Flue gas pollutant combination removal method based on high-activity solid absorbent

A technology of combined removal and absorbent, applied in the field of combined removal of flue gas pollutants, industrial kilns, and coal-fired industrial boilers, can solve the problems of low nitrogen oxide removal efficiency, cumbersome procedures, nozzle blockage, etc. The effect of low operating and equipment cost and high life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

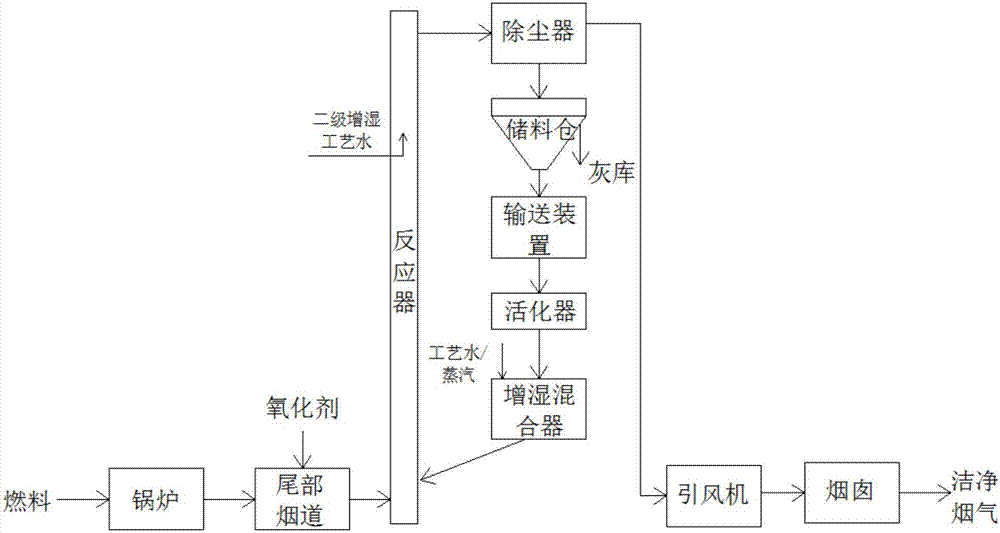

Image

Examples

example 1

[0048] In the tail flue section of the boiler at a temperature of 120°C, spray high-concentration ozone and mix it evenly with the flue gas, O 3 The / N molar ratio is 0.6, and the residence time is 0.5s; NO and zero-valent mercury in the flue gas are oxidized to high-valence nitrogen oxides and mercury compounds.

[0049] After activation, wet solid particles (dust-containing flue gas is dedusted to obtain clean flue gas, solid particles collected at the bottom of the dust collector are sent to the storage bin, part of the solid particles enter the activator through the conveying device, and are sprayed into a certain amount of process Atomized water or steam is used to activate it. The activated material enters the humidification mixer and sprays a certain amount of process atomized water (humidification) into the reactor to quickly reduce the temperature of the flue gas to 70 ° C and combine with the oxidation After the flue gas is in full contact with the SO 2 , SO 3 , Hi...

example 2

[0051] Other steps are the same as Example 1, except that the solid particle humidification is changed into two stages of humidification (the wet solid particles after activation enter the reactor, and the temperature of the flue gas is rapidly reduced to 80 ° C, which is suitable in the middle of the reactor. Spray a small amount of process atomized water into the position for secondary humidification, and the temperature of the flue gas is further reduced to 70°C), SO 2 The removal rate is 92%, and the NO removal rate is 82%.

example 3

[0053] Other steps are the same as example 2, a small amount of process water that is sprayed into the middle of the reactor is replaced with a concentration of 80% NaClO solution. It not only plays the role of humidification, but also can continue to oxidize the fully oxidized NO and Hg in the reactor, further improving the absorption rate. SO 2 The removal rate is 92%, and the NO removal rate is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com