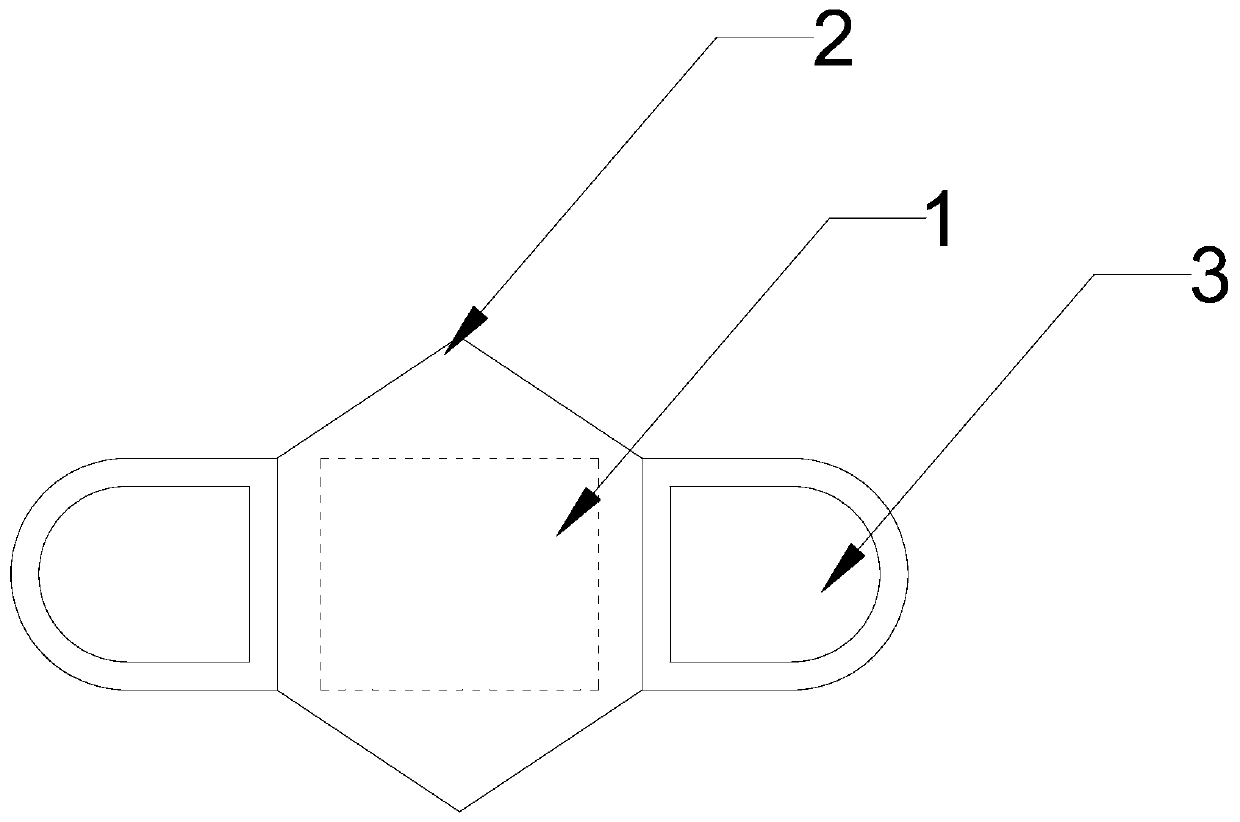

Antibacterial mask and preparation method thereof

A mask and intermediate layer technology, applied in the field of sanitary products, can solve the problems of inability to completely isolate germs and smog, poor protective effect of masks, etc., to improve antibacterial ability and ability to filter harmful gases, improve catalytic ability, and increase load volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

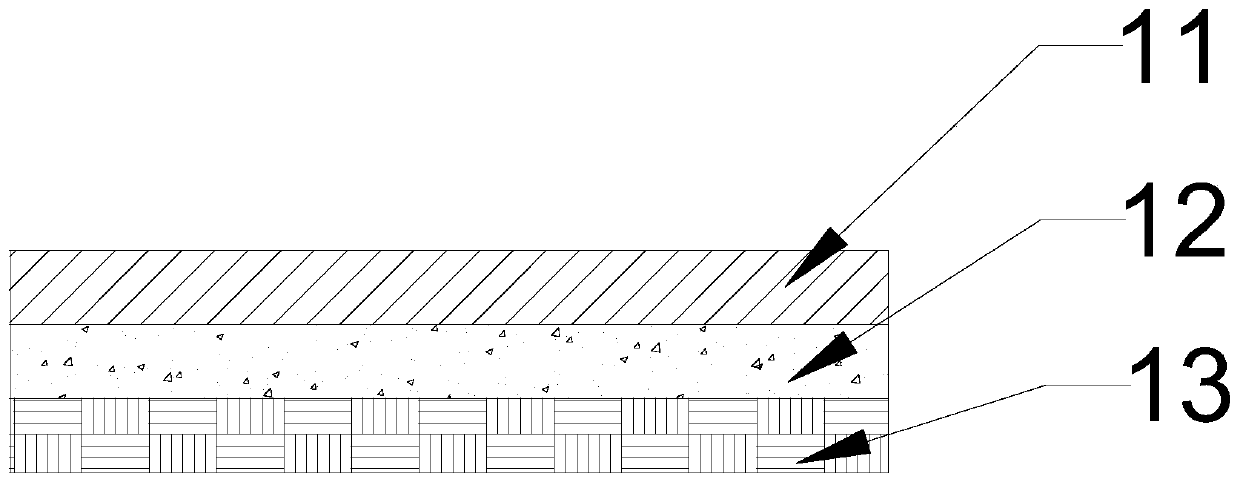

preparation example Construction

[0034] The preparation method of above-mentioned antibacterial mouth mask, comprises the following steps:

[0035] S1. Preparation of outer layer

[0036] S11. Soak the fibers in the adhesive, and then pass through the container with nano-silica;

[0037] S12. Weaving the fibers processed in step S11 into cloth;

[0038] S2. Preparation of the middle layer

[0039] S21. Immersing the textile in a sulfuric acid solution with a concentration of 1 to 3 mol / L for 2 to 4 hours;

[0040] S22. Immerse the textile fabric treated in step S21 in an aqueous graphene oxide solution with a concentration of 1-2 mg / mL, boil for 1-2 hours and then dry it;

[0041] S23. dissolving nano-titanium dioxide and ammonium methacrylate in absolute ethanol, the mass fraction of ammonium methacrylate is 0.1% to 1%; the mass fraction of nano-titanium dioxide is 0.1%;

[0042] S24. Coating the nano-titanium dioxide solution prepared in step S23 on the fabric treated in step S22, then drying and curing...

Embodiment 2

[0045] A kind of antibacterial mouth mask, its structure is the same as embodiment 1.

[0046] The preparation method of above-mentioned antibacterial mouth mask, comprises the following steps:

[0047] S1. Preparation of outer layer

[0048] S11. Soak the fibers in the adhesive, and then pass through the container with nano-silica;

[0049] S12. Weaving the fibers processed in step S11 into cloth;

[0050] S2. Preparation of the middle layer

[0051] S21. Immersing the textile in a sulfuric acid solution with a concentration of 1 to 3 mol / L for 2 to 4 hours;

[0052] S22. Immerse the textile fabric treated in step S21 in an aqueous graphene oxide solution with a concentration of 1-2 mg / mL, boil for 1-2 hours and then dry it;

[0053] S23. dissolving nano titanium dioxide and ammonium methacrylate in absolute ethanol, the mass fraction of ammonium methacrylate is 0.1%-1%; the mass fraction of nano titanium dioxide is 1%;

Embodiment 3

[0057] A kind of antibacterial mouth mask, its structure is the same as embodiment 1.

[0058] The preparation method of above-mentioned antibacterial mouth mask, comprises the following steps:

[0059] S1. Preparation of outer layer

[0060] S11. Soak the fibers in the adhesive, and then pass through the container with nano-silica;

[0061]S12. Weaving the fibers processed in step S11 into cloth;

[0062] S2. Preparation of the middle layer

[0063] S21. Immersing the textile in a sulfuric acid solution with a concentration of 1 to 3 mol / L for 2 to 4 hours;

[0064] S22. Immerse the textile fabric treated in step S21 in an aqueous graphene oxide solution with a concentration of 1-2 mg / mL, boil for 1-2 hours and then dry it;

[0065] S23. dissolving nano titanium dioxide and ammonium methacrylate in absolute ethanol, the mass fraction of ammonium methacrylate is 0.1% to 1%; the mass fraction of nano titanium dioxide is 0.5%;

[0066] S24. Coating the nano-titanium dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com