Method for preparing electronic-grade N, N-dimethylformamide by ion exchange resin method

A technology of dimethylformamide and ion exchange resin, which is applied in the field of purification technology, can solve the problems of affecting, affecting the adjustment of polymerization reaction speed, and not considering the problem of metal ion removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

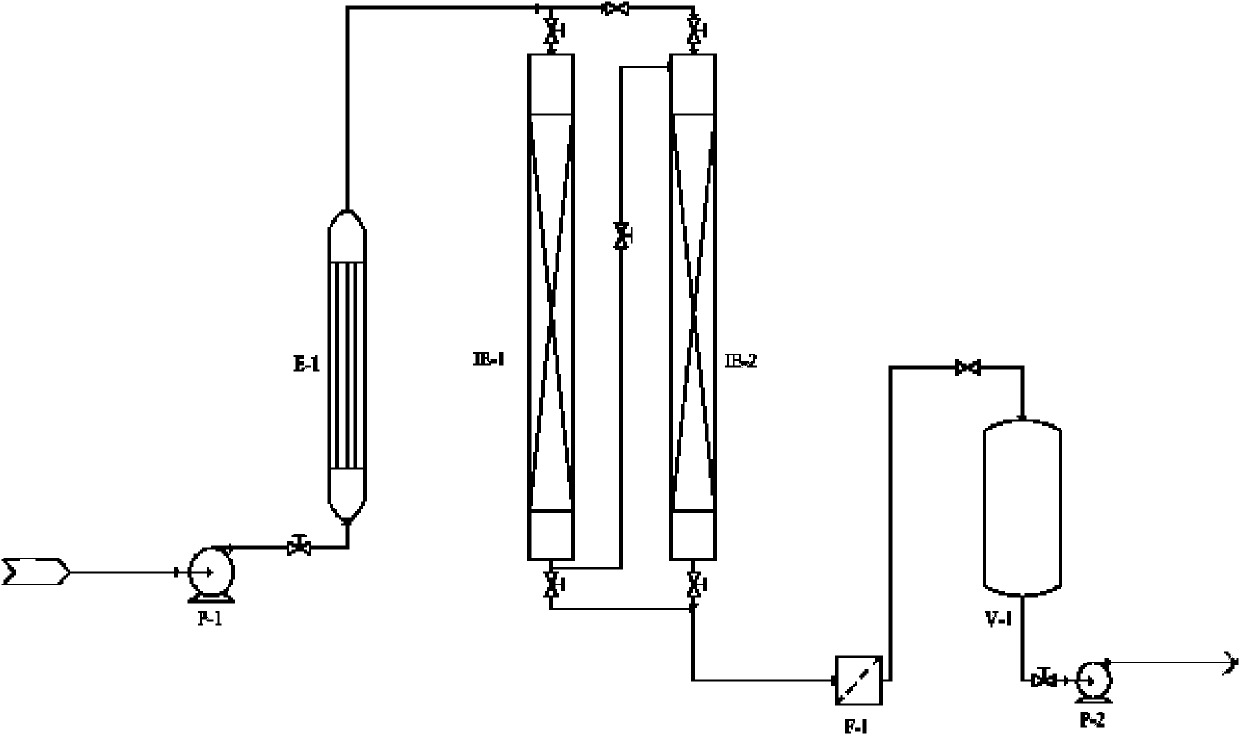

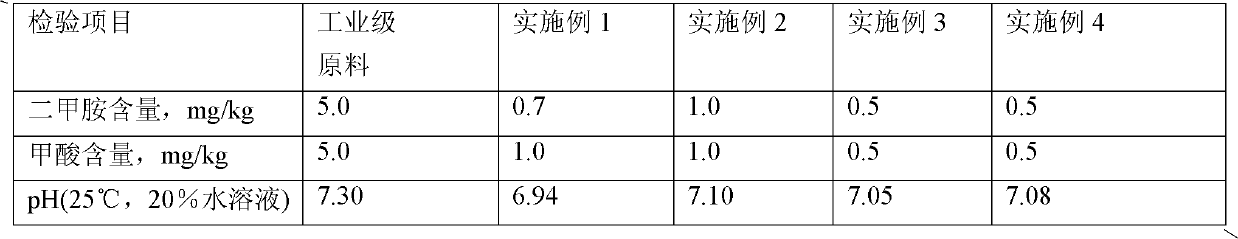

[0024] Such as figure 1As shown, the DMF is purified in the form of multiple beds. The ion exchange column IE-1 is a cation exchange column. Column IE-2 is an anion exchange column, and the column is equipped with a commercial brand of 201×7 Styrene DVB strong basic styrene-based anion exchange resin. The material of the resin column is glass, and its specification is Φ30×1000mm. The height of the exchange resin is 500mm. The resin in the ion exchange column is pretreated before use. For the cation exchange resin, first wash the resin with deionized water, then drain the water in the resin column, and soak the resin with DMF solution 8 hours, then replace the DMF in the resin with deionized water, rinse until the DMF weight percent concentration at the outlet of the exchange column is 0.3%, and then use 4% NH 4 OH is rinsed at 10mL / min, and the molar number of alkali used is three times the exchange capacity of the resin, followed by rinsing with deionized water to neutrality...

Embodiment 2

[0028] The process flow and equipment are the same as in Example 1, except that the cation exchange column IE-1 is equipped with a macroporous strongly acidic cation exchange resin of D072 Styrene DVB, and the anion exchange column IE-2 is equipped with a brand of Styrene DVB D301T macroporous weakly basic anion exchange resin, the anion and cation exchange resins are pretreated according to the pretreatment process and conditions of embodiment 1, and then according to the technical process figure 1 The process of industrial grade DMF is purified, the conductivity of DMF treated by this process and equipment is reduced from 0.165 μs / cm to 0.150 μs / cm, and the pH value of 20% (v / v) DMF aqueous solution is changed from 7.3 It is 7.10, and the content of each metal ion measured is less than 10ppb. Other properties are shown in Table 1.

Embodiment 3

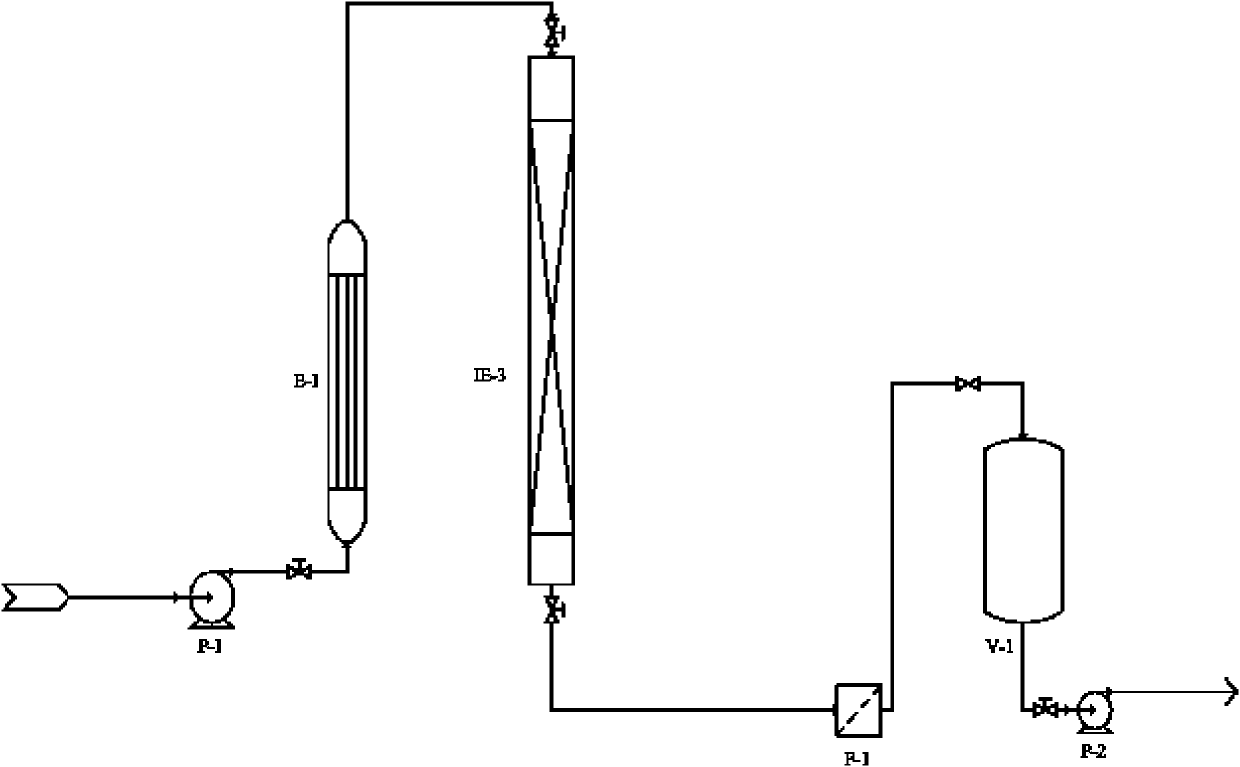

[0030] Such as figure 2 As shown, DMF is purified in the form of a mixed bed. The ion exchange column IE-3 is a mixed bed ion exchange column. The material of the resin column is glass, and its specification is Φ30×1000mm. A mixture of DVB macroporous strongly acidic styrene-based anion exchange resin and Styrene DVB D301T macroporous weakly basic styrene-based cation exchange resin. First, pretreat the anion exchange resin. The pretreatment method is to wash the resin with water first. , then soak the resin with N, N-dimethylformamide solution for 6 hours, then replace N, N-dimethylformamide with deionized water, and rinse until the exchange column outlet N, N-dimethylformamide weight The percentage concentration is 0.4%, and then rinse with HCl with a concentration of 4.0% at a flow rate of 20mL / min. The molar number of acid used is twice the exchange capacity of the resin, and then rinse with deionized water until neutral, and then use The DMF solution replaces the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com