Method and device of processing excess sludge

A technology for excess sludge and treatment methods, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high-priced ozone generators and expensive treatment equipment, and achieve the goal of simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

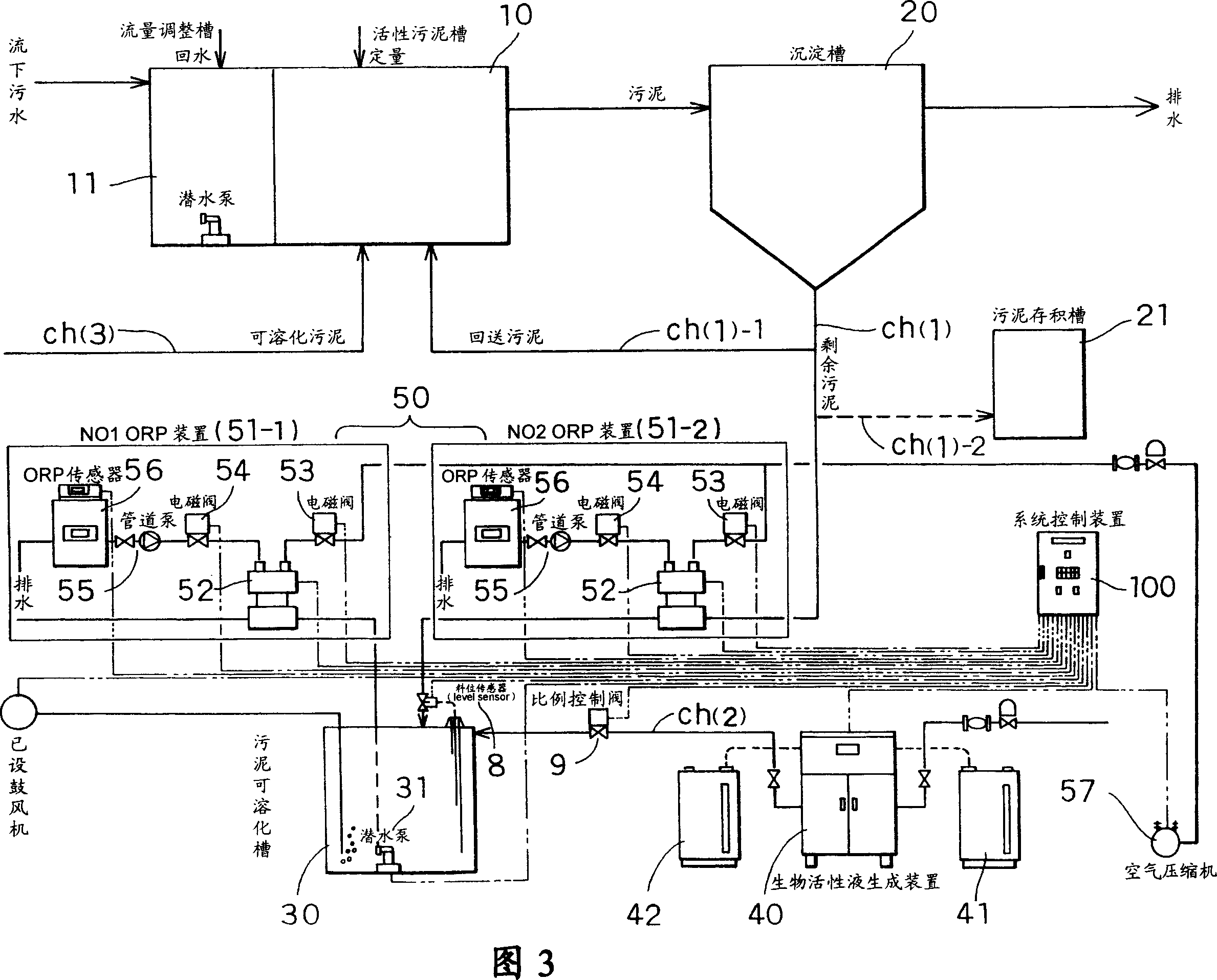

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

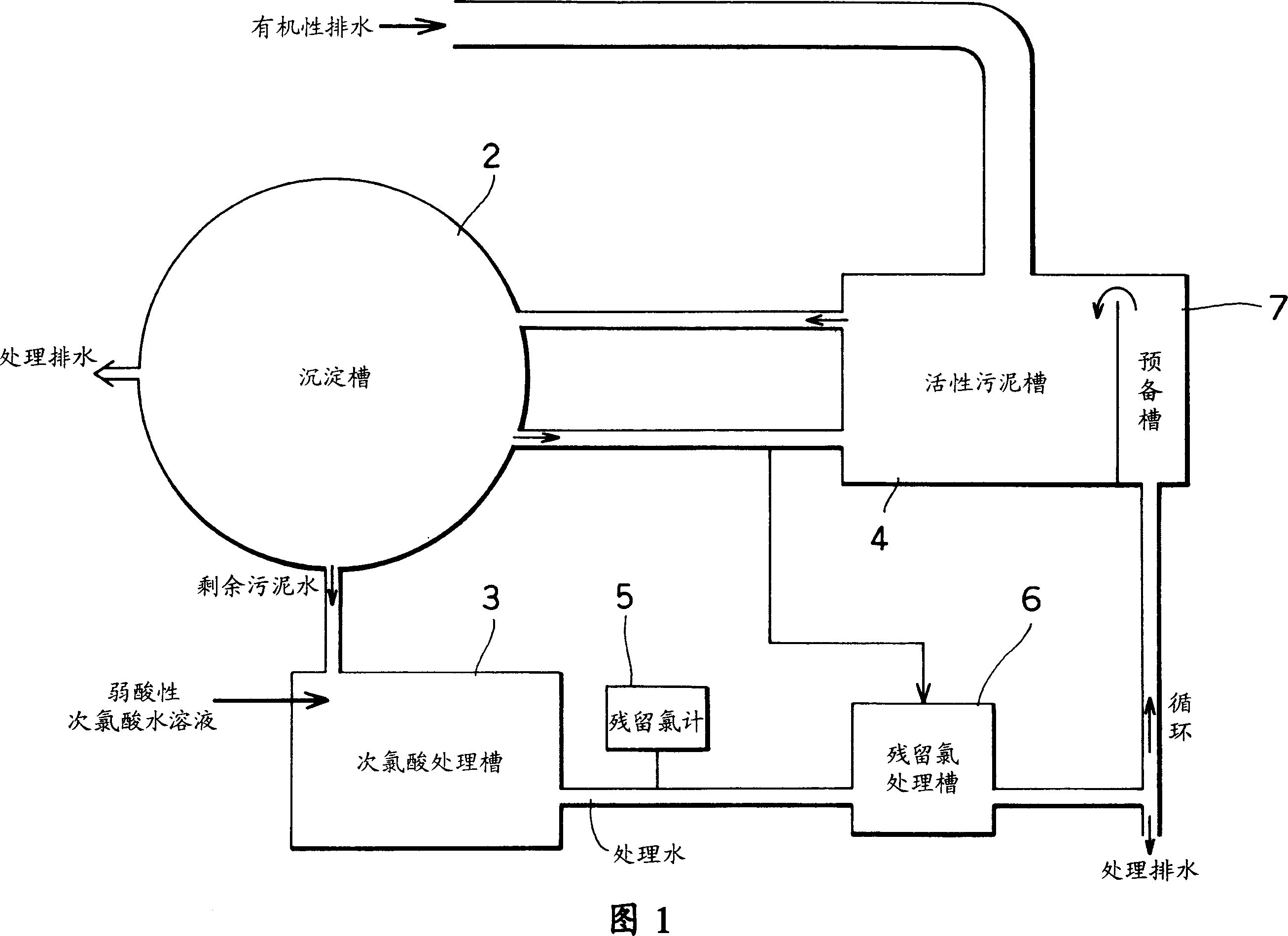

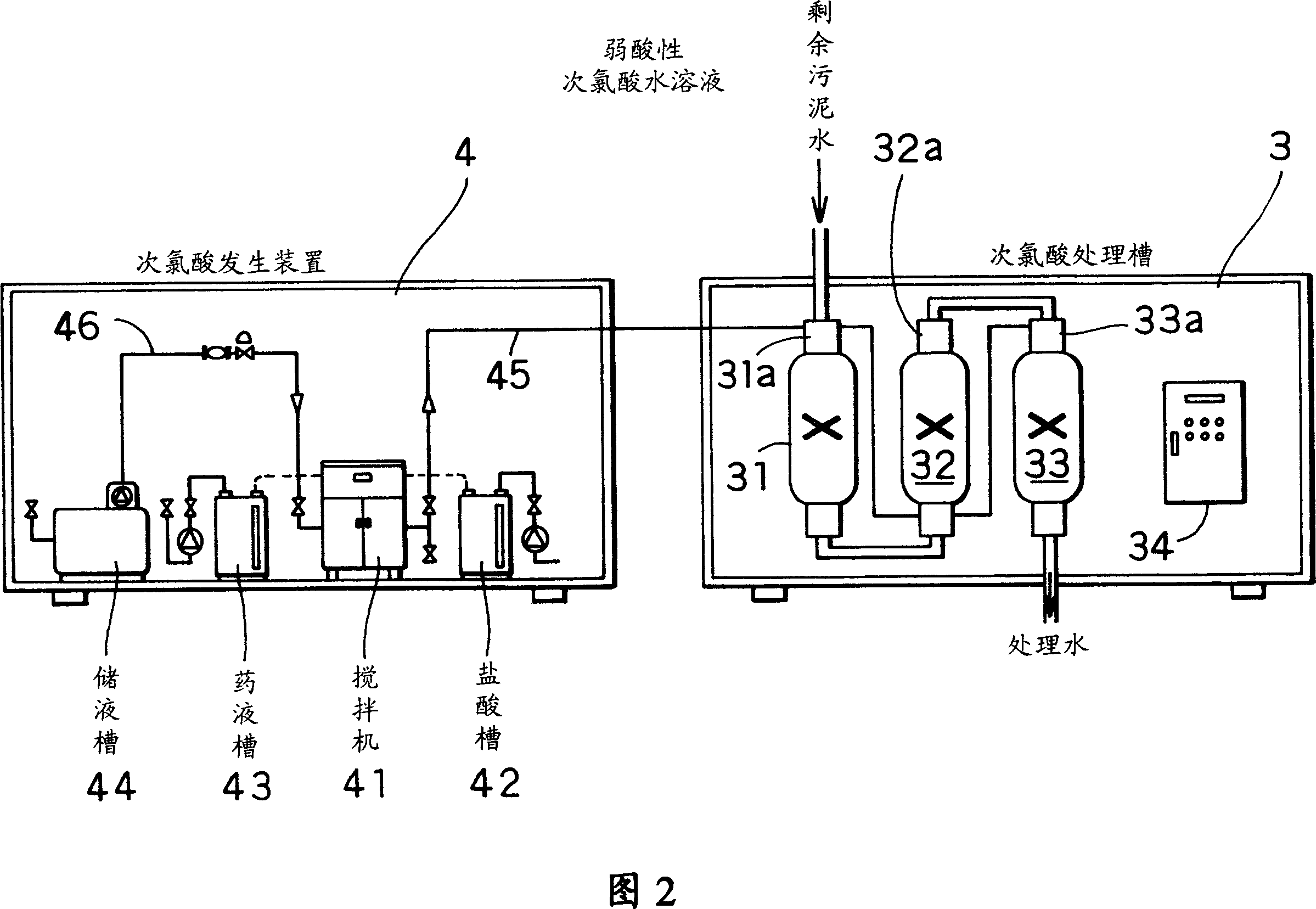

[0026] FIG. 1 is a system diagram showing an embodiment of an excess sludge treatment apparatus of the present invention.

[0027] The excess sludge treatment apparatus in FIG. 1 includes an activated sludge tank 1 , a sedimentation tank 2 , and an excess sludge tank 3 , and solubilizes and circulates excess sludge extracted from the sedimentation tank 2 .

[0028] In this activated sludge treatment facility, raw water (organic drainage) is treated with activated sludge in the activated sludge tank 1, solid-liquid is separated in the sedimentation tank 2, and the separated liquid is discharged out of the system as treated wastewater. On the other hand, in order to adjust the sludge concentration of the activated sludge tank 1 to an appropriate concentration of, for example, 2000 to 5000 mg / L, a part of the separated sludge is returned to the activated sludge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com