Method for recovering cobalt nickel through electrolytic manganese industrial ion exchange method

An ion exchange method and electrolytic manganese technology, applied in the field of chemistry, can solve the problems affecting the deposition of electrolytic manganese metal, decrease in current efficiency, and high cost, achieve significant economic and social benefits, reduce energy consumption, and facilitate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

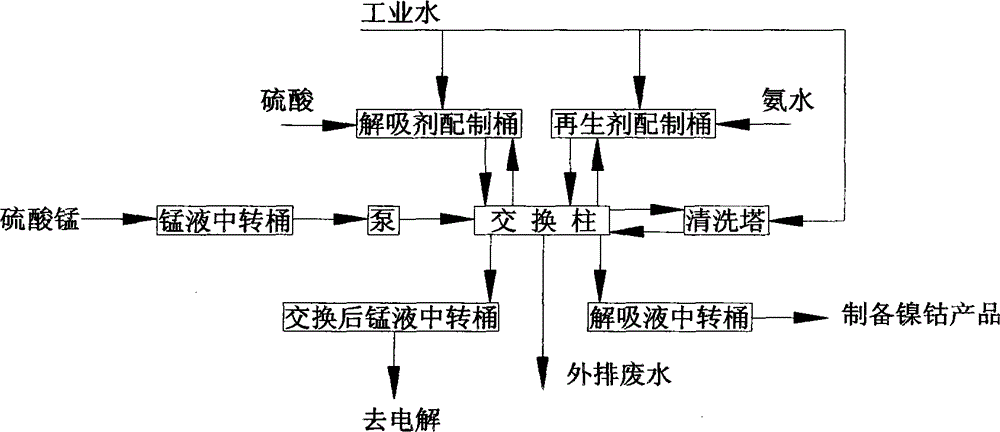

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] refer to figure 1 , a kind of electrolytic manganese industrial ion exchange method reclaims cobalt nickel method, comprises the following steps:

[0030] (1) After the chelating resin is loaded into the column, it is put into use after transformation and regeneration. After iron removal in the manganese liquid transfer barrel, the manganese sulfate liquid is pumped into the ion exchange column from the bottom at a flow rate of 1.0 to 6.0 BV / h. Cobalt and nickel heavy metal ions are adsorbed into the resin, and the average concentration of cobalt and nickel in the adsorption tail water is detected. When the control index is ≤2mg / L, the liquid intake is stopped, and the adsorption tail water directly enters the manganese liquid transfer tank after exchange;

[0031] (2) The resin after the adsorption is completed is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com