Method for preparing hydrogen sulfide by using high-concentration sulfur dioxide and natural gas

A sulfur dioxide, high-concentration technology, applied in hydrogen sulfide, chemical instruments and methods, sulfur compounds, etc., can solve the problems of expensive carbon disulfide and poor economy, and achieve the effect of ensuring production safety, easy adjustment, and controllable scale of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

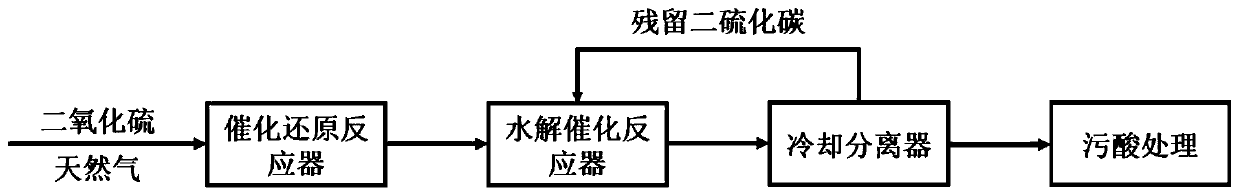

[0030] In this embodiment, a small-scale experimental system has been set up, which includes a simulated flue gas generation system, the simulated flue gas flow rate is 1L / min, and the steel cylinder provides high concentration SO 2 and CH 4 Gas, and use nitrogen as a carrier gas to provide different concentrations of water vapor to the secondary reactor. The flue gas passes through the primary reactor and the secondary reactor; both reactors are equipped with a temperature control system, which can regulate the temperature of the flue gas in the reaction device within the range of 100-1000°C. Using the above-mentioned small test platform for research, such as figure 1 shown.

[0031] (1) In the primary reactor with high concentration SO 2 Raw material (the volume concentration containing sulfur dioxide is 20%), natural gas is used as reducing agent (wherein CH 4 Concentration is 20%), through high-temperature catalytic reduction reaction, produces primary mixed gas; Descr...

Embodiment 2

[0036] A kind of method utilizing natural gas and sulfur to prepare hydrogen sulfide, this method comprises the following steps:

[0037] 1) The method is divided into two stages. In the first reactor, the high-concentration SO 2 As the raw material, natural gas is used as the reducing agent to generate carbon disulfide and hydrogen sulfide through high-temperature catalytic reduction reaction. The reduction reaction temperature is controlled at 500°C and the pressure is 0.1MPa. The catalytic reduction reaction of methane and sulfur dioxide occurs on the catalyst with a space velocity of 200h-1 . The catalyst uses titanium oxide as a carrier, CeO as an active component, wherein the mass of the active component is 20% of the carrier, and is prepared by a conventional catalyst preparation method in the field such as a roasting method.

[0038] 2) The first-stage mixed gas produced by the reaction of step (1) is hydrolyzed with water vapor in the second-stage reactor, so that the...

Embodiment 3

[0042] A kind of method utilizing natural gas and sulfur to prepare hydrogen sulfide, this method comprises the following steps:

[0043] 1) The method is divided into two stages. In the first reactor, the high-concentration SO 2 As the raw material, natural gas is used as the reducing agent to generate carbon disulfide and hydrogen sulfide through high-temperature catalytic reduction reaction. The reduction reaction temperature is controlled at 800°C and the pressure is 0.5MPa. The catalytic reduction reaction of methane and sulfur dioxide occurs on the catalyst with a space velocity of 2000h -1 . The catalyst is supported by zirconia, MoO 3 It is an active component, wherein the mass of the active component is 5% of the carrier, and it is prepared by a conventional catalyst preparation method in the field, such as an impregnation-calcination method.

[0044] 2) The first-stage mixed gas produced by the reaction of step (1) is hydrolyzed with water vapor in the second-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com