Method for preparing CoSb3 nanometer particle film

A nanoparticle and film technology, which is applied in the field of CoSb3 nanoparticle film preparation, can solve the problems of low thermoelectric conversion efficiency and achieve low thermal conductivity, less process parameters and excellent thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

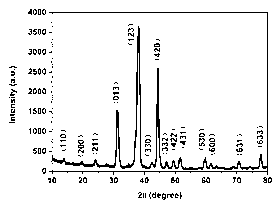

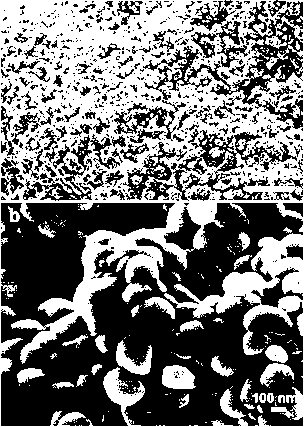

[0028] Weigh 0.02855 g of CoCl 2 ·6H 2 O powder (purity 98%), and 0.04392 g Sb powder (purity 99.5%) were put into respective crucibles, and CoCl 2 ·6H 2 Put the crucible of O powder into the upstream of the quartz tube, 5cm away from the center of the quartz tube, put the crucible with Sb powder into the upstream of the quartz tube, 10cm away from the center of the quartz tube, and put the crucible with a size of 0.5 × 1 cm 2Put the glass slide into the downstream of the quartz tube, 16cm away from the center of the quartz tube, put the quartz tube into a horizontal tube furnace, and align the center positions of the two; use a mechanical pump to evacuate the quartz tube to 10 -3 mbar, then feed 95% argon and 5% hydrogen mixed gas, repeat the process of vacuuming and feeding the mixed gas three times, this process is used to remove the oxygen in the quartz tube, the tube furnace is heated to 800 °C, The heating rate is 30°C / min, and it is kept for 60 minutes after heating....

Embodiment 2

[0030] Weigh out 0.0571 g of CoCl 2 ·6H 2 O powder (98% in purity), and 0.08784 g of Sb powder (99.5% in purity), were put into respective crucibles, and the CoCl 2 ·6H 2 Put the crucible of O powder into the upstream of the quartz tube, 5cm away from the center of the quartz tube, put the crucible with Sb powder into the upstream of the quartz tube, 10cm away from the center, and put the crucible with a size of 0.5 × 1 cm 2 Put the glass slide into the downstream of the quartz tube, 16cm away from the central position, put the quartz tube into a horizontal tube furnace, and align the center positions of the two; use a mechanical pump to evacuate the quartz tube to 10 -3 mbar, then feed 95% argon and 5% hydrogen mixed gas, repeat the process of vacuuming and feeding the mixed gas three times, this process is used to remove the oxygen in the quartz tube, the tube furnace is heated to 800 °C, The heating rate is 30°C / min, and it is kept for 60 minutes after heating. Durin...

Embodiment 3

[0032] Weigh 0.08565 g of CoCl 2 ·6H 2 O powder (purity 98%), and 0.13176 g Sb powder (purity 99.5%) were put into respective crucibles, and the CoCl 2 ·6H 2 Put the crucible of O powder into the inlet of the quartz tube, 5cm away from the center of the quartz tube, put the crucible with Sb powder into the upstream of the quartz tube, 10cm away from the center of the quartz tube, and put the crucible with a size of 0.5 × 1 cm 2 Put the glass slide into the upstream of the quartz tube, 16cm away from the center of the axis of the quartz tube, put the quartz tube into a horizontal tube furnace, and align the center positions of the two; use a mechanical pump to evacuate the quartz tube to 10 -3 mbar, and then feed a mixed gas of 95% argon and 5% hydrogen, and repeat the process of vacuuming and feeding the mixed gas three times. This process is used to eliminate the oxygen in the quartz tube. The tube furnace is heated to 800°C with a heating rate of 30°C / min and kept for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com