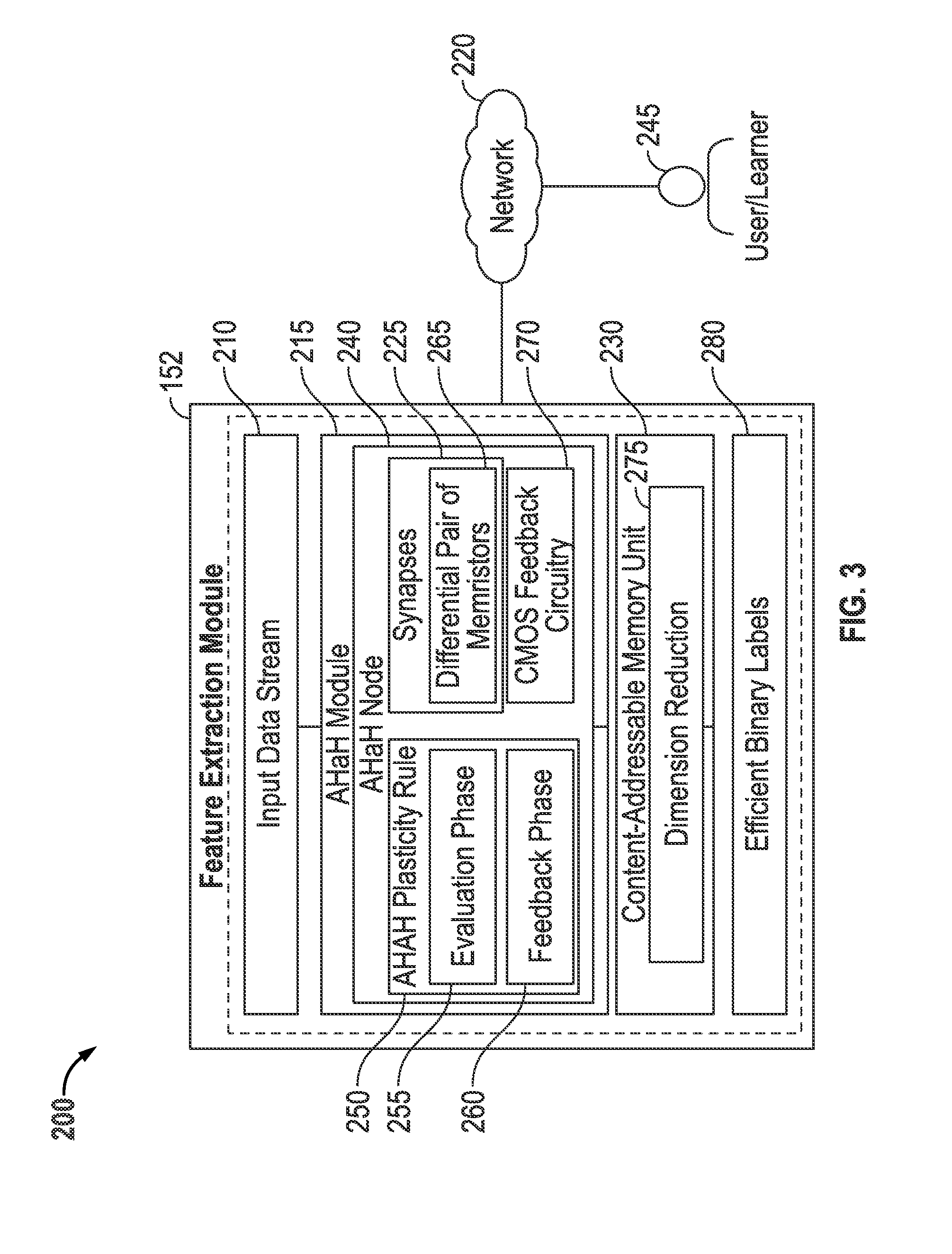

Methods and systems for feature extraction

InactiveUS20130218815A1Improve methodExact matchDigital computer detailsKnowledge representationPhase cycleNull state

A method and system for extracting feature utilizing an AHaH module (Anti-Hebbian and Hebbian). A sparse input data stream can be presented to a synaptic matrix of a collection of AHaH nodes associated with the AHaH module. The AHaH module operates an AHaH plasticity rule via an evaluate phase and a feedback phase cycle. A bias input line can be modulated such that a bias weight do not receive a Hebbian portion of the weight update during the feedback phase in order to prevent occupation of a null state. The input space can be bifurcated when the AHaH nodes fall randomly into an attractor state. The output of the AHaH module that forms a stable bit pattern can then be provided as an input to a content-addressable memory for generating a maximally efficient binary label.

Owner:KNOWM TECH

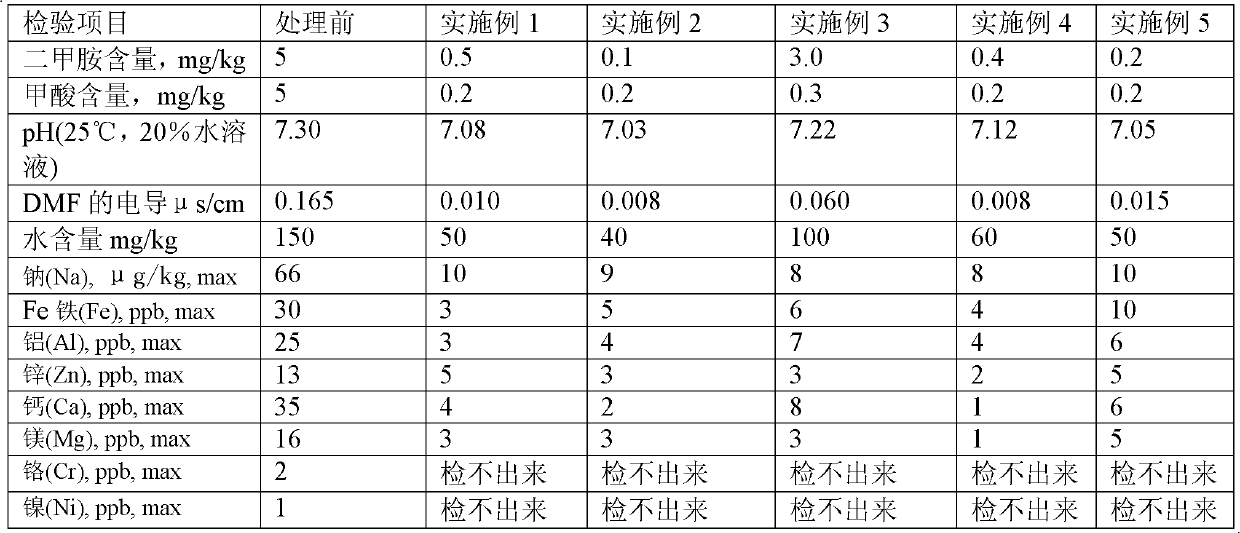

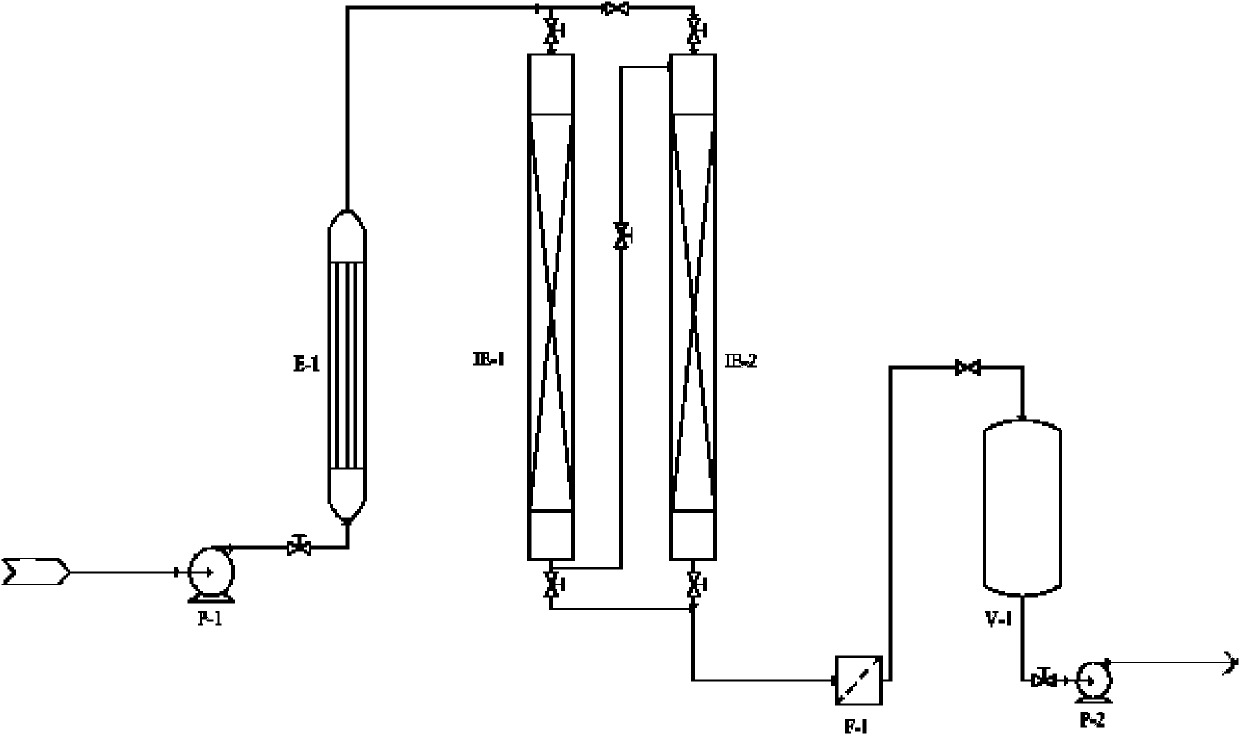

Purifying method for electronic-grade N,N-dimethylformamide

InactiveCN101993387AReduce contentReduce conductanceCarboxylic acid amide separation/purificationN dimethylformamideIon exchange

The invention discloses a purifying method for electronic-grade N,N-dimethylformamide, which is characterized in that the industrial-grade dimethylformamide (DMF) is decompressed and rectified; the material of a decompressing and rectifying tower is stainless steel; the operating pressure is between 8.7 and 27.2 kPa; the operating temperature is from 80 to 110 DEG C; the formic acid with low boiling point, the water and the dimethylamine impurities in the DMF are eliminated from the top of the tower; the DMF from the bottom of the rectifying tower enters a continuous electric deionizing device; and the metal ions, the formic acid, the organic amine and the salt impurities generated by the formic acid and the organic amine in the N,N-dimethylformamide are eliminated by utilizing ion exchange resins and the coupling technique of electrodialysis under an electric field. The invention provides a producing process with the advantages of good purification effect and low energy consumption, and the continuous production purity reaches the purity requirements of electronic chemicals. Thus, the content of the impurity metal ions in the DMF product is lower than 10ppb, the content of the dimethylamine, the formic acid and the electrolyte impurity capable of being ionized is lower than 0.5ppm, the electric conductance of the product DMF is less than 0.010 mu second / cm, and the obtained DMF product can be used for the electronic industries of copper-clad plates and the like.

Owner:TIANJIN UNIV

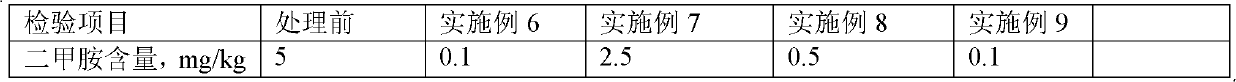

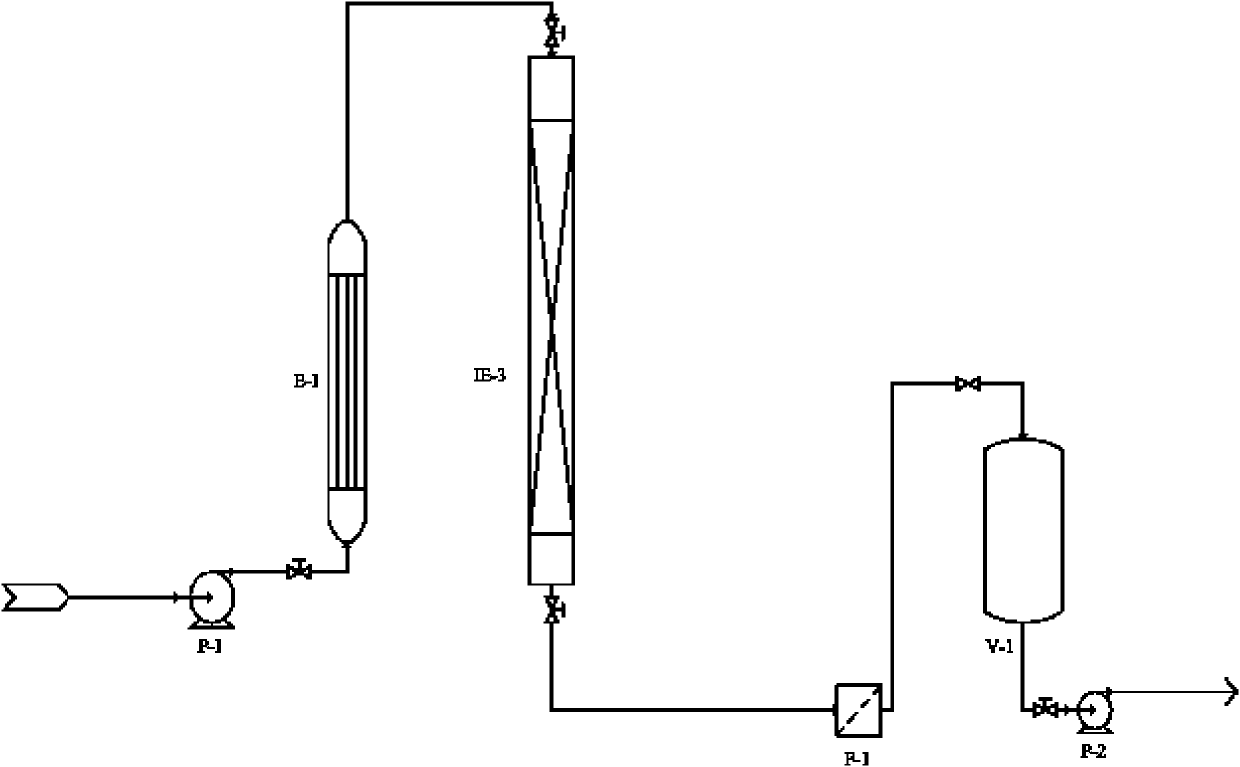

Method for preparing electronic-grade N, N-dimethylformamide by ion exchange resin method

InactiveCN101993386AReduce conductanceCarboxylic acid amide separation/purificationN dimethylformamideIon exchange

The invention discloses a method for preparing electronic-grade N, N-dimethylformamide by an ion exchange resin method, which comprises the steps of: pumping industrial-grade N, N-dimethylformamide into a heat exchanger; reducing the temperature of raw material to room temperature of 40 DEG C; entering an ion exchange unit; removing metal ions, formic acid, dimethylamine and salt impurities generated by the formic acid and the dimethylamine from the N, N-dimethylformamide by an ion exchange method; and filtering broken resin and granular impurities in the N, N-dimethylformamide by a filtering unit to obtain the electronic-grade N, N-dimethylformamide. In the prepared electronic-grade N, N-dimethylformamide DMF, the content of each metal ion is less than 10 ppb; the content of methylamine and the content of the formic acid are reduced to be less than 1 ppm; the pH value of DMF is 7.0 approximately; the conductance of pure DMF is less than 0.010 microsecond / cm; a purified DMF is used as a high-end product for electronics industry of manufacturing copper-clad plates and high-grade pulp industry of polyurethane synthetic leather.

Owner:TIANJIN UNIV

Methods and systems for feature extraction

InactiveUS8918353B2Simple methodReduce conductanceDigital computer detailsMachine learningFeature extractionData stream

A method and system for extracting feature utilizing an AHaH module (Anti-Hebbian and Hebbian). A sparse input data stream can be presented to a synaptic matrix of a collection of AHaH nodes associated with the AHaH module. The AHaH module operates an AHaH plasticity rule via an evaluate phase and a feedback phase cycle. A bias input line can be modulated such that a bias weight do not receive a Hebbian portion of the weight update during the feedback phase in order to prevent occupation of a null state. The input space can be bifurcated when the AHaH nodes fall randomly into an attractor state. The output of the AHaH module that forms a stable bit pattern can then be provided as an input to a content-addressable memory for generating a maximally efficient binary label.

Owner:KNOWM TECH

Heat treatment apparatus

InactiveCN102414800AImprove irradiation efficiencyIncrease configuration densitySemiconductor/solid-state device manufacturingEngineeringHeat treated

Disclosed is a heat treatment apparatus (100) which comprises: a treatment chamber (1) in which a wafer (W) is contained; a substrate supporting unit (4) for horizontally supporting the wafer (W) within the treatment chamber (1); and a lamp unit (3) that is provided above the treatment chamber (1). The lamp unit (3) comprises: a base member (40); a plurality of lamps (45) that are provided on the lower surface of the base member (40) with the front ends facing down; a plurality of ring-shaped reflectors (41, 42, 43) that are concentrically provided on the lower surface of the base member (40) so as to project downward; and a cooling head (47) for supplying a cooling medium into the reflectors (41, 42, 43). At least some of the plurality of lamps (45) are arranged along the reflectors (41, 42, 43), and cooling medium channels (68), each of which is composed of a ring-shaped space, are provided within the reflectors (41, 42, 43) in the arrangement direction of the reflectors.

Owner:TOKYO ELECTRON LTD

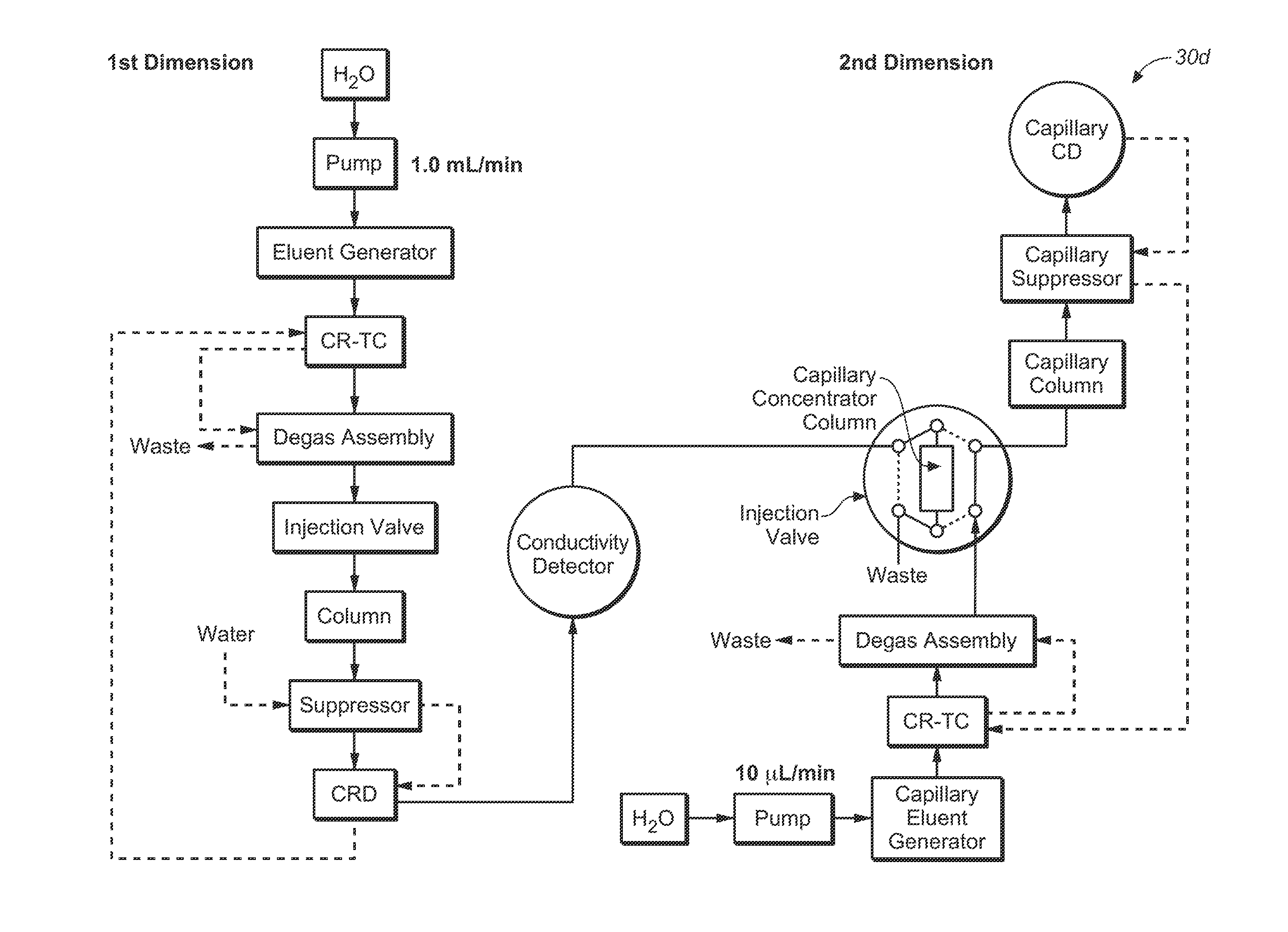

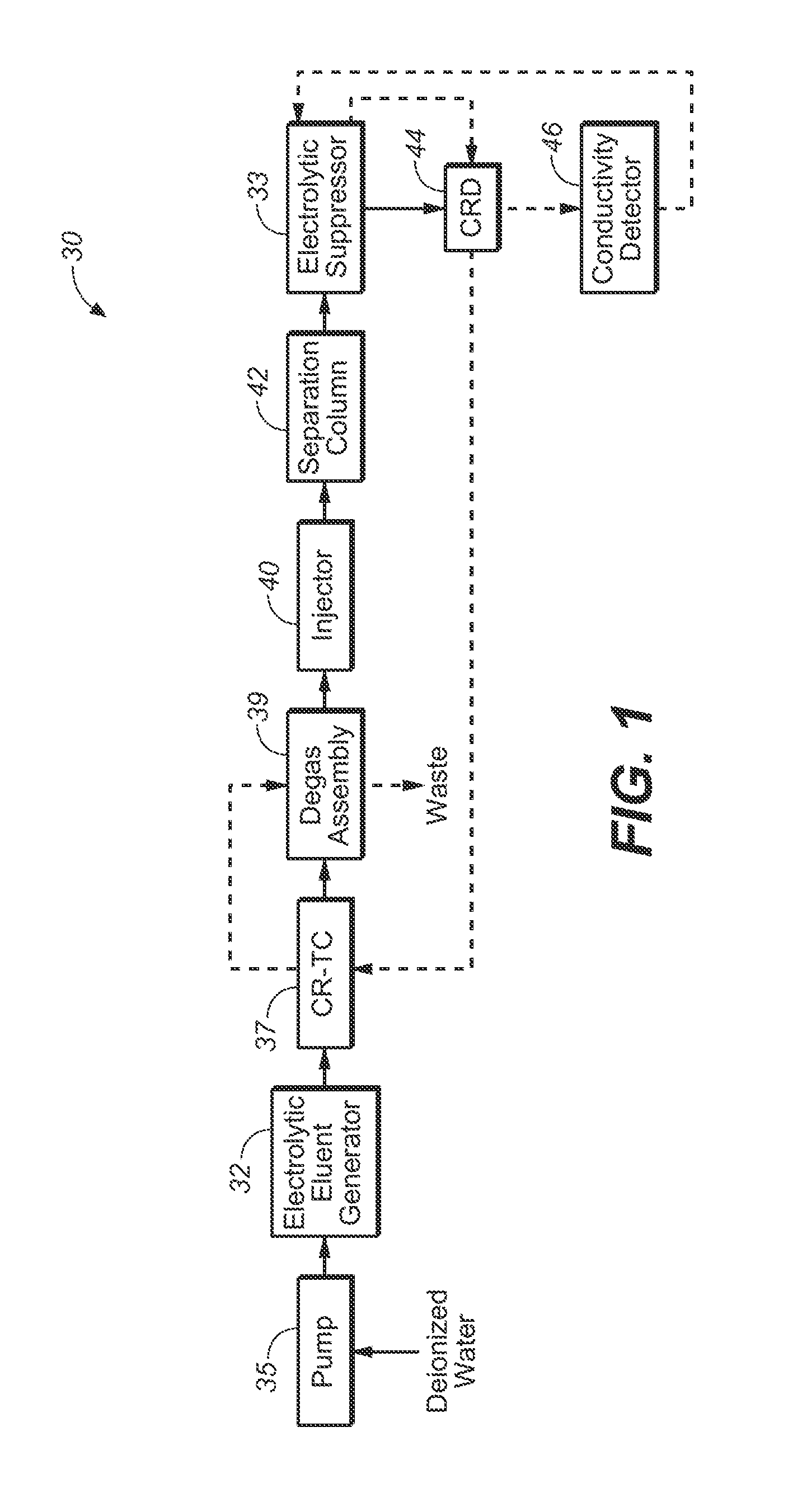

Multichannel ion chromatography system and method

ActiveUS20110174063A1High conductanceReduce conductanceComponent separationSurface/boundary effectChromatographic separationIon chromatography

An ion chromatography housing for easy insertion and removal of a plurality of component cartridges is disclosed. Various components of the IC system are provided in the separate component cartridges. The IC housing includes a capillary separation column and may be connected to conventional-scale components of an IC system. A plurality of IC housings may be provided in a compartment with one or more separation columns. The columns may be capillary columns or conventional-scale columns. A method of using the ion chromatography system is also disclosed. The IC system may be utilized to perform two-dimensional ion chromatographic separation.

Owner:DIONEX CORP

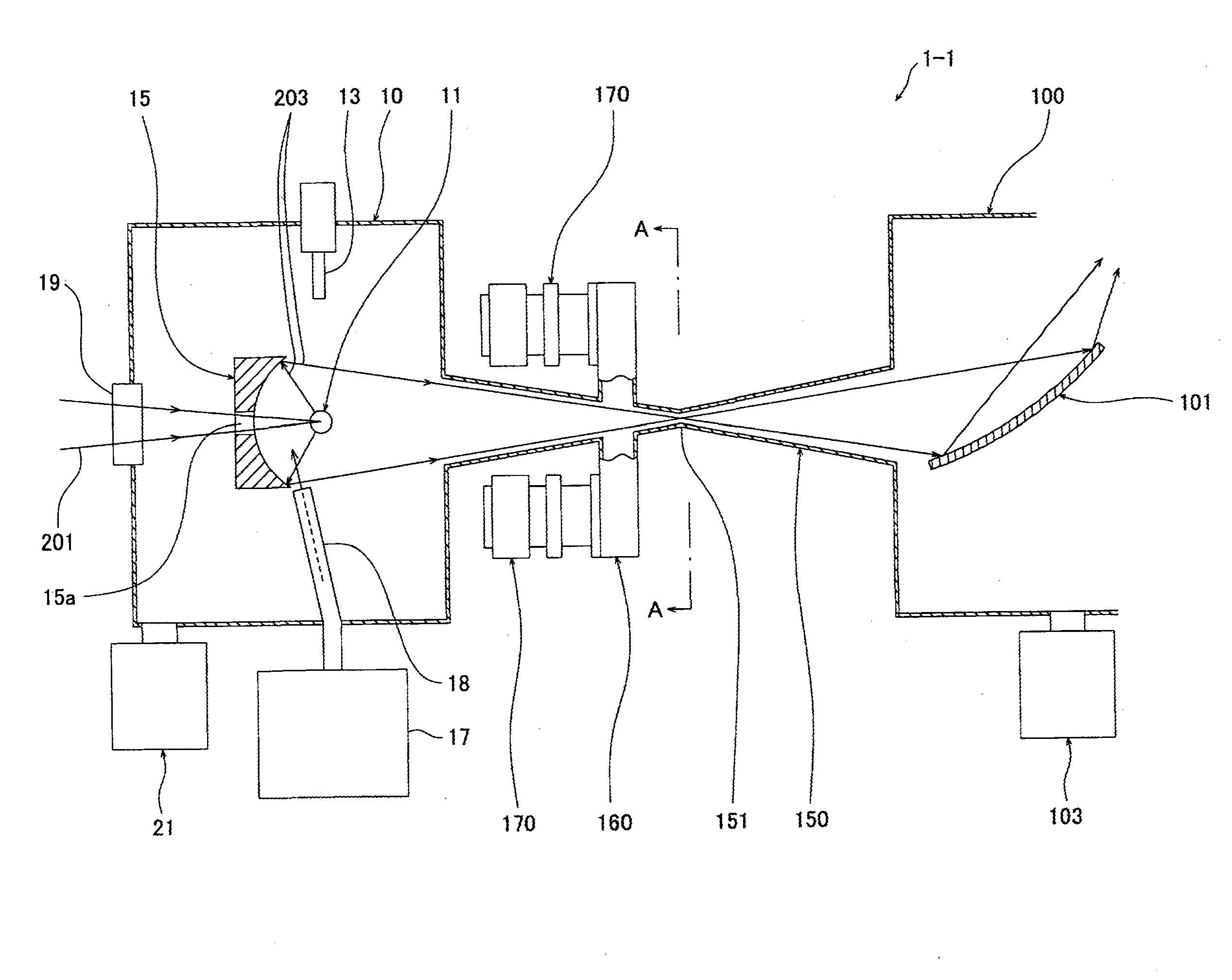

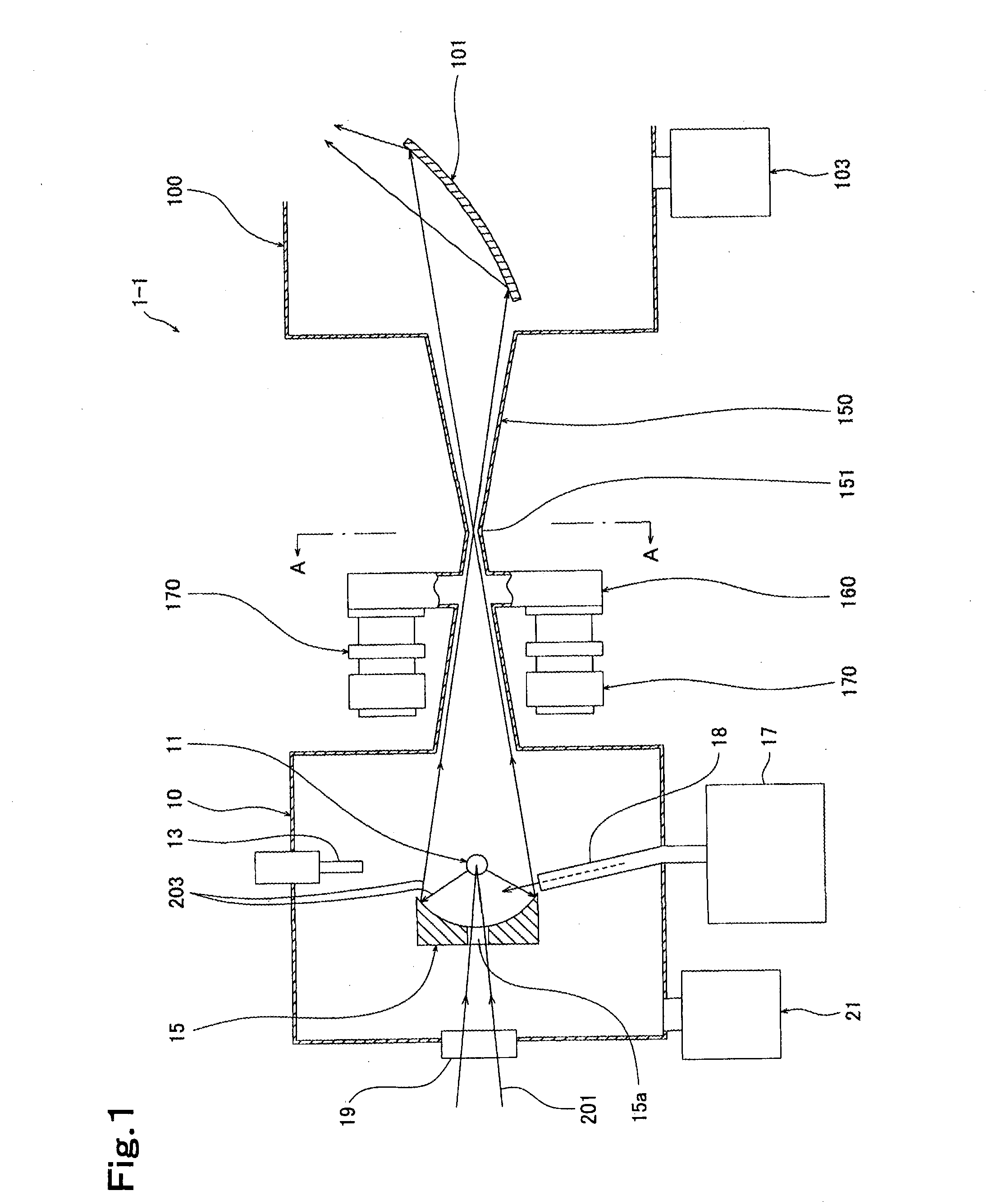

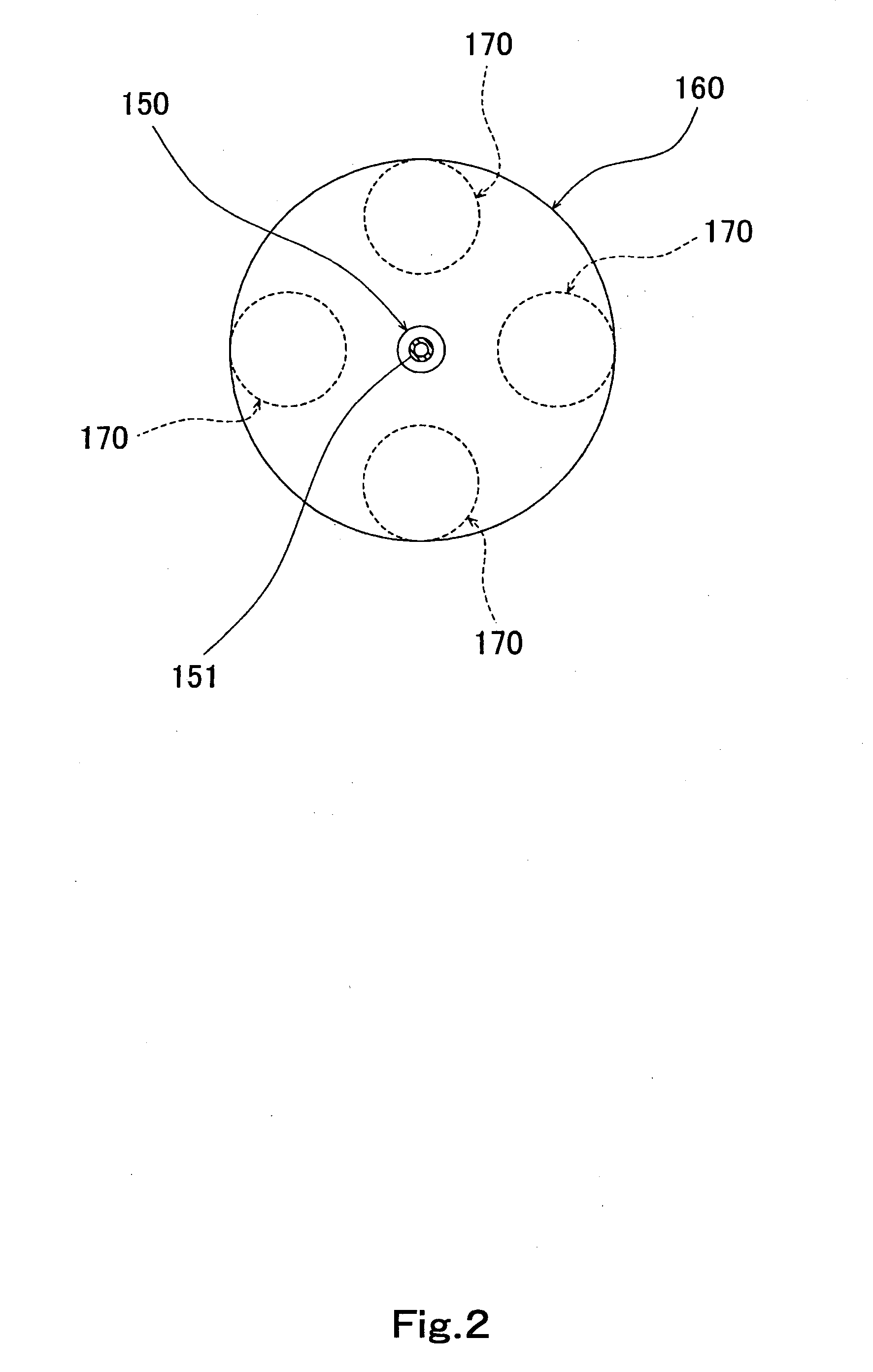

Differential evacuation system

ActiveUS20100181498A1Reduces it conductanceEffective evacuationMaterial analysis using wave/particle radiationPhotomechanical apparatusConical tubeExtreme ultraviolet

[Technical Problem] To provide a differential evacuation system capable of easily maintaining, at a low cost, a large differential pressure between a light generation chamber and an illumination optical chamber in which optical processing, e.g. exposure, is performed by using extreme ultraviolet (EUV) light generated in the light generation chamber, and yet capable of sufficiently ensuring a desired optical path.[Solution to Problem] The differential evacuation system has a light generation chamber 10 that generates EUV light, an illumination optical chamber 100 in which optical processing is performed by using the EUV light generated in the light generation chamber 10, and a chamber connecting passage 150 that connects together the light generation chamber 10 and the illumination optical chamber 100 to guide the EUV light generated in the light generation chamber 10 into the illumination optical chamber 100. The chamber connecting passage 150 has a flow path constricting portion 151 and is increased in inner diameter in a conical tube shape at portions thereof that are at opposite sides, respectively, of the flow path constricting portion 151. An enlarged-diameter part 160 is provided at a position of the chamber connecting passage 150 that is closer to the light generation chamber 10, which is the higher in pressure of the two chambers 10 and 100, than the flow path constricting portion 151, and vacuum pumps 170 are attached to the enlarged-diameter part 160.

Owner:GIGAPHOTON

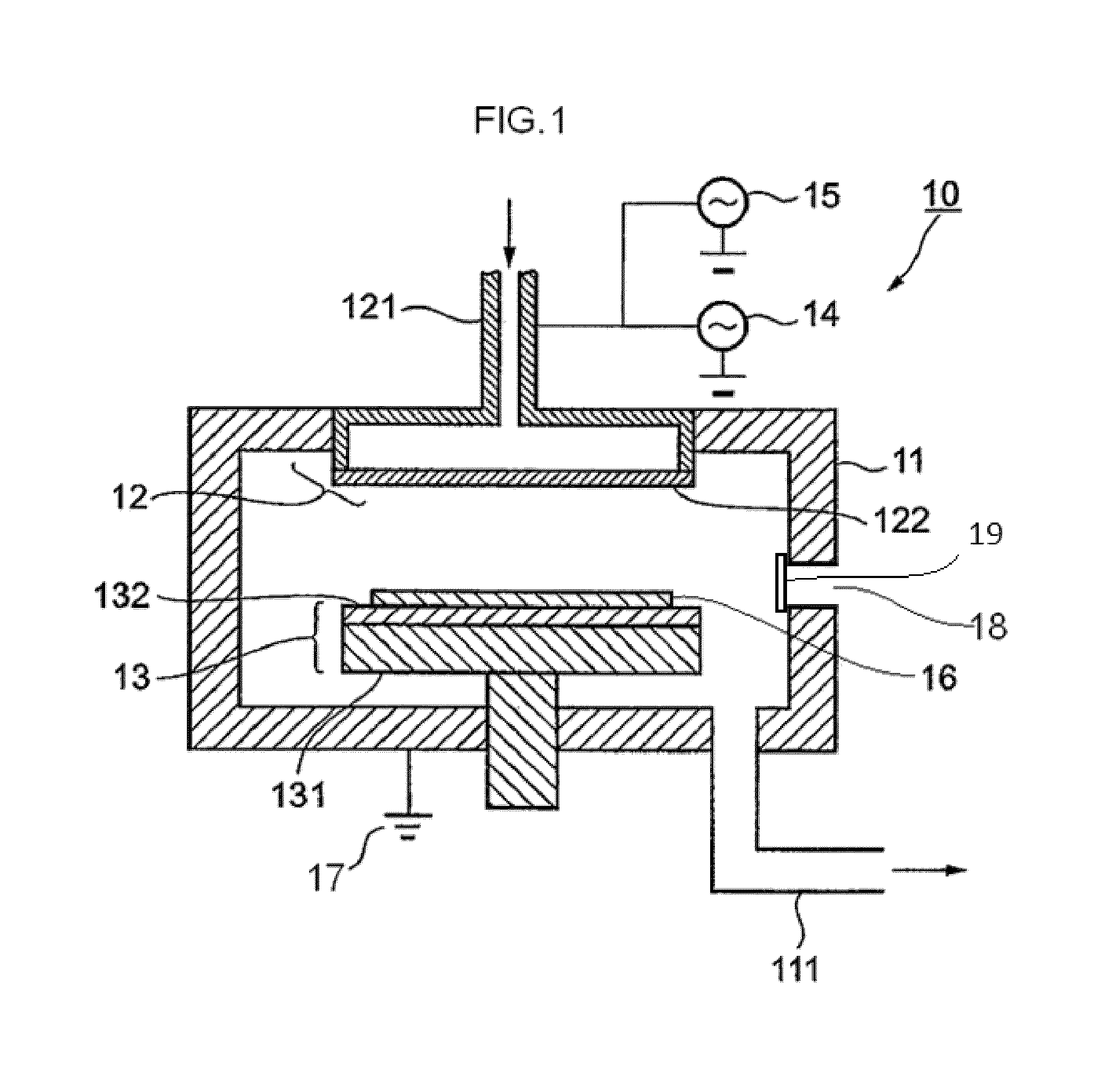

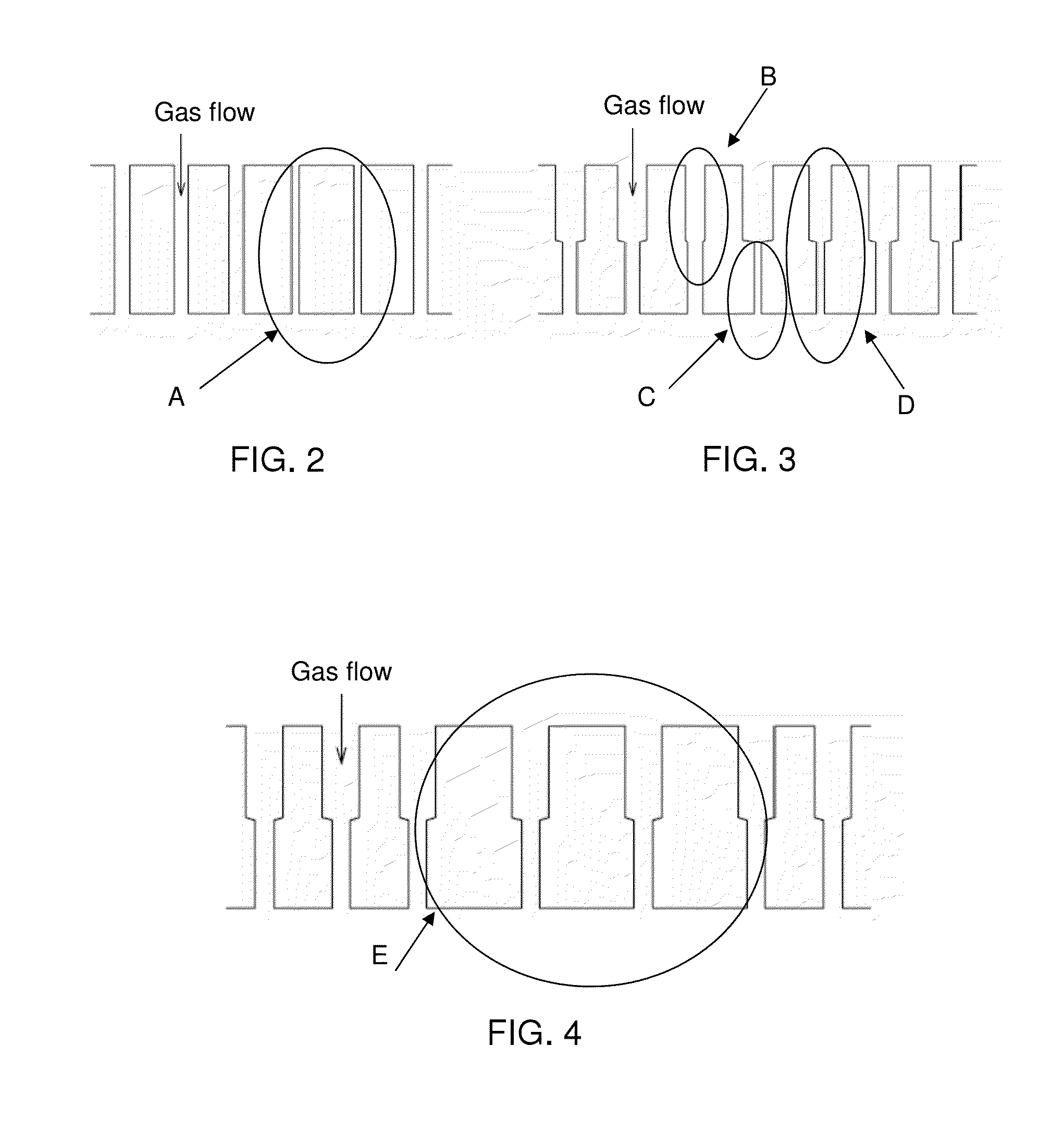

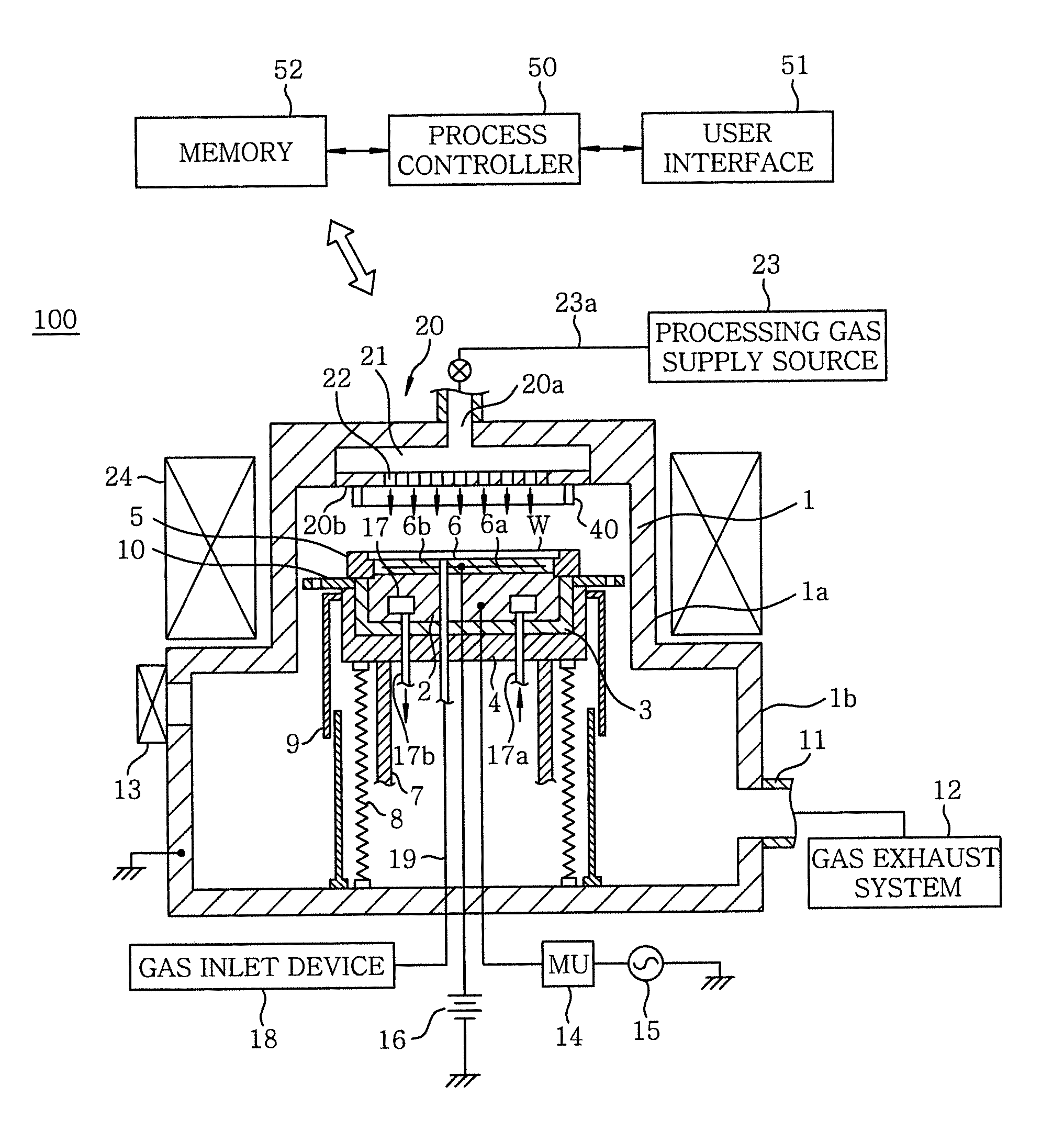

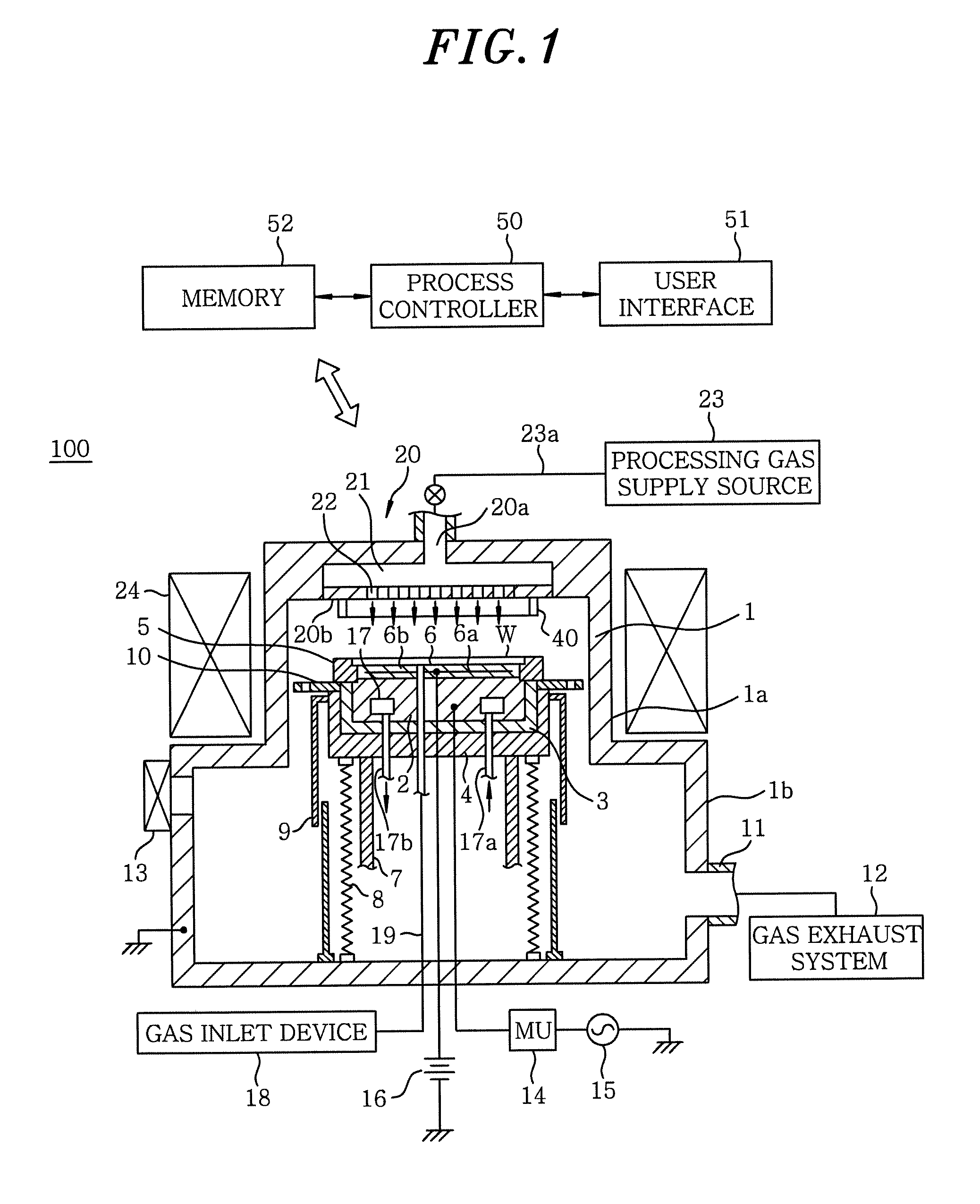

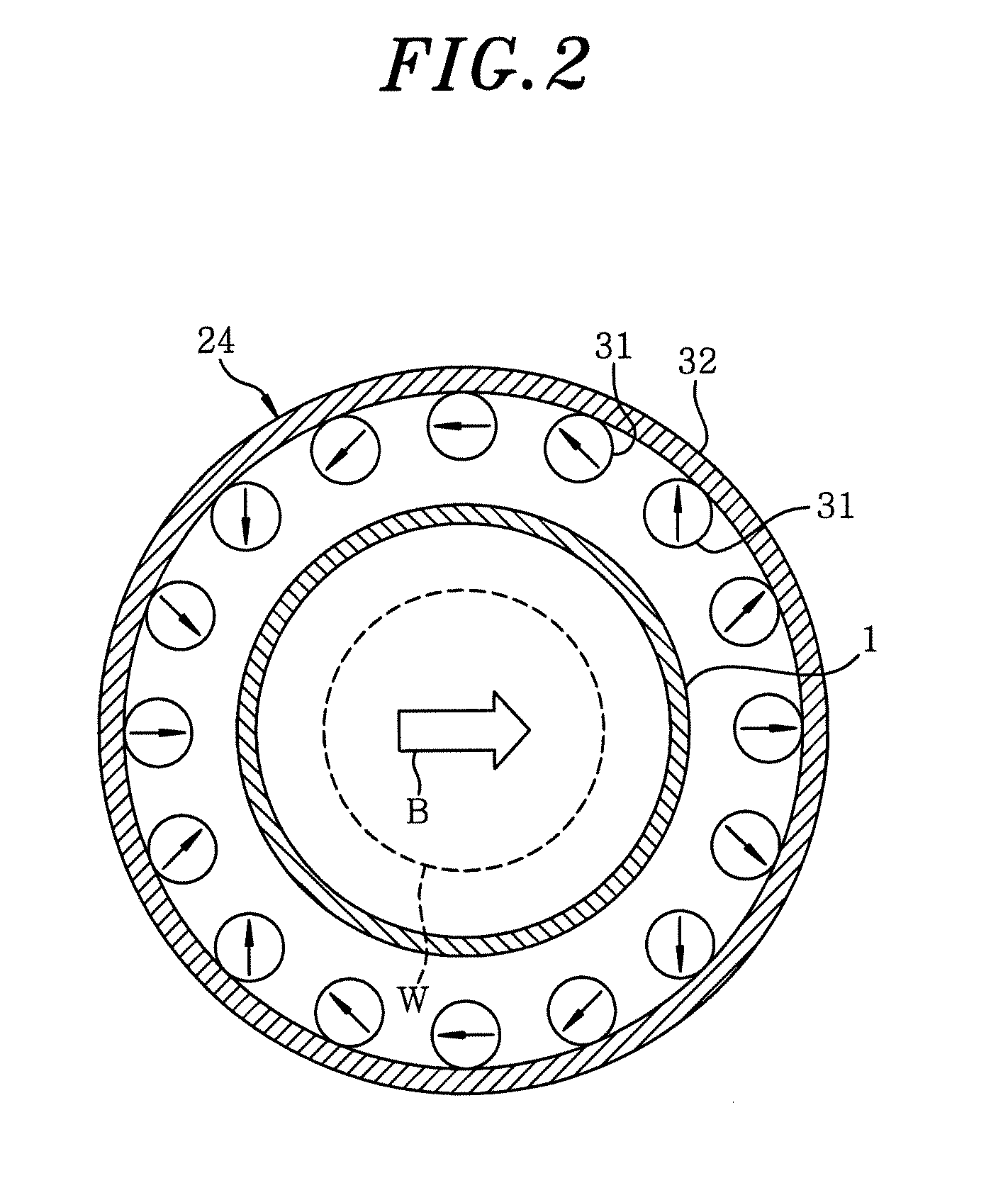

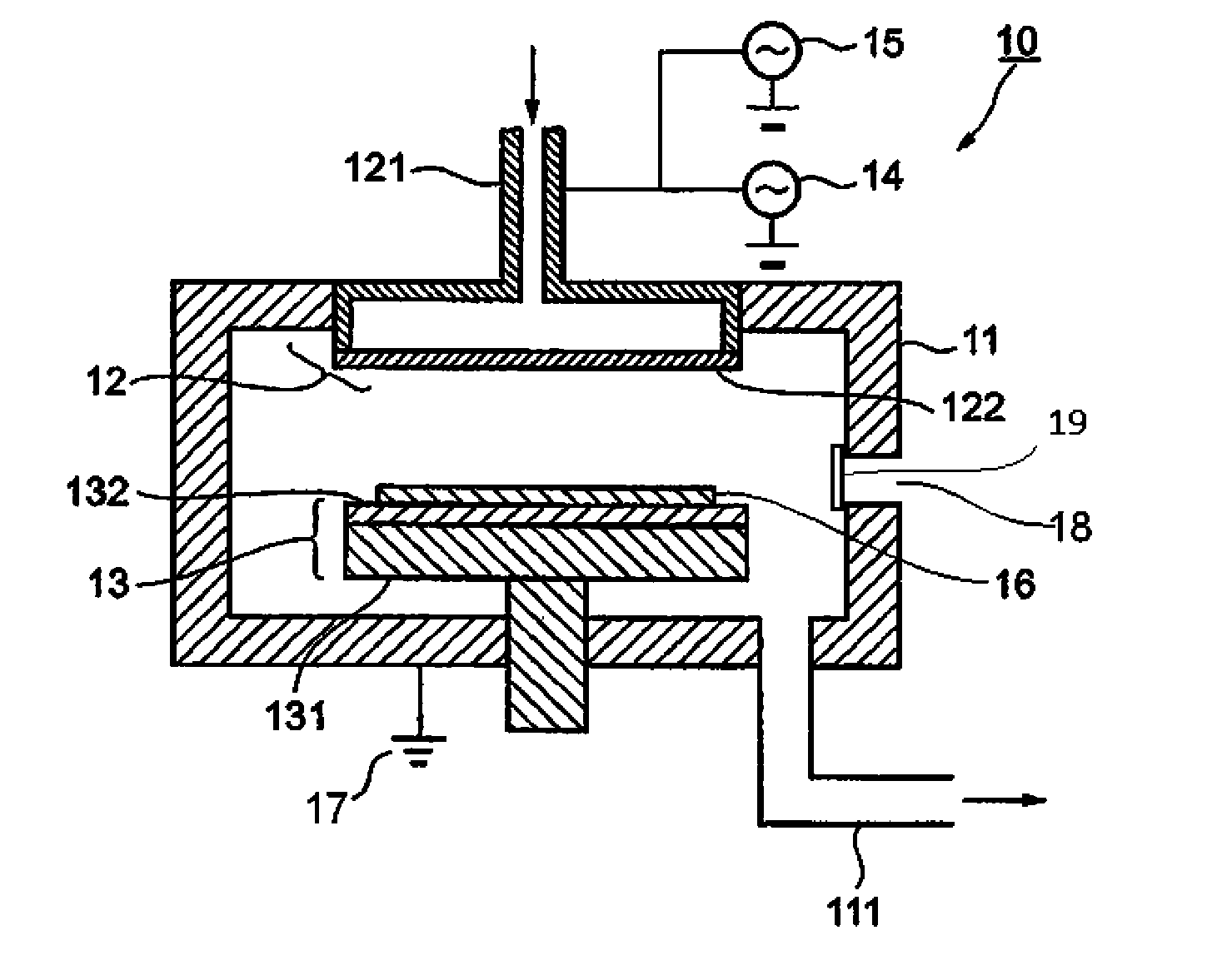

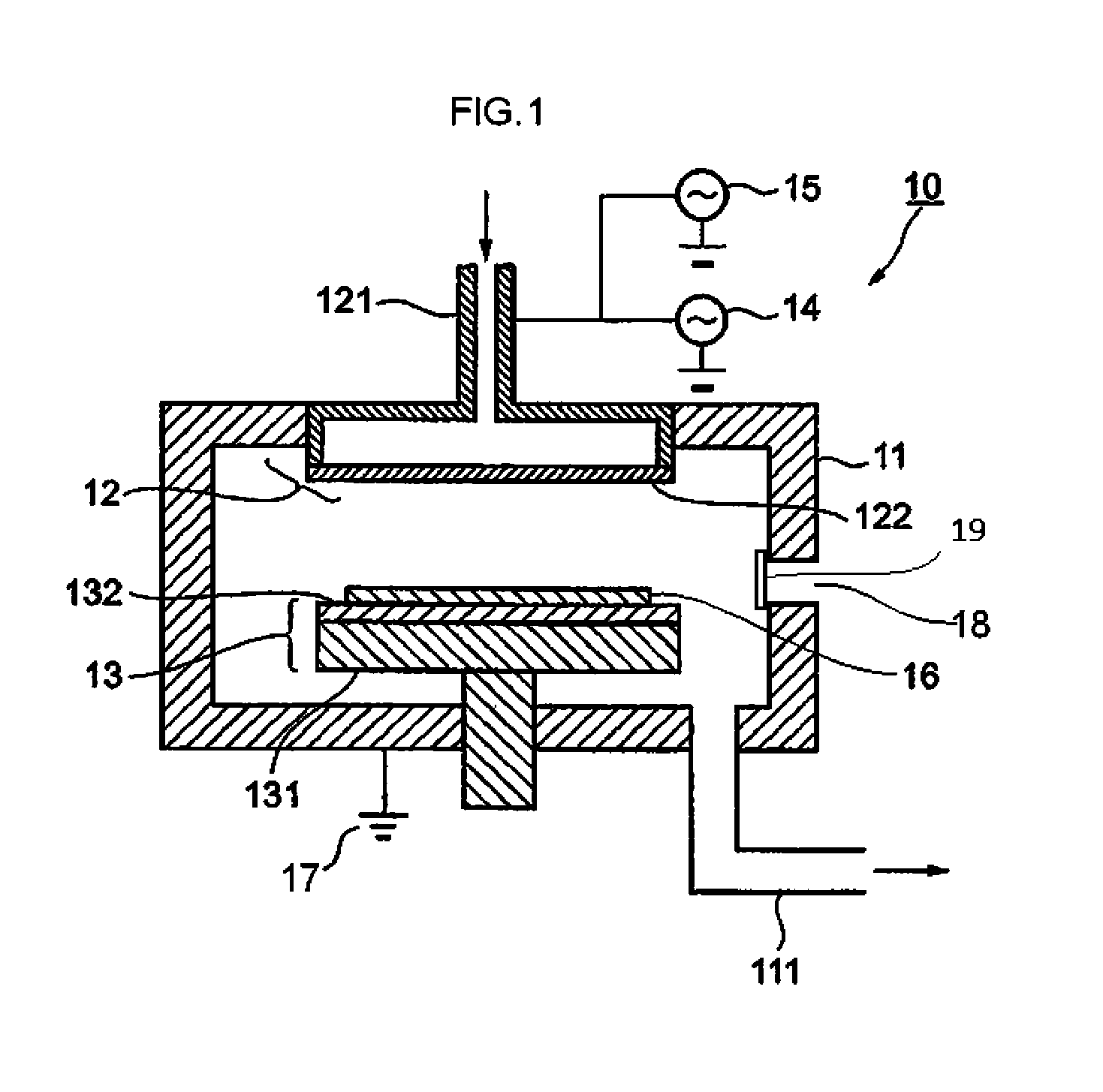

Plasma etching apparatus and method

InactiveUS20070202701A1Easy to useEasy to integrateSemiconductor/solid-state device manufacturingSpecial data processing applicationsEngineeringPlasma etching

A plasma etching apparatus includes an evacuable processing chamber for performing a plasma etching process on a target object; a mounting table for mounting thereon the target object in the processing chamber; and a shower head facing the mounting table, for introducing a processing gas for generating a plasma to the processing chamber. Further, the apparatus includes a ring-shaped protrusion protruded from a bottom surface of the shower head toward the mounting table; and a plurality of gas introducing openings inclusively arranged in an area smaller than the target object in an inner central portion of the ring-shaped protrusion on the bottom surface of the shower head.

Owner:TOKYO ELECTRON LTD

Method of decolouring glucose saccharifying liquid by ion exchange resin

InactiveCN1920056AHighly selective adsorptionPigment dissociation is easyGlucose productionLiquid glucoseActivated carbon

The invention discloses the method for decolouring dextroglucose liquid with ion exchange resin. The method comprises the following steps: confirming the temperature, concentration and flow velocity, putting the 35-45% liquid glucose into ion-exchange device at 40-50Deg.C and 2.5-4.0BV / h; or using activated charcoal to decolour liquid glucose, and then putting it into ion-exchange device. The light transmittance ratio of the decolour liquid is up to 100%, and the conductance is reduced to below 10 mus / cm.

Owner:SHANDONG XIWANG SUGAR

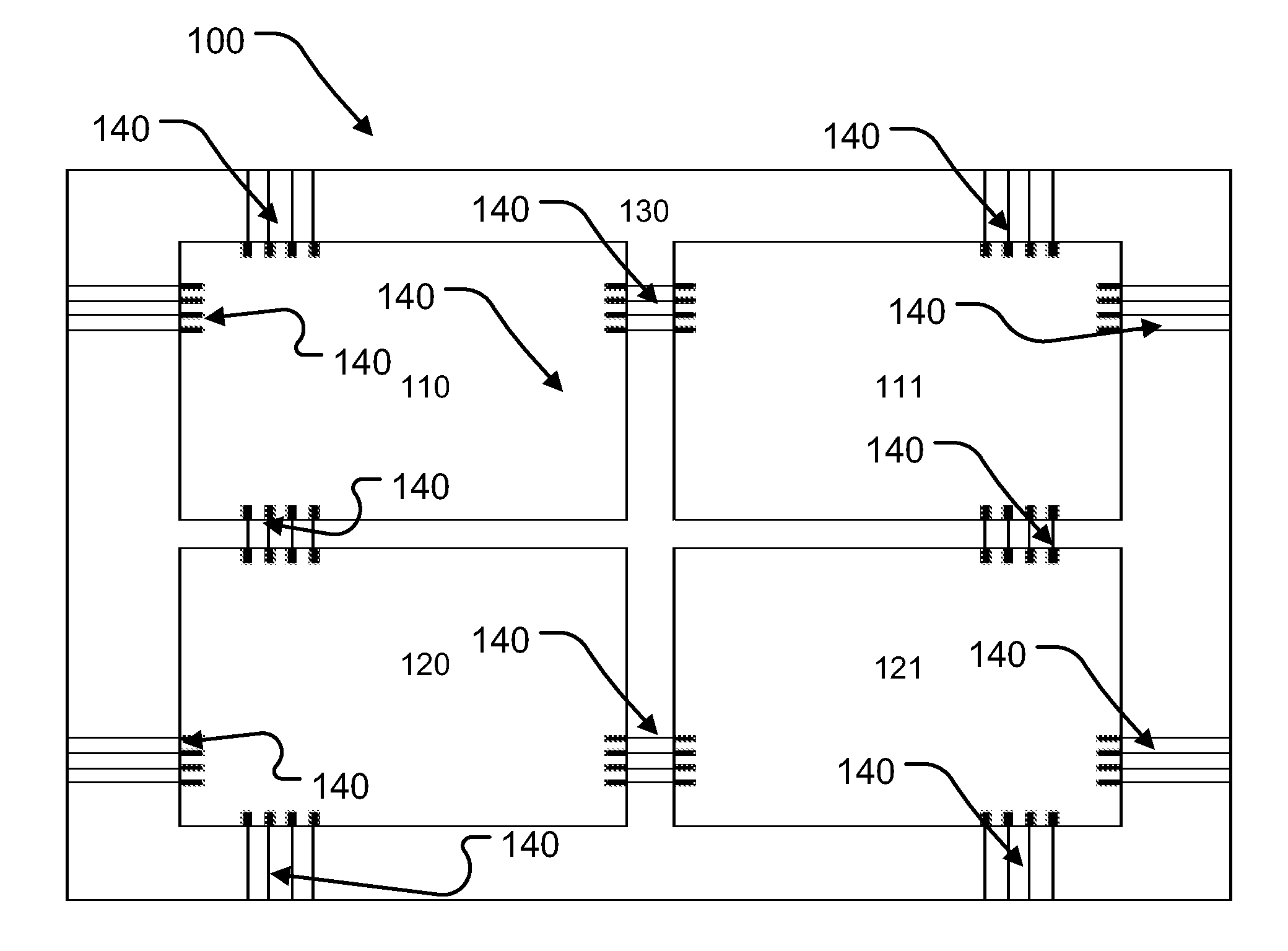

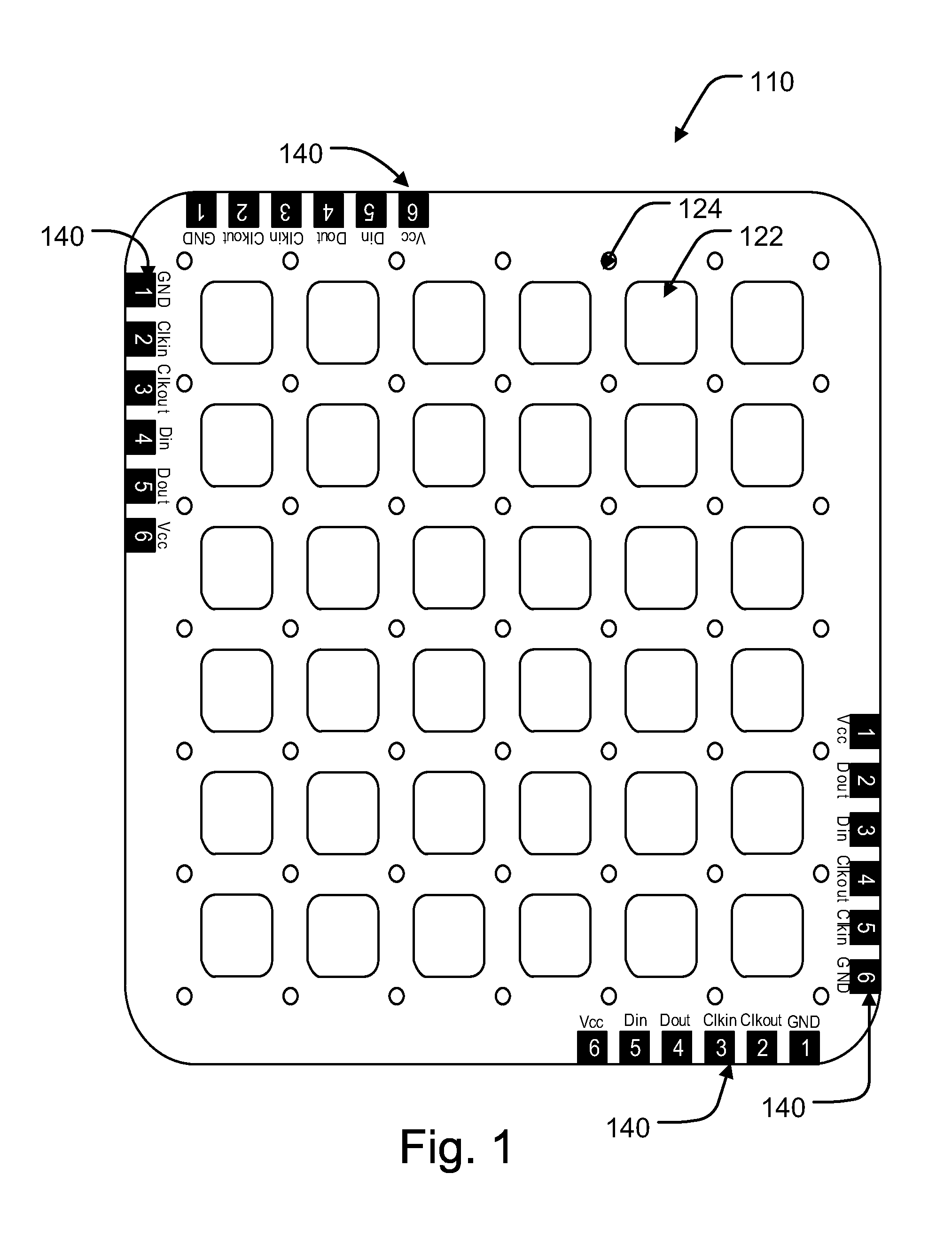

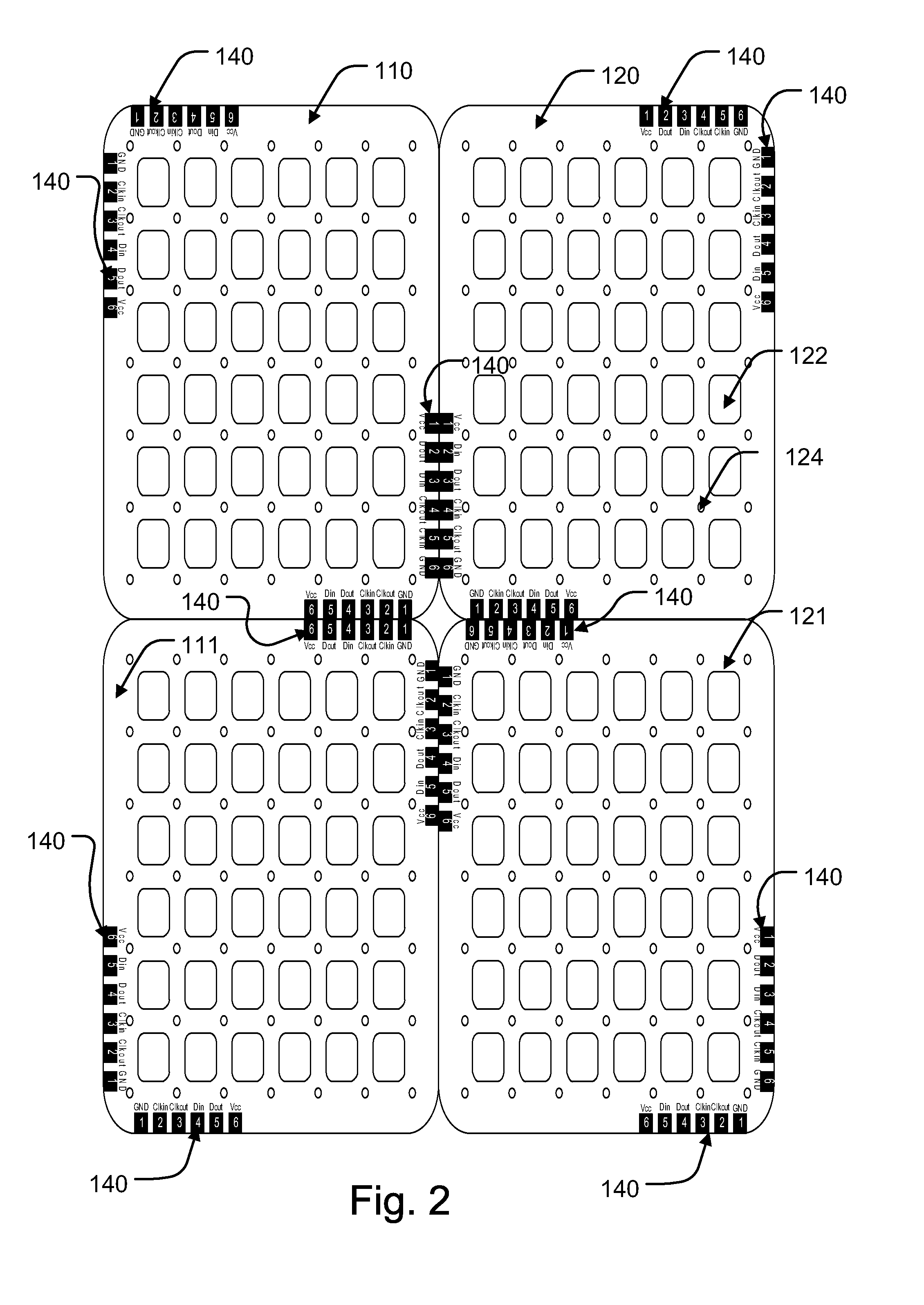

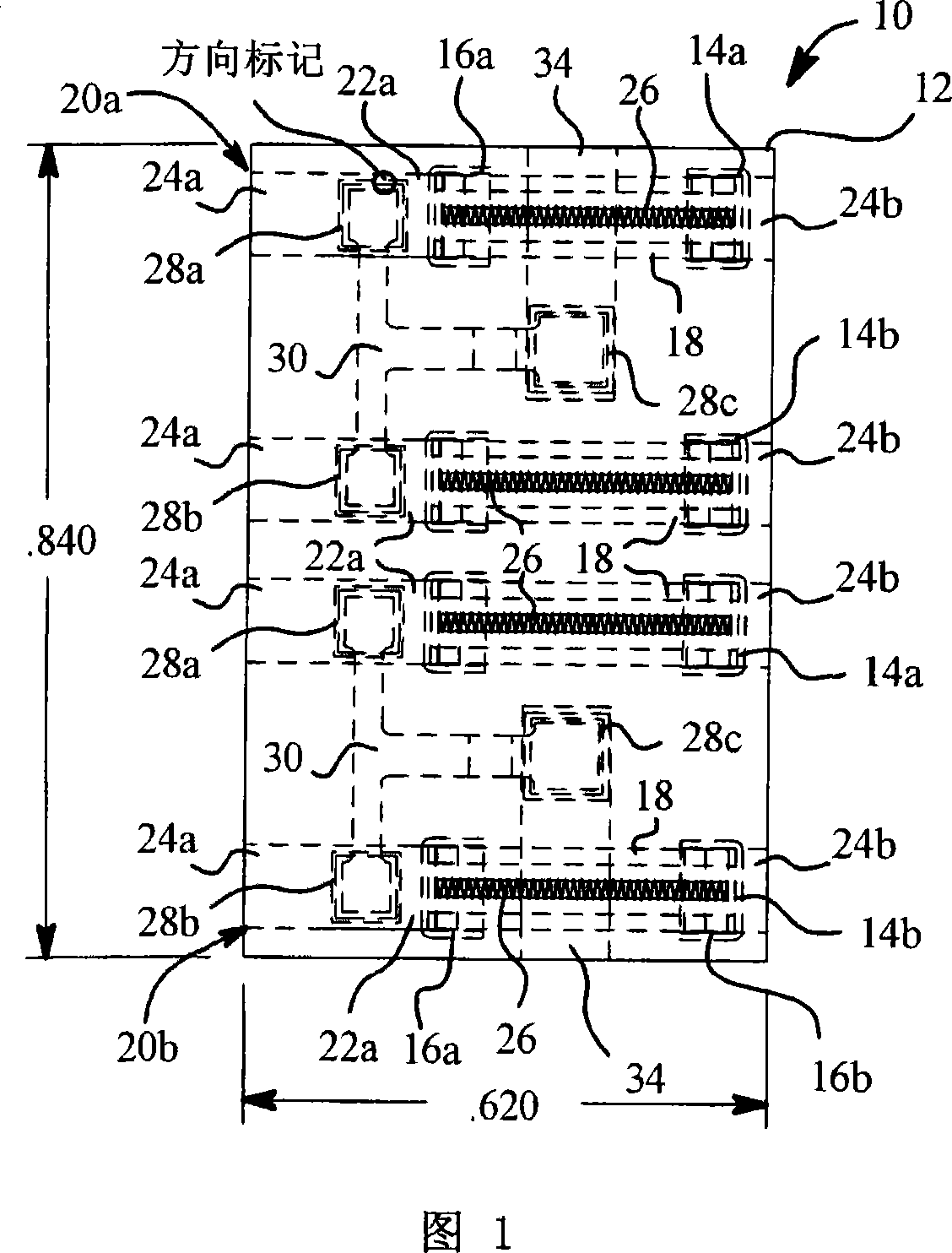

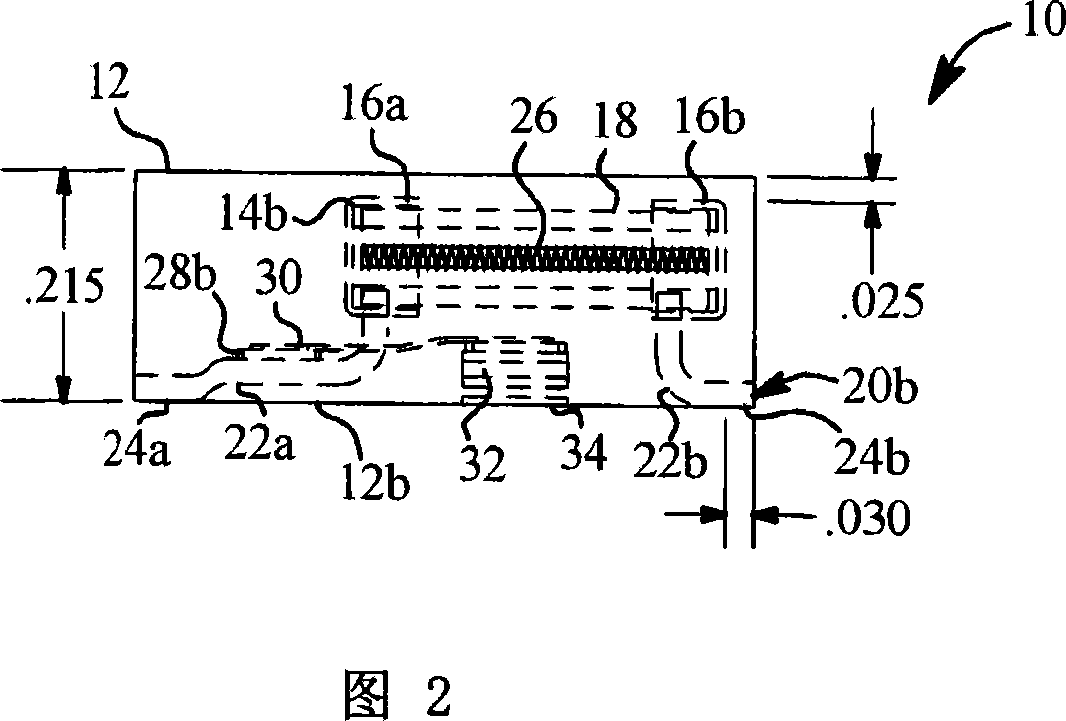

Flexible modular assembly

InactiveUS20110242771A1Improve conductivityHigh currentPrinted circuit aspectsPrinted circuit manufactureElectrical conductorModularity

The present invention relates to a flexible modular assembly (100) comprising at least two flexible electronic modules (110 and 111) supported by a textile support (130). The two flexible electronic modules and the textile support each comprise a set of electrical conductors. The flexible modular assembly further comprises flexible connectors (140) for interconnecting two sets of electrical conductors. The flexible modular assembly of the invention is a modular textile assembly for use in large-area applications of electronic textiles.

Owner:SIGNIFY HLDG BV +1

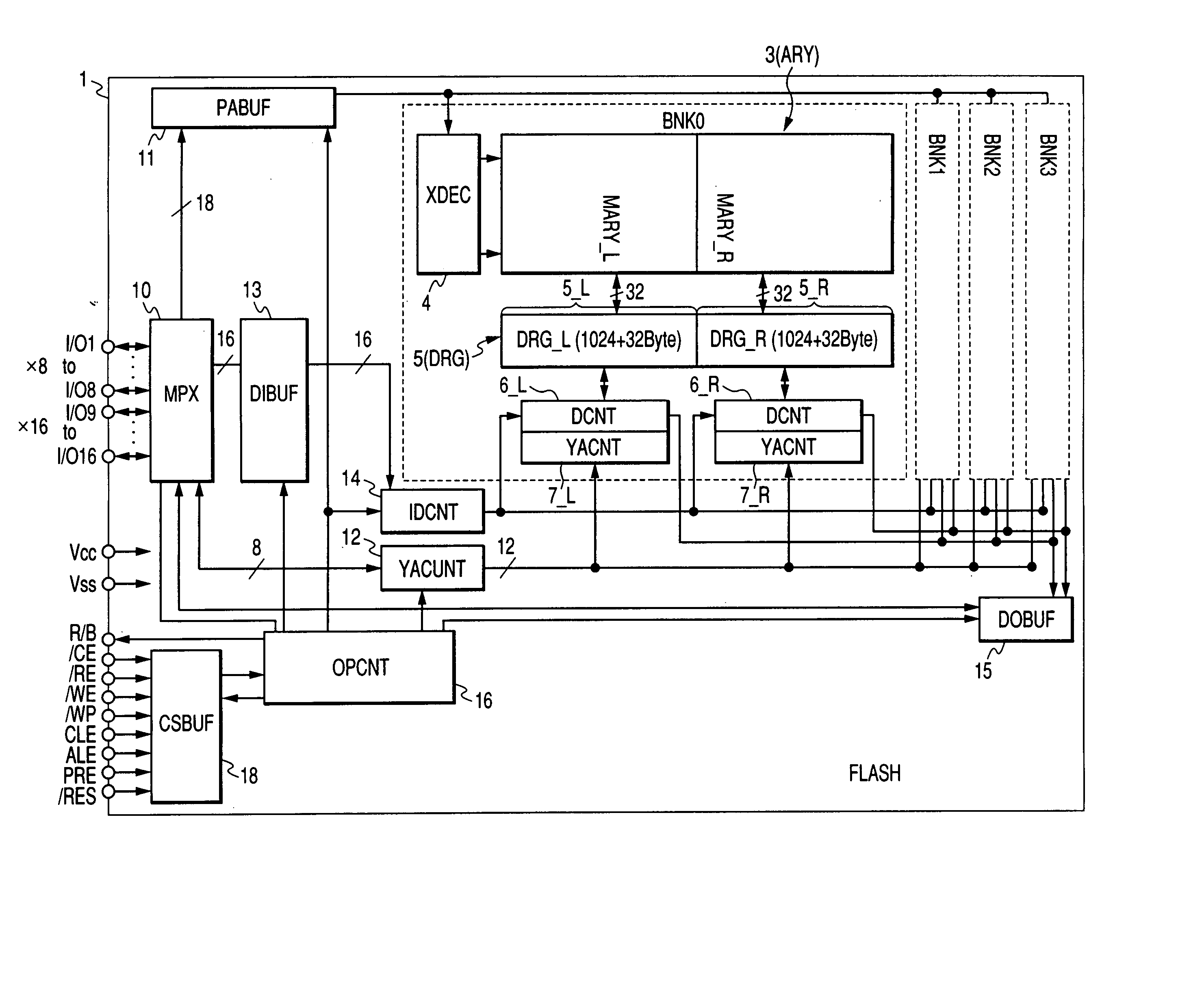

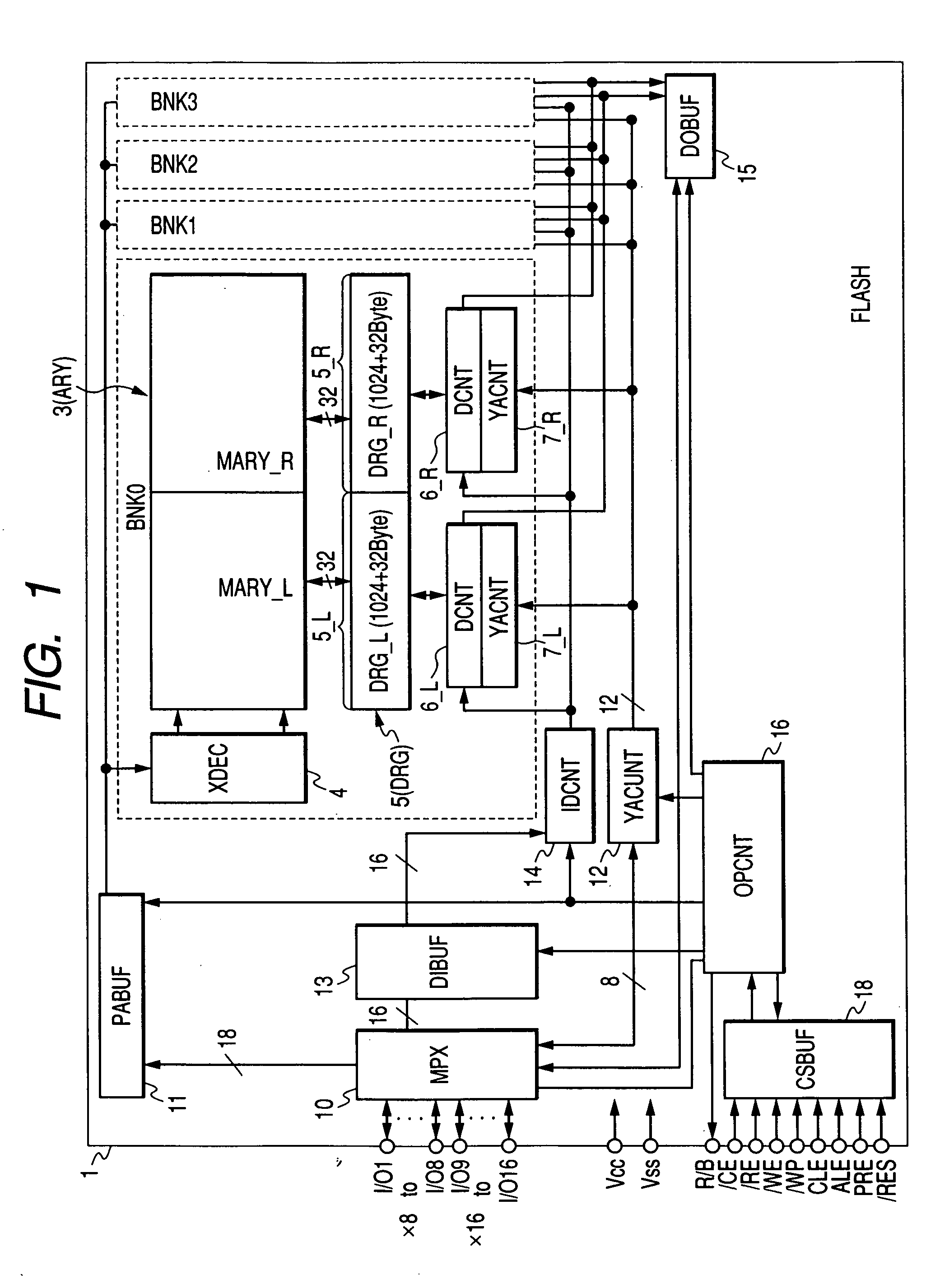

Nonvolatile memory

InactiveUS20060023515A1Improve write performanceReduce conductanceRead-only memoriesDigital storageEngineeringTransistor

A nonvolatile memory includes circuits each having first control transistors, memory transistors, second control transistors and memory transistors repeatedly connected in series in sequence. Inversion layers are formed in the direction intersecting the serial direction with turning on of the control transistors. A selection circuit selects a connection of the inversion layer placed under the first control transistor and its corresponding read / write circuit. The control transistors placed on both sides adjacent to the memory transistor are turned on to perform reading. The first control transistors placed on both sides of the second control transistor as viewed from side to side are turned on to perform writing into the other of the right and left memory transistors via one of the right and left memory transistors. The selection circuit connects the read / write circuit and the inversion layer in such a manner that the same read / write circuit is used in reading and writing for the same memory transistor.

Owner:RENESAS ELECTRONICS CORP

Leadless integrated circuit protection device

InactiveCN101064288ASimple production methodImproved performance characteristicsSemiconductor/solid-state device detailsSolid-state devicesOvervoltageElectrical conductor

A circuit protection device includes a fuse placed in electrical communication with first and second conductors. An overvoltage protection component is placed in electrical communication with the first conductor and a third conductor. An insulative housing encloses the fuse, overvoltage protection component and portions of the first, second and third conductors. The first and second conductors include first and second terminal portions, respectively, that extend through the housing and reside at least substantially flush with an outer surface of the housing.

Owner:LITTELFUSE INC

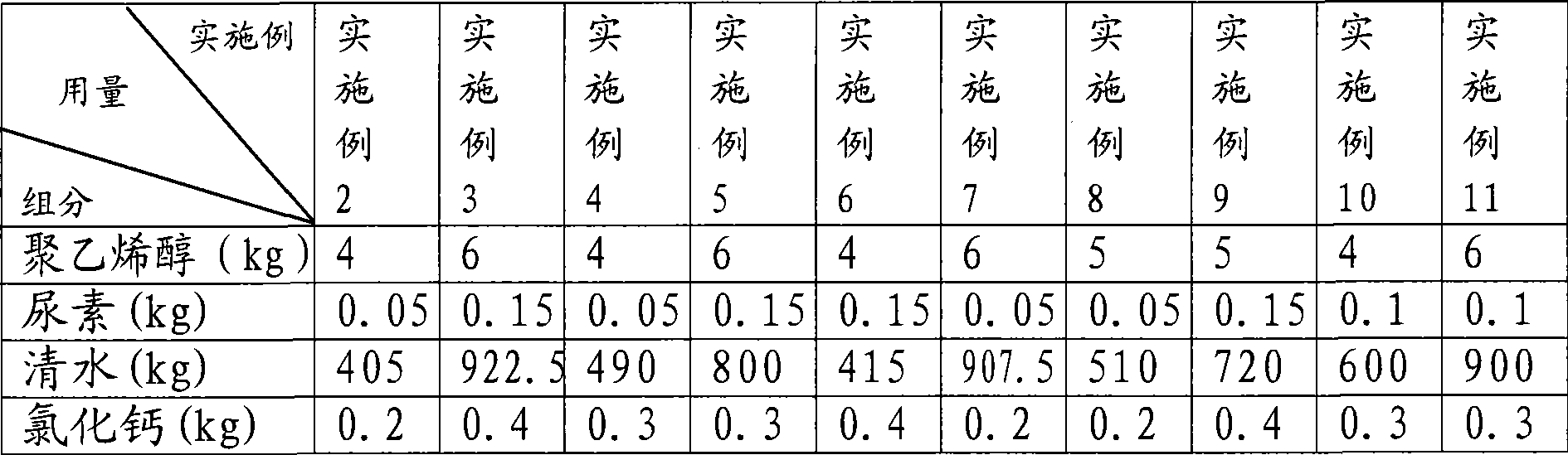

Fruit tree evaporation-reducing agent

InactiveCN101473814AInhibit transpirational dehydrationNo adverse reactionDead plant preservationNutrientUrea

The invention discloses an evaporation reducing agent for fruit trees. The evaporation reducing agent is prepared by 4 to 6 portions of film forming agent, 0.05 to 0.15 portion of anti-freezing agent, and 0.2 to 0.4 portion of liquid film curing agent, can be widely applied to garden plants such as fruit trees and the like to restrain evaporation, water loss and transplant, and has obvious evaporation reducing effect compared with the existing evaporation reducing agent; the evaporation reducing effect can last more than 30 days, and the average evaporation rate can be reduced by 16.98 to 29.74 percent; the evaporation reducing agent does not need to be dissolved by warm water, urea is dissolved in polyvinyl alcohol liquid to form mixed liquid, and then calcium chloride is dissolved in the mixed liquid after dilution during use; the evaporation reducing agent can be sprayed to the fruit trees, has simple and convenient operation, can correspondingly reduce usage time, can lower generation cost greatly, is easily accepted by fruit growers, has long available period, and forms a transparent film after the evaporation reducing agent is used to reduce ineffective water loss of blades; the average stomata conductance can be reduced by 9.96 percent; and the evaporation reducing agent has double evaporation reducing effects, can be directly absorbed by the plant blades after application, can provide nutrient required by growth for the plants, can improve dry substance content of the blades, has no adverse reaction to the plants, and has remarkable social and economic benefits and ecological environment benefit.

Owner:SHIJIAZHUANG POMOLOGY INST OF HEBEI ACADEMY OF AGRI & FORESTRY SCI

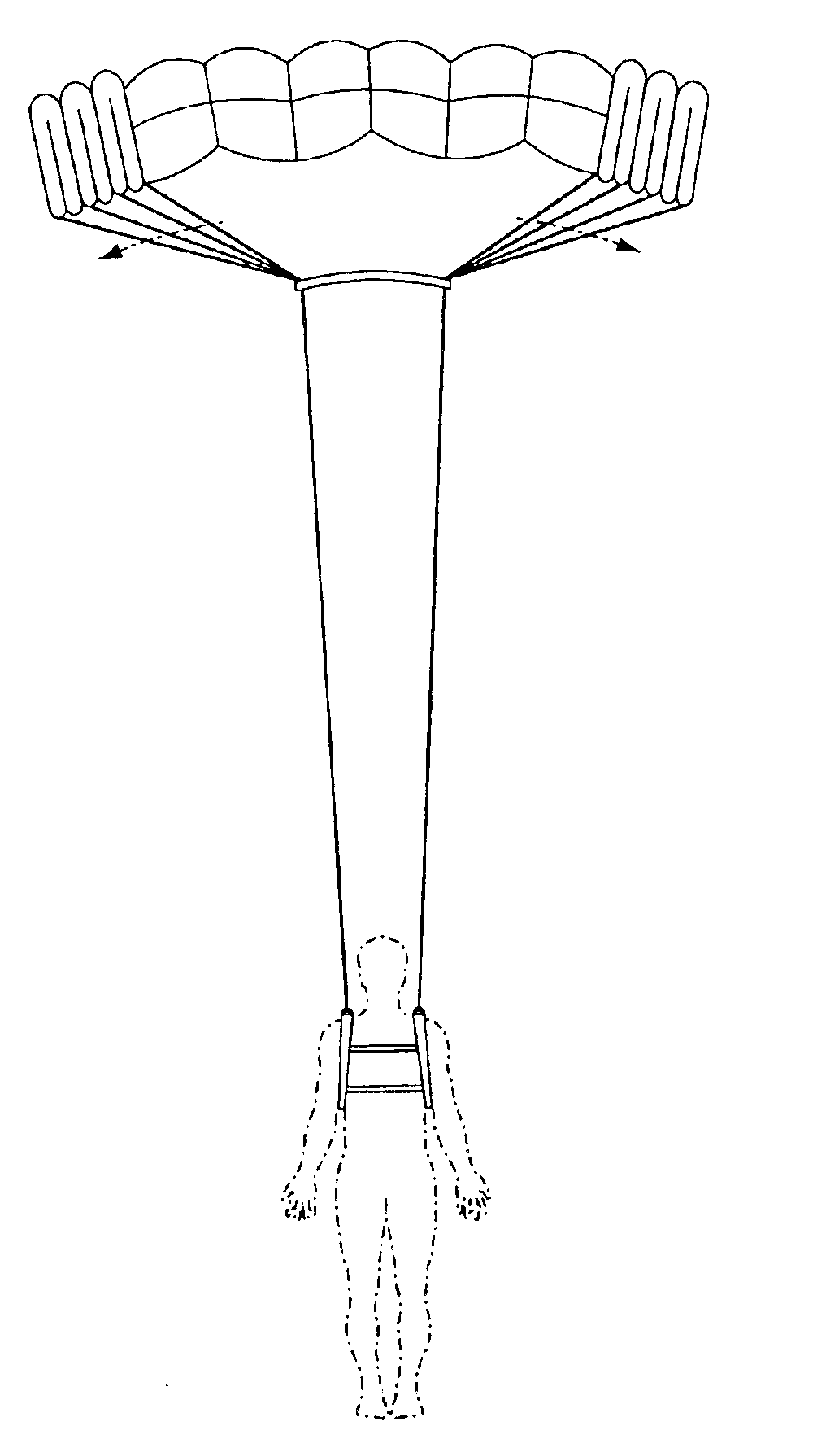

RAM air parachute with multistage deployment

A ram air parachute of the present invention includes specific cross porting of the ribs between certain cells to create a two-stage or multi-stage deployment. Cross ports between certain sets of cells have reduced or no conductance. In this manner, the center cells of the canopy open first, slowing decent, before the outer cells. The staged deployment reduces the opening forces on the pilot particularly in high speed flights.

Owner:ATAIR AEROSPACE +1

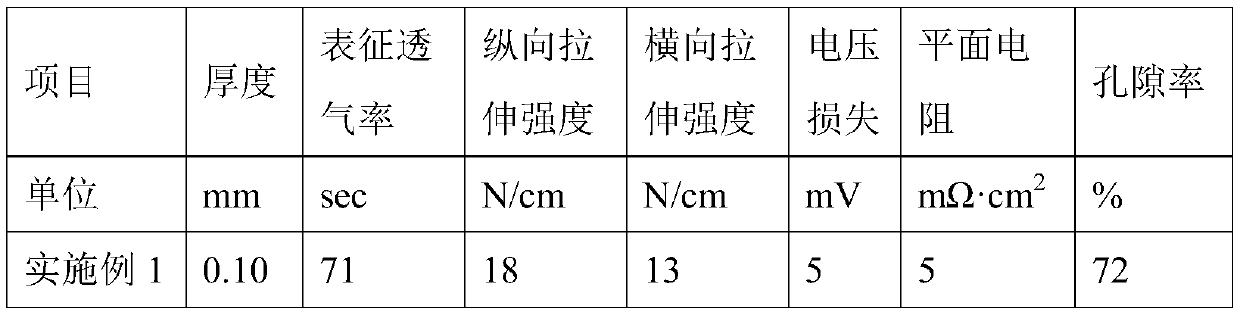

Fuel cell electrode gas diffusion layer carbon fiber paper manufactured with pulp and preparation method thereof

InactiveCN110485191AExcellent gas generationLower resistanceSpecial paperCell electrodesActivated carbonCarbon nanotube

The invention discloses a fuel cell electrode gas diffusion layer carbon fiber paper manufactured with pulp and a preparation method thereof. The preparation method mainly comprises the steps of making the pulp, mixing the pulp, manufacturing the paper in a combined manner of downstream net papermaking and guniting net papermaking, drying, hot pressing and the like. The mechanical property of theprepared carbon fiber paper is improved by adding the bonding fibers, and the carbon nanotubes, graphene and the activated carbon are added when the pulp is mixed. The prepared carbon fiber paper comprises a base paper bottom layer made by downstream net papermaking and a base paper surface layer made by guniting net papermaking, and the graphene, the carbon nanotubes and the activated carbon arecontained in the base paper surface layer. The carbon fiber paper prepared by the invention has a porous structure, the excellent gas-forming property, low resistance and high conductivity, and can provide gas, electron and drainage channels for electrode reaction, has the certain mechanical strength, chemical stability, thermal stability, thermal conductivity, gas dispersion and homogenization characteristics, has a large specific surface area, can adsorb the harmful gas, buffers the system reaction, and avoids the instability after high-temperature treatment.

Owner:CHINA HAISUM ENG

Shower Plate Having Different Aperture Dimensions and/or Distributions

ActiveUS20120100307A1High in-plane uniformityUniform propertyElectric discharge tubesFire rescueEngineeringMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

Semiconductor device and electro-optical device

ActiveUS7626205B2Stable outputPrevent pointLiquid crystal compositionsSemiconductor/solid-state device detailsDrain currentActive layer

A semiconductor device and an electro-optical device that ensures a stable output are provided even when there is a change in a source-drain current in a saturated operation region of a thin film transistor due to kink effects. The thin film transistor has a multi-gate structure with a polycrystalline silicon film as an active layer, and a source-side first thin film transistor portion and a drain-side second thin film transistor portion connected in series. The first thin film transistor portion has a drain-side back gate electrode that is connected with a first front gate electrode. The second thin film transistor portion has a source-side back gate electrode that is connected with a second front gate electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

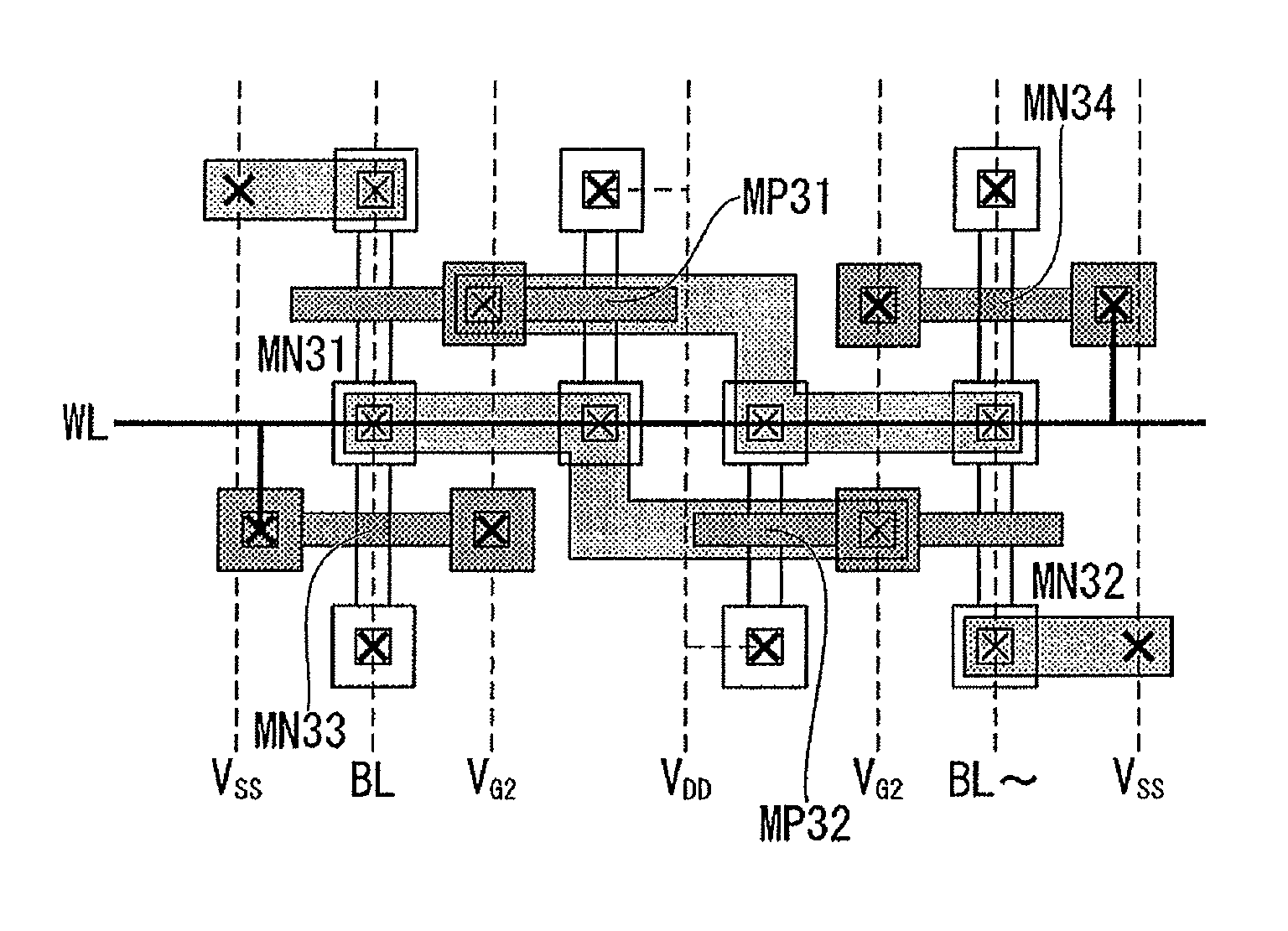

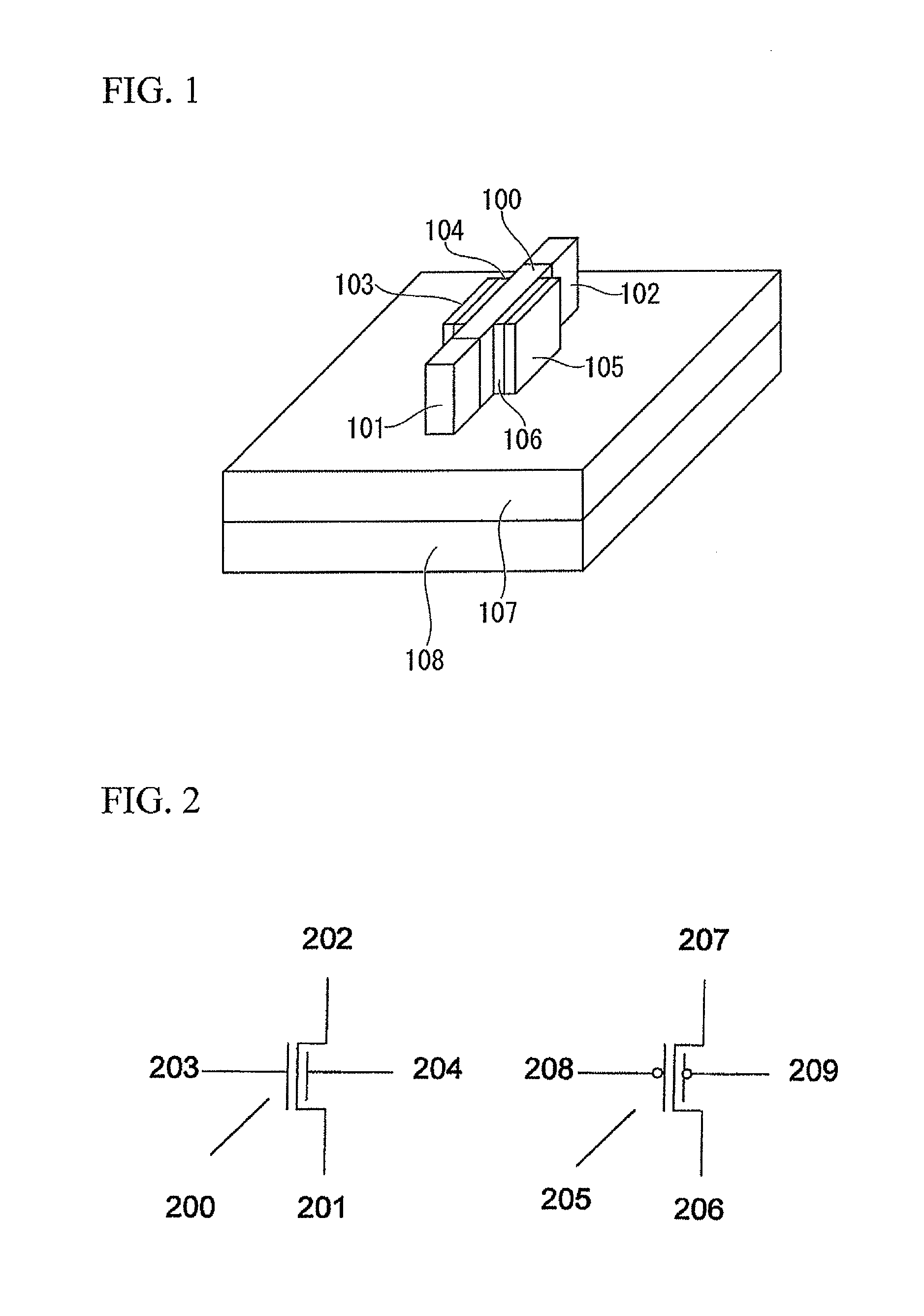

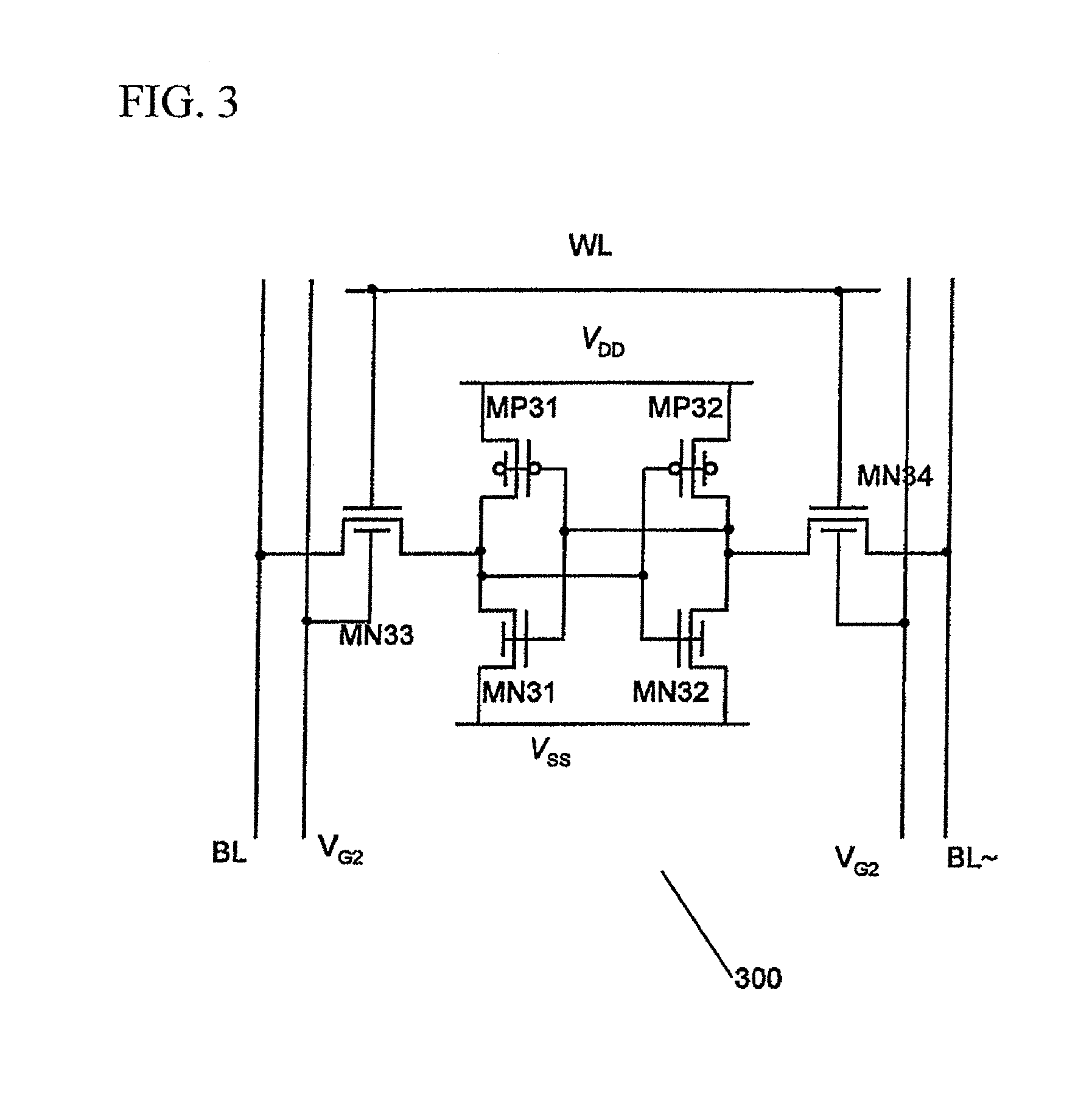

SRAM device

InactiveUS8243501B2Lower average currentIncrease both the read and write marginsTransistorSolid-state devicesWrite marginEngineering

An SRAM device uses a four-terminal double gate field effect transistor as a selection transistor, wherein the four-terminal double gate field effect transistor comprises a gate which drives the transistor and a gate which controls a threshold voltage, which are electrically separated from each other, on both surfaces of a standing semiconductor thin plate, and wherein a voltage used to reduce a threshold voltage is input to the gate which controls the threshold voltage of the selection transistor during a writing operation than during a reading operation. The SRAM device which can increase both the read and write margins is provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com