Detection device and detection method for steel billet sprayed with high-temperature anti-oxidation coating

A technology of high temperature oxidation resistance and detection device, applied in length measuring device, metal rolling, manufacturing tools, etc., can solve problems such as errors, and achieve the effect of eliminating the influence of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

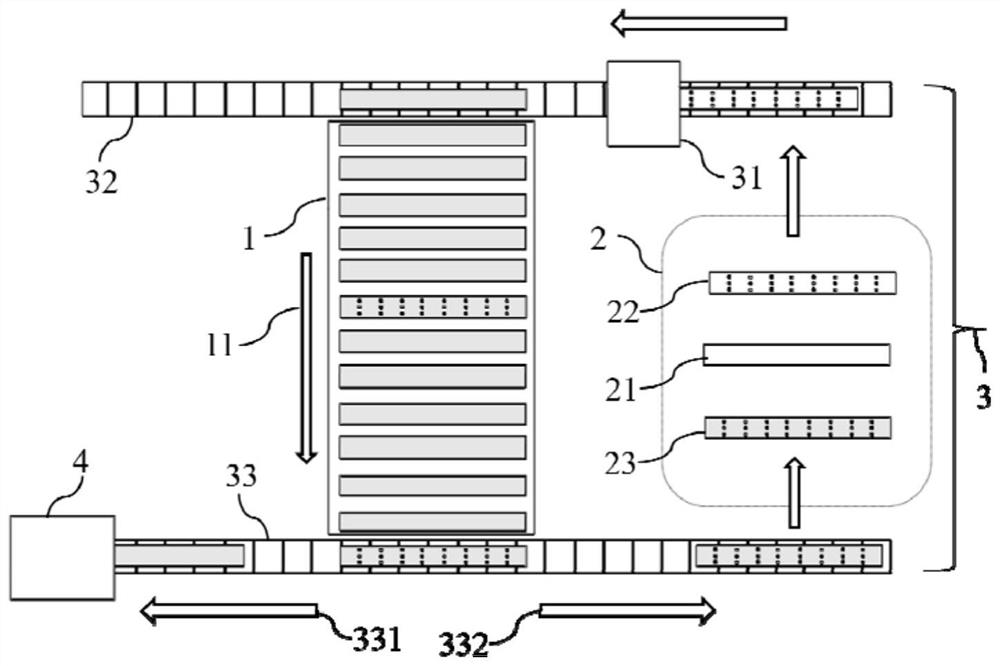

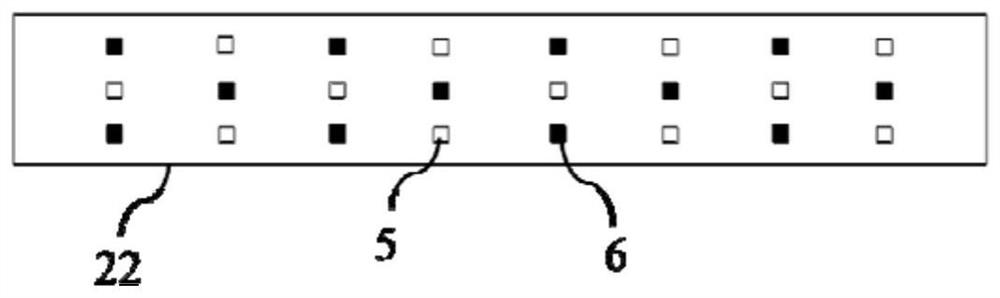

[0030] In this embodiment, a detection device for spraying high-temperature anti-oxidation coating steel billets, such as figure 1 As shown, it includes a heating furnace 1 and a billet storage table 2, on which a test billet 22 is horizontally placed, and the test billet 22 includes a horizontally placed billet 21, such as figure 2 As shown, several sets of blank test blocks 5 and sprayed test blocks 6 are placed at equal intervals on the billet 21. The main purpose of the test billet 22 is to carry the test block to complete the subsequent whole process. Its size and material The production billet is the same, about 0.23×1.4×12m, and the surface of the load-bearing test block needs to be flat; the spraying effect is reflected by the burning loss of the blank test block 5 and spraying test block 6; the steel type of the experimental test block is the same as the production billet, and the size 30×140×140mm is accurate ±1mm, the weight difference between test blocks is ±5g, the...

Embodiment 2

[0032] The detection device of a steel billet sprayed with high-temperature anti-oxidation coating in this embodiment has the same basic structure as that of Embodiment 1. The difference and improvement are as follows: figure 1 As shown, the tapping side roller table 33 is arranged horizontally, one side of which is the rolling mill side 331, the outer end of the rolling mill side 331 is connected to the rolling mill system 4; the other side of the tapping side roller table 33 is the non-rolling mill side 332 The tapped test billet 23 on the non-rolling mill side 332 is transported to the billet storage table 2 along with the roller table; the tapping side roller table 33 is used to transport the heated tapped test billet 23 to the rolling mill system 4 for rolling Or retreat, where the tapped test billet 23 transported along the rolling mill side 331 is transported to the rolling mill system 4 for rolling processing; the tapped experimental billet 23 transported along the non-ro...

Embodiment 3

[0034] The detection device for steel billets sprayed with high-temperature anti-oxidation coatings in this embodiment has the same basic structure as that of Embodiment 2. The difference and improvement lies in that it also includes an on-site test unit, which includes an experimental steel billet 22 and an experimental steel billet after being discharged. 23 and an electronic platform scale. The electronic platform scale has a measurement accuracy of 0.1g and a maximum range of 5000g. The mass of the test block on the experimental billet before and after burning is weighed, and the change in the burning loss of the test block is calculated to reflect the high temperature oxidation resistance Coating effect;

[0035] In this embodiment, the test blocks before and after the experiment are weighed, counted, and calculated to obtain the data in the following table, as shown in Table 1:

[0036] Table 1

[0037]

[0038] It can be seen from Table 1 that after spraying high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com