Steam frying pan for rapeseed processing

A technology of rapeseed and frying pan, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems of affecting the oil yield rate, slow oil output rate of wok pan, and sticky pot, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

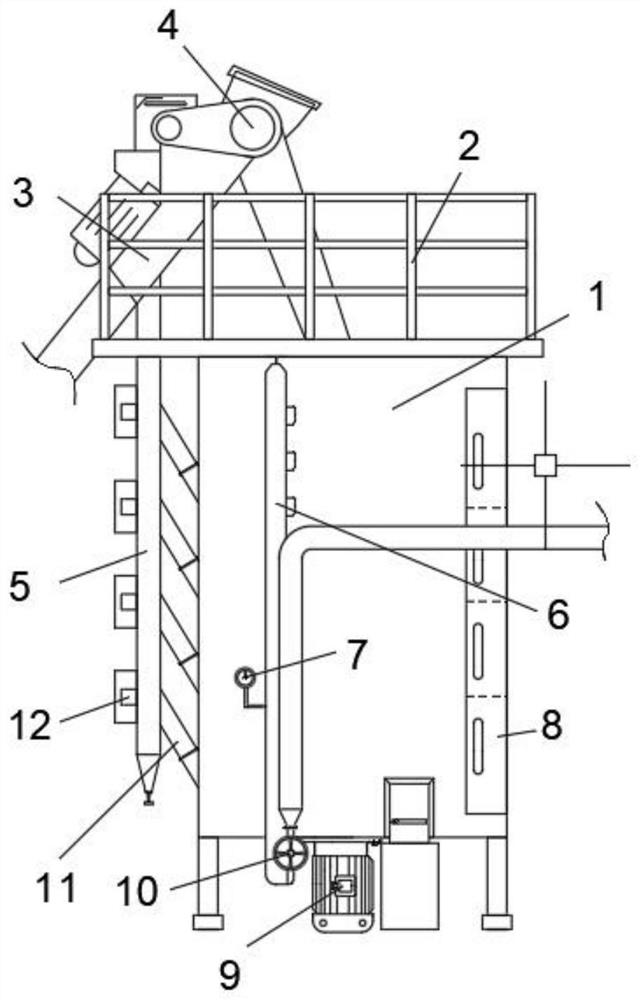

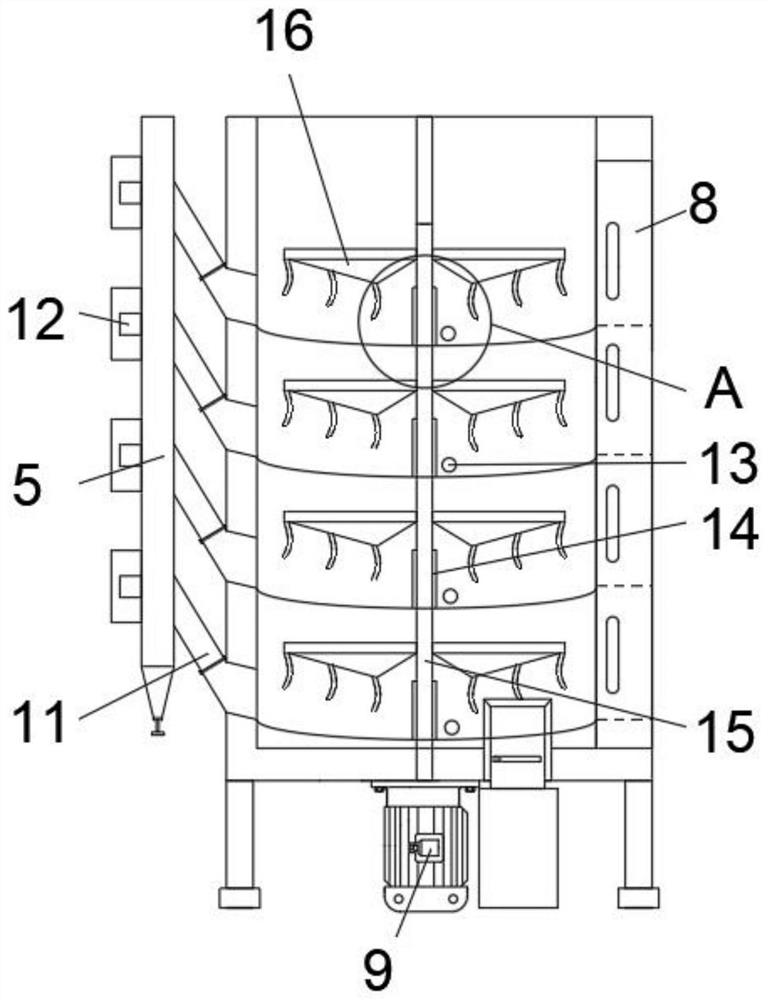

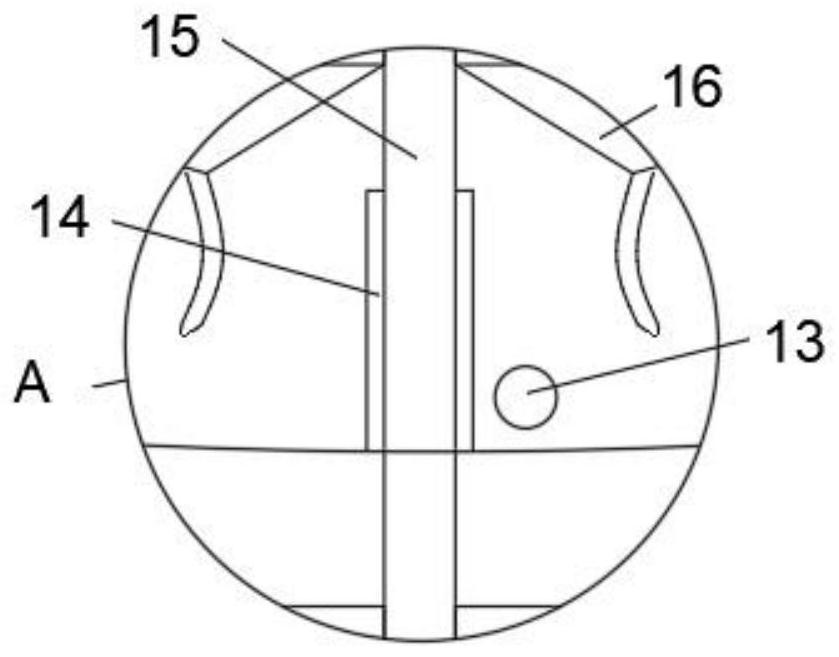

[0025] The following is attached figure 1 To further illustrate the specific implementation of the steam frying pan for rapeseed processing of the present invention. The steam frying pan for rapeseed processing of the present invention is not limited to the description of the following embodiments.

[0026] This embodiment provides a specific structure of a steam wok for rapeseed processing, such as Figure 1-4 As shown, a steam wok for rapeseed processing includes a pot body 1 and a top rack 2 arranged on the top of the pot body 1, and is characterized in that:

[0027] The upper part of the pot 1 is located inside the top frame 2 with a bracket 3, and the top of the bracket 3 is provided with a feeding port 17, and a screeding mechanism 4 is provided in the feeding port 17, and the material in the feeding port 17 is used for passing After connecting the bracket 3 and the feeding trough 5 of the pot 1, enter the pot 1;

[0028] A stirring motor 9 is installed at the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com