Fuel cell electrode gas diffusion layer carbon fiber paper manufactured with pulp and preparation method thereof

A fuel cell electrode and gas diffusion layer technology, which is applied in battery electrodes, papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of easy peeling of carbon fibers, low surface finish, and easy damage. , to achieve the effects of excellent gas dispersibility, high electrical conductivity and excellent gas-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

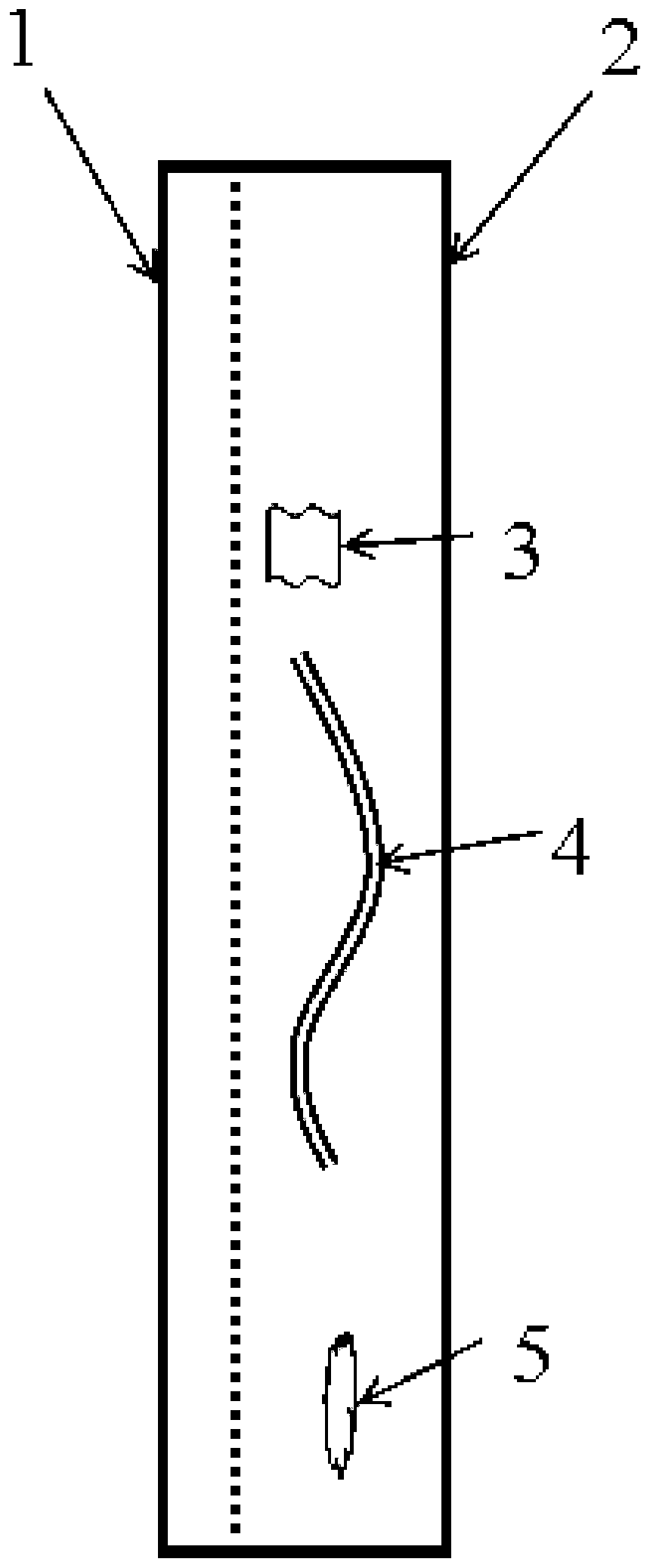

Image

Examples

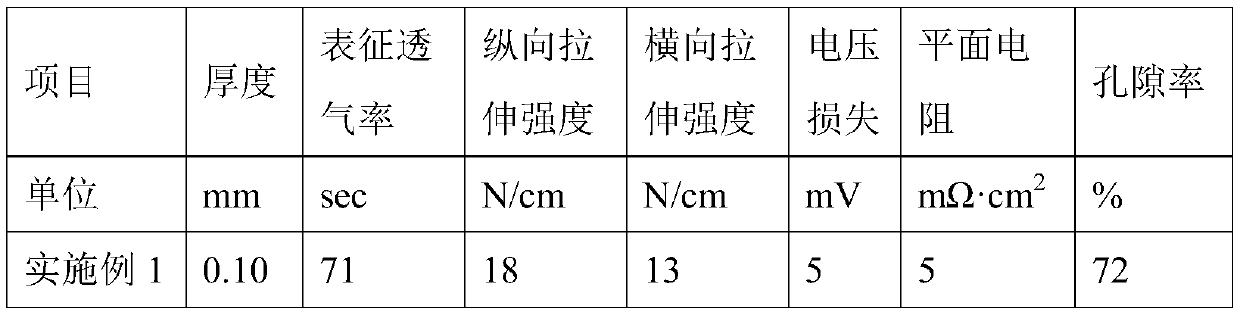

Embodiment 1

[0043] A method for making fuel cell electrode gas diffusion layer carbon fiber paper by wet method, comprising the following steps:

[0044] 1. Pulping A: Mix carbon fibers with an average length of 1 to 4mm and adhesive fibers with an average length of 2mm at a ratio of 88:12, add 50 times of water and stir for 30 minutes, add 1% of PAM and then Pump it into a deflagging machine for 30 minutes, add water to prepare a slurry with a solid content of 1%, and keep stirring for more than 2 hours to obtain slurry A for later use.

[0045] 2. Pulping B: Mix carbon fibers with an average length of 1 to 4mm and adhesive fibers with an average length of 2mm at a ratio of 82:18, add 50 times of water and stir for 30 minutes, add 1% of PAM and then Pump it into a deflagger for 30 minutes, add water to prepare a slurry with a solid content of 1%, and obtain slurry B.

[0046]3. Pulp C: add carbon nanotubes to the slurry B according to 0.2% of the dry matter content of the fiber, add gra...

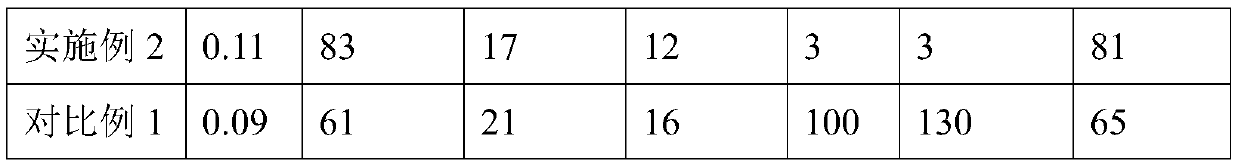

Embodiment 2

[0052] A method for making fuel cell electrode gas diffusion layer carbon fiber paper by wet method, comprising the following steps:

[0053] Except that the flow ratio of the flow rate of flow-type Internet access: spray type Internet access in step 4 in Embodiment 1 is 1:5, the others are completely the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com