Method for reducing acrylamide in starch-type fried food

A fried food and acrylamide technology, which is applied in the direction of food science, etc., can solve the problems such as non-existence of reduction technology, radiation odor, and limited application, and achieve the effect of suppressing radiation odor and increasing the content of acrylamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

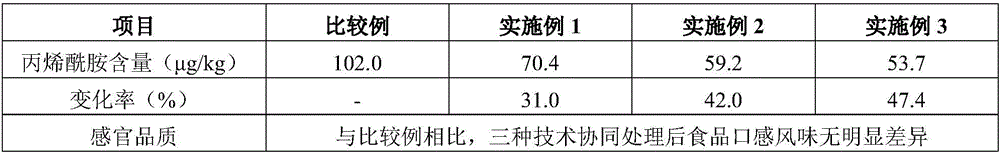

Examples

Embodiment 1

[0026] a) Prepare one or several natural extracts into an aqueous solution with a concentration of 0.1%, heat it in a constant temperature water bath, and control the temperature at 100°C, pretreat the fried food raw materials by soaking in the natural extract solution, and control the processing time in 1min;

[0027] b) Drain the surface moisture of the food raw materials pretreated by natural extracts and then fry them. The frying temperature is controlled at 140°C, the vacuum degree is controlled at 0.01MPa, and the frying time is controlled at 30s;

[0028] c) The fried food is cooled to room temperature, sealed with nitrogen gas in a polyethylene composite packaging bag, and the volume percentage of nitrogen gas is controlled to be 99.9%, and packed into a corrugated box. Place the food packed in the carton on the conveying device of the electron accelerator, and the conveying speed of the conveying device is 0.02-0.3m / s;

[0029]The food placed on the conveying device ...

Embodiment 2

[0032] a) Prepare one or several natural extracts into an aqueous solution with a concentration of 1.0%, heat it in a constant temperature water bath, and control the temperature at 40°C, pretreat the fried food raw materials by soaking them in the natural extract solution, and control the processing time at 50min;

[0033] b) Drain the surface moisture of the food raw materials pretreated by natural extracts and then fry them. The frying temperature is controlled at 80°C, the vacuum degree is controlled at 0.1MPa, and the frying time is controlled at 300s;

[0034] c) The fried food is cooled to room temperature, sealed with nitrogen gas in a polyethylene composite packaging bag, and the volume percentage of nitrogen gas is controlled to be 70%, and packed into a corrugated box. Place the food packed in the carton on the conveying device of the electron accelerator, and the conveying speed of the conveying device is 0.02-0.3m / s;

[0035] The food placed on the conveying devi...

Embodiment 3

[0038] a) Prepare one or several natural extracts into an aqueous solution with a concentration of 0.5%, heat it in a constant temperature water bath, and control the temperature at 70°C, pretreat the fried food raw materials by soaking them in the natural extract solution, and control the processing time in 30 minutes;

[0039] b) Drain the surface moisture of the food raw materials pretreated by natural extracts and then fry them. The frying temperature is controlled at 110°C, the vacuum degree is controlled at 0.05MPa, and the frying time is controlled at 200s;

[0040] c) The fried food is cooled to room temperature, sealed with nitrogen gas in a polyethylene composite packaging bag, and the volume percentage of nitrogen gas is controlled to be 85%, and packed into a corrugated box. Place the food packed in the carton on the conveying device of the electron accelerator, and the conveying speed of the conveying device is 0.02-0.3m / s;

[0041] The food placed on the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com