Separation and purification method for lithium ion battery positive electrode material and obtained lithium ion battery positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in the field of waste lithium ion battery recycling and resource recycling, can solve problems such as flammability, changing particle size, and destroying surface structure, and achieves less temperature treatment steps, mild treatment temperature, and recycling. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1) Cut the 532 secondary ball waste pole piece dismantled from the decommissioned battery into 4cm 2 The size of the bowl is 1kg / bowl (330*330*65mm).

[0061] 2) at 5m 3 Under the air atmosphere of / h, the PVDF was pyrolyzed at a constant temperature of 450°C / 2h at a heating rate of 5°C / min. Each furnace sinters 4 pot materials, placed in double layers and double rows.

[0062] 3) Use 50-mesh and 300-mesh sieves to vibrate the sintered pole piece for depowdering. After shaking for 7 minutes, the depowdering efficiency is 98%. The aluminum foil is mainly concentrated above 50 mesh, the powder is mainly concentrated below 300 mesh, and there is almost no 300 mesh sieve.

[0063] 4) Remove impurities from the powder below 300 mesh with a wind separation pressure of 1 MPa to obtain the separation and purification material 1.

[0064] Separation and purification material 1 is tested, and the results are as follows:

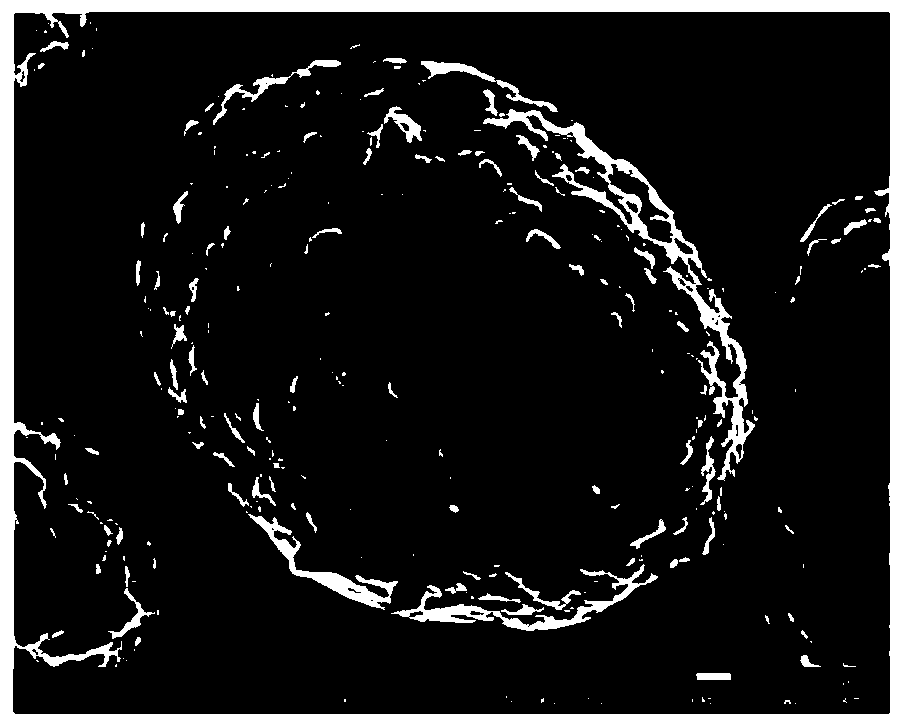

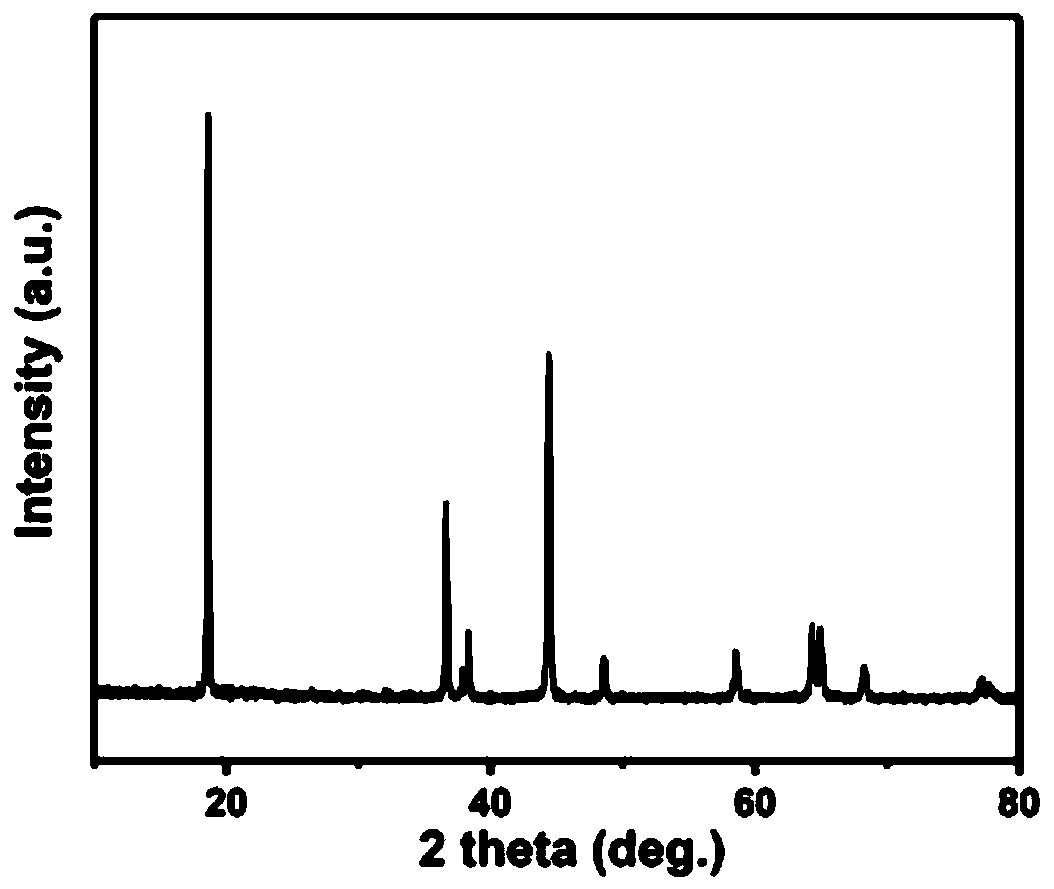

[0065] Such as figure 1 As shown, the SEM image show...

Embodiment 2

[0071] 1) Cut the waste electrode pieces of LCO and NCM111 blended materials disassembled from decommissioned batteries into 4cm 2 The size of the bowl is 1kg / bowl (330*330*65mm).

[0072] 2) at 5m 3 Under the air atmosphere of / h, the PVDF was pyrolyzed at a constant temperature of 490°C / 2h at a heating rate of 5°C / min. Each furnace sinters 4 pot materials, placed in double layers and double rows.

[0073] 3) Use 50-mesh and 300-mesh screens to vibrate the sintered pole piece for depowdering. After shaking for 5 minutes, if the depowdering efficiency is greater than >95%, it is considered to be completely depowdered, and the vibration is stopped. The aluminum foil is mainly concentrated above 50 mesh, the powder is mainly concentrated below 300 mesh, and there is almost no 300 mesh sieve.

[0074] 4) Remove impurities from the powder below 300 mesh with 1MPa air separation pressure to obtain the separation and purification material 2.

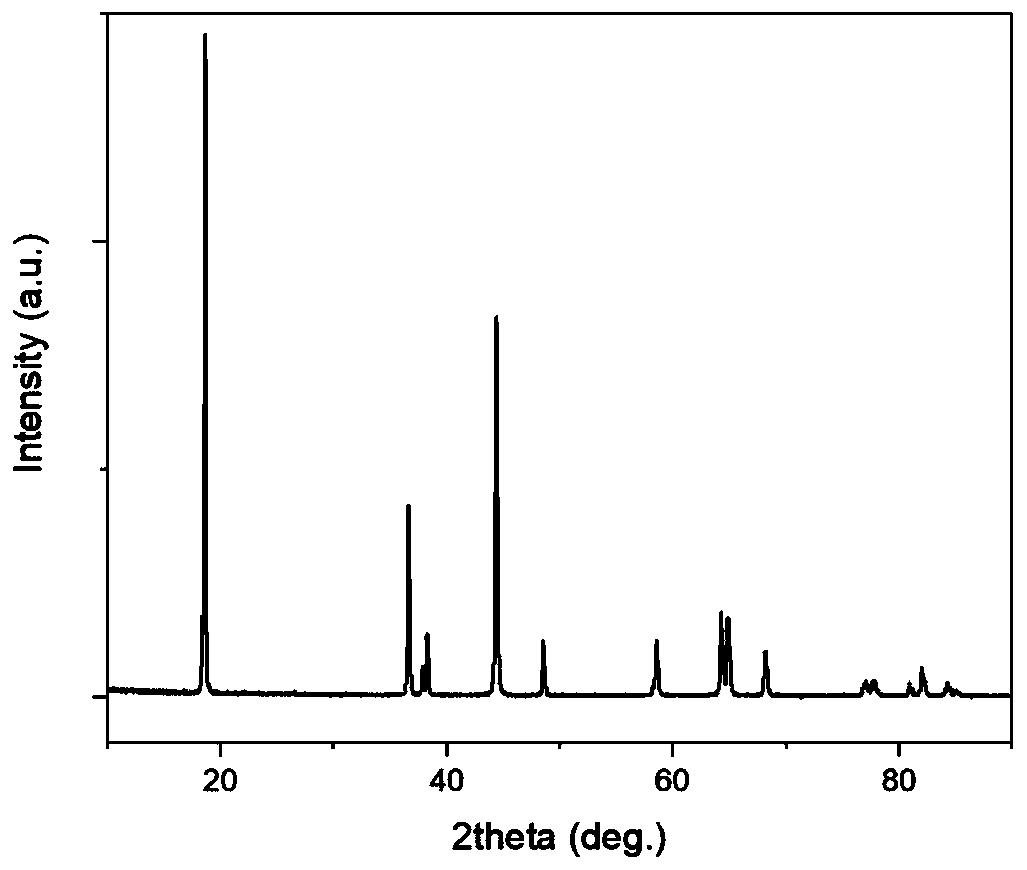

[0075] Purified material 2 is teste...

Embodiment 3

[0081] 1) Cut the 532 secondary ball scraps to 10cm 2 The size of the bowl is 1kg / bowl (330*330*65mm).

[0082] 2) at 5m 3 Under the air atmosphere of / h, the PVDF was pyrolyzed at a constant temperature of 450°C / 1h at a heating rate of 5°C / min. Each furnace sinters 4 pot materials, placed in double layers and double rows.

[0083] 3) Use 50-mesh and 300-mesh screens to vibrate the sintered pole piece for depowdering. After shaking for 10 minutes, if the depowdering efficiency is greater than >95%, it is considered to be completely depowdered, and the vibration is stopped. The aluminum foil is mainly concentrated above 50 mesh, the powder is mainly concentrated below 300 mesh, and there is almost no 300 mesh sieve.

[0084] 4) Remove impurities from the powder below 300 mesh with 1 MPa air separation pressure to obtain the separated and purified material 3 .

[0085] 5) Since the raw material is leftover material, the material does not have defects such as lithium deficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com