Full-dry purification method of lithium ion battery positive electrode material and lithium ion battery positive electrode material obtained through purification

A technology for lithium-ion batteries and positive electrode materials, applied in the field of comprehensive utilization of lithium-ion battery positive electrode materials, can solve the problems of destroying the structure of positive electrode materials, complicated selection and investment, and difficult industrial production, etc., and achieves simple recovery process, high purity, and mild processing temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Use a shearing machine to cut the positive electrode sheet obtained from the decommissioned 523 soft bag into a size of 2cm*2cm, according to 2kg / bowl (330*330*100mm 3 ), hold 4 bowls.

[0058] 2) In a dry air atmosphere (5m 3 / h), 3°C / min heating rate, under the condition of 400°C / 0.5h, the pole piece is pyrolyzed.

[0059] 3) Ultrasonic vibrating sieving to separate the powder from the aluminum foil, and the sieve meshes are 50 mesh and 300 mesh. The powder below 300 mesh is collected for high-temperature impurity removal, the recovery rate is 98.5%, >95%, and the separation is considered complete. Since the aluminum foil is hardly oxidized and pulverized, and the PVDF is basically invalid, the 50-mesh screen is almost clean aluminum foil, and the aluminum impurity in the powder is 0.13%.

[0060] 4) High temperature removal of impurities. The amount of bowl is 4kg / burning bowl (330*330*100mm 3 ); in a dry air atmosphere, sinter at 600° C. for 1 h, pass throug...

Embodiment 2

[0070] 1) Use a shearing machine to cut the leftovers of the lithium iron phosphate positive electrode sheet into a size of 10cm*10cm, take 100g and put it into a crucible.

[0071] 2) Under the conditions of high-purity nitrogen atmosphere (1.6L / min), heating rate of 3°C / min, and 500°C / 0.5h, the pole piece is pyrolyzed.

[0072] 3) Knock off manually to separate the powder from the aluminum foil, and the separated powder forms into flakes, such as Figure 4 After being ground, pass through a 300-mesh sieve. The powder below 300 mesh is collected for high-temperature impurity removal, and the recovery rate is 99%, >95%, and the separation is considered complete.

[0073] 4) High temperature removal of impurities. The amount of potting is 1cm in depth; in a high-purity nitrogen atmosphere, sinter at 650°C for 1 hour, and pass through a 300-mesh sieve to obtain the purified material 2.

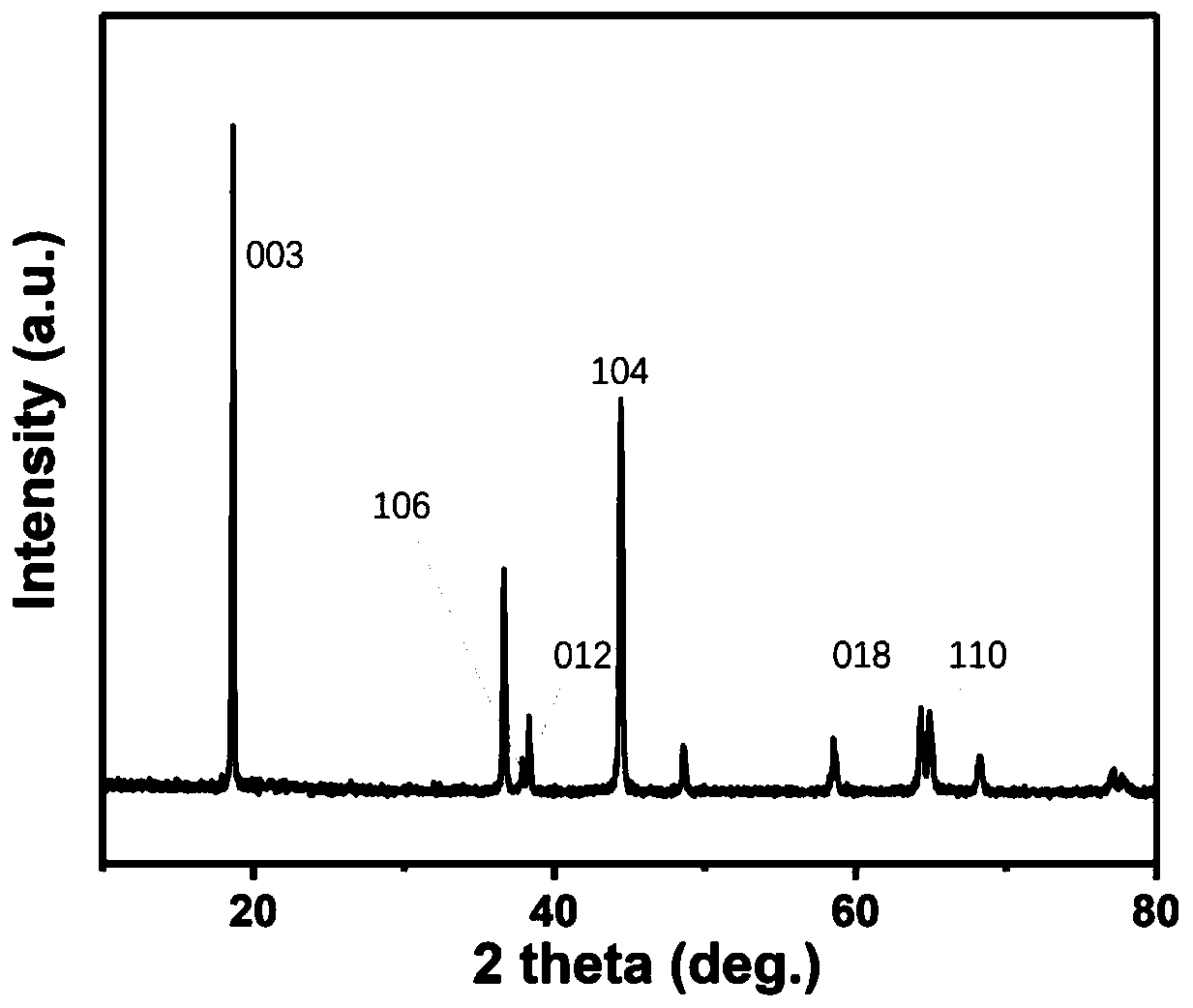

[0074] SEM characterization was carried out on the powder obtained by peeling off and th...

Embodiment 3

[0076] 1) Use a shearing machine to cut the 523 leftover positive electrode sheet into a size of 2cm*2cm, and press 2kg / bowl (330*330*100mm 3 ), hold 4 bowls.

[0077] 2) In a dry air atmosphere (3m 3 / h), 5°C / min heating rate, under the condition of 400°C / 2h, the pole piece is pyrolyzed.

[0078] 3) Ultrasonic vibrating sieving to separate the powder from the aluminum foil, and the sieve meshes are 50 mesh and 300 mesh. The powder below 300 mesh is collected for high-temperature impurity removal, the recovery rate is >95%, and the separation is considered complete. Since the aluminum foil is hardly oxidized and pulverized, and the PVDF is basically invalid, the 50-mesh screen is almost clean aluminum foil, and the aluminum impurity in the powder is 0.216%.

[0079] 4) High temperature removal of impurities. The amount of bowl is 1kg / burning bowl (330*330*100mm 3 ); in a dry air atmosphere, sinter at 600°C for 0.5h, pass through a 300-mesh sieve, and obtain the purified m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com