Patents

Literature

76results about How to "No need to deal with" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

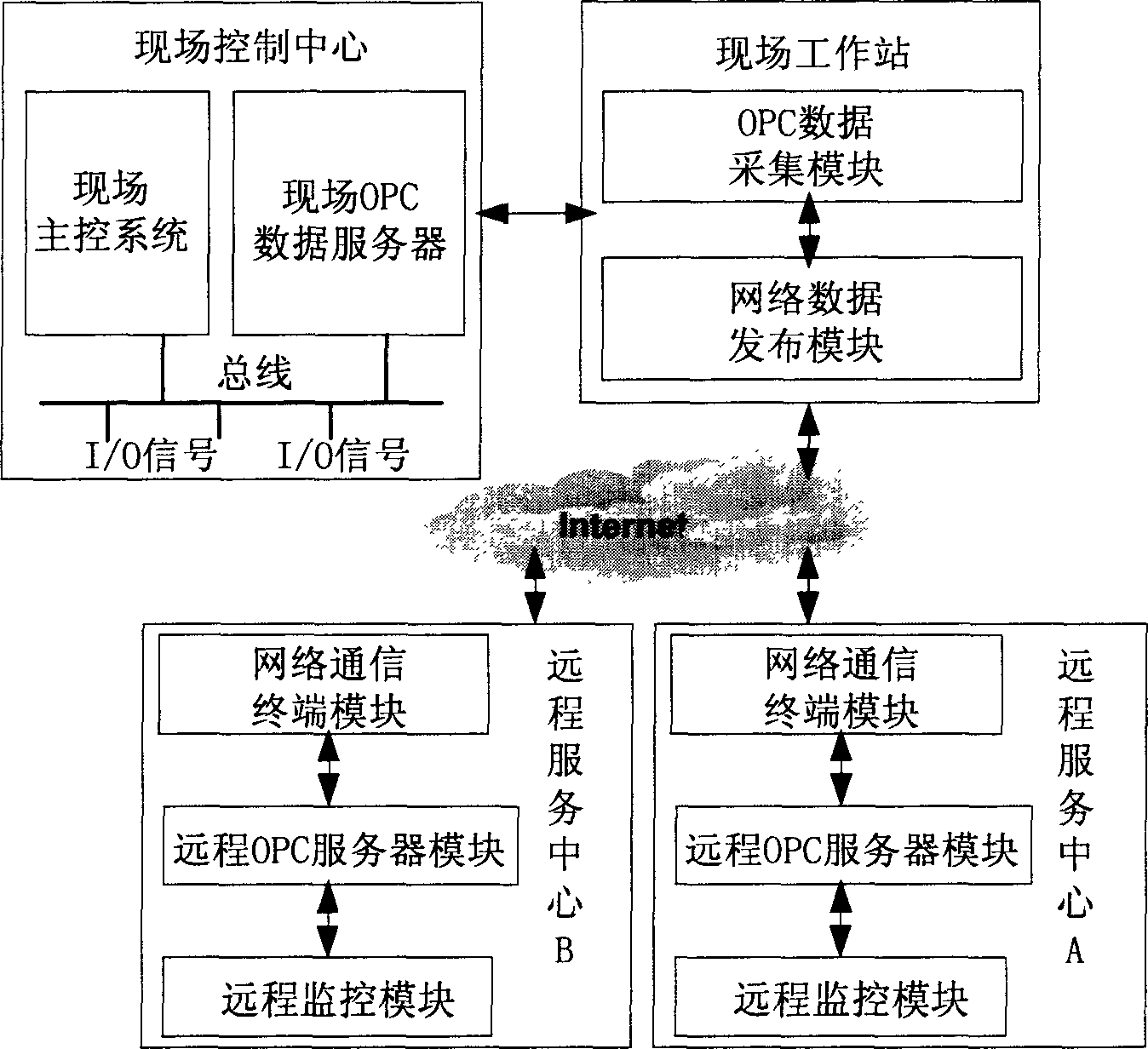

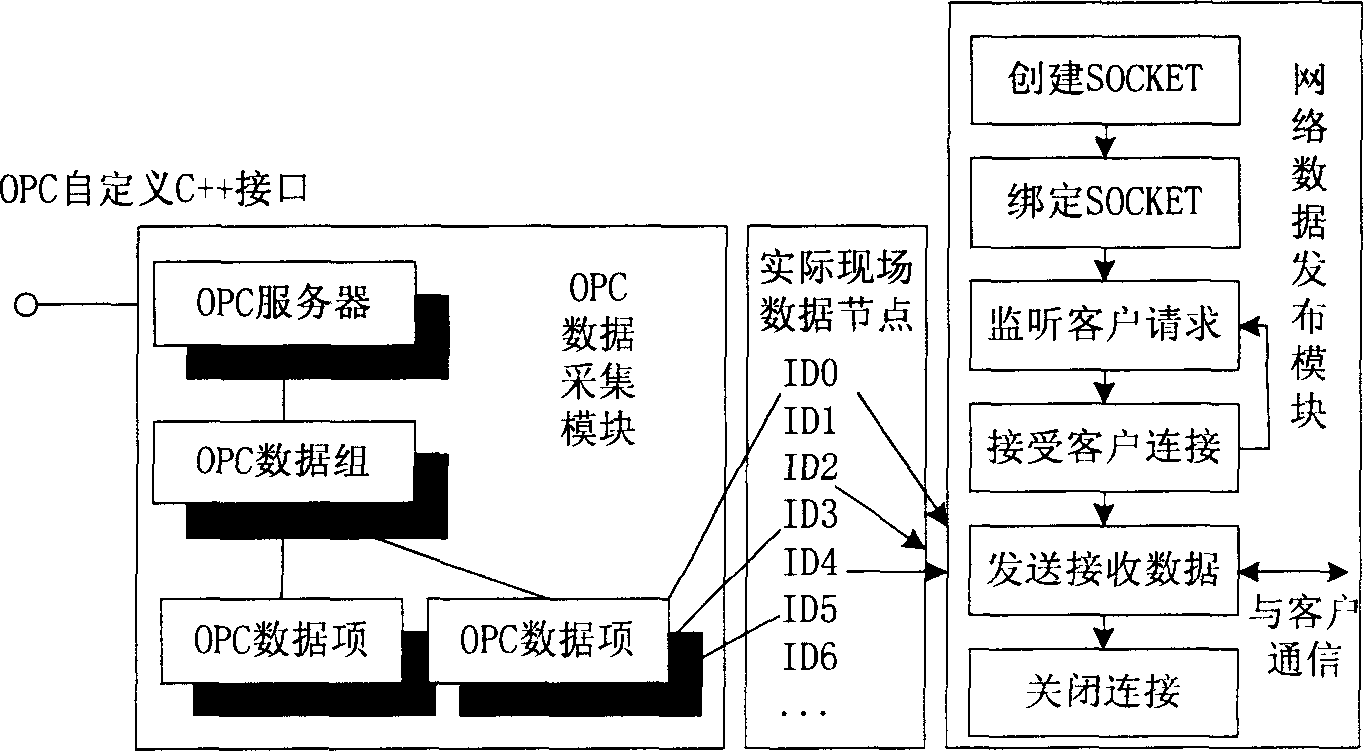

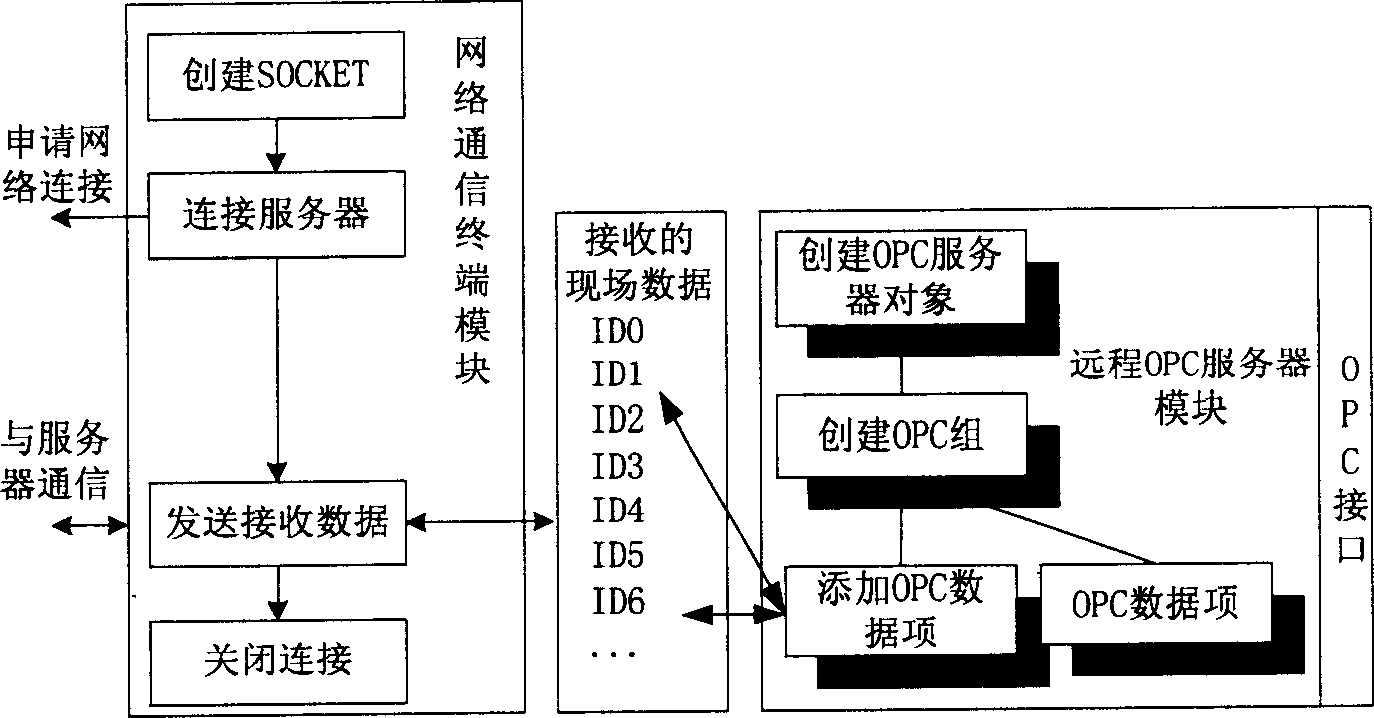

System accorded with OPC standard for monitoring remote configuration

InactiveCN1798141ATroubleshoot Remote TroubleshootingSolve problemsData switching networksTotal factory controlRemote controlData acquisition

The system includes a field working station and a remote service center. The field working station runs the OPC data collection module and the network data releasing module conforming to TCP / IP protocol by using the OPC data collection and network data releasing application program, and is connected to the field control center through OPC interface. The remote service center runs the network terminal module conforming to TCP / IP protocol, the remote OPC server module and the remote control module supporting OPC interface by using network terminal application program and the remote OPC service application program. The network communication terminal module receives the field data released by the network data releasing module, and then releases the received data to the remote OPC service module by which the data is transmitted to the remote monitoring module.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for eliminating dioxins in flue gas

InactiveCN101249378ASimple processNo equipment bottleneckDispersed particle separationUreaEnvironmental chemistry

The invention relates to a method used for eliminating dioxin in fume. The method has the following steps that water solution containing substance of hydrazine type is sprayed into the fume containing dioxin or potentially containing dioxin so that the fume fully touches and reacts with the water solution, and the water in the solution is completely evaporated at the temperature above 160 DEG C. In this way, dioxin in the fume is eliminated. The water solution with hydrazine type substance is fresh solution prepared based on 0.05 percent to 1 percent by weight before use, and is sprayed into the fume with the temperature ranging from 200 DEG C to 600 DEG C, or into the fume with the temperature ranging from 600 DEG C to 850 DEG C. At the temperature ranging from 600 DEG C to 850 DEG C, the water in the water solution containing hydrazine can adopt urea or ammonia. At the temperature ranging from 200 DEG C to 600 DEG C, the water to dissolve hydrazine can adopt alkaline solution or urea solution in combination with purification of other noxious gases such as SOx and NOx by using a prior or a late established purification device or system, so that NOx and acidic gases in the fume are eliminated, and toxicant content in fly ash is reduced. By adopting the method, dioxin in the fume is eliminated without production of noxious byproducts. Throughout the course, no waste water or waste solid is produced; the concentration of dioxin in fly ash is reduced; the treating process is simple, and the cost of disposal is low.

Owner:TONGJI UNIV

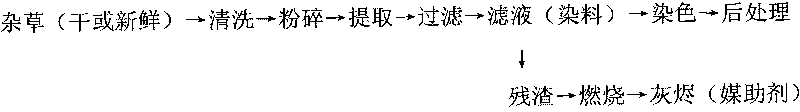

Natural plant dye, preparation method and application thereof

InactiveCN101709152ANo need to saveNo need to deal withNatural dyesDyeing processInvasive WeedsWater Hyacinths

The invention relates to the field of natural dyes, and specifically relates to a natural plant dye, a preparation method and application thereof. According to the invention, the natural plant dye is obtained by extracting vicious weeds serving as raw materials, wherein the vicious weeds are one or more in a group including chromolaena odorata, mikania cordata, water hyacinth, alternanthera philoxeroides, alternanthera pungens, spartina anglica s, ragweed, lantana camara, solanum aculeatissimum and lolium temulentum. The extraction method comprises the steps of grinding and extracting through water. The invention provides a novel scheme for utilizing exotic vicious weeds; the preparation of the natural plant dye by taking exotic invasive weeds as raw materials can protect environment and bring conomic benefits; residue produced during dye extraction can be burnt and combustion can provide a heat source for a dyeing process; and obtained ash can be used as mordanting assistants for dyeing with no storage or treatment so as to really achieve environmental protection.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

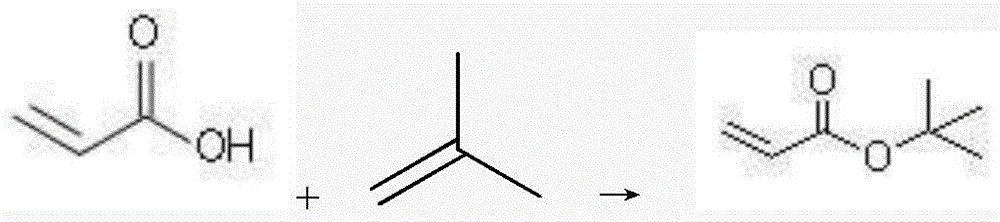

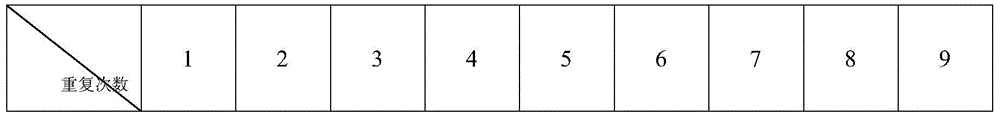

Preparation process for catalyzing and synthesizing tert-butyl acrylate by using strong acid cation exchange resin as catalyst

ActiveCN103073426ASimple stepsReduce processOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a preparation process for catalyzing and synthesizing tert-butyl acrylate by using strong acid cation exchange resin as a catalyst, belonging to the technical field of organic synthesis. The preparation process is characterized by comprising the steps of: adding crylic acid, strong acid cation exchange resin, a polymerization inhibitor A and a polymerization inhibitor B into a closed reaction kettle, dropwise adding liquefied isobutene for carrying out esterification reaction; after dropwise adding is completed, carrying out thermal insulation; after the thermal insulation is finished, releasing the pressure of the closed reaction kettle, filtering, extracting a liquid component to enter a rectifying tower; and sequentially separating byproducts of tertiary butanol and diisobutylene and a target project of the tert-butyl acrylate. The preparation process has the beneficial effects that the liquefied isobutene is adopted to be directly catalyzed together with the crylic acid and the cation exchange resin under the action of the polymerization inhibitor A and the polymerization inhibitor B to form a specific catalysis system, gaseous isobutene is not needed to be dissolved in a solvent containing crylic acid for carrying out esterification reaction under the action of the catalyst, and thus the procedure of absorbing a solvent in subsequent operation is removed, resources are saved and procedures are saved.

Owner:山东敏德化工有限公司

Production method of large-size titanium alloy intermediate rod material

ActiveCN1657197ASolve technical problems that are prone to cracksAvoid formingMetal-working apparatusSurface cleaningIngot

Owner:宝武特冶钛金科技有限公司

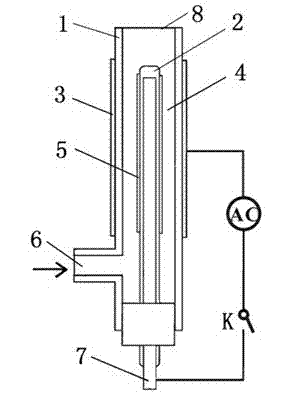

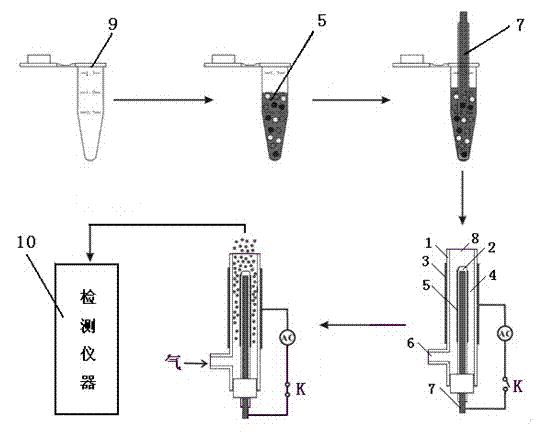

Method of evaporating sample injecting inducted by dielectric barrier discharge microplasma

InactiveCN102353799ASimple structureEasy to manufacturePlasma techniqueMaterial analysisEngineeringLow power dissipation

The invention relates to a method of evaporating sample injecting inducted by dielectric barrier discharge microplasma. The method comprises steps that first a barrier discharge apparatus capable of producing microplasma is prepared, wherein the apparatus comprises a power, a switch, two insulating dielectric layers with concentric cylindrical pipe structure, two electrodes, an air inlet and a steam outlet; a discharge chamber is between the two dielectric layers, and an external electrode is covered outside the outer cylindrical pipe, and an inner electrode is inserted in the inner cylindrical pipe; and two electrodes are connected with the power; then a solution sample is added into a centrifuge tube, the inner cylindrical pipe of the dielectric barrier discharge apparatus is taken out and inserted into the centrifuge tube, and will be inserted back into the apparatus after sampling; carrier gas is let in, and the power is tuned on; the sample is absorbed by microplasma generated by dielectric barrier discharge; generated steam is purged by the carrier gas and enters a detector from the steam outlet, wherein the whole flow is finished in 90 s. The method is simply operated, without sample treatment, at low power dissipation, rapid and is especially suitable for analysis of small volume sample and trace and ultra trace elements.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

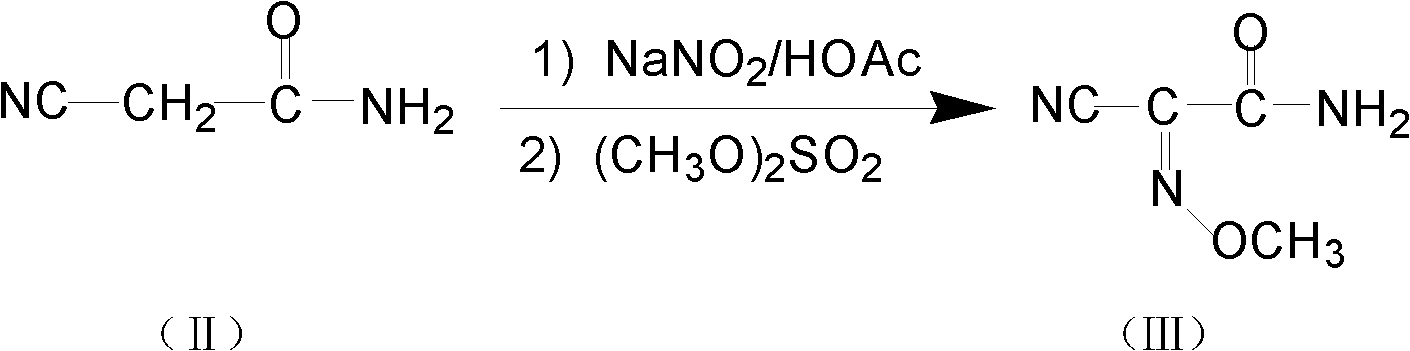

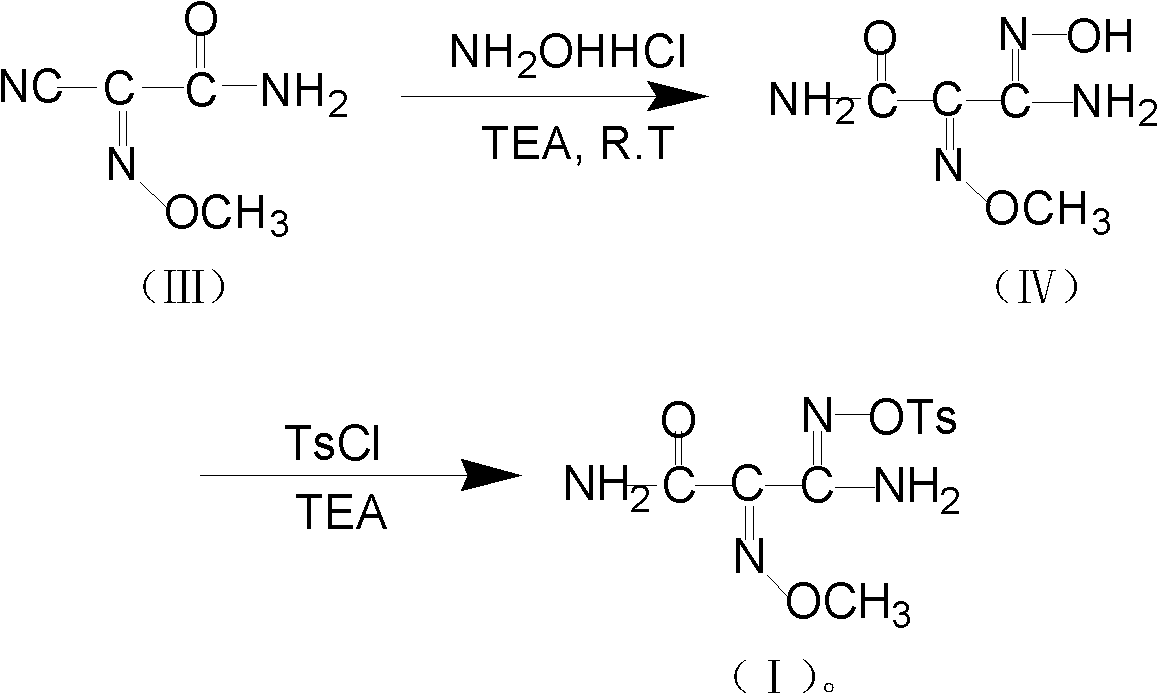

Method for preparing O-tosyl-2-carbamoyl-2-methoxyl-imido-acetamido-oxime

ActiveCN102093266AShort processReduce manufacturing costSulfonic acid esters preparationSulfonyl chlorideReaction intermediate

The invention relates to a method for preparing O-tosyl-2-carbamoyl-2-methoxyl-imido-acetamido-oxime, which comprises the following steps: (1) reacting cyanoacetamide, which is used as an initial raw material, with sodium nitrite in a nitrosation mode to obtain a reaction intermediate, and reacting the reaction intermediate with dimethyl sulfate in an esterification mode to obtain 2-cyano-2-methoxyl-imido-acetamide; and (2) under the action of hydroxylamine hydrochloride, hydrolyzing cyano groups in the 2-cyano-2-methoxyl-imido-acetamide obtained in the step (1) into amino groups, and reacting with p-methylbenzene sulfonyl chloride in an esterification mode to generate the O-tosyl-2-carbamoyl-2-methoxyl-imido-acetamido-oxime. The preparation method provided by the invention has the advantages of accessible raw materials, short technical process and high yield, and is suitable for industrial production.

Owner:BENGBU BBCA MEDICINE SCI DEV

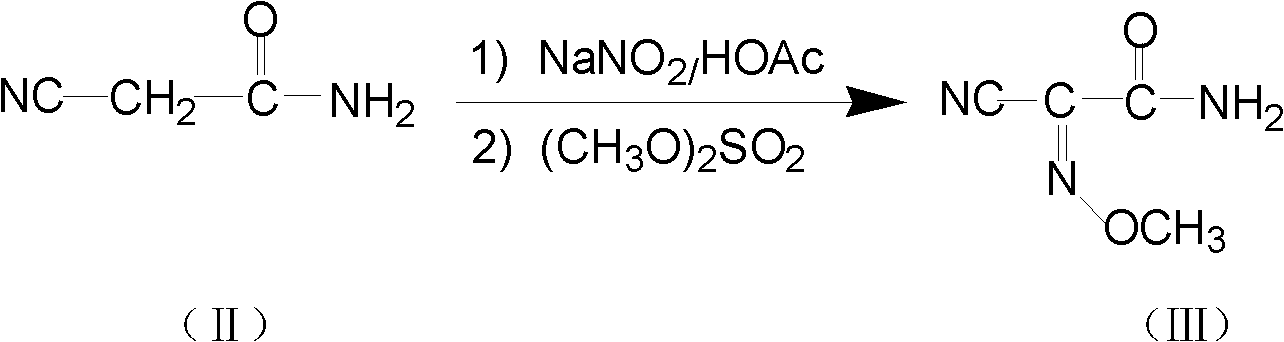

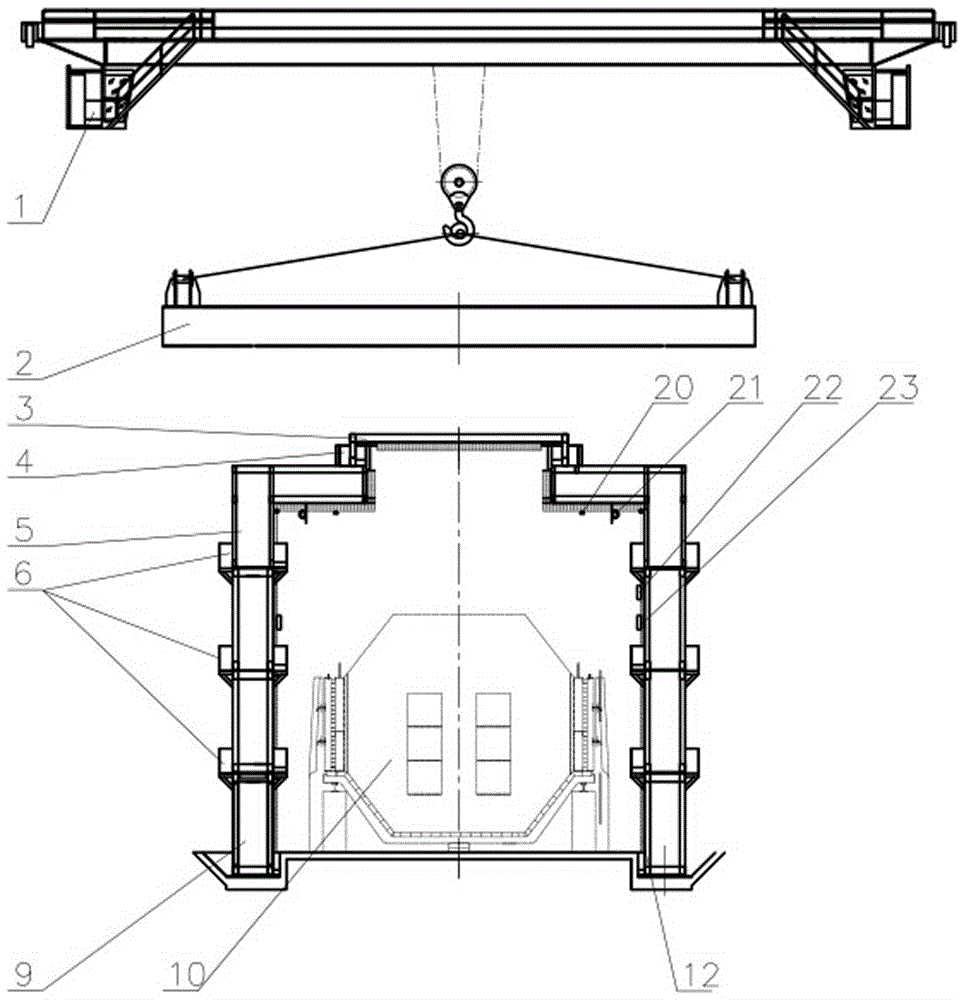

Three-dimensional color high-speed printer

The present invention relates to a three-dimensional color high-speed printer, which comprises a moving printing sprayer, a color distribution ink supply box, a work tank, a computer and a peripheral circuit, wherein the work tank comprises a powder supply tank, a forming tank and an overflow tank, the powder supply tank, the forming tank and the overflow tank are laterally and sequentially arranged side by side, a lifting powder supply plate is arranged inside the powder supply tank, a lifting production platform is arranged inside the forming tank, two lateral bracket guide rails are flatly arranged on the work tank, the longitudinal ink roller device capable of laterally moving along the lateral bracket guide rails is arranged on the two lateral bracket guide rails, the two lateral bracket guide rails are further provided with longitudinal guide rails capable of laterally moving, the moving printing sprayer is movably arranged on the longitudinal guide rail, and the material outlet of the color distribution ink supply box is connected with the material inlet of the moving printing sprayer through an ink supply pipe. The three-dimensional color high-speed printer has characteristics of simple structure, easy operation, broad application range, good environmental protection, capability of outputting vibrant color model, and achievement of time-saving and rapid automated operation and easily-used printing process.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Full-dry purification method of lithium ion battery positive electrode material and lithium ion battery positive electrode material obtained through purification

InactiveCN110828888ANo need to deal withSimple recycling processCell electrodesWaste accumulators reclaimingPhysical chemistryLithium-ion battery

The invention belongs to the technical field of comprehensive utilization of lithium ion battery positive electrode materials, and particularly relates to a full-dry purification method of a lithium ion battery positive electrode material and the lithium ion battery positive electrode material obtained through purification. The method comprises the following steps: (1) heating crushed materials ofa lithium battery positive electrode recycled material at a low temperature until an adhesive is invalid to obtain a mixture where a current collector and a lithium battery positive electrode to-be-purified material is separated; 2) performing vibration sieving on the mixture where the current collector and the lithium battery positive electrode to-be-purified material is separated to obtain thelithium battery positive electrode to-be-purified material from which the current collector is removed; and 3) carrying out sintering on the lithium battery positive electrode to-be-purified materialfrom which the current collector is removed to obtain the lithium battery positive electrode purified material. Full-dry purification of the lithium ion battery positive electrode material is realized, and the lithium battery positive electrode purified material obtained through purification is high in purity.

Owner:武汉瑞杰特材料有限责任公司

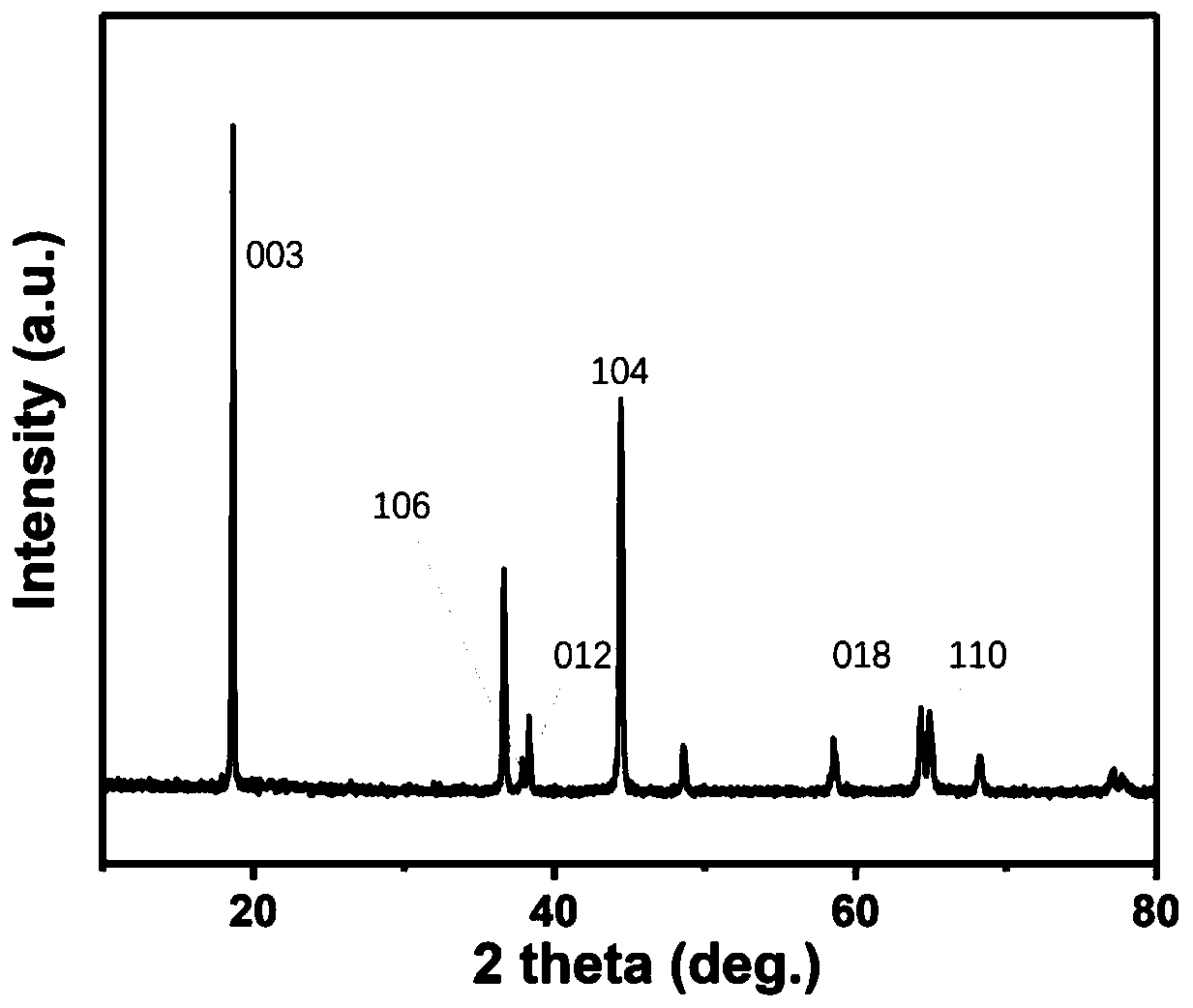

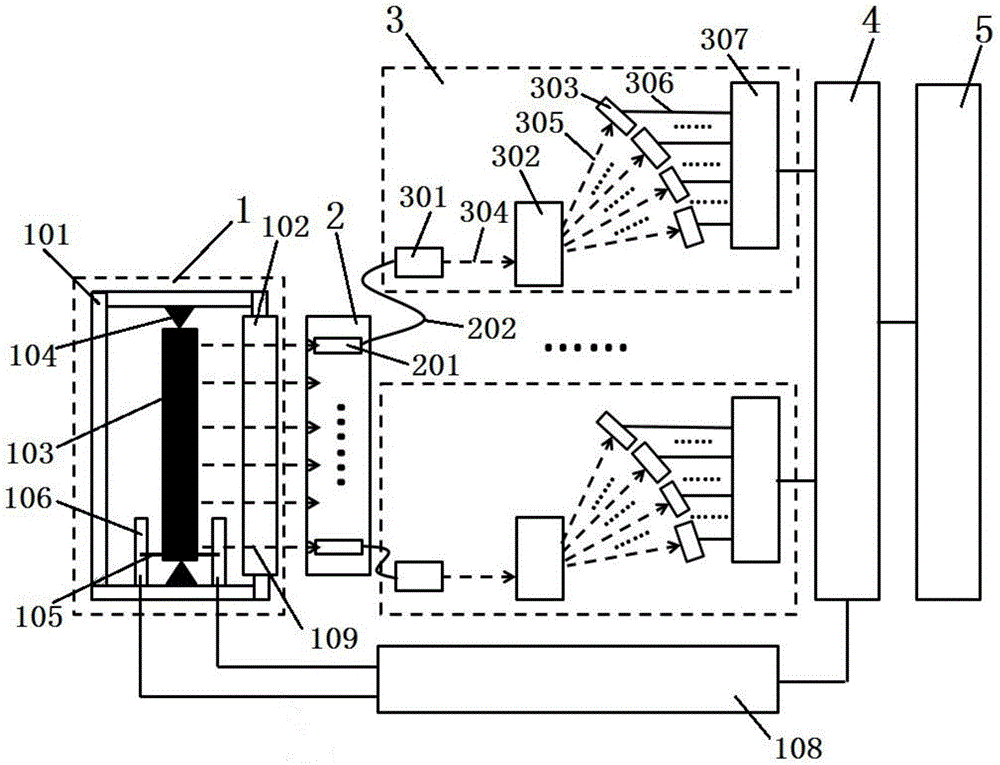

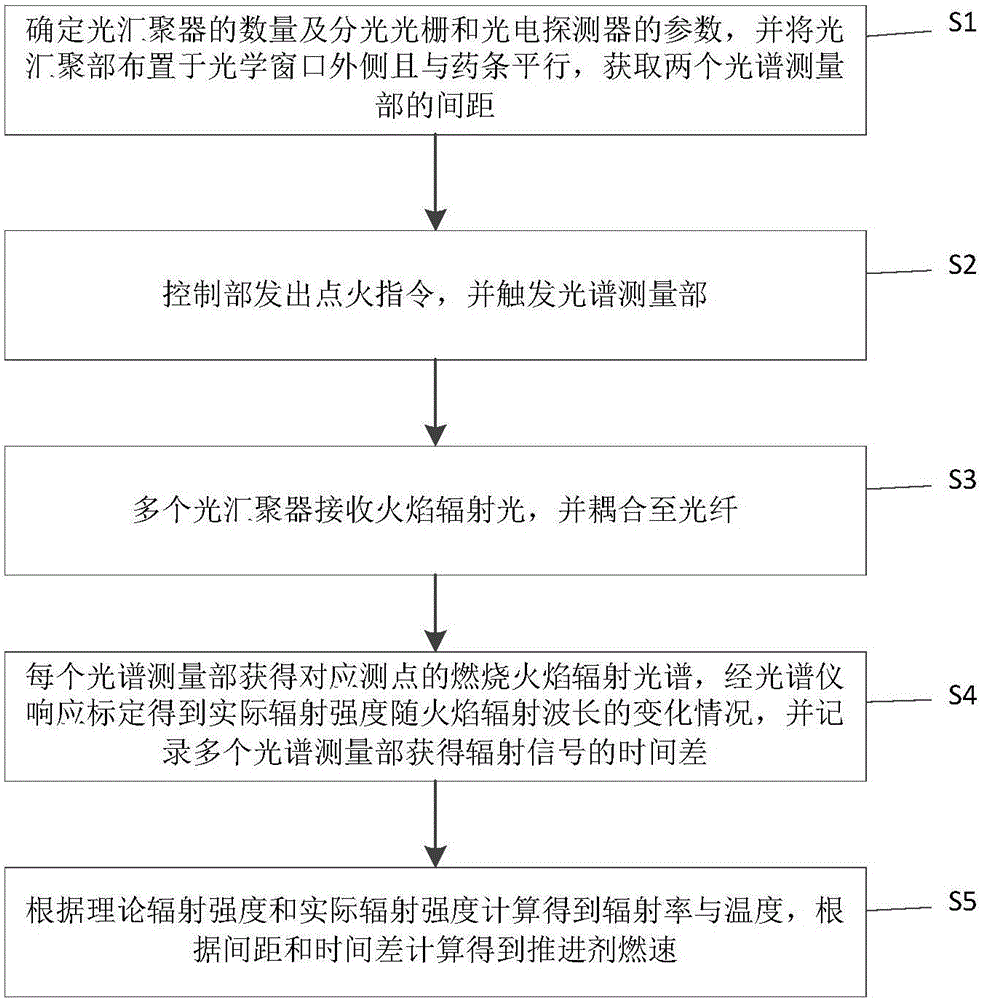

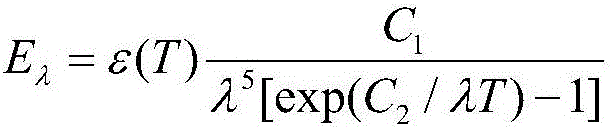

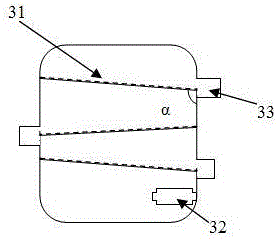

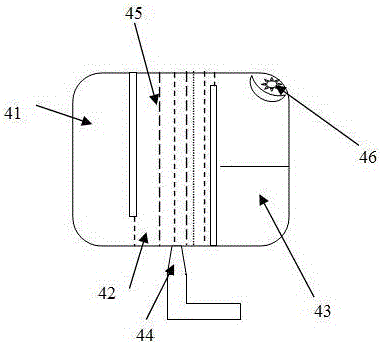

Flame-radiation-based combustion measuring apparatus and measuring method for solid rocket propellant

ActiveCN106482790ARealize online non-contact multi-parameter measurementNo need to deal withMeasurement devicesFiberOptical radiation

The invention provides a flame-radiation-based combustion measuring apparatus for a solid rocket propellant. The apparatus comprises a light convergence part, a plurality of spectral measurement parts, an ignition device, a control part, and a signal processing part. The light convergence part is formed by a plurality of light convergence devices arranged at the same straight line; the light convergence devices corresponding to the spectral measurement parts one by one; and the light convergence devices and the corresponding spectral measurement parts are connected by fibers. The control part is connected with the ignition device, the signal processing part, and the plurality of spectral measurement parts electrically. In addition, a measuring method based on the measuring apparatus is characterized in that temperature and radiance parameters are obtained by fitting of a flame radiation, so that the measuring precision of the optical radiation measuring method can be improved. And with combination of the array arrangement method, a combustion speed parameter can be obtained. For propellant combustion testing, multi-parameter simultaneous on-line non-contact measurement is realized; processing on a medical stick is avoided; and the apparatus is easy to repair.

Owner:ELECTROMECHANICAL ENG INST OF SICHUAN AEROSPACE +1

Separation and purification method for lithium ion battery positive electrode material and obtained lithium ion battery positive electrode material

PendingCN110808430AMild processing temperatureFewer temperature processing stepsPositive electrodesWaste accumulators reclaimingPhysicsChemistry

The invention belongs to the technical field of waste lithium ion battery recovery and resource cyclic utilization, and particularly relates to a separation and purification method for a lithium ion battery positive electrode material and the obtained lithium ion battery positive electrode material. The method comprises the following steps of: (1) heating crushed materials of a lithium battery positive electrode recycled material at a low temperature until an adhesive is invalid to obtain a mixture with a current collector and a to-be-purified lithium battery positive electrode material separated, 2) performing vibration screening on the mixture with the current collector and the to-be-purified lithium battery positive electrode material separated to obtain the to-be-purified lithium battery positive electrode material from which the current collector is separated, and 3) winnowing the to-be-purified lithium battery positive electrode material from which the current collector is separated to obtain the lithium battery positive electrode separation and purification material. Full-dry purification of the lithium ion battery positive electrode material is realized, and the lithium battery positive electrode purification material obtained by purification is high in purity.

Owner:武汉瑞杰特材料有限责任公司

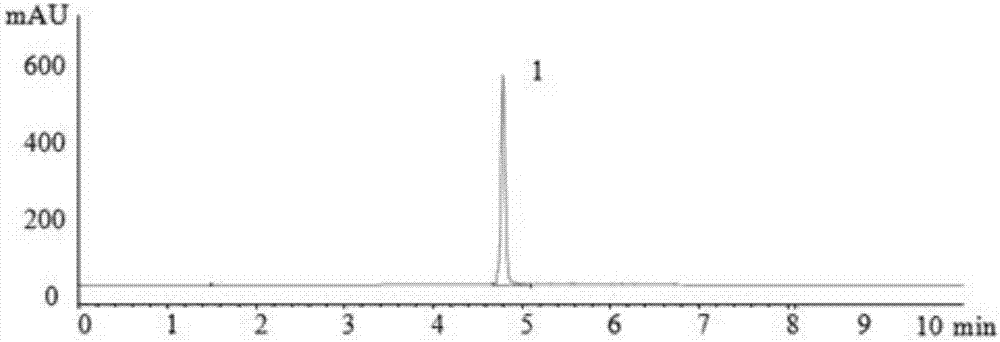

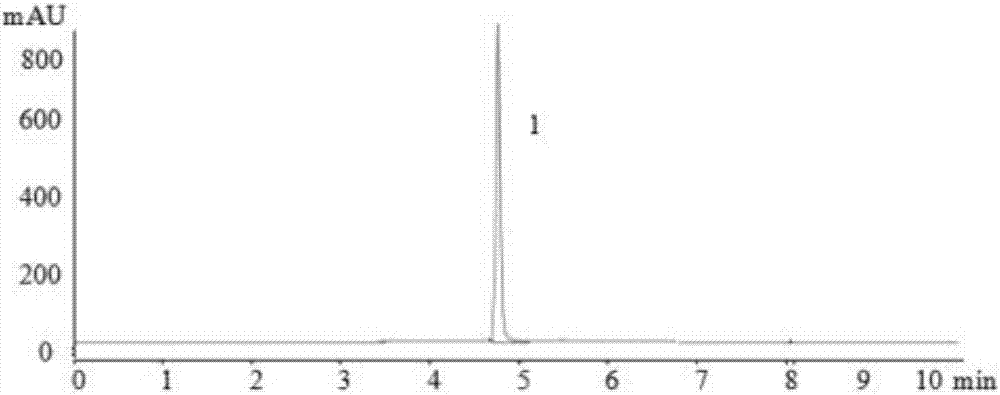

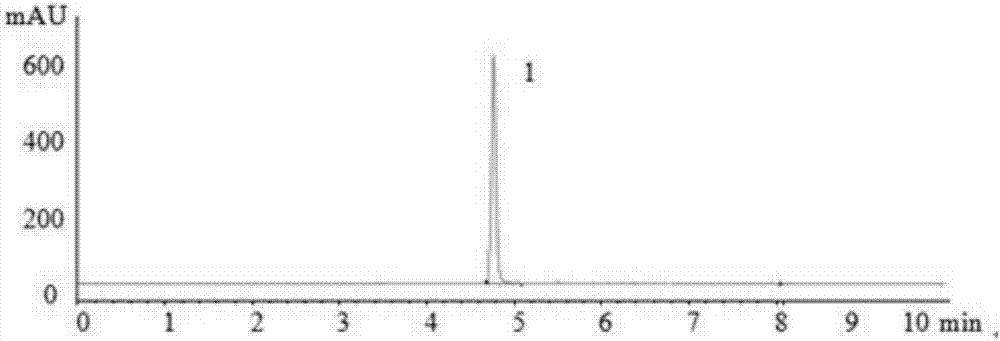

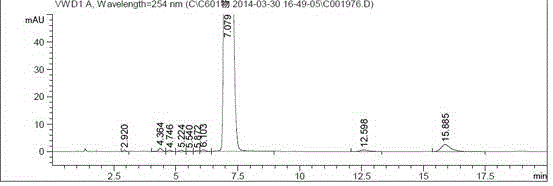

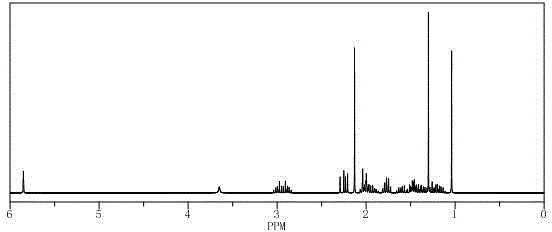

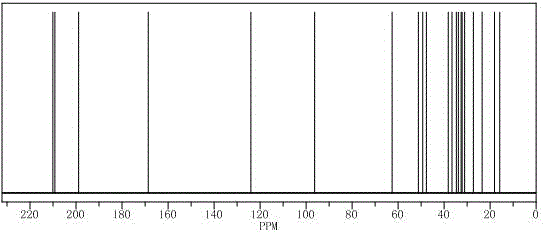

EGCG preparation method

ActiveCN106967036AReduce the use effectReduce recyclingOrganic chemistryOrganic solventFreeze-drying

The invention provides an EGCG preparation method, particularly relates to a preparation method for industrial production of high-purity EGCG and belongs to the field of separation and purification of plant monomers. For solving the problem that at present, a process for preparing the EGCG based on an organic solvent extraction method is complicated, adopts a large number of organic solvents in the production process and is not safe and environment-friendly enough, the EGCG preparation method comprises the following steps of green tea smashing, vacuum high-temperature extraction with deionized water, inorganic ceramic membrane filtration, enrichment with macroporous adsorption resin, reversed phase chromatography, vacuum concentration and freeze-drying. The method only adopts water, aqueous ethanol and other solvents in the whole preparation process of the process, the usage and recovery amount of a large amount of organic solvents is decreased, the non-toxic, safe and simple process is achieved, ceramic membrane, resin and reverse chromatographic column filler are recyclable, the cost is greatly reduced, meanwhile the purity of the EGCG is improved, and the process is more suitable for large-scale EGCG production.

Owner:盛林

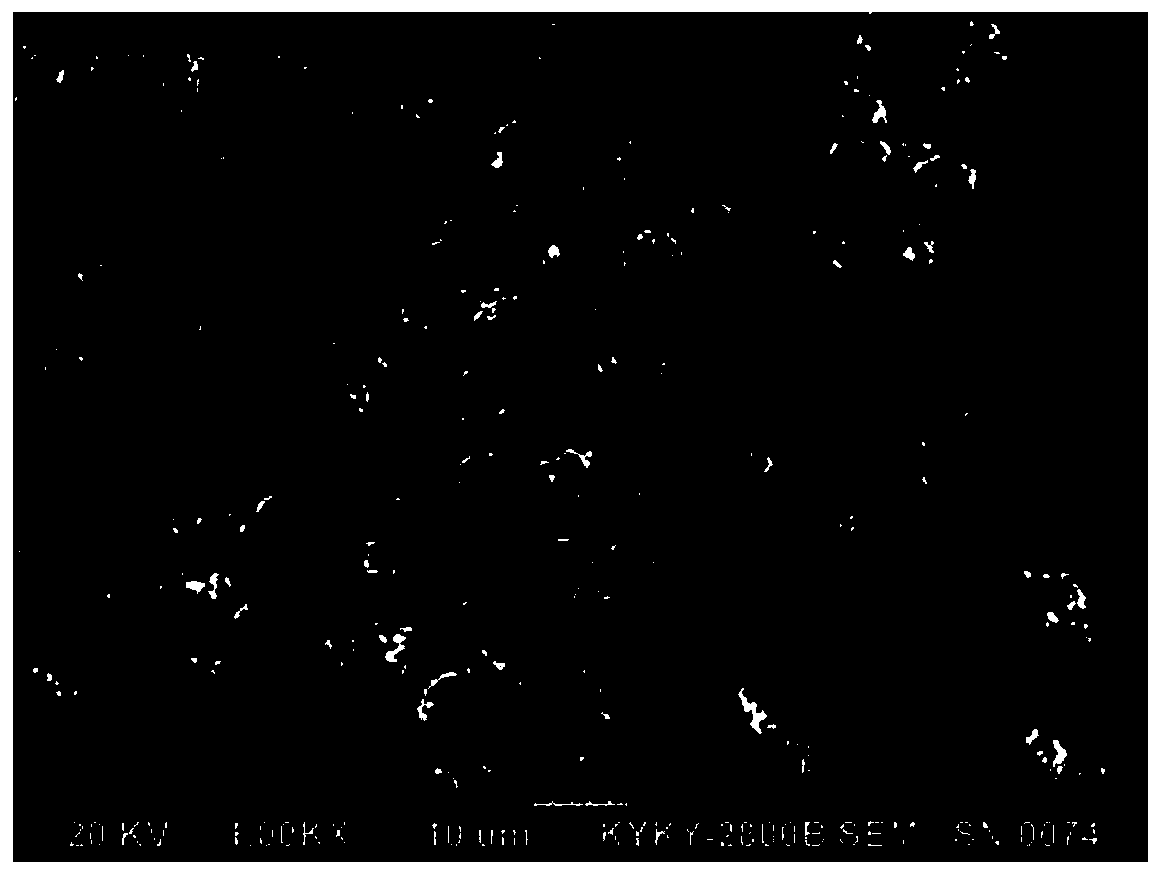

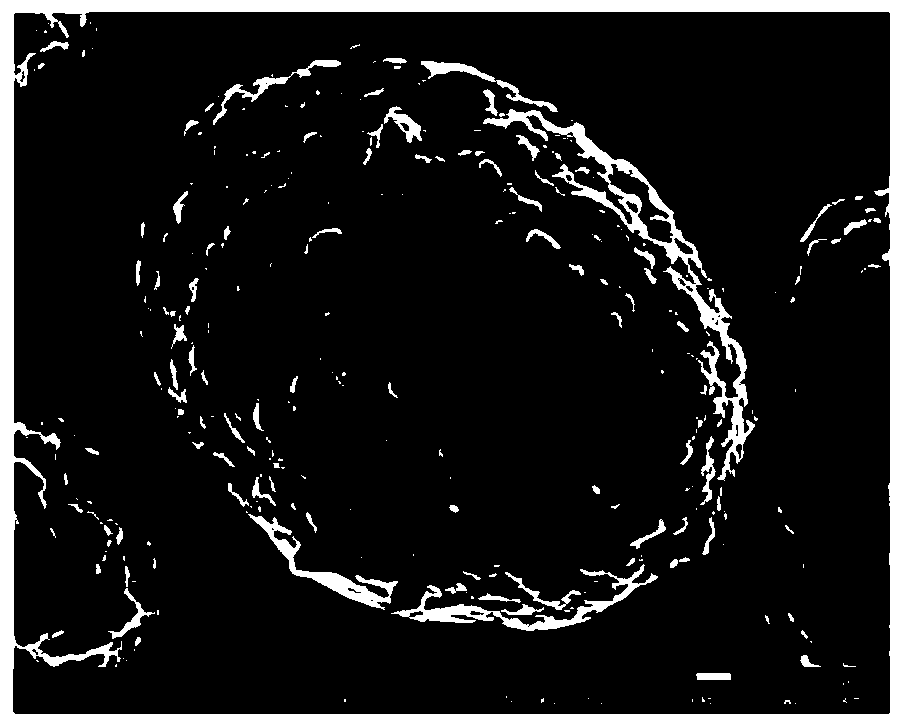

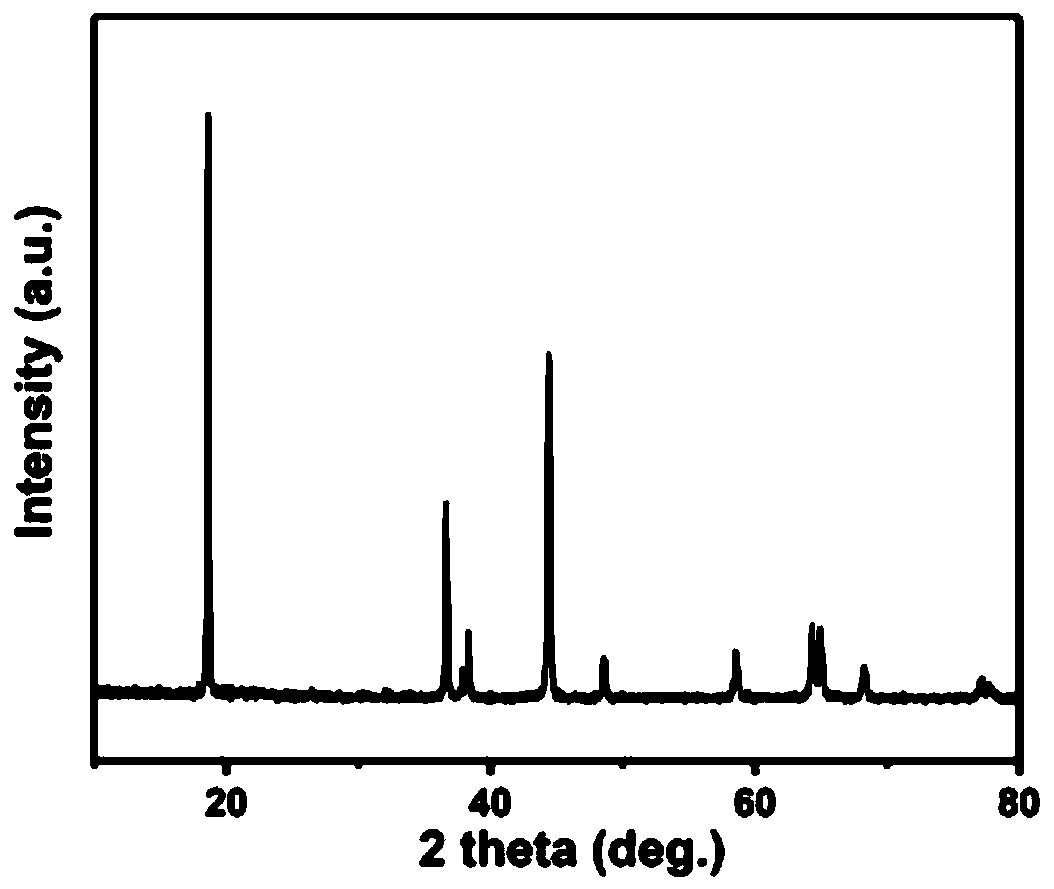

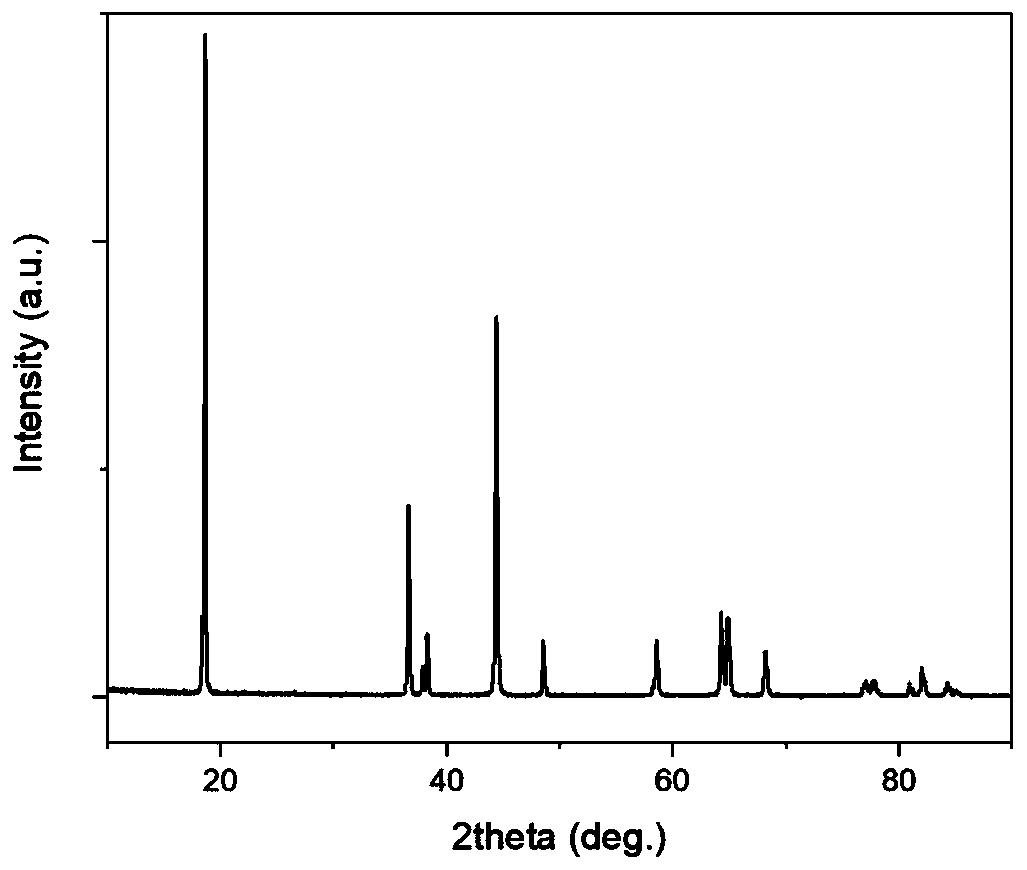

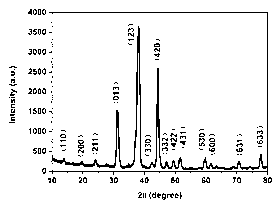

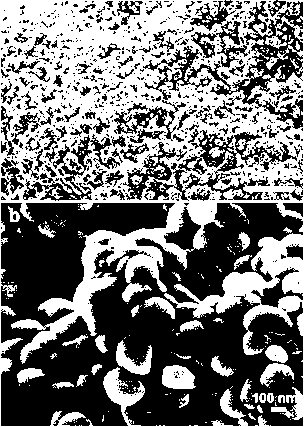

Method for preparing CoSb3 nanometer particle film

InactiveCN102796994ANo need to deal withImprove conductivityNanotechnologyChemical vapor deposition coatingThermoelectric materialsGas phase

The invention relates to a CoSb3 thermoelectric material, in particular to a method for preparing a CoSb3 nanometer particle film. The method comprises the following steps of: firstly, weighing CoC12.6H2O powder and Sb powder according to the molar ratio of 1:3; respectively filling the powder into respective crucible; putting the crucibles and glass slide substrates into a quartz pipe; placing the quartz pipe into a horizontal pipe type furnace; vacuumizing and aerating mixed air of 95 percent of argon and 5 percent of hydrogen for multiple times and removing oxygen in the quartz pipe; raising the temperature of the tubular pipe; performing chemical vapor deposition on the glass slide substrates in a low-pressure state to acquire the CoSb3 nanometer particle film; and testing Seebeck coefficient, conductivity and heat conductivity of the CoSb3 nanometer particle film and calculating a zone time (ZT) value of the CoSb3 nanometer particle film. According to the invention, the CoSb3 nanometer particle film is synthesized by one step, the process is simple, and the diameter of the prepared CoSb3 nanometer particle is between 200 and 400nm; and moreover, the CoSb3 thermoelectric material has good conductivity and low heat conductivity, can be directly used for thermoelectricity researches, and is used for novel high-efficiency thermoelectric conversion devices.

Owner:CHANGZHOU UNIV

Hydrogenation technology of sugar alcohol

InactiveCN109336939AQuick reaction to waterNo solubility issuesSugar derivativesSugar derivatives preparationPtru catalystAlcohol sugars

The invention relates to a hydrogenation technology of sugar alcohol. The hydrogenation technology comprises the processes of sequentially adding a catalyst and hydrogen into a sugar solution and raising the temperature. The hydrogenation technology is characterized by comprising the following steps: after adding the catalyst into the sugar solution and before raising the temperature of the sugarsolution and adding the hydrogen, adding magnesium powder of which the weight is 0.05 to 1.5 percent of the weight of the catalyst into the sugar solution and controlling the pH value of the sugar solution within the variation range of 5.5 to 7.0. According to the hydrogenation technology disclosed by the invention, by adding the magnesium powder when the sugar solution is hydrogenated, the pH value of the reaction process is stabilized, the content is improved, the catalyst loss in the reaction process is reduced, the quality of hydrogenated liquid is improved and refining purification is facilitated.

Owner:ZHEJIANG HUAKANG PHARMA

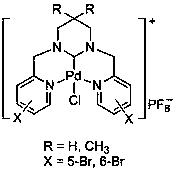

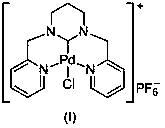

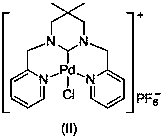

Ring enlargement azoheterocyclic carbene-palladium compound containing picolyl

ActiveCN104744519AUnique structural featuresReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsPalladium organic compoundsSimple Organic CompoundsMetal catalyst

The invention belongs to the field of organic compounds, and relates to a pincer ring enlargement azoheterocyclic carbene-palladium compound. The pincer ring enlargement azoheterocyclic carbene-palladium compound has a structure shown in the specification. The pincer ring enlargement azoheterocyclic carbene-palladium compound disclosed by the invention provides a kind of novel metal catalyst for C-N coupled reaction; when being used for catalyzing the C-N coupled reaction, the pincer ring enlargement azoheterocyclic carbene-palladium compound is short in reaction time, low in use amount of the catalyst, simple to operate and high in catalytic yield; alkali cheap and easy to obtain is used; and a reaction solvent is unnecessary to process.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

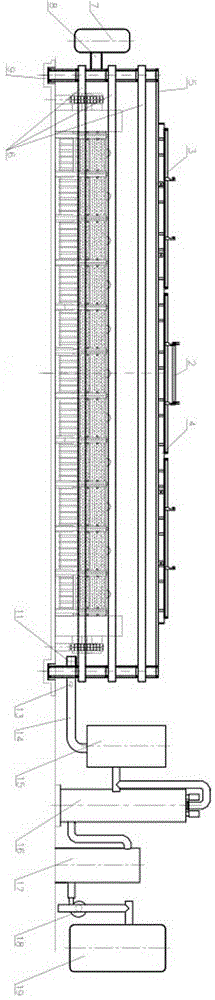

Silicon carbide smelting waste gas collecting and purifying device

InactiveCN106178757AEasy to liftEnsure stabilityGas treatmentUsing liquid separation agentPositive pressureSmelting process

The invention discloses a silicon carbide smelting waste gas collecting and purifying device. The device comprises a fully-closed gas collecting hood of a silicon carbide smelting furnace, the silicon carbide smelting furnace is arranged in the gas collecting hood, one end of the gas collecting hood is communicated with a recycling pipeline system, the recycling pipeline system is communicated with a desulphurization and purification system through a pipeline, the desulphurization and purification system is communicated with an exhaust fan through a pipeline, and the exhaust fan is communicated with a gas storage device through a pipeline; the gas collecting hood is composed of a lower hood body and an upper hood body which are horizontally overlaid, second water sealing tanks are arranged between the lower hood body and the upper hood body and arranged between the lower hood body and the bottom face respectively, and a pressure relieving and sealing device is arranged at the top of the upper hood body. According to the device, collection is conducted through the fully-closed gas collecting hood, and the whole system runs under the micro-positive pressure, the zero pressure and the micro-negative pressure and is closed and not leaked; the hood bodies are divided into multiple sections, the lower hood body sections are installed in an interchanged mode, hoisting is convenient, the desulphurization and purification system can completely remove H2S generated in the smelting process, and collected CO can be directly reutilized without being treated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

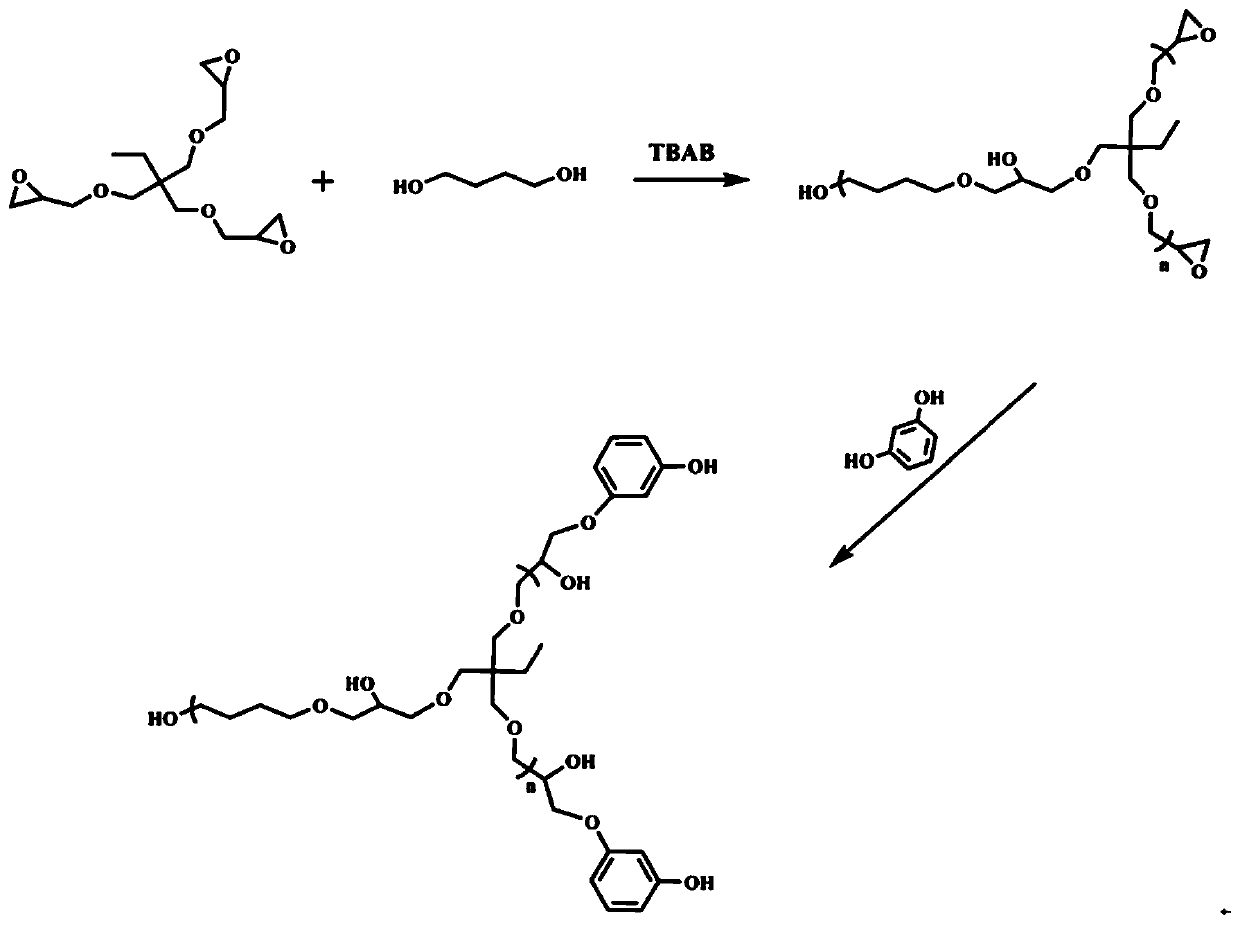

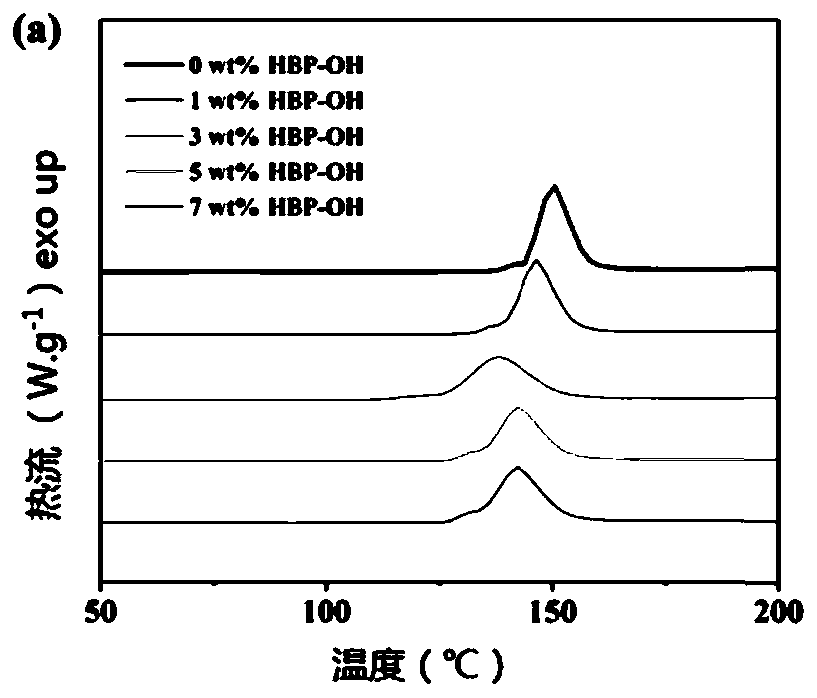

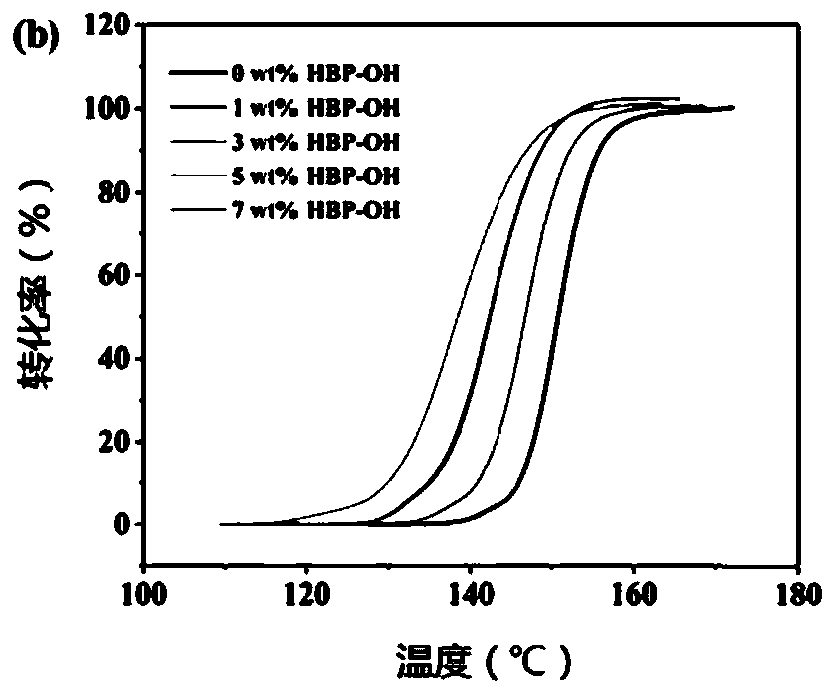

Polyhydroxy hyperbranched polymer, preparation method of polymer and application of polymer in dental composite resin

ActiveCN110527109AEasy accessThe synthesis process is simpleImpression capsDentistry preparationsEpoxyPolymer science

The invention belongs to the field of polymer materials, and relates to a polyhydroxy hyperbranched polymer, a preparation method of the polymer and an application of the polymer in dental composite resin. The polyhydroxy hyperbranched polymer has a structure represented by a formula I shown in the specification. The polyhydroxy hyperbranched polymer provided by the invention is simple to obtain and simple to use, and can improve the bending strength of the dental epoxy resin and reduce the curing shrinkage rate of the dental epoxy resin.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

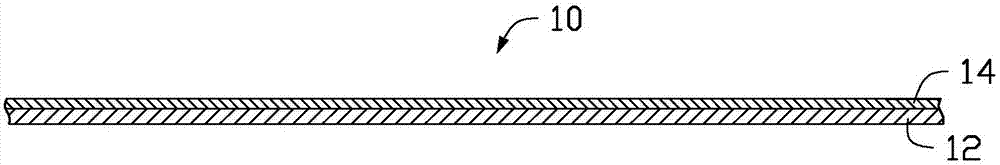

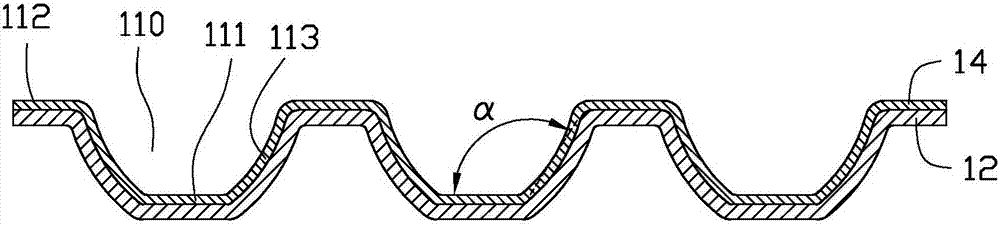

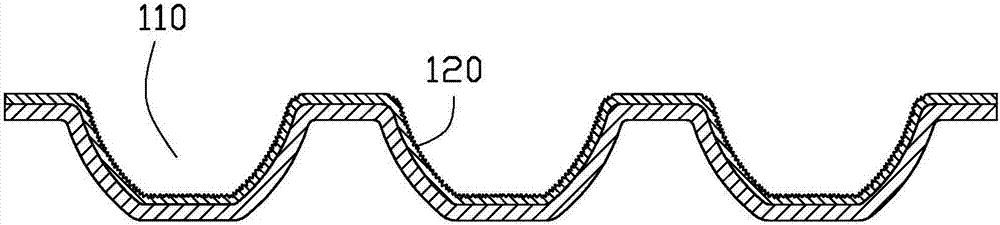

Heat radiation structure and manufacturing method thereof

ActiveCN107360695AAchieving bendable propertiesFew stepsSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopperPhase change

The present invention provides a manufacturing method of a heat radiation structure. The method comprises the following steps: providing a one-side flexible copper-clad substrate which comprises a copper-clad layer, wherein the one-side flexible copper-clad substrate is subjected to pressing and molding to form at least one holding tank, the copper-clad layer is configured to form the inner surface of the at least one holding tank, a support portion is formed around the at least one holding tank, and the support portion encircles the at least one holding tank; forming a bonding portion on the support portion; filling phase-change materials in the holding tank; and providing a covering portion, pressing the covering portion to the one-side flexible copper-clad substrate, wherein the covering portion is fixed with the copper-clad layer through the bonding portion to seal the holding tank, the covering portion and the at least one holding tank form a sealed cavity, and the phase-change materials are held in the sealed cavity. The present invention further relates to a heat radiation structure.

Owner:AVARY HLDG (SHENZHEN) CO LTD +2

Low-cost synthesis method of ARK-Cu

ActiveCN107936090AAvoid bringingNo need to deal withPeptide preparation methodsHybrid peptidesDipeptideSynthesis methods

The invention discloses a low-cost synthesis method of ARK-Cu. The low-cost synthesis method of ARK-Cu comprises the following steps: bonding Cbz-Ala-OH and H-Arg(NO2)-OH by adopting a liquid-phase synthesis method to obtain dipeptide Cbz-Ala-Arg(NO2)-OH, enabling the dipeptide Cbz-Ala-Arg(NO2)-OH to react with Lys(Cbz)-OH to generate full-protection tripeptide Cbz-Ala-Arg(NO2)-Lys(Cbz)-OH, then performing hydrogen / palladium carbon deprotection to generate H-Ala-Arg-Lys-OH, and finally enabling the H-Ala-Arg-Lys-OH to react with copper acetate in water to generate ARK-Cu. The synthesis methoddisclosed by the invention is simple, has no need of column chromatography purification, can obtain Cbz-Ala-Arg(NO2)-Lys(Cbz)-OH of which the purity is 97% or more by ethyl acetate re-crystallization,is low in synthesis cost, and can be used for synthesizing a lot of ARK-Cu.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

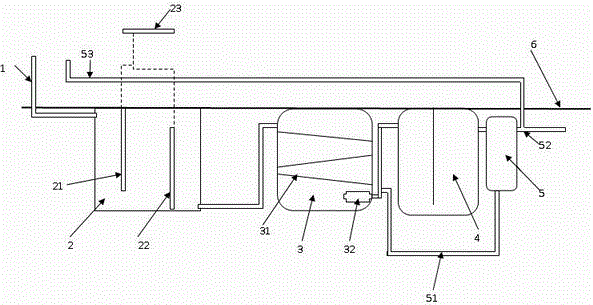

Small domestic sewage treatment device

InactiveCN106396266AStandard technical parameters are stableAchieve miniaturizationWater/sewage treatment by irradiationSpecific water treatment objectivesExternal energyDecomposition

The invention relates to a small domestic sewage treatment device which comprises a domestic sewage collecting pipeline, an excrement decomposition device, a regulating tank, a microbiological treatment device and a reclaimed water storage and detection tank. The small domestic sewage treatment device has the technical advantages that the particular structures of the excrement decomposition device, the regulating tank and the microbiological treatment device are improved, and accordingly domestic sewage can be treated without consumption of external energy; sludge treatment can be omitted, the small domestic sewage treatment device can automatically run and is high in reclaimed water qualification ratio, and the like.

Owner:申忠领

Method for comprehensive recovery of indium and phosphorus from indium phosphide waste material

The invention provides a method for comprehensive recovery of indium and phosphorus from an indium phosphide waste material; the indium phosphide waste material is crushed, then is placed in a vacuum tube furnace and is subjected to vacuum heating, indium phosphide is decomposed into indium and phosphorus vapor, and by using programmed cooling, the phosphorus vapor is converted into red phosphorus. According to the method, indium and phosphorus in indium phosphide can be efficiently recovered, the utilization rate of resources is improved, no toxic gas is produced, waste liquor and waste residues are not needed to be treated, and the method is safe and environmentally friendly.

Owner:FIRST RARE MATERIALS CO LTD

Method for Comprehensive Recovery of Indium and Phosphorus from Indium Phosphide Waste

Owner:FIRST RARE MATERIALS CO LTD

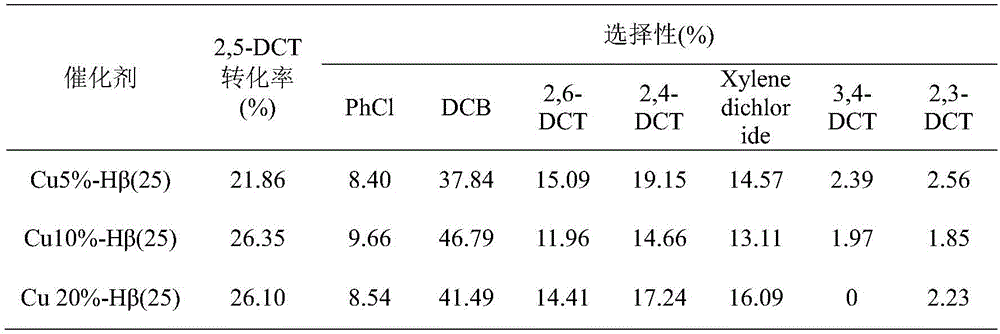

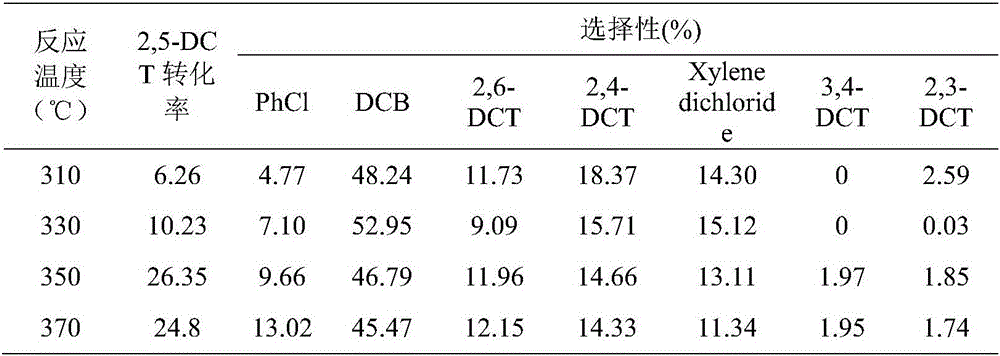

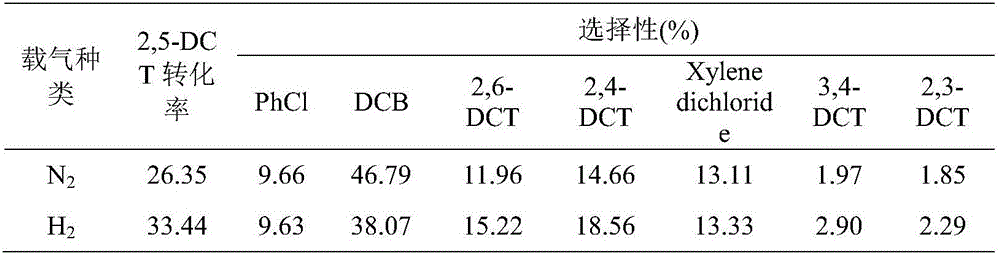

Method for catalyzing 2,5-dichlorotoluene reaction by modified H type molecular sieve

ActiveCN106831318ANo need to deal withLow costMolecular sieve catalystsPreparation by halogenatd hydrocarbon disproportionationMolecular sievePtru catalyst

The invention relates to a method for catalyzing 2, 5-dichlorotoluene reaction by a modified H type molecular sieve, and belongs to the technical field of chlorotoluene derivatives. The method comprises the following steps: dissolving Cu(NO3)2 3H2O into distilled water, fully mixing and stirring with an H type molecular sieve after completely dissolving, standing for 12 hours under a condition that the environment temperature is 110 DEG C after standing and drying, and drying in a muffle furnace of which the temperature is 400 DEG C for 2 hours; performing a modified molecular sieve, grinding, sieving, and selecting sieved molecular sieve particles as a catalyst; filling a constant-temperature zone of a fixed bed reactor with the catalyst; conveying raw materials to the fixed bed reactor through a constant flow pump, and continuously bringing rapidly vaporized raw material steam in the constant-temperature zone into a catalyst bed layer through a gas; finally collecting a product through water bath condensation. According to the method disclosed by the invention, the modified H type molecular sieve is adopted as the catalyst, no toxicity and no harm exist, better stability and higher catalytic activity are obtained, cyclic and repeated utilization can be carried out, and sustained industrial production is facilitated.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

A kind of technique of catalytically synthesizing tert-butyl acrylate

InactiveCN104844455BSimple stepsHigh yieldOrganic compound preparationCarboxylic acid esters preparationFiltrationAmberlyst-15

The invention relates to a method used for catalyzed synthesis of tert-butyl acrylate. The method comprises following steps successively:1) acrylic acid, a catalyst combination, a polymerization inhibitor A, and a polymerization inhibitor B are delivered into a sealed reaction kettle, and liquefied isobutylene is added dropwise for esterification, wherein the catalyst combination is composed of nanosolid superacid SO<4><2-> / SnO<2>, Amberlyst-15, D001 resin, and NKC-9 resin; 2) after adding, heat preservation is carried out; 3) after heat preservation, the sealed reaction kettle is subjected to pressure relief, an obtained mixture is subjected to filtration, and an obtain liquid ingredient is pumped into a rectifying tower; and 4) by-products tert-butyl alcohol, diisobutylene, and the target product tert-butyl acrylate are obtained via separation successively. Yield of tert-butyl acrylate is higher than 98%; reuse ratio of the catalyst is high; the method is simple; and no pollution is caused.

Owner:徐德良 +1

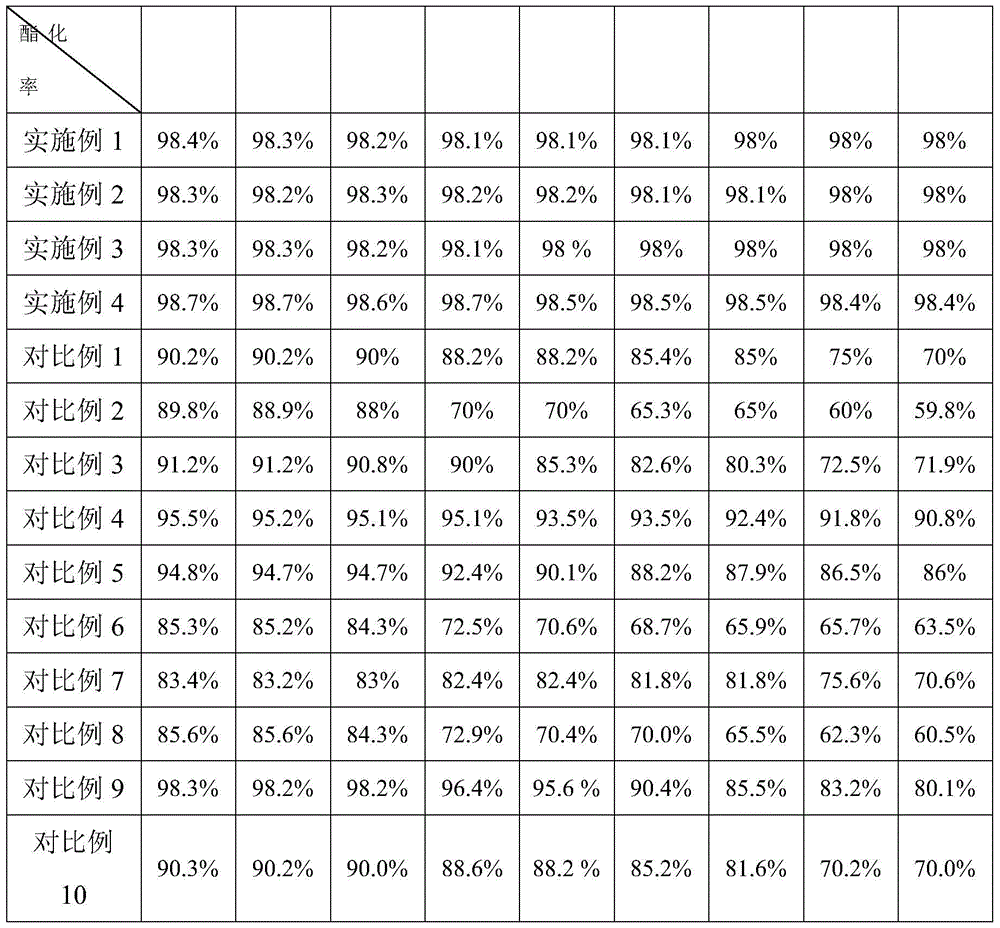

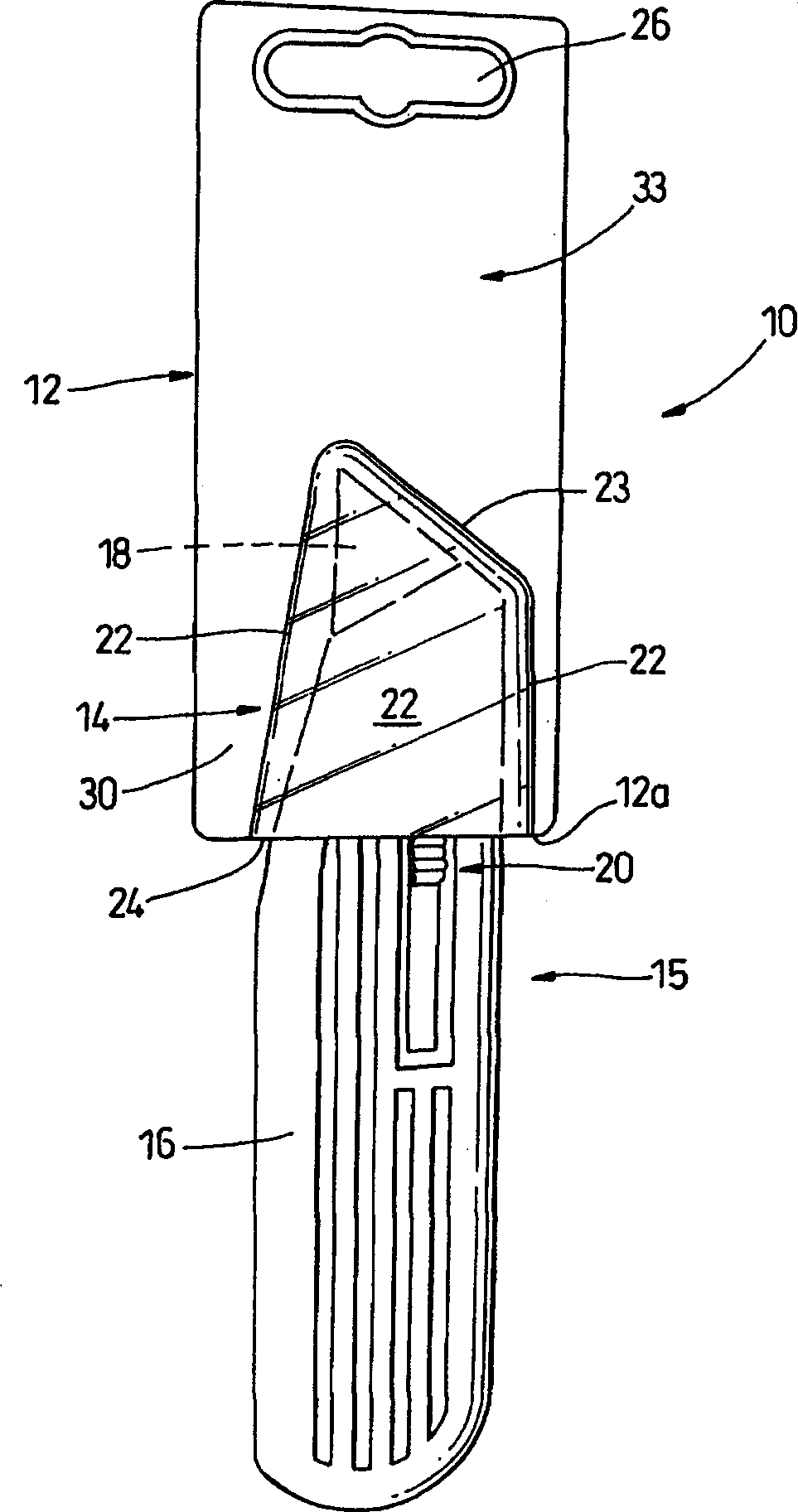

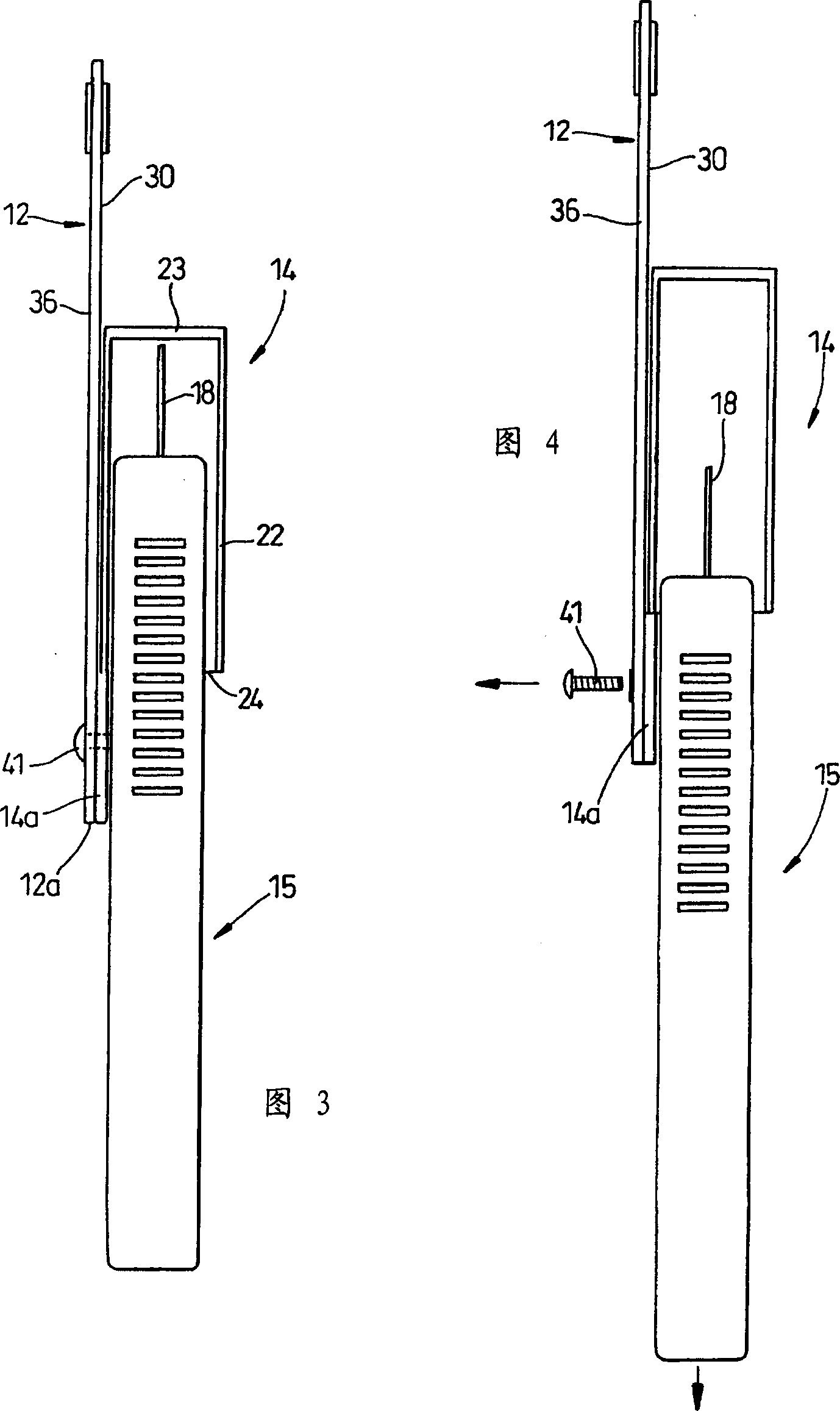

Demonstrating hanging device

InactiveCN1338417ANo need to deal withExternal framesOther domestic articlesEngineeringMechanical engineering

Owner:PLASPRAGES

Preparation method of important intermediate of cortisone acetate

Owner:JIANGSU YUANDA XIANLE PHARMA

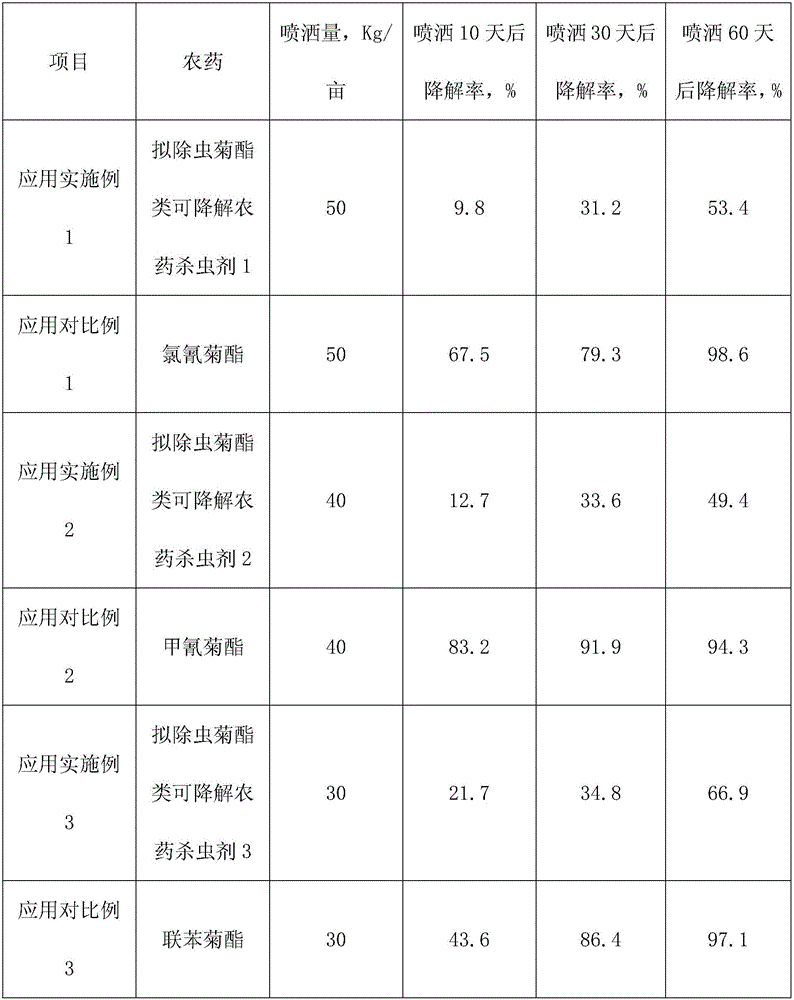

Preparation method of pyrethroid degradable pesticide insecticide and pesticide insecticide prepared by method

InactiveCN105994344AImprove degradation rateEasy to prepareBiocideDead animal preservationEnzymeAqueous solution

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

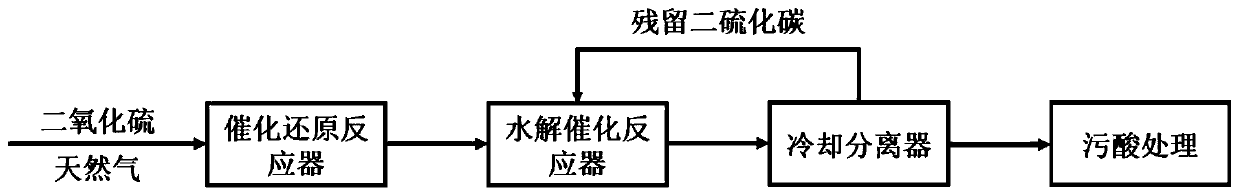

Method for preparing hydrogen sulfide by using high-concentration sulfur dioxide and natural gas

ActiveCN110357043ANothing producedNo need to deal withCarbon compoundsHydrogen sulfidesCarbon disulfideChemistry

The invention relates to a method for preparing hydrogen sulfide by using high-concentration sulfur dioxide and natural gas. The method comprises the following steps of: firstly, reacting an appropriate amount of methane with high-concentration sulfur dioxide at a proper temperature to produce carbon disulfide, hydrogen sulfide, carbon dioxide and water; allowing the produced products to enter a secondary reactor for catalytic hydrolysis of the carbon disulfide into hydrogen sulfide; and finally, subjecting residual carbon disulfide and water to cooling and separation to obtain high-concentration gas mixture of hydrogen sulfide and carbon dioxide, and introducing the obtained high-concentration hydrogen sulfide gas to a sewage acid treatment device. Compared with the prior art, the invention has the advantages that raw materials are economical and easily available, the problem of sulfur dioxide pollution is overcome, valuable sulfur resources are recovered, the requirements of sustainable development are met, the process requirements of sewage acid treatment in the smelting industry are met, etc.

Owner:SHANGHAI JIAO TONG UNIV +1

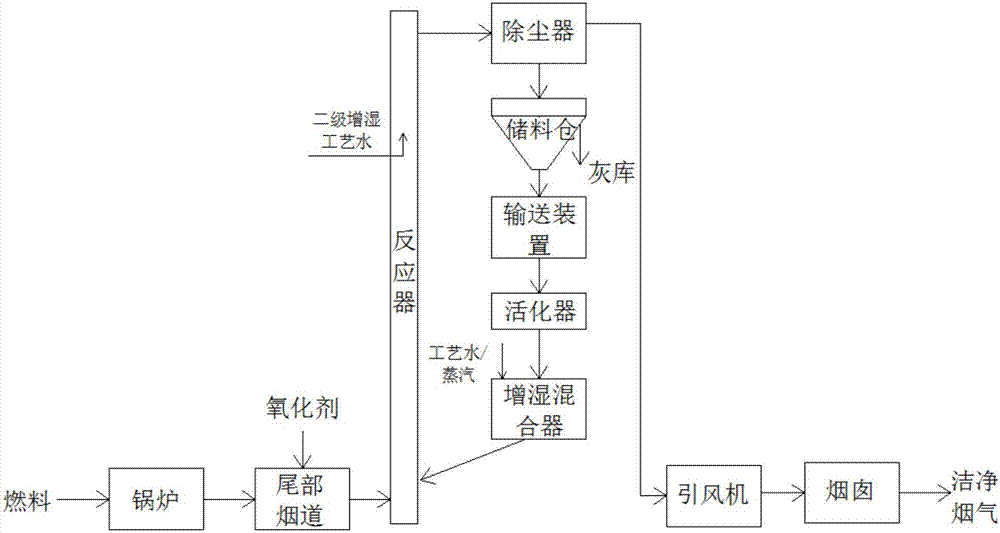

Flue gas pollutant combination removal method based on high-activity solid absorbent

InactiveCN107998856AReduce layout requirementsLarge specific surface areaGas treatmentDispersed particle separationFlue gasOxidizing agent

The invention provides a flue gas pollutant combination removal method based on a high-activity solid absorbent. The flue gas pollutant combination removal method comprises: uniformly mixing an oxidant into boil tail flue gas to obtain oxidized flue gas, wherein the NO in the flue gas is oxidized into a high-valence nitrogen oxide, and the zero-valence mercury is oxidized to a high-valence mercuride; making the oxidized flue gas completely contact solid particles, and simultaneously removing the sulfur oxide, the high-valence nitrogen oxide and the high-valence mercuride in the flue gas so asto obtain pollutant-removed dust-containing flue gas; and carrying out dust removing on the dust-containing flue gas to obtain clean flue gas, wherein the solid particles collected from the bottom portion of a dust removing device are fed into a material storage bin, the partial solid particles are activated and humidified, the activated and humidified solid particles returns to the reactor so asto continuously participate in the reaction, and the remaining solid particles are discharged from the bottom portion of the material storage bin so as to maintain the material balance. According to the present invention, the semi-dry absorption method is used, wherein the calcium-based absorbent is sprayed into the reactor in the form of the humidified solid particles, such that the water consumption is low, the final product is the solid-state product, the treatment of the wastewater is not required, the process is simple, and the method can be widely used in the industrial flue gas treatment.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

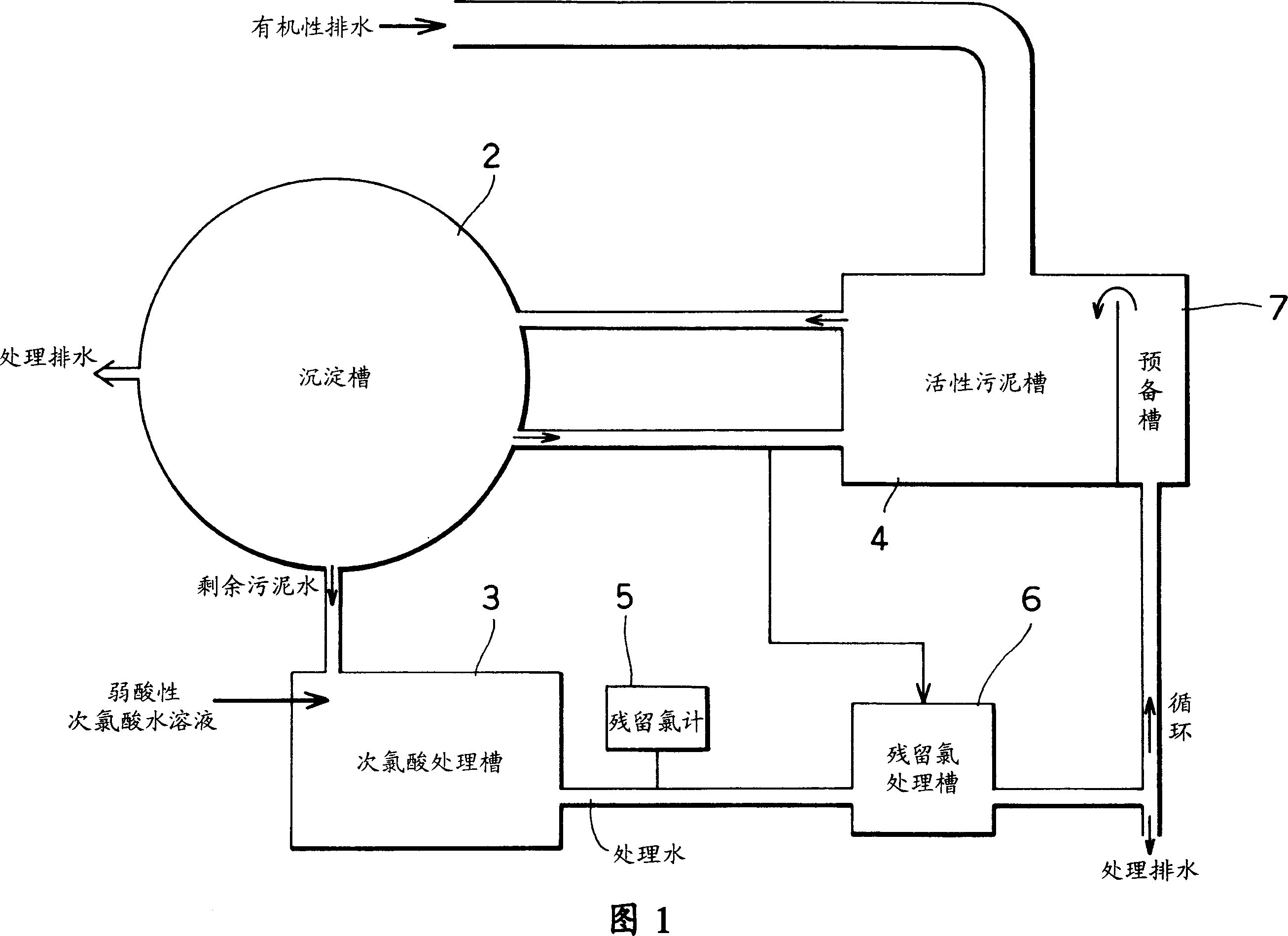

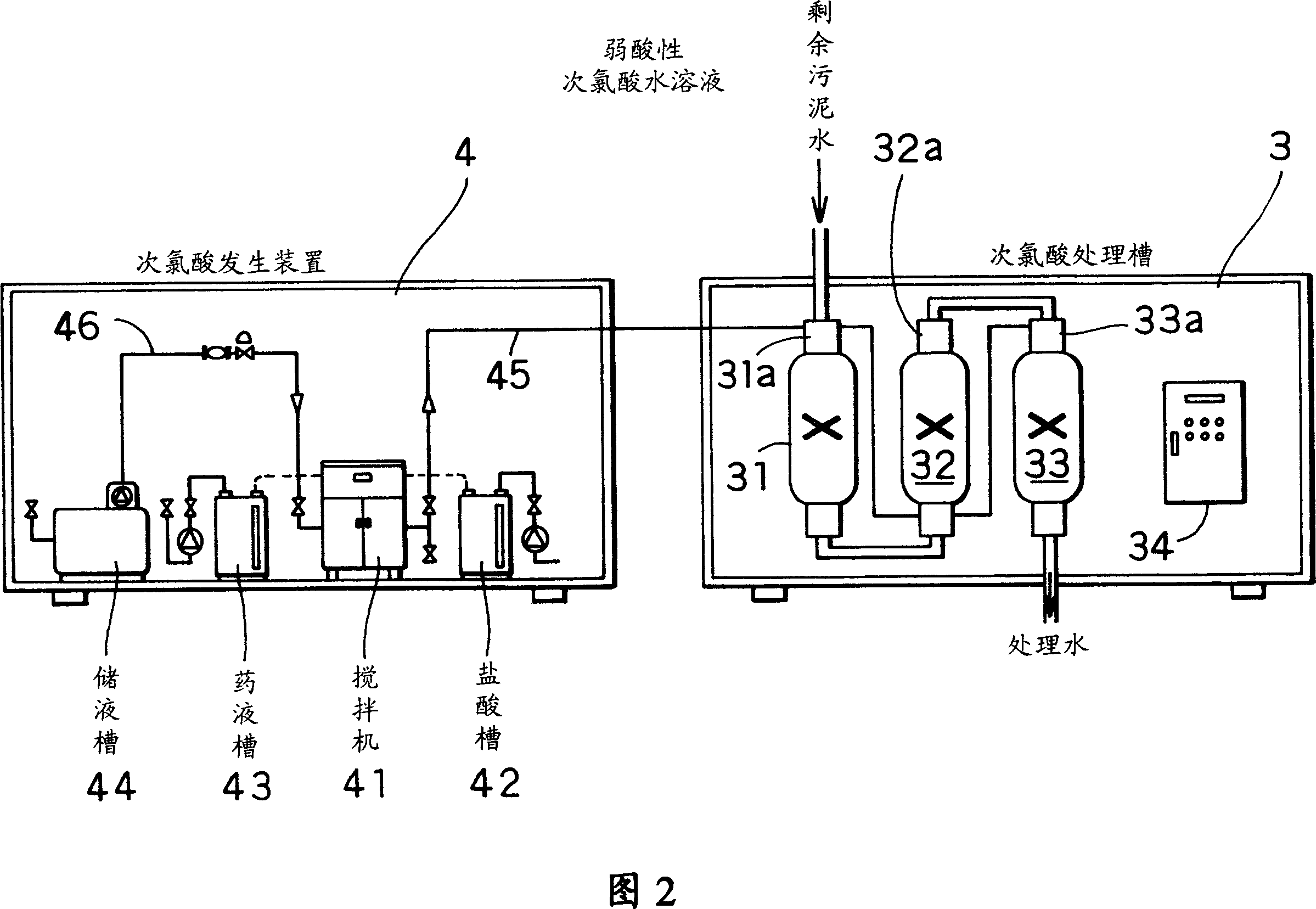

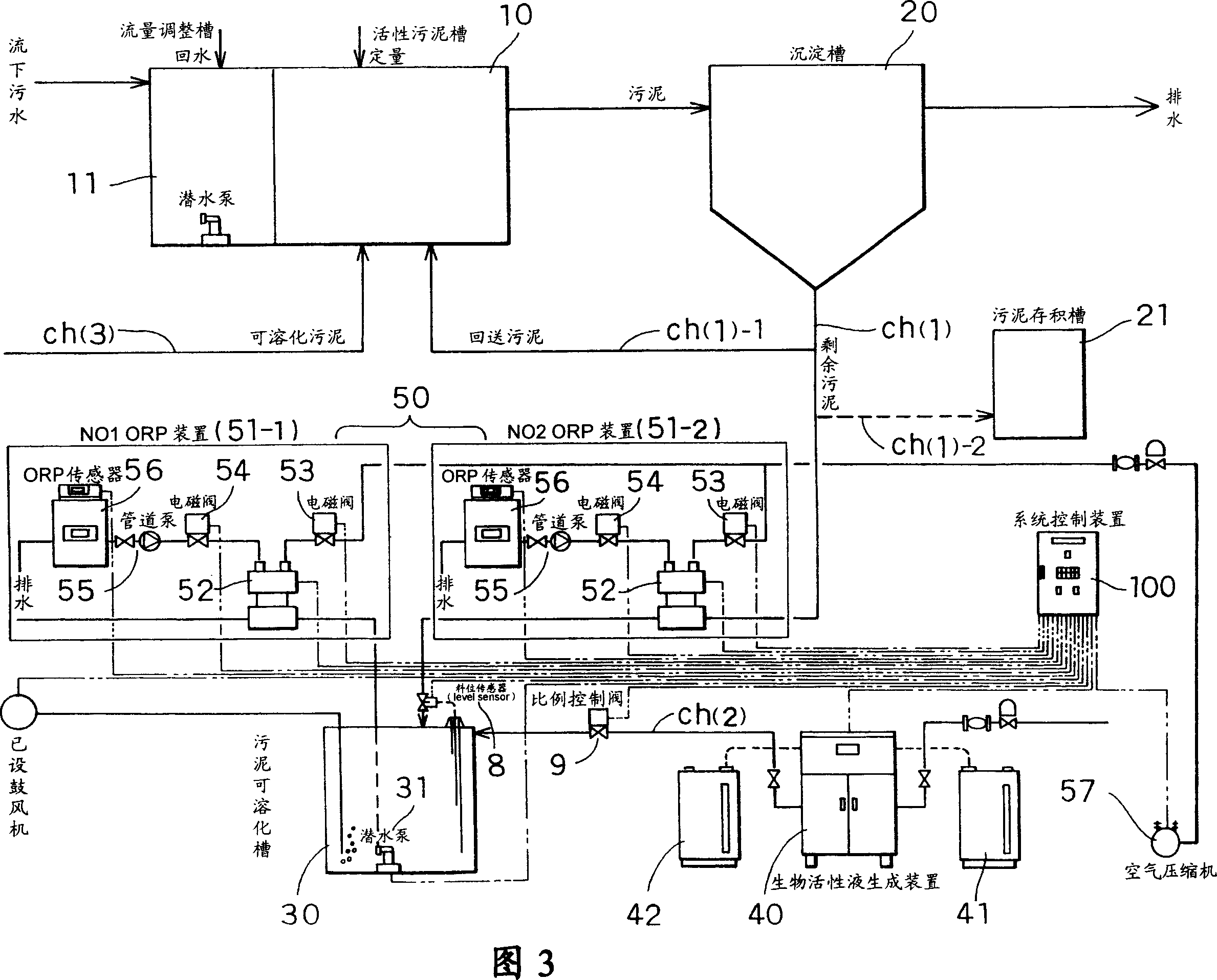

Method and device of processing excess sludge

In an activated sludge treatment of organic waste water, excess sludge from the activated sludge aeration vessel is processed with hypochlorous acid in place of ozone without set up of aeration vessels and blowers to improve volume reduction cost of sludge without deterioration of water quality. The hypochlorous acid process is carried out by using an acidulous sodium hypochlorite aqueous solution which is prepared by mixing sodium hypochlorite aqueous solution with a dilute hydrochloric acid and diluting the resulting mixture with water of available chlorine concentration at a pH zone of more than 4 to less than 7.

Owner:株式会社阿卡迈托

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com