Heat treatment apparatus

A technology for heat treatment devices and treatment containers, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc. It can solve the problems of low conductance of cooling water flow path, hindering the flow of cooling medium, and inability to cool efficiently, so as to increase the configuration density. , improve energy efficiency, reduce the effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

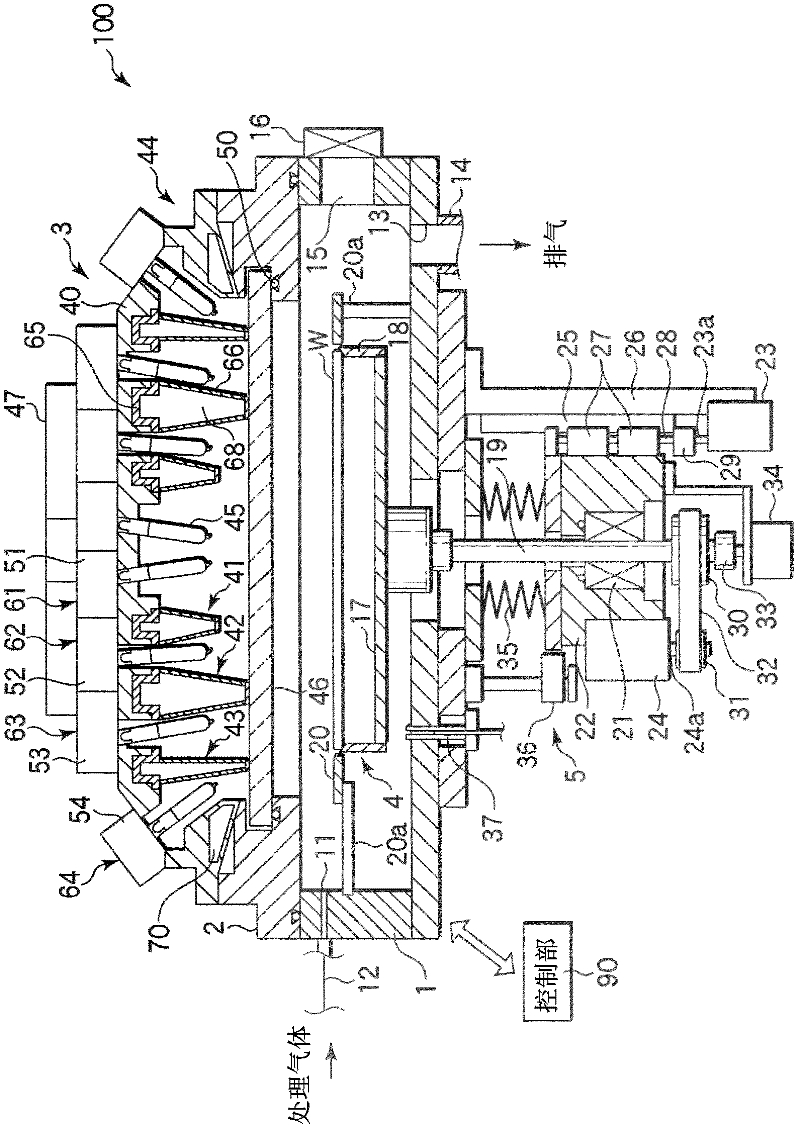

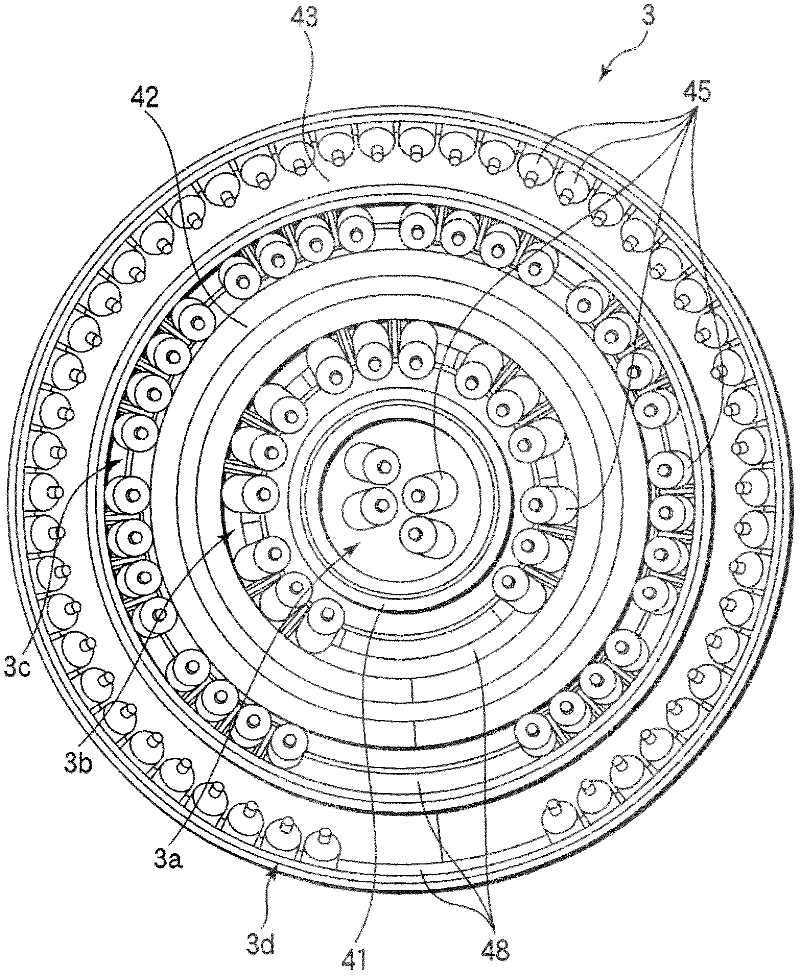

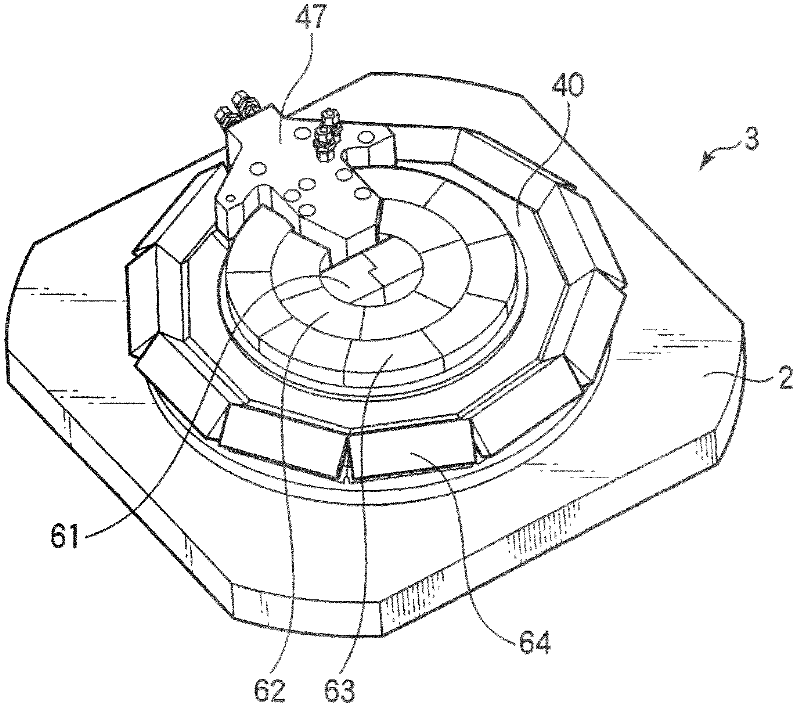

[0035] figure 1 is a cross-sectional view of an annealing apparatus showing a first embodiment of the heat treatment apparatus of the present invention, figure 2 is a bottom view showing its lamp assembly, image 3 It is a perspective view showing the appearance of the lamp unit, Figure 4 It is a perspective view showing a state where a lamp module is detached from a lamp unit, and FIG. 5 is a schematic view showing a configuration of each lamp module.

[0036] The annealing apparatus 100 includes the following main components: a processing container 1, which specifies a processing space for processing a wafer W as a substrate to be processed; a cover 2, which is fixed on the upper end of the processing container 1, and is ring-shaped; a lamp assembly 3, It is supported by a cover 2, and is provided with a plurality of halogen lamps; a wafer supporting part 4, which supports a wafer W in the processing container 1; Supported wafer W.

[0037] A gas introduction hole 11 i...

no. 2 approach

[0066] Next, a second embodiment of the present invention will be described.

[0067] The purpose of this embodiment is to protect the power supply terminal 57 of the halogen lamp 45 . When the halogen lamp 45 is turned on during the annealing process, the heat supply terminal 57 is heated through the heat supply terminal 57 . When the temperature of the power supply terminal 57 exceeds 350° C. by heating, the Mo foil used as a conductor is rapidly oxidized and disconnected. Therefore, in the present embodiment, cooling of the power supply terminal 57 and light shielding from the halogen lamp 45 to the power supply terminal 57 are performed.

[0068] Figure 12 is a partial sectional view showing a lamp unit of an annealing apparatus according to a second embodiment of the present invention, Figure 13 is a sectional view showing its main parts, Figure 14 It is a perspective view showing the mounting state of the halogen lamp. In the lamp unit 103 of the present embodime...

no. 3 approach

[0075] Next, a third embodiment of the present invention will be described.

[0076] In the lamp assembly, the sealing ring installed between the light transmission plate and the cover is provided close to the halogen lamp 45, so in the lamp assembly by the heat generated from the halogen lamp, and also by being irradiated by light emitted from the halogen lamp, Thermal deformation and melting may occur due to heating. Therefore, in this embodiment, the structure for protecting such a seal ring will be mainly described.

[0077] Figure 15 is a cross-sectional view showing main parts of an annealing apparatus according to a third embodiment of the present invention, Figure 16 It is a sectional view showing the light transmission plate supporting part of the annealing apparatus of the third embodiment. The annealing apparatus of the present embodiment includes a lamp unit 203 having a light transmission plate 46 ′ formed with a flange portion (step portion) 46 a. The flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com