Power-saving rate verification method for main line type power-saving equipment in construction distribution system

A technology of power distribution system and verification method, applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve problems such as complex procedures, inability to truly reflect the power saving rate, large quantities, etc., and achieve the effect of clear economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

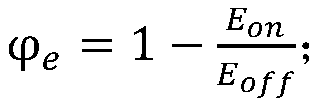

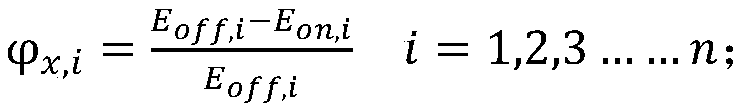

[0029] The present invention provides a method for verifying the power-saving rate of trunk-type power-saving equipment in the construction power distribution system, which can effectively reflect the overall use effect of the power-saving equipment on the construction site, and the process is as follows:

[0030] (1) Determine the main electrical equipment within the scope of the power distribution system of the test site (such as concrete mixing station, beam making yard, tunnel and other sites of different types of business), and the number of processes in a construction cycle of the site is n, n≥1;

[0031] (2) Select the base period and statistical reporting period for the power saving rate of the test product; the base period specifically refers to the time period when no power saving measures are implemented; the statistical reporting period specifically refers to the time period after the power saving measures are implemented ;

[0032] (3) Install trunk-type energy-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com